Standard profile sizes for drywall

Drywall has long taken a strong place in the market of building materials. Typically, such material is attached to the crate.

The main structure is a frame of vertical and horizontal profiles. Their range is classified by type, size, purpose and other characteristics.

Special features

Modern profile for GKL provides great opportunities in creating a variety of geometric shapes and shapes. It helps to avoid monotony in the interior. With it, you can make an original suspended ceiling and any module, sheathe the walls, assemble the inner pier, partition and many other structures.

The unification of the profile structures facilitates the work of professional craftsmen and home craftsmen.

The metal frame for plasterboard sheeting is much strongerthan a similar construction of wooden beams.

The profile is made on special machines, which allows to achieve accuracy in size and line ideality. In addition, the metal has greater durability than wood.

The peculiarity of the calculation and selection of profile sizes is that they need to be made based on several factors.

One of them is the thickness of the gypsum board, affecting the overall load of the structure. This is especially important when choosing rack profiles.

If a single-layer profile cladding with plasterboard is assumed (load up to 8.5 kg per m²), it will suffice to use products with dimensions of 50x50 or 50x40 mm. If the expected load is higher, the profile should be 65x50 or 75x50 mm.

Kinds

To avoid mistakes with the choice and confusion in a diverse range of drywall profiles, some knowledge of their types may be required. Between themselves, they differ in size characteristics, the thickness of the metal, the shape of the section and the raw materials from which they are made.

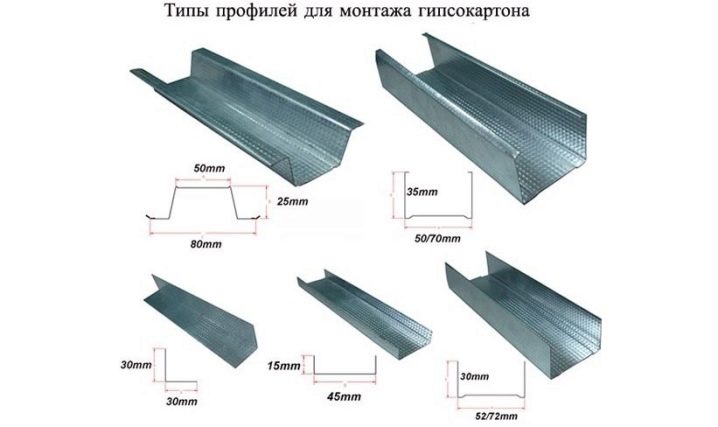

The main profiles for creating frame bases of ceilings and walls are of several types.

Guide

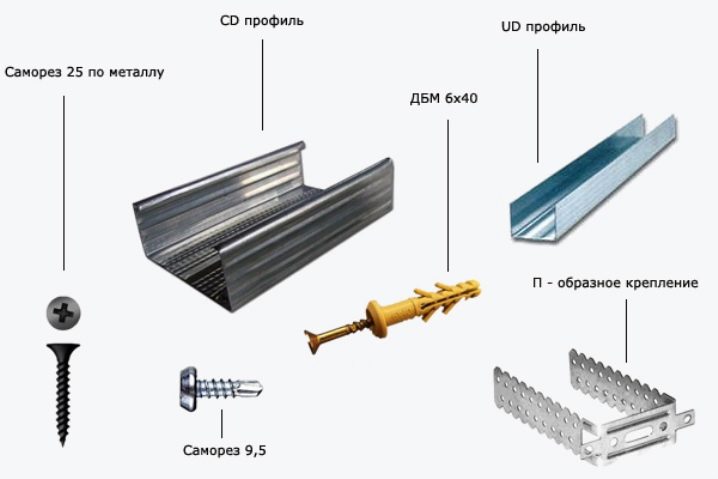

Such a profile is marked MON (UD), which means "guide profile".Its cross-section is U-shaped, the side walls are smooth, in the back there are holes for fastening.

A guide or start profile is used to create the main support (for racks and lintels).

It is attached around the perimeter of the structure, then the remaining components are installed into it.

Standing

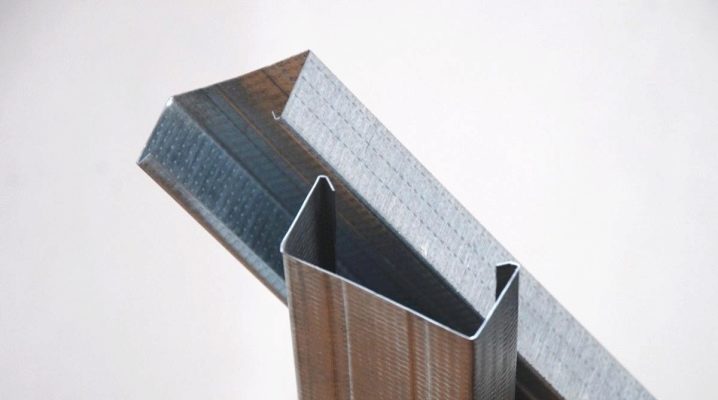

This option is marked PS (CD), means "rack profile." It is inserted into the guides, drywall sheets are attached to it.. In this regard, the main burden falls on him. therefore the rigidity of the rack profile should be maximum.

Its cross section has the shape of the letter P, but the PS design is equipped with additional shelves and stiffening ribs.

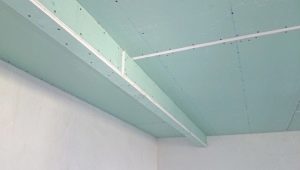

Ceiling

It is marked PP and PPN, which means "profile ceiling guide" and "profile ceiling bearing." The sections of PP and PPN are shaped in the form of the letter P, but they are smaller than the wall profile. The ceiling profile has shelves of lesser height and stiffeners. The low height of the shelves is due to the need to reduce the "selection" of height at the premises of the plasterboard ceiling.

Reinforced for the ceiling

It is marked UA, metal thickness 2 mm.It is used to create reinforced frame bases of suspended ceilings.

In addition, it is used as part of the design for fastening window and door frames.

Arched

Is a kind of rack and guide profiles. It is denoted by the abbreviation PA (CD). Used to assemble structures with radial bends..

The main distinguishing features for this type are pronounced perforation and the presence of lateral cuts, which provide an opportunity for profile bending. In some cases, the arched profile can be made independently, cutting the shelves of the ceiling plinth into sectors, and then bending in a given radius and direction.

Partitioning

This category includes 2 types of profiles:

- Guide. Has UW marking. By principle, it is similar to the UD profile, but has slightly different characteristics: a large height (40 mm) and a width (usually 50, 65, 75 and 100 mm).

- Bearing or rack. Has CW marking and shelf height 50mm.

Additional profiles and accessories

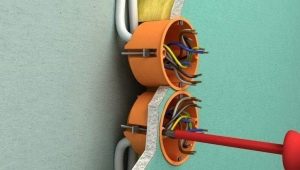

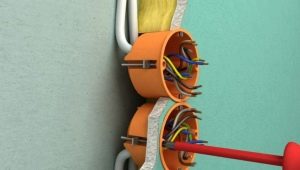

When creating structures that use drywall and metal profiles, one cannot do without additional elements.Their range is diverse and includes several varieties.

Angular

It has a rectangular cross-section with a slightly protruding center portion.

It is used to form corners of drywall constructions.

Corner profiles also have several subspecies:

- Both shelves are perforated with large holes., which allow the corner to become part of the plaster layer and due to this securely hold.

- With mesh, which is glued on the edges of the profile in the form of strips. The result is enhanced adhesion with subsequent finishing measures.

- On paper basis. In this case, 2 metallized strips are glued onto high-density paper. Such elements are used where a small load is assumed (in window openings, edges of shelves and niches).

Mayachkovy (PM)

It is used as a beacon or support rail for the purpose of acquiring a smoother surface during plastering. The most widely used beacon profiles with a length of 3 m and sections: 22x6, 23x10, 62x6.6 mm.

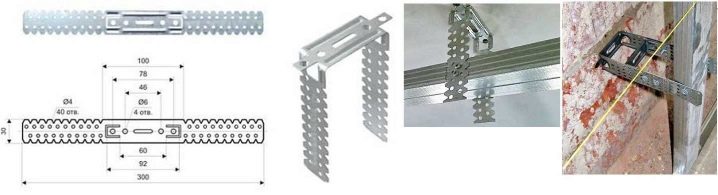

Perforated suspensions

This item is made in the form of a ribbon 125x60mm. The tape is divided into 3 parts. In this case, the middle part is used for fixing the suspension to the ceiling or wall, and the extreme parts with perforation are bent by 90 degrees. Profiles are attached to them.

Metallic

Metal anchor suspensions for ceiling profiles are used for the design and installation of suspended ceilings.

With the help of anchor suspensions, height adjustment is easy, as well as setting the ceiling plane.

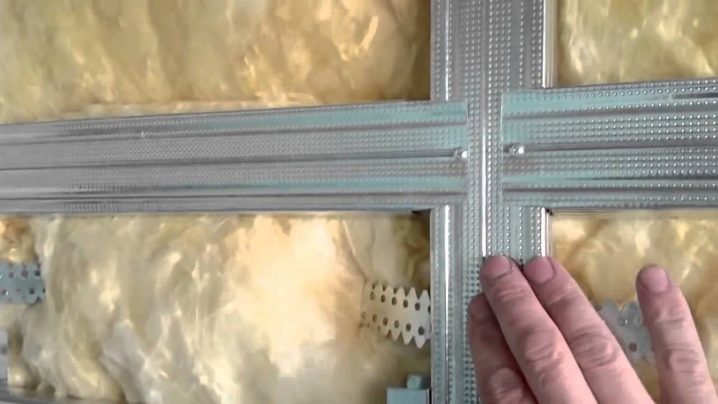

Connectors

The connector is single-level and two-level for the ceiling profile is called "crab". It is a plate with clamps for mounting cross profiles.

Used for installation of suspended ceilings.

Extension

The profile extension is a small bracket with a size of 110x58 mm for splicing two segments of the same size.

Materials

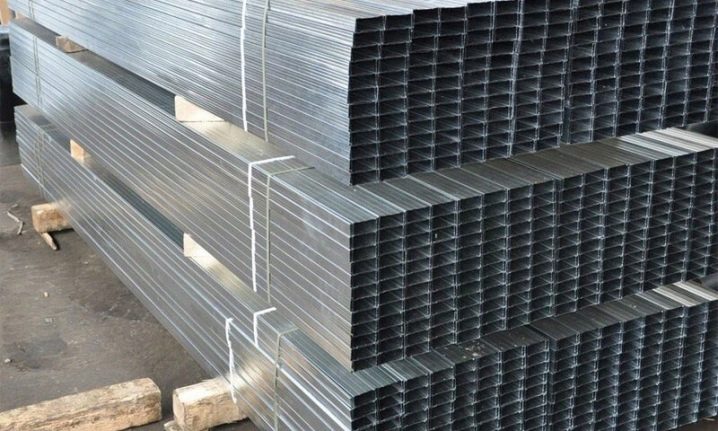

Profiles for drywall are made from steel and aluminum. Steel profiles (simple or galvanized) are more common in the finishing work.

Aluminum, despite the excellent properties of the characteristics, are much more expensive.

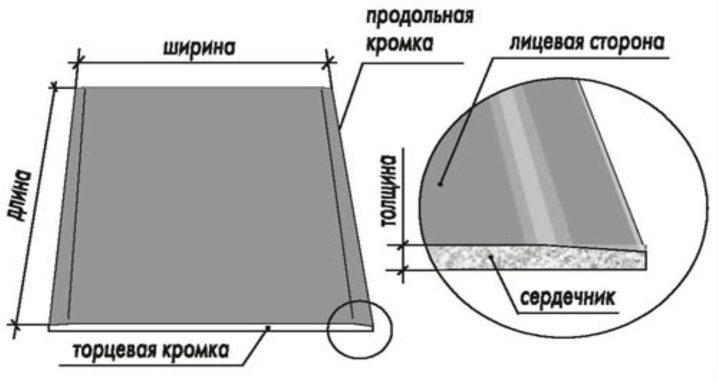

Dimensions

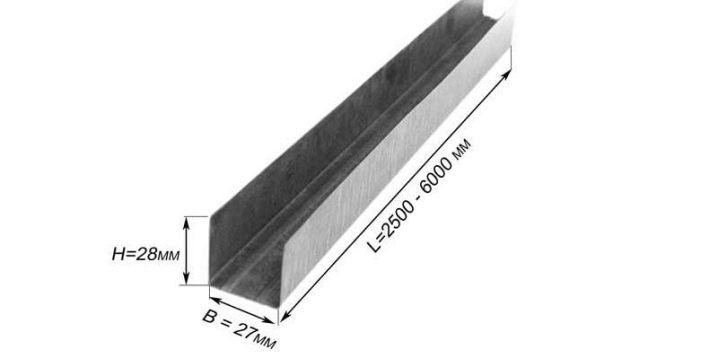

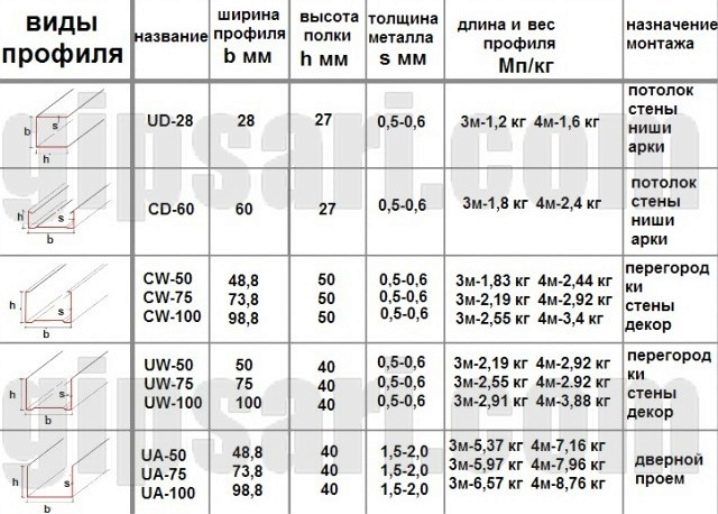

For the convenience of installation work and to make it easier to choose the material for the work, the standard system of dimensions of profiles for drywall provides several options for the main parameters. Guide profiles come in various lengths and widths, but The main dimensions of the PN profile are as follows (the first parameter is width, and the second is height):

- 28 x 27 (for wall and ceiling structures);

- 50x40mm, 65x40mm (some manufacturers have a CD profile width of 60 mm);

- 75x40mm, 100x40mm (for partitions).

As for the length, it is usually presented in four versions: 2.5 (2.6), 3, 3.5 and 4 meters. If a longer profile is required, for example, 5 m, it is made to order or combined from separate segments. The wall thickness depends on the manufacturer; it can be from 0.4 to 0.6 mm.

Rack-mount profiles usually come in four basic sizes:

- 50x50mm;

- 65x50mm;

- 75x50 mm;

- 100x50mm

Their standard length assumes dimensions of 2.5 (2.6), 3, 3.5 and 4 m. Many manufacturers of metal-roll accept orders for products of greater length.

Ceiling profiles have a size of 60x27 mm (ceiling guide) and 27x28 mm (ceiling bearing).

What to cut?

Before you start working with a metal profile, you need to know what it can be cut. You need to prepare the appropriate tools. Usually for this use jigsaw, grinder, hacksaw or scissors for metal.

Electric fretsaw

In the tool establish a file on metal. Cutting start with one of the edges of the profile.First, sawing the back part, and then the side faces. When using this method, a high quality of cutting and the absence of burrs are noted.

Bulgarian

Angle grinder (angle grinder) will be a great help in cutting the profile. With this tool, the cut will turn out faster than using a jigsaw.

However, working with an angle grinder requires certain skills. With a lack of experience, there is a high probability of getting off the marking line and obtaining an oblique cut.

Hacksaw

When the work of power tools is not available, the usual manual hacksaw comes to the rescue. Cut in this case, you need to start with the edge, then you need to go to the rear and side of the profile.

The disadvantage of this method is that in the process of cutting with a mechanical impact, the profile can be deformed. In addition, time and power costs are much higher than when working with an electric jigsaw or a grinder.

Scissors for metal

This is a fairly simple and most common method of cutting metal profiles. The scissors cut is made strictly along the marking line.The use of a quality tool is one of the guarantees of getting a beautiful cut.

The hardest part of this method is the probability of getting off the marking line when passing the edge.

For a perfect result, you may need a little training or combining cutting edges with a hacksaw, followed by cutting with scissors.

Tips and tricks

Despite the fact that the dimensions of the profile elements are sufficiently standardized, form a set of profiles to create a metal frame preferably from the range of one manufacturer. Otherwise, you run the risk of encountering some inconsistencies, such as: various parameters of the length, width and depth of the profile, thickness of the metal, as well as its quality. This significantly increases the risk of mounting a metal structure with reduced strength. This may affect the final result of the work.

Choosing the thickness of the sheet, you need to think about that the thicker the metal, the stronger the design, but its cost increases. Therefore, experts recommend optimizing all parameters and focus on the choice of metal 0.5 mm for ceilings and 0.6 mm for walls. The thicker the metal, the more reliable the design will be. Economy option using thin steel may not withstand significant loads.

If you are going to mount something heavy on the wall, you must first make sure that the profile is strong. To do this, you can try to bend it with your hands. If the product yielded to you without difficulty, it is not the best choice. A hard profile may sag slightly, but it must retain its shape.. You need to buy it in a reputable store with a good reputation.

The shape of the metal profile also matters. This is especially true for rack profiles that have curved ends and special ribs to enhance strength. Each manufacturer adheres to a specific product design. Therefore, it is necessary to pay attention to these features. According to the observations of experts corrugated steel metal profiles are much more reliable than analogs made of smooth material. At the same time the price of the design increases by 20-30%.

When you purchase also need to pay attention to the coverage of products. There should be no trace of rust on it, as this leads to a decrease in the quality indicators of the material.The service life of such products is significantly less.

In order to make the frame assembly and profile size matches ideal, it is best to use a laser level when marking the location of the profiles. It is set in the desired position and a line is drawn on the marks.

Profile elements are applied to these lines, if necessary, trimming is performed. When mounting the profile products on the walls take into account the deviations of the walls, their irregularities. If the unevenness of the wall is pronounced, U-shaped distance brackets are used.. They level wall slopes and bulges.

When calculating the number of profile elements required for mounting the frame base of the ceiling, determine the complexity of the masonry, the number of middle elements, taking into account the construction step and the length of the room. For walls and partitions, it is not the length of the room that is taken into account, but the perimeter of the wall. Also the type of a suspended design, and also the number of levels from gypsum cardboard matters. In addition, the configuration of the structure is important. If the perspective of the ceiling is broken, the material will need more.

For how to choose a profile for drywall, see the video below.