How to cut tiles at 45 degrees?

The presence of corners or protuberances on the wall, various ways of laying tiles, as well as non-standard dimensions of the room play a huge role in the working process on the lining, causing additional difficulties. Therefore, it is often faced with the need to cut tiles.

Right external corners, which are cut at 45 degrees, form a neat, straight angle with a smooth transition, which means that you do not need to resort to using overhead aluminum or plastic corners. However, in order for the cuts to be accurate and coincide with other parts of the tile, it is necessary to use special tools.

What is it for?

Basically, I washed down the corner edges of the tile at 45 degrees in the following cases:

- to match the inner and outer corner of a rectangular tile during their joining in the process of laying;

- for forming a beautiful edge in the form of a bevel;

- with a diagonal tile layout.

Trimming the edge of the tile products under a special angular slope makes it possible to forget about the use of overhead corners forever.

Instruments

It is possible to make a high-quality and even cut without chips and cracks only with the help of special tools, each of which has its own advantages.

Electric machine

The main advantage of this tile cutter is a clear and high-quality cut on the tile, which is carried out in two directions: an ordinary straight cut and a special cut at an angle of 45 degrees. Due to the turns of the cutting wheel at a certain angle to the cut part of the tile, it is easy to cut, ranging from 0 to 45 degrees. An electric machine may have the function of water supply, due to which a smaller amount of dust is released, and it may have a conventional design. However, both versions of the devices provide the same quality of work and ensure that a large amount of tile is washed down in a short time.

In the case of cutting tiles with concave shapes, the electric tile cutter does not repeat the concave deflection of the product. Therefore, you can cut only the back side,so as not to touch the enamel on the front. This is especially true for porcelain stoneware.

Necessary accessories:

- special masking tape;

- simple pencil;

- small ruler;

- tile cutting machine;

- Bulgarian with adjustable speed.

On the part of the tile where the saw will pass, you need to paste the masking tape. Pencil and ruler to make the necessary markup. Then place the tile on a specific area of the device at a 45 degree angle. According to the principle of a circular saw with the help of a diamond ribbon, tile cutting is performed. In some models during the cut water is supplied, which protects the tile from melting and washes away the dust.

In case of damage to the glaze of the outer part of the tile, the cut will be ugly with cracks and chipped edges, which, when laid together, will look sloppy. Therefore, when working with an electric tile cutter, you need to carefully remove only the clay layer.

Professional secrets experienced tilers:

- using a tile cutter it is necessary to achieve an even cut;

- then form the required angle on the back side of the product;

- The frosting, which has been touched in the working process, is rubbed with sandpaper.

Manual tile cutter

Manual tile cutter is popular not only among professional tile builders, but also among amateurs. Many models of such tile cutters are equipped with a special swivel base and a built-in ruler, which allow you to make high-quality gash tiles at 45 degrees. Having inserted a tile into a tile cutter under a certain degree, it is necessary to combine the mark on the tile and on the construction tool. Lowering the handle down, you need slow movements with the same speed and uniform pressing to move it away from you.

Bulgarian

Despite the fact that such a construction device is present in almost every home, it is very difficult to grind a tile at a 45 degree angle by a grinder.

For a quick and smooth gash tile, you must install a diamond wheel on the device. The tile should be placed under the edge of the outer side to the bottom. Now the grinder needs to grind off at the angle of 45 degrees the back side of the ceramic tile.

From the first time to make a smooth and clean cut will not work. Therefore, after the angle has been formed, it is necessary to repeat the process and walk along the cut diamond edge of the grinder.Only in this way will the angle become even.

For the formation of the angle on the tile it is necessary to choose the right grinder, since not all models can perform the necessary functions. In this case, it is worth buying a construction tool from which you can adjust the speed.

At the beginning of work, you should set the minimum speed, on which the edges of the tile will be polished, not burnt.

Fundamental rules

When tapping the tiles, it is necessary to remember that you can only cut the clay, before reaching the glaze of 0.5-1 mm. In this case the corner of the tile will turn out beautiful and smooth, without damages and jags.

Modern capabilities and the ability of specialists make it possible to cut a tile under 45 degrees not only from the edge, but also in the middle of the product. To do this, the tiles need to measure and cut in accordance with the required size, and then cut at 45 degrees. To get a quality result, you should seal up the cut edge with sandpaper.

How to form a sharp angle?

The next stage after the process washed down the tiles under the degree of a certain angle is its worthy use, as well as the organization of the right angle. To do this, observe the following points:

- With the help of a special construction level, it is necessary to glue the first part of the tile evenly. Its clipped edge should slightly climb over the base of the right angle;

- The second tile should be glued in the same way on the contrary, while the adhesive fixation period allows you to move and adjust the touching tiles in order to achieve a tight contact.

Before you start facing the corner should check the consistency of the vertical walls. With even the lowest elevation differences, the angle at the top may not converge and not turn out to be even. Disguise or seal this flaw in the future will be impossible.

The sphere of using a battered tile at an angle of forty-five degrees has certain limitations. As a result of the cut clay from the back side, the narrowed edges of the tile become thin and fragile, so they can easily break off.

It is not recommended to form right angles from cropped tiles in places where there is heavy traffic.

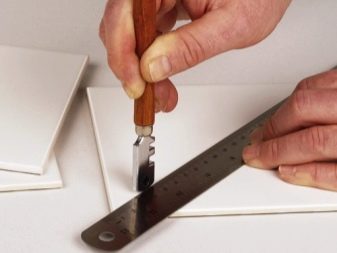

Cutting without special tools

The backing up of the tile is not necessary with the help of special devices. At home, you can easily manually wash down the tiles at 45 degrees. To do this, proceed as follows:

- on the outer part of the tile (glaze) a glass cutter is held;

- using a grinder on the back of the tile, a small groove in the shape of an English letter “V” is formed, which is arranged across the width of the entire tile;

- then you need to gently break the bend of the cut and sandpaper it to process.

How to make saw cut mosaic?

Today, many modern designers use mosaic, a small ceramic tile that is no different from ordinary tile, except for its size. Therefore, when using this tile, it is often necessary to cut it at an angle of 45 degrees.

For washing down the small tile, it will be most convenient to use an electric tile cutter, in which it is necessary to place the moving small parts of the mosaic with the glaze down. Conveniently fixing them on the reverse side of the cutting disk, you can start the implementation of gash while holding the tiles with your hand. Just like when you start a regular ceramic tile, when filling the mosaic, remember the outer layer of glaze, which is not recommended to reach.

Not less complex process washed down the mosaic - the usual grinder, which is accompanied by a large amount of dust. In this case, the tile should also be fixed with the outer side down. Only during the work it is necessary to find a suitable object and hold small parts of the tile that are constantly moving.

The work of the grinder should be at the smallest speed. Slow movements need to remove the back layer of clay using a diamond wheel. However, the cut edge of the tile grinder gently will not work, so at the end of the process must be sealed with sandpaper.

Trimming and gouging should ideally be done by a professional.

Today, the use of aluminum or plastic corners has decreased due to the possibility of washing down the tiles at 45 degrees. This method, as well as joining tiles at a right angle, has been known for a long time. Previously, such methods were used in facing works on the facades of various buildings. Now, such options for laying ceramic tiles can be found in almost every home.

However, with all the positive characteristics of gash tile, this process also has negative sides.This corner of the tile becomes too thin and vulnerable, so it can easily crumble, which will lead to unnecessary trouble and waste.

To learn how to make a 45 degree jigsaw cleaned down, see below.