Plywood ceilings: advantages and disadvantages of structures

When the question arises about how to sheathe the ceiling, then very few people remember such wonderful material as plywood. Meanwhile, the plywood ceiling is very rational and looks quite attractive. It is a material that is light, practical, durable and inexpensive. For some reason, in our country there was a myth that plywood is only suitable for finishing summer cottages.

Consider the advantages and disadvantages of ceiling structures made of this material.

Special features

Plywood as a finishing material for the ceiling is a very good option. The tree and in our time remains one of the most popular and versatile materials, while no synthetics can replace it.

The advantages of plywood:

- excellent sound insulation;

- keeps warm well;

- high strength;

- moisture resistance with proper processing;

- aesthetic appeal;

- low price;

- small weight;

- functionality;

- easy installation

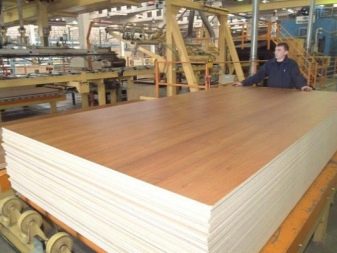

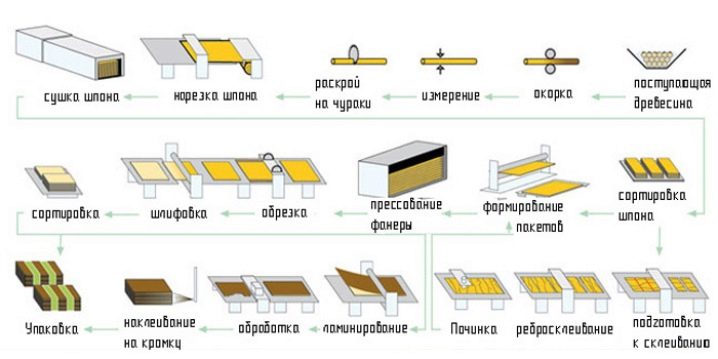

Plywood consists of glued sheets, it should be noted that the number of layers should be at least 3-4. The outer planes, as a rule, are glued with veneer, the front side may consist of a layer of valuable wood.

Modern antiseptic primers effectively protect any wood. The material treated with similar substances is moisture resistant and confidently resists both temperature and other adverse factors.

Plywood sheets can be rectangular or square and have different sizes:

- 1220x1220 mm;

- 1525x1220 mm;

- 1525x1525 mm, etc.

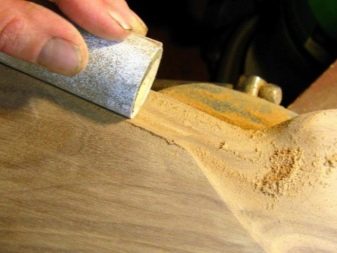

Plywood sheets are necessarily polished, without this material can not be taken to work.

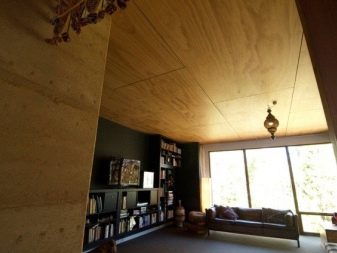

The plywood ceiling looks very impressive in classic interiors. Of this material often perform two-tier or three-tier structures.. This material is much cheaper than drywall, with its installation requires a minimum of fasteners. This is a completely safe finish option, in terms of ecology.

Ceilings of plywood or OSB can be found in business centers, catering establishments, private households.Plywood does not have such wide popularity as drywall, but rather it can be attributed to the problems of advertising and marketing technologies.

Types of material

Before starting work, you should find quality material. It is not recommended to look for good plywood in retail outlets such as markets, it should be bought only in stores that enjoy a positive reputation.

Since the material has a low weight, it noticeably reduces the load on the ceiling, which means that the supporting frame guides will work for a long time without any problems. In compliance with all standards in construction and operation, of course.

If the thickness of the plywood is about 4-5 mm, then this is the best option.. If the material is thicker, it will noticeably weigh down the structure, which can adversely affect the quality of the coating, which can be deformed.

Plywood sheets have a specific marking:

- FC - plywood, which is used in rooms with high humidity.

- FCM - not inferior in quality to the first option, a special melamine resin is added to this material. Possible release of toxins, working with it, you should apply precautions.

- FOF. It has a high moisture resistance, it is widely used in furniture production, and is used as decoration for decoration.

- FSF. The letter "C" characterizes the average level of moisture resistance. In the production of such plywood, a special resin (phenol-formaldehyde) is used, which confidently withstands the effects of both moisture and microorganisms. Often, this material is used even in the exterior.

- Fb. In this material, a special lacquer (bakelite) is actively used, which makes it possible to exploit it for a long time.

Such an abbreviation should be present on all sheets, it allows you to quickly navigate and make the right decision when choosing.

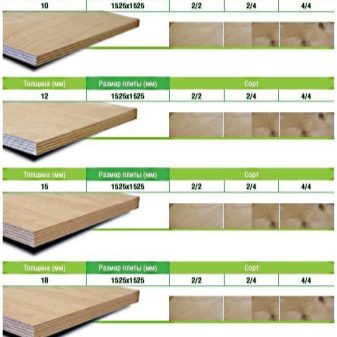

By type of grinding material is divided into 2 groups:

- W-1 - grinding was performed on one side;

- W-2 - grinding was performed on both sides.

The more cycles of material processing, the more expensive it is. Grinding from one side is enough to sheathe the ceiling.. There is plywood and unpolished (NSH), it is the most inexpensive.

The grade of the material depends on the number of defects present on it:

- 1st grade contains no more than three defects (knots, dents);

- 2nd grade - six defects;

- 3rd grade - 8 defects.

The worst quality material is fourth grade plywood.

Usually marking is done this way: I / I or II / III - this means that the grade is determined from two sides of the sheet. The material of the second and third grade can only be used in utility rooms.

Design

For the decoration of the plywood ceiling is most often used staining. Painting the ceiling consists of several stages. This applies both to the carved ceiling with a special decor, and to simple inexpensive sheets of the 2nd grade.

Before starting work, it is recommended to determine the final result well.

If you only need a decorative cosmetic painting, then the surface is slightly moistened, and then covered with a dye composition.

Before processing the plane, it must be primed with a special primer. Paint will need to put a few layers, each of which must completely dry.

Usually the surface is covered in three layers. To preserve the original color of plywood is often used varnish, after coating the surface is treated with stain.

Paints used to decorate the ceiling of plywood can be of two types according to the type of coating formed:

- glossy;

- matte.

Glossy paints give surface defects, if any. Before you start processing sheets, you should consider this factor. Matte paints can "hide" quite significant unevenness or damage to the plane.

The composition of the paint can be:

- silicate, guarantee maximum adhesion coefficient;

- latex, protects the plywood from moisture by almost 100%;

- water-based, lightweight and practical, allow you to get a beautiful decorative coating.

If the room is residential, it often has small children, then it is better to find something difficult with water-based paint.

We should also highlight alkyd enamel, which makes the surface particularly protected. In the case where the ceiling surface has a large number of chips and cracks, it is recommended to use a silicone coatingwhile the layer should not be thicker than three millimeters.

Various types of enamels that imitate the shades of natural oak, cedar, alder, birch, fine wood, etc. can be used to paint plywood.

It is necessary to dry the paint for a certain time (it is best to cut it out with a margin), this is the type of work where rush can only hurt. The better the lower layers of paint dries, the more reliable, stronger and more durable the finished coating will be.

Consider other popular design options:

- Openwork carved ceiling, it can often be found in the bedrooms and guest rooms.

- To give the ceiling more decorative often use all sorts of variations of spotlights. With their help, you can make a coating that is called "bulk cells". Prerequisite: the ceiling must be over 3.5 meters in height for the desired effect to appear.

- Often an original, effective plinth is selected from the plywood ceiling.

- Often plywood sheets are combined with wooden or metal stripes.

How to do it yourself?

Finishing by plywood is process slow, careful. Beautifully and correctly finish the ceiling is possible only when all technological standards are complied with. Before you start trim, it is recommended to choose a certain material. Plywood sheets can be made of coniferous (larch, pine, fir, spruce), hardwood (birch) wood species and even poplar.

Filing the ceiling with birch plywood sheets is a very rational solution.. Birch is a very durable material, it is often used in rooms where excessive humidity is present in the 7/24 time mode. To hem the ceiling with such material means to ensure the design of the room for many years.

During the work it is necessary to be able to handle the stain and varnish, only in this case the material will reveal all its best sides. If the plywood is properly fastened, then the filing can hide engineering communications, curvature of walls, etc.

Consider the stages of work:

- Training. The working plane must be cleaned of plaster and paint, embroidered and sealed with cement mortar cracks, remove the conspicuous joints. After that, the ceiling is covered with a primer, which should effectively counteract the occurrence of fungus and mold.

- Before starting work, you should draw a few rough sketches of the future product in order to have a more complete idea of how the structure should look.

- Work begins with markup using a level. The following tools will also be needed:

- screwdriver;

- perforator;

- electric drill;

- hammer.

- The crate is made, it consists of a log (wooden bars with a section of 30x30 mm, treated with a primer). Bars are mounted at a distance of 40-50 cm from each other. Then the sheets are laid.

- Sheets can be fixed and using suspensions. In this case, the coating should not bear any load. Suspensions are attached to the ceiling, bars are bolted to them. Then hem sheets of material to the bars themselves.

In residential premises of a wooden house, sheets of 5 mm thickness are used; if you attach sheets thinner, there is a risk of their deformation. If the thickness of the plywood is five millimeters or more, then the distance between the guide bars increases to 60-70 cm.

Beautiful examples in the interior

In the photos below, a wide range of material applications is clearly visible; they can sheathe ceilings both in the rooms of expensive premium hotels and in construction huts.

- Such a ceiling is easy to do yourself.

- Plywood ceiling, lined in squares, looks very stylish and elegant.

- This version will perfectly fit into the classic and modern interiors.

- Decorative plywood ceiling in the reception room.

In the video below you will see the option of finishing the ceiling with plywood decorations.