How to make a false ceiling?

In the modern interior suspended ceilings occupy an honorable place. They come in a wide variety of forms and are assembled from various finishing materials. Their undoubted advantage is a simple installation with a minimum period of performance.

Special features

When plastering builders need a certain accumulated experience. This process cannot be carried out without preparation. But to put the frame on the ceiling with a minimum of tools will be able to almost everyone. The main thing to have in the arsenal: drill, jigsaw, screwdriver and level. It should be noted that there is a type of ceiling that requires the attention of professionals. This is a system of stretch ceilings. Installation is carried out with the help of special equipment, heat gun. The house master can independently mount a suspended ceiling system made from plasterboard, plastic, and wall paneling. And also to master the Armstrong ceiling structure.

To choose the right type of ceiling, you need to consider the following factors:

- functionality;

- aesthetics;

- technical and operational aspects.

When determining the functional characteristics of suspended structures, you should use the instructions and technical sheets from the manufacturer. They describe in detail how to install, for what type of premises different types of ceiling are suitable. In the technical descriptions are examples of calculations of design features, as well as tables with all the data. Therefore, experts have developed approved documents that state for which premises this or that type of ceiling covering is more suitable.

It is necessary to choose not only the material for installation, but also to develop the configuration of the ceiling. Bearing frame must clearly perform its functions.

The choice of the type of ceiling significantly affect:

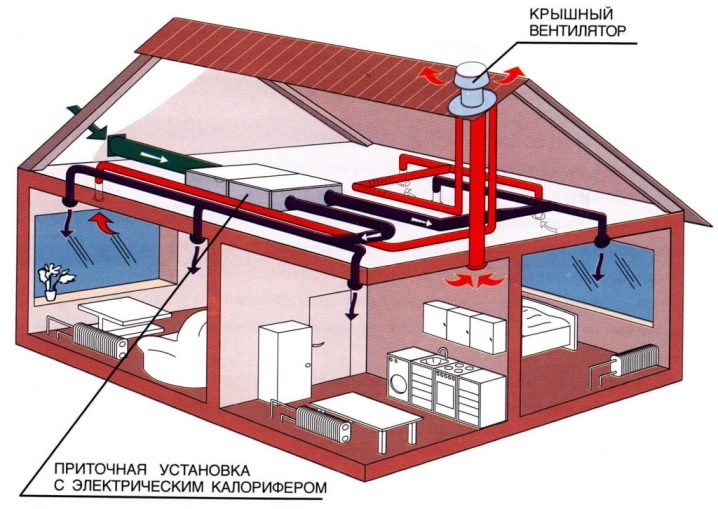

- the need to install a ventilation system;

- laying communications to connect electricity;

- conditioning;

- the need for specific properties of the material (sound absorption, fire safety, impact resistance);

- service life and the ability to replace individual items.

Each consumer has a list of their requirements, especially aesthetic and design. But there are also generally accepted, from manufacturers of suspended ceiling systems. These include functionality, moisture resistance, heat insulation, operational life. On them, and you need to focus.

Acoustics is a way to spread sound. For office space this is a very important criterion. Low noise has a beneficial effect on the workflow and increases productivity. There are special acoustic plates from German manufacturers that absorb sound well. Their use is justified in areas with high noise levels.

Suspended ceilings can provide free access to communications, pipes, ventilation systems, heating, fire alarms. To fix the problem, it is enough to remove the decorative ceiling tiles, which will provide access to the ceiling. With the help of a suspended ceiling, you can easily hide the defects and cracks of the base. Work on installation, dismantling and maintenance is less time consuming when compared with other types of finishes. The suspension system allows you to place more lights and absorbs noise.

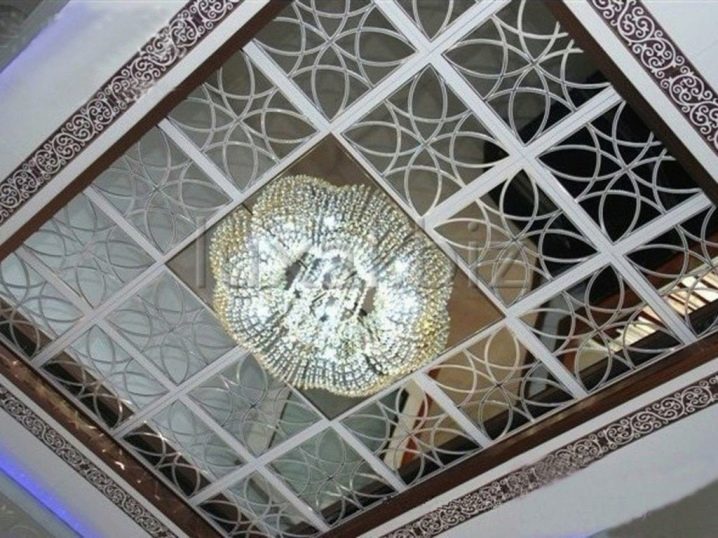

Development of exclusive designer ceilings of various, sometimes fancy shapes, can cost the owner very expensive. But she will be the only one of its kind. Modern materials allow us to make the cellular structure of the suspended ceiling almost invisible. You can order a different design of the plates, and then collect from them on the ceiling an intricate individual design.

The positive aspects of the ceiling structures are as follows:

- hide defects and flaws of the base. This is true when carrying out repairs in old buildings, where the ceilings, as a rule, plastered. Over time, the final layer went cracks and even in some places could fall off. This type of coating must be completely upholstered and applied again;

- manufacturers of building materials offer a variety of solutions for the design, shape and design of ceilings. The cost depends on the cost estimate of the customer: from inexpensive to exclusive solutions;

- A very large selection of coatings is glass ceiling tiles, plastic, metal, plasterboard, made of wood. There are shiny and matte ceilings, as well as with a 3D effect;

- no need to disassemble the entire ceiling to replace part of the coating;

- easy to care for.Enough wet wiping, besides coatings have anti-dust properties;

- communications, wiring, pipes, ventilation can be laid in the interceiling space;

- suspended ceilings involve the use of a variety of lighting fixtures, such as raster lamps, spotlights, LED systems, chandeliers;

- long service life. The elements of the frame are warranted from 15 years of use. With proper care, the elements of the harness last longer;

- possess heat-insulating properties, absorb sound, are fireproof, do not depend on sudden change of temperatures.

The negative sides of the ceiling structures are in the following points:

- decrease the distance from the floor to the ceiling. The suspended structure, as a rule, is supported by needles, the length of which is 25 cm. In small apartments, there will be a very noticeable decrease in the height of the room;

- high prices relative to other materials. To whiten the ceiling is cheaper, taking into account the development of the construction industry, it is better to choose more expensive and durable material. Each customer strives for individuality, and this can be achieved using modern solutions;

- fear of high humidity. In the event of flooding, you will need to replace the decorative coating and bearing elements.

Materials

Suspended ceiling consists of a metal frame, which occupies the entire area of the base, and ceiling tiles attached to the supporting structures.

Plates can have different types of connections:

- Cells. The entire ceiling is divided into squares or rectangles, which are covered with plates at the back.

- Tiles. Mainly used in office space.

- Panels. A panel in the form of a rectangle more than 30 cm wide is taken as a decorative element.

- Cassette. The squares of the frame construction are covered with panels of the same size.

- Reiki. When installing using decorative slats of different lengths and widths.

- Solid ceiling. Most often collected from sheets of drywall.

- Stretch ceiling. PVC film is used.

Decorative finishing consists of different materials:

- Sheets of drywall. They make it possible to create a perfectly smooth coating that can be puttied, covered with wallpaper, painted, applied decorative plaster. With the help of sheets of drywall in the interior appear ceilings of different levels and geometric shapes.Drywall is environmentally friendly, meets sanitary standards. Its disadvantages include the fact that he is afraid of conditions of high humidity and needs a finishing coat.

- Plastic panels. They are made from polycarbonate. The mirror surface of plastic ceilings is an excellent replacement for glass panels. This ceiling is easy to install, moisture resistant, resistant to mechanical stress, easy to clean.

- Metal. These are aluminum or steel strips, cassettes, panels. They can be matte or glossy, with a mirror coating.

- Tree. Any product made of natural wood is the key to quality and durability. Wood products will never go out of fashion, but their big minus is the high cost. Manufacturers propose to use in the decoration of a cheaper way. The use of chipboard and MDF boards, the surface of which is covered with patterns that mimic natural wood. You can find slabs covered with veneer.

Frame

Before proceeding with the installation, you must calculate the amount of materials, purchase a tool, process the base and apply the markup.

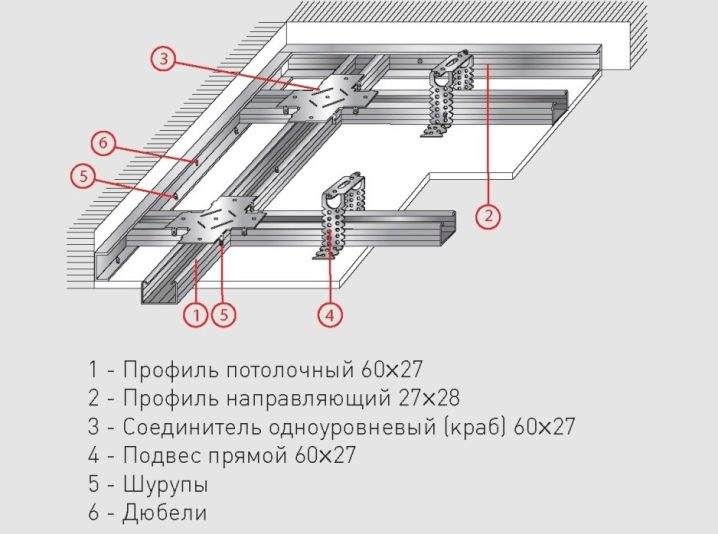

The crate is made of galvanized steel profiles.She is not afraid of moisture, as the profile is protected by zinc. Ceiling strips (60x27 mm) and guides (27x28 mm), as well as suspensions, which will hold the structure: butterflies, coupling couplings, anchor suspensions, connecting elements, will be needed to install the ceiling from plasterboard or plastic. For fixing you need to purchase metal screws and polypropylene dowels.

Instruments

The main tools for self-installation of frame structures are as follows:

- angle grinder;

- perforator;

- laser level;

- tape measure, pencil, ruler;

- construction knife and files for metal or wood;

- the rule;

- plummet;

- scissors for metal;

- protective glasses;

- hammer with a nail catcher;

- pliers, crimping pliers;

- hacksaw with a fine tooth;

- screwdrivers, awl.

The level is needed in order to mark the installation of the guide element. The rule is used when cutting sheets of drywall. After installation of drywall will require further finishing. Tools and materials you may need:

- tape for reinforcement of seams;

- sealing tape;

- priming solution;

- putty;

- paint roller and brush;

- putty knife;

- abrasive sheet number 240.

How to calculate the flow?

Armstrong ceiling rate norms

These are special factors by which you can independently calculate how much frame elements and decorative plates will be needed, knowing the size of the ceiling.

Knowing the rate of consumption, you can:

- independently calculate the amount of materials required;

- calculate the approximate cost of the purchase;

- make an estimate;

- allocate a budget for work.

Using the example of a square-shaped ceiling with a total area of 100 m², we will make calculations. The length of the guide bar is 3.6 m. It is mounted in 1.2 m increments. To find the quantity you need, divide the ceiling width 10 m by the installation pitch (1.2 m). It turns out 8.33 rows of carriers. Multiply the length of the room 10 m on the number of rows. Almost 84 rm. m, and it is 28 pieces of the bearing profiles. The crossbar of 1.2 m is placed in 60 cm increments. We repeat a similar calculation: we find out the number of rows (10 m of length can be divided by 0.6 m of the mounting step). We have almost 17 of them. In running meters it turns out 167. And in pieces it turns out almost 140 (167 linear meters should be divided by 1.2 m - the length of the bar).

0.6 m rails are placed in 1.2 m increments. We calculate in the same way and it turns out that 84 running meters are required. m reekTheir number will be 140 pieces. Suspensions are placed on slats of 3.6 m with a pitch of 1.2 m. At a ceiling of 1m ² you will need 0.7 suspension pieces. The angular profile is calculated around the perimeter of the room, its length is 3 m. For 0.4 m², it is necessary 0.4 running. m

Using these calculations, it is possible to calculate the consumption of slatted, acoustic ceilings. Do not forget that this is an average calculation. In any estimate it is better to lay 7-10 additional percent, so that there are no unpleasant situations later. Take into account the need to such factors:

- room shape;

- the possibility of the location of the rails diagonally;

- trimming plates;

- reject rate.

Norms ceiling costs of plasterboard sheets

Let's take as an example a ceiling 10 m long and 10 m wide. The size of the ceiling gypsum board is 2500x1200x9.5 mm. As a result of the calculations, the work will require the following materials:

- drywall - 100 m²;

- CD profile - 87 pieces;

- UD profile - 14 pieces;

- 60/27 suspension - 160 pieces;

- longitudinal connector - 70 pieces;

- cruciform coupling - 160 pieces;

- ceiling dowel - 1600 pieces;

- self-tapping screw "flea" - 900 pieces;

- dowel 6x40 - 200 pieces;

- putty - 40 kg;

- fiberglass ribbon - 130 line meters m

Installation

Installation of suspended ceiling plasterboard

The first thing to do is find an assistant.Self-fix sheets of drywall is very difficult, you need safety net. It is better to start with a simple single-level ceiling, preferably a small area.

- Preparation for installation. It is necessary to carefully examine the walls and ceilings, remove everything that may interfere. To lay communications, to close up cracks in the ceiling basis.

- Mark the ceiling. At this step, you need to decide on lighting devices and their connection. When using spotlights, the ceiling is lowered by 3–4 cm below their total length, and when using raster lamps - by 5–10 cm. Look at the degree of curvature of the old ceiling and prevent such errors with the new one. Using the level to find the lowest angle from which to start the markup. Having marked the corners, the rule is to measure a flat horizontal line on the walls. This is the bottom line of the UD profile.

- Mounting frame elements. Fasten around the perimeter of the guide profile. To do this, at a distance of 30 cm with a perforator, we make holes for dowels. We screw in the screws on the tree. The length of the plug should be at least 40 mm. CD profiles are set in 60 cm increments. They come in 3 and 4 meters.To make the frame stiffness you need to use suspensions for rack profiles with a pitch of 40 cm.

- Laying communications and the choice of place for the lamp. To install a spotlight, you need to use a crown to make a hole in the drywall. Not allowed into the profile. In the case of a chandelier, it is attached to the base or guide profile. The profile must be additionally reinforced with suspensions. Wires are stacked in a special corrugated pipe. Communications for the overhead luminaire are output through a hole in drywall.

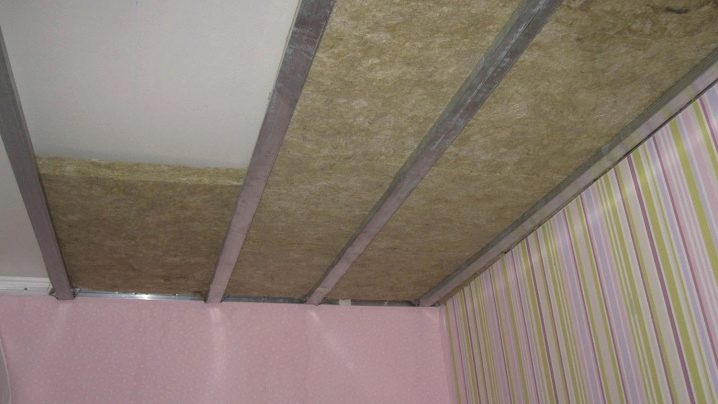

- Thermal insulation. The frame structure can and should be insulated with sheets of mineral wool. It not only serves as insulation, but also absorbs sound.

- Fixing plasterboard sheets. Knowing the width between the walls, you need to calculate how many whole sheets you need and how many pieces. Cut the sheets with a construction knife or a plasterboard file. Fasten HL sheets with 25 cm increments with self-tapping screws. The heads of the fastening elements are embedded in the gypsum board so that they do not rust with time. Subsequently, they will close the putty. At the junction of two sheets paste a special tape and putty plaster mix.After complete drying, the seams need to be sanded. The entire surface must be primed to ensure that the finish is better kept.

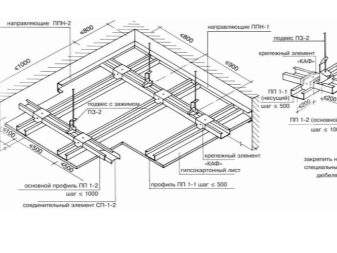

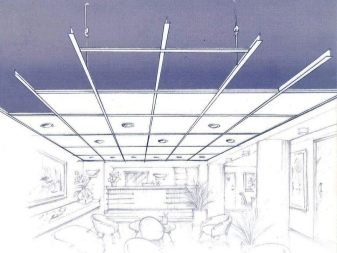

Installation of Armstrong-type suspended structures

- Layout and charting. As in the previous case, you first need to make the layout of structures. Then proceed to markup. Profiles in such a system are not attached to the base, but the master will orient faster along the marking lines, where the profile carriers and the remaining jumpers will be located.

- To mount a false ceiling, you need it lower by at least 15 cm. This is a constructive minimum clearance for laying communications and installing fixtures. You can also lay insulation in this space. The most convenient way to mark a wall is to use a laser level. Ordinary bubble levels can be used instead.

- Laying communications. Before you start to mount the frame, you need to carry out all the work associated with electrical wiring. For example, if it is known that the lighting device will be large, then the place of its attachment must be further strengthened with hangers.

- Frame installation. After all the work is completed, you can proceed to the installation of profiles. Corner profiles are attached to concrete bases with dowels. Their diameter is 6 mm, they are placed in increments of 30 cm around the perimeter. The angle of the wooden base is fastened with wood screws. Their length is 30 cm.

If it is planned to sheathe the walls of the room with sheets of plasterboard, then an additional horizontal profile is put in the metal wall sheathing. This is done for the rigidity of the structure. On this additional profile is mounted wall corner. According to the marked lines you need to fasten a set of mounts (pendant, butterfly, knitting needle). For 1m ² one set of suspensions is required. In those places where lamps are planned, you can put additional fasteners.

Profile carriers (3600) are placed on the wall corners and fastened with hangers. The distance between them is 1.2 or 0.6 m. It depends on the drawn scheme. All work must be controlled by level. Fixed carriers should be strictly horizontally. The hooks of the suspensions are tightened slightly with pliers so that the carriers hold well. 1200 carriers are placed in 60 cm increments.They enter the slots, which are located on profiles 3600, and snap into place. Some masters bend them, but this is not necessary. The frame and so will be tough.

- Installation of ceiling tiles. After all the installation work on the frame construction has been completed, lamps and decorative plates are installed. Electrical wires are pre-supplied to the desired square, where the lighting fixture will be located. A luminaire is connected via terminal blocks. First install the whole plate. They are not attached, just put on the prepared frame. As a rule, the extreme cells may not coincide with the size of the plates, so you need trimming. Plates are easily sawn with a hacksaw, and then placed in holes.

After their installation, the installation of the ceiling can be considered complete. Additional finishing is required. This is the simplest pattern of laying plates, but there are more complex options when the plates are stacked diagonally or with a shift. Bearing elements allow you to perform the frame of different configurations. Choosing a ceiling, the master gets the opportunity to do their own design. After all, these coatings can be painted in different colors, combined with each other.

It should be noted such type of panels as LED lamps. These are panels that look like a screen covered with a matte film. They are designed for a suspended ceiling system and have a standard size of 600x600 mm. In such panels are built very powerful LEDs that distribute bright but soft light. It is enough to have one such lamp to create ambient daylight in the room.

Manufacturers

The main producers of Armstrong suspended ceilings:

- Amf;

- Owa;

- Geipel;

- Armstrong;

- Albes;

- Lyumsset;

- "Bard";

- Hunter Douflas.

Suspended structures of these European manufacturers are made of steel (0.6 mm), which is coated with a special powder composition. The standard size of a plate is 600х600 mm.

Rack ceilings are made of aluminum alloy. Their surface is protected by a lacquer coating, which is applied in two layers. Reiki width from 3 to 30 cm.

The main producers of drywall:

- Knauf;

- Gyproc;

- Lafarge;

- Rigs.

Stretch ceiling manufacturers:

- Barrisol;

- CTN;

- Extenzo;

- Pongs;

- Lackfolie;

- Renolit Ag;

- Saros Design;

- Cool stretch;

- Cesal;

- Simplex.

Tips and tricks

It is necessary to use only proven, high-quality materials and tools. Mounted ceiling for many years will delight and design, and workmanship.

It is always necessary to begin work with a marking and drawing up the layout of elements. Spending time compiling a list and calculating correctly can save time in the future. No need to then run to the store and buy more missing.

Experts recommend sticking to the following tips:

- installation work with drywall should be carried out in a dry room;

- use the level at all stages of work;

- Soundproof ceilings can be using mineral wool. It fills the space in the mounted frame;

- cleaning the suspended ceiling with lighting is not necessary very often. It is necessary to look at the degree of contamination;

- the thickness of such a ceiling should be sufficient. Step-by-step installation technology and the drawing itself depends on this indicator. Build better material is easier;

- doing repairs, do not forget to pre-purchase components, fasteners, bead, and others, do not forget to also leave indentation under the curtains;

- sheets GKL should lie some time in a horizontal position, so it will be easier to assemble.

A suspended ceiling is a simple and inexpensive way to level the base, which provides additional sound insulation. To carry out self-installation of suspended structures is easy.But you should follow the instructions from the manufacturer, have all the necessary tools and minimal knowledge of the installation. With the help of decorative finishing elements, you can create a stylish, high-quality and unique ceiling covering. It will last a very long time, as manufacturers provide a long warranty period for all structural elements. Now such ceiling cover hang often enough.

You can safely experiment with the design and design of the cassette ceiling with your own hands. Under all conditions, the ceilings will decorate the room for more than a dozen years. Each type of ceiling is unique in its own way. Drywall expands the range of design solutions, Armstrong suspended ceilings are durable and easy to install, the stretch ceiling system provides a huge selection of colors.

To learn how to install a CESAL cassette ceiling in the toilet, you can watch this video.