Peculiarities of mineral wool ceiling insulation

To reduce heat loss in the living space, it is necessary to warm the ceiling. This applies not only to the walls, but also to the ceiling. Currently, there are many different heaters that have different characteristics and cost. One of the most popular and effective insulation materials is mineral wool. Let's get acquainted with this heater closer and consider what features it has.

Special features

Mineral wool is a special category of insulation materials of inorganic origin, having a fiber structure. Such products are made from rocks, slags and glass.

Such heat insulators are responsible for “fixing” the warm air layer, perfectly isolating the living space from the cold. Mineral insulation mats consist of a huge number of tiny fibers that are intertwined with each other in a specific order.

There are several subtypes of mineral wool.However, regardless of the type of materials, the principle of their production is about the same. In the manufacture of this insulation used only non-combustible components.

The following technologies are used in the creation of mineral insulation:

- blowing;

- centrifugal roller;

- centrifugal casting;

- centrifugal-spouting and other high-tech techniques.

Modern mineral wool is available in rolls, plates and cylinders.

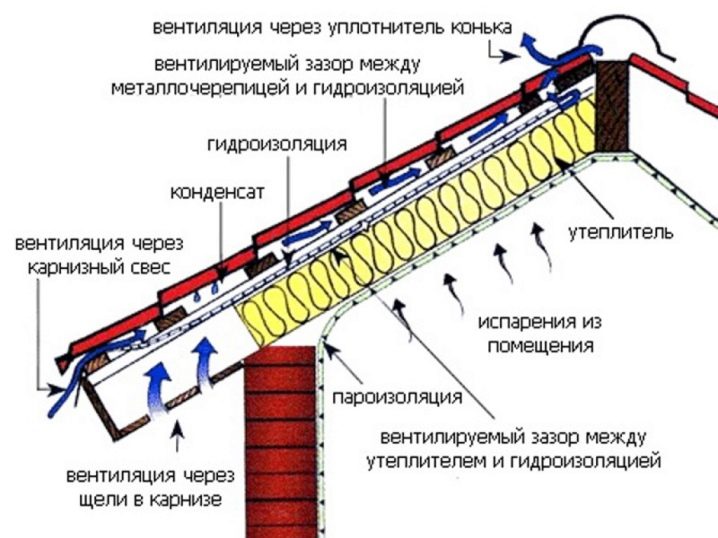

Thermal insulation of the ceiling must be made in order to extend its service life and protect it from the damaging effects of moisture and condensate. In addition, it is worth considering that the warm air can leave the room, rising up, so there must wait for him a reliable barrier. If the insulating layer is installed correctly, the heat will not be able to leave the living space.

A comfortable microclimate is always preserved in a dwelling with a well-warmed ceiling. Being in such conditions is cozy and safe for health.

Warming with mineral wool can be made both inside the home and outside. Both types of work can be done by hand, without resorting to the expensive services of specialists.The main thing is to choose quality materials and strictly adhere to the action plan. Then the result will not disappoint you.

Advantages and disadvantages

Mineral wool - one of the most popular heat insulators. It is chosen by many consumers due to its many positive characteristics:

- Minwat provides excellent thermal insulation. This heater has a low thermal conductivity, so it is permissible to use it in various fields. Weather conditions at the same time can be absolutely any. In addition, mineral wool does not require additional insulation.

- This insulation is waterproof. For example, high-quality basalt and glass wool (varieties of mineral wool) perfectly let in steam, but do not absorb moisture. Thanks to this feature, areas warmed with similar materials are reliably protected from the appearance of dampness.

- Mineral wool is not terrible aggressive chemicals. High quality insulation is not destroyed or deformed by contact with acids and alkalis.

- Such a heat-insulating layer distinguishes the possibility of air exchange.Minvat is a “breathing” raw material that provides air circulation in the surrounding space. This material virtually eliminates condensation.

- Mineral wool is also distinguished by good noise insulation characteristics. This heat-insulating material has a special elastic structure, which ensures its acoustic qualities.

- This material is recognized as flame retardant. Even in the event of a fire, the mineral wool will not sustain combustion and promote the spread of fire. Moreover, when confronted with a flame, the mineral wool does not emit acrid smoke.

- Minvat is a durable material. Its service life is on average 25-50 years. Such a heat-insulating layer is not exposed to "invasions" of rodents and parasites, and various microorganisms do not multiply in it.

- Such a heat insulator is considered environmentally friendly. It can be laid out without fear on the ceiling in a private house or apartment. Mineral wool does not contain hazardous chemicals that adversely affect human health.

- It should be noted that the mineral wool is a very durable material with reliable fibers. Such a heat insulator easily withstands impressive loads.without losing useful properties.

- Minvat is not a rare material. It can be found in any hardware store.

Despite the many advantages, this insulator has disadvantages:

- When wet, mineral wool loses its positive qualities. When this material absorbs moisture, it loses some of the insulating properties.

- Also, the heat insulator has a strong dusting. This minus is noticeable when laying glass wool or slag wool. Such materials have brittle fibers, and their fragments are thin and sharp. If they fall under the master's clothes, they provoke intolerable itching and skin irritations. In addition, it is very harmful to breathe air in which there are particles of insulation. Because of these shortcomings, it is recommended to work with a similar product only in special clothes and goggles.

- Some experts argue that mineral wool can adversely affect human well-being, since it emits phenol-formaldehyde resins. However, many studies have shown that the content of toxic compounds in this insulation is too small to harm health.

Characteristics and composition

Another name for mineral wool is stone wool. The main characteristics of this popular thermal insulating material are:

- low thermal conductivity;

- not subject to rotting;

- non-susceptibility to shrinkage (neither natural nor thermal);

- heat and sound insulating qualities.

In the manufacture of mineral wool used non-combustible components. They melt at a temperature of +1500 degrees. When a fiery liquid substance is obtained from these ingredients, fibers of different sizes are extracted from it.

Today, many of the well-known manufacturers implement the mineral wool industry. This material may contain several main components:

- At the heart of the insulator may be different rocks. Gabbro-basalt and carbonate rocks are products of metal production. They are used as raw material for the manufacture of glass wool fibers. 90% of the content of this material are rocks, and the remaining 10% - impurities.

- To make the insulation fibers more viscous, special binders are added - phenol-based resins, bentonite clay.

- On top of the insulating material is covered with a very thin paper layer.As a rule, special kraft paper combined with aluminum or polyethylene is used for this.

All the listed components are basic in the content of mineral wool. Of them consists of the "lion" share of such heat insulators. To find out what kind of mineral wool is in front of you, and what ingredients it contains, you should read the information on the package.

Preparatory work

Before insulating the ceiling of the mineral pool, it is necessary to prepare the base. To do this, you will need the following materials and tools:

- insulation (it is advisable to purchase mineral wool in the plates, because it is more dense and easier to install);

- bars of wood for the frame;

- fasteners;

- suspensions;

- ladder;

- level.

For fixing mineral wool, you need to buy a special glue. To protect the material from getting wet, it is recommended to prepare a vapor barrier layer.

Before laying insulation, it is recommended to remove old finishing coatings from the ceiling. If there are traces of mold or mildew on the base, they must be removed. After that you should finish the ceiling with primer.

Manufacturing frame

The framework for laying the insulator can be made by hand. However, you first need to make a layout of the ceiling base.

Few ceilings have unsurpassed horizontal position, therefore it is necessary to measure the distance from the floor to the ceiling in several places. The smallest value should be taken as a basis. Further, on the ceilings, it is necessary to set marks and connect them with a line, constantly controlling the horizontal position.

Following the guidelines, it is necessary to mount bars or metal profiles. If the walls are made of wood, then the parts need to be fastened with screws. If the ceiling is more dense, for example, concrete, then the frame can be fixed using dowels.

Then you should proceed to fixing the intermediate components of the frame structure. They should correspond to the height of the guides already on the walls. If the crate is wooden, then under the bars you need to put pieces of wood to create a horizontal position. If the mineral wool is a slab, then the intermediate frame parts should be installed so that the slab fits tightly between them.

Insulation technology

For thermal insulation mineral material can be put both indoors and outdoors. Consider step by step how such work is done.

Inside

To put a minvata from inside the dwelling, you must:

- make a frame;

- put waterproofing;

- make a vapor barrier;

- lay out insulation;

- lay out the finish facing - plasterboard plates.

Waterproofing inside the room is not necessary, especially since the arrangement of the frame it will be deformed.

Outside

Sometimes it is not possible to put insulation inside. In this case, it is necessary to refer to the method of external installation of the insulator. For exterior work it is not necessary to choose the type of frame (metal or wood), since it simply will not be needed.

Works include several stages:

- free the attic from debris and unnecessary items;

- remove dust and dirt;

- put waterproofing material (it should be laid with an overlap of 10-15 cm);

- seal joints with duct tape;

- vapor barrier material must be wound on the sides to a height of 15-20 cm (if possible), and then secure it with scotch tape or battens;

- lay the mineral wool (it is better to lay out the insulation in 2 layers);

- the upper layer must be placed so that it closes the lower joints;

- in the attic, experts advise the use of insulation in a roll (the plates will turn out not to be placed everywhere);

- the heat insulator must be laid tightly between the beams along their upper edge;

- in this case, it is not required to close the heat insulator, except in cases where the organization of the living space is planned in the attic.

For information on how to properly heat the ceiling with mineral wool, see the following video.

Useful tips

- To determine whether the insulator is properly laid out, you can use a thermal imager. If the work was done poorly, and the mineral wool subsided, then on the device all the affected areas will have a red color.

- For ceiling plating is recommended to use self-tapping screws from hardened steel. These parts have excellent strength characteristics (they are not afraid of heavy loads).

- Never press stone wool, because the insulating qualities of this material are provided by bubbles in its structure.

- If it so happens that the heat insulating material is one level above the beams, then additional bars should be nailed to them.At the same time, it is necessary to take into account the thickness of the insulating layer.

- If you set the mineral wool in two layers, then the room will be much warmer. In this case, the method of laying insulation will be similar to laying brick - the upper layer will overlap the joints of the lower one.

- In areas where spotlights will be installed, it is necessary to leave a small space for air circulation. This will help to avoid problems associated with frequent blown bulbs.

- If you insulate a flat roof, it is recommended to buy the mineral wool in the form of slabs and lay this material in two layers.

- External insulation of the ceiling is recommended to be carried out in those rooms in which there is free access to the outer half of the ceiling structure.

- Choosing the thickness of mineral wool, it is necessary to pay attention to its density. If this parameter is 50 kg per 1 cubic meter, you can search for a thicker material.

- It is possible to warm the ceiling with mineral wool not only manually, but also with the use of a special blow molding installation.

- It is recommended to warm the mineral wool ceiling in summer. It will be easier to remove excess moisture and condensate.

- It is possible to proceed to the finishing of the ceiling only after all the layers of glue have completely dried. At the same time, mineral wool is permissible to paint, plaster and even cover with such material as siding.