Metal siding: characteristics, advantages and installation

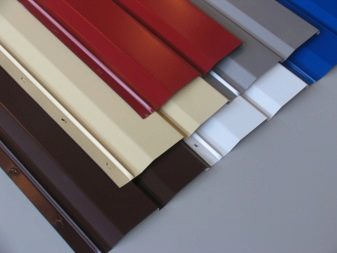

Metal siding is a fairly popular building material. The scope of its application is facing the walls of private buildings, as well as industrial facilities and other types of buildings. Metal siding is a special galvanized sheet, which has a coating based on polymers. The demand for this material in private and any other kind of construction has led to the fact that it has a large number of colors.

Special features

It should be noted that finishing the house in this way is considered to be quite a budget option for finishing buildings. As a rule, reviews of such material are often positive, and affordability makes it an excellent solution even for people who have a limited budget for such work.

At first, this lining option was used only for public and commercial buildings. But today it is increasingly possible to see the use of such a solution for private homes.This is not surprising, because quite good technical characteristics, as well as a huge color palette and the ability to choose the optimal dimensions of the panel and the necessary additional parts make this choice quite relevant.

At the same time, it would not be superfluous to note that for arranging the façade of a structure such an option is only gaining popularity, but those who have already made such an installation as a house covering are very pleased with their choice. Houses that are lined with metal siding look stylish and expensive.

Advantages and disadvantages

If we talk about the merits of the material in question, then The following characteristics should be mentioned:

- Low fire hazard. The fact is that the materials used in its manufacture do not have combustible characteristics, which is why metal siding itself is not afraid of the effects of fire.

- Durability and strength. The considered decision belongs to the category of especially durable solutions. A number of manufacturers give a guarantee on their products for 50 years.

- Versatility in terms of size. In each case, the individual production of the material, which is oriented specifically to the parameters required by each specific client, makes it possible to save time.Of course, if you do not take into account the cost of fitting the sheets during installation, as well as the cost of the lining, there will be no scrap for which you will also have to pay.

- Easy to install and use. Installation of siding sheets can be easily carried out personally, which will make it possible to seriously reduce the cost of the cost of facing the building. In addition, we note that the siding itself resists the effects of various natural factors and the effects of a physical nature. It is easy to clean and repair, if necessary.

- Environmental friendliness. Metal siding is made from environmentally friendly materials, for which reason it does not contain any harmful or hazardous substances that can have a negative impact on the human body.

- Resistance to temperature changes. It should be said that siding has almost zero susceptibility to temperature variations. It also has pretty good frost resistance characteristics.

- Excellent color and corrosion resistance. Metal siding has a multilayer structure, which makes this material resistant to such phenomena as color loss and corrosion.

- Great opportunities in the field of staining.As already noted, the siding is painted in a huge number of colors. In addition, it can have a different stylization: under a stone, brick, timber, granite, and so on.

But this material, like any other, has its drawbacks. For example, we are talking about the fact that it has a rather low thermal insulation coefficient. In addition, it should be called a small mechanical strength, as well as the lack of repair, if such a coating is still damaged. But it should be noted that the strength indicators of the physical type depend on each particular manufacturer, as well as on the materials from which they make their products.

Note that in some European countries the thickness of the siding sheet can not be lower than 0.6 millimeter. But domestic, as well as manufacturers from the Middle Kingdom can make sheet panels with a thickness of only 0.45 millimeter. It is for this reason that the indicators of mechanical strength can drop significantly.

Also to the disadvantages include the fact that when the appearance of dents, the panel should be immediately changed to prevent the formation of corrosion.In addition, it has not very good sound insulation characteristics - a knock on metal siding will be heard much better than on any other similar material.

It should be said that the production of siding is carried out from steel sheets with galvanized coating and a variety of polymeric compounds. As a rule, it has a smooth or profiled surface. It is usually made in the form of sheets, the length of which does not exceed 10 meters. The width is not clearly regulated. According to need, the sheets are simply cut in such a way as is convenient for the customer.

Note that the siding is fixed on the crate, which is made of wood or metal, which is attached to the house. Siding panels are usually attached horizontally.

Kinds

If we talk about the categories of metal siding, then today manufacturers produce its various types. The first type that is worth mentioning is the so-called “shipboard”. This name is chosen for the reason that its shape resembles such a board, which is usually used to create a ship covering. This model is one of the most popular and can be calledclassic. Metal profiles of this form are simply installed. This is usually done in a horizontal position.

Such a profile quite simply fits, which causes excellent surface strength., a large operational life, and also makes it a great solution for exterior decoration, because the building gets a very aesthetic look. The surface of this material perfectly resists fire. It is environmentally friendly and can withstand considerable physical exertion.

The length of this type of material is up to 6 meters, and the thickness is about 0.5 mm. As a rule, its installation is done on a light vertical frame.

The next type to be mentioned is the mechanical block house. This option gives the buildings a nice modern look in a log design. Such a panel is stylized as a natural log. This type can be used not only for external, but also for interior decoration of a private house or any building. The advantage of this type of material is that it is not necessary to additionally treat it with antiseptic mixtures, as well as to paint it throughout the entire period of its operation.

As a rule, this type is installed on the crate.If necessary, this design makes it possible to carry out additional insulation. At the same time, the weight of the siding is small, which does not create additional loads on the construction of the house.

This type is often made on an individual order, which makes it possible to save money. Yes, and the installation is easy to do in any time period during the year.

The next common type is eurobar. This version of siding is a single-row panel, which will be similar to the form discussed earlier. It can be used in both exterior and interior decoration of the building. A variant of this type will be classified as fire resistant. This type of siding also does not need any processing. Use the profile can be in different positions.

The installation of this siding also occurs on the batten, which allows, in this case, to carry out the installation of thermal insulation.

The next type of metal siding is called the "crown". Its difference from other materials - in special strength, as well as maximum resistance to fire. Using this version of the coating, you can hide any external flaws of the building.If the installation is carried out correctly and efficiently, the coating will serve for several decades. Even with a permanent impact, specifically this option will not lose either its appearance or its main characteristics. It should be said that this siding, which is based on the metal, is not affected by fungus, insect attacks, and rotting. In addition, the building itself can breathe, which will not cause the appearance of mold. This siding is also called steel, since cold-rolled steel, which is half a centimeter thick, is used for its manufacture.

Steel treated with polymer and zinc coating. Recently, this material is available in a large range of colors, and also has a coating of plastisol and polyester.

The advantage of it will be mounting. It is made so that you can make hydro-and thermal insulation under the panels. This allows the building to be heated, as well as to protect it from excessive temperature extremes.

Aluminum siding - one of the options for metal siding. This option is used only for exterior decoration of industrial premises.After the lining is created, it is covered with special polymeric structures that protect the panels.

Aluminum siding is an excellent solution also because they are light, strong and durable. But they are more difficult to install than PVC-based panels. They are perfect for finishing private buildings. The only negative is the lack of elasticity of the material.

Steel version may have a different surface - profiled, smooth, and so on. This profile is intended for trimming the outer facade of various buildings. The use of these profiles is carried out in the construction of buildings requiring mechanical strength and durability of the material.

Dimensions

This facing material is made in the form of various kinds of panels, which have different sizes. Their length can be 3, 4, 5 and more meters. It is necessary to choose the length in accordance with the parameters of the building with which you will work. Select this material should be in accordance with the physical parameters of the house. It is better to take sheets with a small margin so that in the process of installing the joints there is a minimum amount.

If we talk about width, the standard step in this case will be 120, 300 and 550 millimeters.

You can install such siding both horizontally and vertically. Everything will depend on the direction of the building to get rid of.

Design

In order to satisfy the demands of customers with different wishes, manufacturers today produce this material in the following varieties:

- smooth;

- wall;

- metal soffit;

- under the stone;

- under the tree.

Now let's talk about each type in a little more detail.

A variant of metallophyte is made with different surfaces. It can be smooth, perforated or partially perforated. Using perforation allows the siding to breathe and not accumulate moisture, as well as precipitation. Typically, this siding is used to trim the slopes of the roof, as well as gables and cornices. Panels of this category have special elements of the castle type, which makes it possible to clearly fix them together.

Fastening metal-metal construction to the surface frame is carried out using self-tapping screws. Such panels are usually made of the same color.

The next view is wall. This type of design is usually done in a panel version with a smooth surface, as well as an angular type profile, made under the “herringbone” - double or single. Also a kind of wall covering will be “shipboard timber”, which was discussed a little higher. This option is considered universal. The fact is that facing it is possible both residential and industrial buildings.

Wall siding is usually installed on the frame or metal profile. If you fasten such panels with screws, then a clear monolithic structure is formed, which will become a reliable protection of the walls from external destructive impact.

Another type of material under consideration is flat or, as it is also called, flat. As a rule, it is made of aluminum, which helps protect it from corrosion and easily withstand high temperatures. In addition, it is very easy. The only drawback is its susceptibility to physical deformations.

It should be said that on this type of siding, unlike all the others, there is no special groove. Usually, the panels are placed on a horizontal frame in an upright position during installation and secured with self-tapping screws.After the installation is completed, the metal part is coated with polymers for protection.

Wood siding has a front surface that simulates a smooth wooden plank. Coating of this type, in contrast to natural wood, does not require constant paint treatment, as well as coating varnishing. Yes, and cladding such panels will be significantly cheaper than natural wood.

This option is an excellent solution for exterior facades of buildings for various purposes. And if we talk about siding, which is an imitation of logs, it is extremely popular in order to design the facade of an elite house, cottage building or any structure.

Installation of this type of coating is carried out on a frame made of metal or wood, which makes it possible, if necessary, to additionally lay a layer of thermal insulation. Docking in this case will be invisible due to the presence of a wooden pattern.

The last option that you want to consider - siding under a stone. Such a coating is most often made of galvanized and polymerized panels.In drawing, as well as texture, these panels look similar to the original masonry of stone or brick. Figure may have a different location. The advantage of the material will be the presence of the polymer protection of the embossed face layer.

This option is used for finishing the facades of expensive country houses, as well as an ornament for the basement and the foundation of summer houses.

Installation

Before starting the installation of metal siding, everything should be carefully measured so that the material itself is somewhat larger, since natural losses will occur during the process of cutting it. In addition, you should not save on mounts, because they will ensure the reliability of the facade design. Also, before direct installation should be well prepared surface of the walls.

The first stage of installation is the installation of the batten. It is the most important, because it will set the strength of the whole structure. To do this successfully, it is best to use metal profiles, which are used for cladding with plasterboard, or the slats of wood. The location of the batten will depend on the type of siding installation.If its location is vertical, the crate will be mounted horizontally, and vice versa.

Also, in order to have a solid construction, it is necessary to choose the correct distance between the bars. The best step will be 40 centimeters.

In the second stage, you will need to attach the frame to the surface of the wall. In order to design in the future looked great, you should know a few rules. Siding panels must lie on two profiles and two slats at the same time. At the same time, the crate should not peep. Fasteners must be sturdy, and the flatness of all surfaces should be checked using a level.

Before you start directly mounting the siding, you should mount the insulation layer. Polyfoam, polystyrene, and also other types are quite good decisions. But if you want to achieve the maximum effect, it is best to use mineral wool. It perfectly retains heat and at the same time allows the walls to breathe. To mount it, simply cut the material into strips, then lay tightly between the profiles.

In order for the insulation not to be damaged, the next step is to install a vapor barrier film.It should be laid from the bottom of the facade, moving up. And it must be done in such a way that the sheets overlap each other.

After that, the last step remains - the installation of metal siding panels. To do this, you need to unpack it and remove the film. Now you can proceed to the immediate installation of panels. It should be carried out from the bottom up.

Each panel that is inserted into the beam of the guide type must be attached to the sheathing with nails and screws. A certain complexity can be caused by the installation of the last panel, which most likely will have to be trimmed with the help of a grinder.

Hide the place of the cut will help install the finishing bar of metal siding. This will be the final stage, after which the installation process will be completed.

If everything was done according to the above instructions, then the facade of the house will delight you for more than a decade. As mentioned above, the service life of sheets is about 50 years. In addition, you do not have to paint the walls of the house every few years.

Although if you wish, you can easily change the white color to green or any other - as the material performed its tasks qualitatively, it will continue to do so.

For more details on the installation of metal siding, see the following video.

Tips

Sheet cutting should be done exclusively with a hacksaw or with scissors. If you want to use an angle grinder, then you should know that it will almost completely damage the coating based on polymers, which is why after some time rust and corrosion will start to form on the panel. In addition, one should not fasten the sheets to the crate too much, because if there is a temperature difference, then such a sheet can bend.

Screws must be screwed clearly perpendicular, mounting them in the perforation center. Each sheet should be fixed at each crake rack without exception. Another important rule is that the installation of panels of this type should be carried out exclusively from the bottom up, starting from the left corner to the right.

For cladding private homes would be best to use siding, stylized as a log. It practically does not undergo temperature changes, and its external part burns out very weakly.When installing cladding, only horizontal or vertical siding should be used. Connect together both options can not.

When buying a siding, be sure to ask the seller for documentation on it. And at the time of purchase, be sure to check the warranty period for this material.

In addition, the main criteria that should be paid attention to when buying are:

- panel thickness;

- quality of the outer surface;

- presence of fasteners;

- weight per 1 m2;

- Colour.

Exactly install vertical siding only in the direction from top to bottom. It would not be superfluous to say that when installing the siding must be installed metal crate. This will make the structure really strong and will protect from the formation of various kinds of deflections on the walls.

It will not be superfluous before purchasing the material and get acquainted with the rating of various manufacturers, as well as read customer reviews about the use of products of a particular brand.

There are cases when purchasing a cheap material there is a substantial overpayment for its component parts.For this reason, you should carefully analyze the cost of not only the material, but also additions to it.

Also beware of fakes. It is for this reason that it is imperative in the stores to require certificates of conformity with seals and all the other documentation for the goods you are interested in.

It is best to buy siding in companies that offer its services for the sale, delivery, and installation.

Beautiful examples

Iron shipboard brown siding looks very good. This option will be a very interesting solution for small buildings for various purposes.

Also an interesting solution would be a combination of this material in various colors. For private homes, white and brown siding would be a good color option.

And the block house today is a good option for private construction, at least for the reason that allows you to make any building looks like a house made of high-quality timber. Moreover, there are various solutions that allow you to make a sheathed house under pine, oak or other types of wood.