The subtleties of the house siding with insulation

Siding siding has a protective and decorative value, and if a layer of insulation is laid under the panels, it will be possible to improve the thermal efficiency of the house. True, a positive result is possible only with the correct selection of materials, the correct calculation of their quantity and thickness and compliance with the installation technology.

Special features

House siding allows you to immediately solve several problems:

- protect the facade of the building from the negative impact of the environment, and thus extend its integrity and durability;

- improve the thermal efficiency of the building through the installation of siding on the principle of ventilated technology, as well as through the insulation of the facade;

- to give the building an aesthetic appeal, to unify or, on the contrary, to distinguish it from others.

Siding is a panel that are mounted in a "dry" way., that is, they do not require the use of concrete mixes, but are mounted on dowels or nailed.

This can significantly reduce the complexity and size of the estimate for construction.

Fastening of the panels is usually made on the frame, which is packed on top of the facade. Due to this, you can not achieve a perfectly smooth surface of the walls, close your eyes to minor defects - they will not be noticeable under the crate. Moreover, by adjusting the thickness of the batten and its distance from the wall, it is possible to insert a heater of the desired thickness between the facade and the siding.

As you know, outdoor insulation is more effective than internal, does not take away the useful area of the room. By installing a heat insulator in conjunction with siding, it is possible to make this process even more convenient, quick and less costly. It is important that all the work can be done by hand, not being a professional builder.

By itself, ventilated cladding technology allows for some thermal efficiency, since there is an air gap between the siding and the facade that prevents heat loss.In the conditions of the Russian climate, a thermal “cushion” with a thickness of 3-5 cm, of course, is indispensable; installation of a warming material is necessary.

However, it is the siding covering with simultaneous insulation of the facade, produced by ventilated technology, which is currently considered the most rational - it is possible to reduce the heat loss coefficient of the walls of the building to optimal performance. The process is quite simple, all materials are affordable.

In addition to thermal insulation, the air gap acts as an additional method of ventilation of the facade., allowing the insulation not to absorb moisture, which, in turn, prevents it from getting wet.

Siding panels are lightweight, therefore they do not require (in most cases) preliminary reinforcement. They are suitable for all types of surfaces and most varieties of soil.

Selection of materials

Having decided to perform facade insulation with simultaneous siding, it is necessary to select the material required for work. It can be divided into several groups.

Crate material

The crate is a metal or wooden frame, fixed to the facade,on which are mounted siding panels. Metallic has a greater bearing capacity and durability. Wooden counterpart in some cases has a lower cost, but is suitable for small wooden and frame houses, and also has a shorter service life.

Regardless of the type of crates selected, its elements need preliminary preparation. Metal profiles are galvanized or another anti-corrosion protection method. The wooden logs of the frame must be thoroughly dried (permissible moisture - no more than 14%) and impregnated with antiseptics and fire retardants.

Siding type

Vinyl is a panel of polyvinyl chloride, characterized by low weight and affordability. They are weather resistant, shockproof, durable. However, with significant mechanical damage such panels can be deformed, crack or break. They have a rather tangible coefficient of expansion depending on temperature, which should be taken into account during installation.

There is an acrylic kind of vinyl panels. These products contain a certain amount of acrylic, which makes them more durable, stabilizes shade, slightly improves performance.

At the base of metal siding is a sheet of metal with anti-corrosion protection. This allows to level the main drawback of metal siding - susceptibility to corrosion, which, in turn, reduces the quality and durability of the material.

This siding is much stronger than vinyl, it is not damaged by strong blows.

Despite the fact that the metal counterpart is also fairly light, in some cases reinforcement of a weakened foundation is required. The greater weight of the material compared to vinyl panels makes the installation heavier.

Metal siding is also resistant to the negative effects of the environment, and besides, it is non-combustible, demonstrates a longer service life.

The basis of fiber cement panels is a material based on Portland cement or other cements with improved technical characteristics and recycled cellulose. Due to the peculiarities of the composition and production technology, they get very durable and durable siding, which, however, has an impressive weight. This allows you to use it only for buildings that have a solid foundation and installed on solid ground.

The siding can differ not only material of production, but also design. They emit colored panels (they can have a bright or pastel color, be matte or glossy), and also imitate wood, stone and brick surfaces.

Heater

For exterior plating, you should choose a heater that has a minimum coefficient of heat loss. In addition, it is important that it is resistant to moisture (otherwise a powerful waterproofing system and additional ventilation will be required).

It is recommended to choose fireproof insulators or, if possible, combine incombustible panels with weakly combustible insulators, and vice versa. Attention should also be paid to the ability of the material to emit toxic substances during combustion.

Of course, its biostability, durability, ease of installation is important. As practice shows, the simplest from the point of installation are materials in sheets, mats, as well as sprayed (however, they require the involvement of professionals and the use of special equipment).

To date, the most common are the following types of heaters:

Styrofoam

Under this group hides a well-known foam and its improved version - extruded polystyrene foam. The heat efficiency of the sheets is related to the peculiarities of their structure - they consist of air chambers, however, in the extruded version these chambers are additionally isolated from each other. Due to this, it is possible to provide higher technical characteristics of the material. It is characterized by low heat loss (0.4 W / (m · ° C)), demonstrates maximum moisture resistance. Expanded polystyrene is a combustible material and even the addition of flame retardants to the extruded version cannot significantly change the situation.

It is possible to achieve even higher operational characteristics, warming walls with a penopleks. It is a type of polystyrene insulation. The best option for foam block and aerated concrete, brickwork.

Insulation is produced in the form of sheets having different thickness and density. Sheets are easy to cut with a regular construction knife, they are well fixed to the surface due to the smooth surface.

Mineral wool

A material representing fine fibers laid in a chaotic manner. Between the fibers remain the air cavities, which provide the insulating effect. Indicators of heat loss are similar to the coefficient of expanded polystyrene.

Available in 3 varieties, but only 2 are suitable for use in construction - glass wool and stone wool.

The first one is made of glass breakage and quartz sand, it is distinguished by plasticity (it is optimal for warming round or other surfaces of complex shapes), the burning temperature is 500 degrees. The disadvantage is low moisture resistance, a tendency to shrinkage (which is why the insulation layer becomes thinner over time, which negatively affects its heat efficiency), the need to work in a respirator, protective suit and glasses (the finest glass wool prick, easily penetrate the skin).

Stone wool is made of molten rock, therefore it is an eco-friendly and non-combustible material. It is less elastic (does not shrink), it is more resistant to water (but not able to repel moisture). Basalt (other name) cotton wool does not penetrate the skin and does not prick, but also breaks down into tiny particles that are dangerous to the respiratory tract.In this regard, it is better to work in a respirator.

Minvat is available in rolls and sheets, and if we are talking about high density material - in slabs. The most convenient from the point of view of installation is insulation minplitoy and sheet analogs.

Polyurethane foam

Warming polyurethane foam allows you to quickly organize a thin layer of insulation, which will be enough for high-quality insulation. The coefficient of its heat loss is 0.3 W / (m · ° C), it is moisture resistant, non-combustible, environmentally friendly.

The advantage of polyurethane foam is the absence of seams and gaps in the layer of insulation, which prevents heat leakage.

Spraying requires special equipment, so you have to invite specialists, which increases costs.

Penoflex

Modern insulation based on polyethylene foam, a feature of which is the presence of a metallized layer on one side. By itself, polyethylene has a rather low thermal conductivity, but the main thermal efficiency is achieved due to the reflectivity of the foil layer - it draws back inside the room up to 97% of thermal energy.

This allows you to use the material for both external and internal insulation, especially since it has a small (up to 0.5 cm) thickness.

The use of penoflex eliminates the need for additional hydro- and vapor-permeable layers. Insulation also has good sound absorption, easy to install. Available in rolls of various widths.

Materials for hydro wind protection, vapor permeable materials

This category can be attributed primarily moisture-proof film, which is placed on top of the insulation and protects it from moisture penetration, blowing by the wind. A more modern variation of this film is the diffuse membrane - it has the ability to remove vapors of moisture, but does not allow drops of liquid. In other words, at the same time provides vapor barrier and moisture protection.

Application area

It is not enough to know what materials are used for the insulation and cladding of the facade, it is important to combine them correctly. First of all, when choosing, one should take into account the material of the walls and the type of the house, its bearing capacity.

Houses on a pile and column foundation are usually built on unstable soils.therefore, heavy fiber cement, and sometimes metal siding, can hardly be used for plating. The most acceptable option is vinyl or metal (not all houses) panels.

For covering a brick house on a stable soil with sufficient bearing capacity, you can use all types of finishes, for cinder block it is better to abandon fiber cement siding and increase the thickness of insulation.

For registration of a country house, providing only seasonal accommodation, it makes no sense to spend money on more expensive metal siding, vinyl will be quite enough.

For houses in the construction of which wood is used, that is, lumber, panel, frame, it is undesirable to use polystyrene foam and polyurethane foam insulation. The wall under such heat insulators begins to get wet and rot, due to their low vapor permeability. The best choice for a log house or a timber house is mineral wool, always with a waterproofing system.

It is important to consider which part of the outer wall is revetted. So, for the base, more susceptible to mechanical damage and negative atmospheric influence,thicker and more durable basement panels should be selected, for the rest of the facade - wall panels.

What to insulate?

It is important to achieve the right combination of type siding and insulation. In general, there are no strict restrictions on certain combinations. However, from the point of view of fire safety, it is better to combine combustible materials with non-combustible materials, which will prevent the rapid spread of the flame around the ventilated facade in case of fire.

For example, low-combustible vinyl siding is recommended to be combined with polyurethane foam or mineral wool. Metal siding is a more expensive and fire-resistant material, so when choosing insulation, you can save a little and choose the polystyrene insulation.

Fiber cement boards themselves have a low coefficient of heat loss, so in some cases (for example, when covering the summer house), they can be used without an additional layer of insulation.

Scheme

Once the materials used have been identified, you should plan the house outside. It is necessary to calculate the number of siding panels, insulation, waterproofing film.In this case, calculations should be made taking into account a wooden or metal frame, since after its installation the width of each wall will increase by 3-7 cm.

First of all, it is necessary to calculate the thickness of the insulating layer. To do this, it is necessary to find out what resistance to heat loss should have an external wall in a particular region, as well as to clarify the degree of resistance to heat loss of the material of walls and other facing materials. These indicators are constant, they can be found in the building codes, learn from the official developers of a particular region.

Next, from the value of the required resistance to heat loss, subtract the coefficient of resistance to heat loss of the wall, cladding, etc. The remaining value is the coefficient of resistance to heat loss for a heat insulator. It remains to choose a material corresponding to the density and thickness.

You can do it easier and use the online calculator, which is usually available on the official websites of manufacturers of heaters or shops selling them.

It is enough to enter the required data so that the program automatically calculates the required material thickness, depending on whether you insulate the facade with mineral wool or other material.

The calculation of the number of siding panels is based on the size of the house. It is necessary to determine the area of the house (multiply the height and width of each of the walls and sum up the result), then subtract from it the area of areas that will not be sheathed with siding (window and door openings, balconies, etc.). Knowing this factor, you can calculate the number of panels, given the width and height of a single element.

As a result of such calculations, a number will be obtained, meaning the total number of panels required for finishing. It remains to divide it by the amount of siding in the package in order to find out the necessary number of the latter.

Typically, the material is purchased with a small margin, which is 7-10% for houses of simple construction and 10-15% for buildings with complex architectural elements, unusual geometry.

External insulation is important to produce without gaps, which strive to occur in the joints of insulation and elements of the batten. To fill them, you can purchase mounting foam.

Preparatory work

In contrast to the contact trim (painting, plaster), siding does not require a large amount of work.First of all, from the surface of the walls should be removed elements of communications - wiring, pipes.

Large cracks and gaps should be puttied, collapsed parts of the facade should be strengthened. If you intend to stick sheets of polystyrene foam on the painted facade, the paint should be repelled. The solvents which are its part destroy expanded polystyrene. The same applies to oil, gasoline stains - they should be eliminated.

A small (up to 2 cm) difference in the height of the facade can be not corrected - it will be hidden by the batten system. Wood surfaces should be coated with two layers of deep penetration primer.

The next stage of the preparatory work is the installation of the subsystem. First, large panels are installed along the perimeter of the facade, then comes the laying of vertical panels with a pitch corresponding to the siding width. After this, the verticals are connected by shorter horizontal elements.

The crate is mounted on brackets. Its height is determined by the thickness of the insulation, taking into account the fact that between the layer of insulation and siding should remain an air gap of 3-5 cm.

Installation

The step-by-step instruction for siding trim is quite simple:

- corner elements are mounted on the mounted frame system;

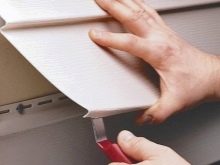

- at the starting level installed at a height of 15 cm from the ground, the first panel is fastened, which comes under the corner element, engaging with it (thus, you should always start from the corners);

- the remaining panels of the first row are laid out in a similar way, then you can proceed to the installation of the second row, which is engaged with the previous grooves;

- the last row is slung over the edge of the pre-installed finish bar.

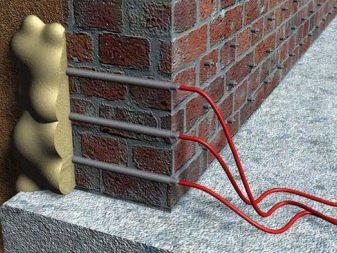

Facing together with warming provides preliminary laying of a heater. Its width should be similar to the step of crates, in order to exclude the appearance of “cold bridges” at the points of junction of the insulation and the frame profile. Insulation is usually glued to the surface or fixed with temporary plastic dowels. A wind-proof film or membrane is laid over the insulation. Its strips are glued overlapping, the joints are taped.

If you decide to decorate the walls with penofol, then it is placed inside with a metallized surface, fixed with dowels or small studs. A layer of waterproofing and windscreen is not required.

After the waterproofing layer has been glued, it is important to additionally strengthen the insulation on the wall. This can be done with the help of dowels of the umbrella type, which simultaneously “pick up” both the film and the insulation. On 1 m2 of insulation enough 3-4 fasteners, one of which should fall in the middle.

After this process is completed, the frame should be sheathed with siding, the technology is described above.

For finishing horizontal surfaces and facing the gable usually use a special kind of siding - spotlights. They are designed for mounting on horizontal surfaces and for filing the eaves of the roof.

For finishing openings, you should also use special elements - near-window profile or trim.

Reviews

As already mentioned, cladding facade siding with insulation is one of the most common methods of design and insulation of external walls. This technology has many positive reviews.

Homeowners note the effectiveness of this method - it becomes noticeably warmer at the end of work in the house, and the cost of heating it is reduced.

It is important that the work can be done by hand,although a large number of users recommend still to entrust the calculations of the required amount of insulation and its thickness, siding professionals.

Sometimes you can hear that the insulation when using this system is wet. This should not be considered a disadvantage of the applied plating method, the point here is a violation of the technology: either the quality of vapor insulation and insulation of the insulation is not provided, or there is no leak-proof moisture-proof layer on top of the insulation.

It is important to choose the insulation depending on the type of surfaces. It is considered optimal if the vapor barrier values are close to those of the material itself.

Tips and tricks

If necessary, laying a thick insulation layer, experts recommend using 2 layers of thinner insulation. Lay the next layer should be offset, so that the joints between the plates of the first layer do not fall into the gap between the material of the second layer.

Screw the screws or hammer the nails into the perforations provided for this purpose strictly in the center of the holes. Fasteners must be purchased galvanized.

If you need to make a through hole in the siding under the screw it should be pre-drilled, and only then insert fasteners. Preference should be given dowels with a seal, the presence of which will prevent moisture from entering through the hole into the system.

When installing vinyl panels should be remembered that they tend to change their linear dimensions depending on air temperature. To avoid deformation and damage to the material allows the preservation of a gap of 3-10 mm between the panels.

Installation tips are in the next video.