The subtleties of warming the house mineral wool under siding

With the insulation of a country house it is quite possible to cope on your own, it is only important to know some of the features and comply with the technology. We will tell you about some important points of the work on mineral wool insulation for siding.

Special features

Warming of a wooden country house is associated with certain rules and features. So, it is not always necessary to warm the house directly after construction: most of the wooden houses are warm enough by themselves, without additional warming. However, if a wooden house was built many years ago, and cracks formed in a timber or logs due to humidity and frost, then warming the house outside the mineral wool becomes really necessary.

Siding will be useful for small country houses, when the thickness of wooden walls does not meet the requirements of thermal insulation and the owners have to spend too much money on heating. Vinyl siding is an affordable finishing material that has a long service life and is easy to install. It is not enough one siding for high-grade warming, therefore as a external heater under a siding mineral wool is most often used.

To preserve the optimum microclimate in the premises after the insulation works, the following conditions must be observed:

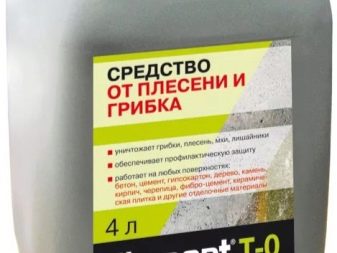

- Before carrying out thermal insulation works, wood is treated with special compounds against fungi, mold and wood beetle.

- Warming should not block the water vapor out, therefore, in the production of works strictly follow the appropriate technology.

- A vapor-permeable membrane (also called a diffuse windproof film), which is fixed on the outside of the insulation, will help to maintain the balance of humidity. Even if water suddenly seeps under the siding, it will not fall into the layer of stone wool or wooden walls.

Advantages and disadvantages

It is easy to replace any panel of siding with your own hands, moreover, this material is durable and durable.And mineral wool, and siding - materials are not heavy, so even one person can handle installation.

The humidity of wood at home depends on the difference in outdoor air temperature and indoor temperature., and if the figures vary greatly, the tree begins to actively absorb moisture from the inside, giving it away from the outside. This process suggests that the house "breathes", not allowing moisture to accumulate in the structure of the tree. External insulation will shift the "dew point" to itself, and wooden buildings will be protected from moisture.

If the house is located near the noisy highway, then the insulation of mineral wool will help to create excellent sound insulation. All types of mineral wool have good thermal insulation properties.

Neither mineral wool, nor vinyl siding are not damaged by insects and rodents. Also, these materials do not develop fungi and mold. Mineral wool has excellent resistance to fire, it is universal and suitable for buildings built in a warm climate, and in a cold one.

Scope of application

Minwat today is widely used in a variety of designs. So, with the help of it insulate the roof, insulate floors and walls.Minvat will retain heat and microclimate of not only a log house, but also a brick house. Thermal insulation with this material will make living in stone buildings more comfortable.

Basalt mineral wool is an excellent barrier to fire, therefore it often protects ventilation shafts and similar structures. Due to the fact that basalt wool is resistant to high humidity, it can warm baths and saunas, protect “wet” facades and even ship structures.

Basalt wool is suitable for protecting pipelines, as this material is resistant to both rising and falling temperatures. If serious loads on the surface, insulated by mineral wool, are assumed, then mats of the highest rigidity should be chosen.

Experts recommend that when exterior insulation of the facade of a log house does not use polystyrene foam and other synthetic or foil-coated materials, as they do not allow water vapor to pass through, which means they will not allow the house to “breathe”. Improper insulation can lead to the destruction of wood due to mold and mildew, harmful to human health.That is why wooden houses are best insulated with mineral basalt insulation - mineral wool.

This insulation is made of various materials - from blast furnace slag, glass and sand to recycled volcanic rocks, for example, basalt. The best option is considered basalt (stone wool), which is considered to be very durable and has a very low hygroscopicity.

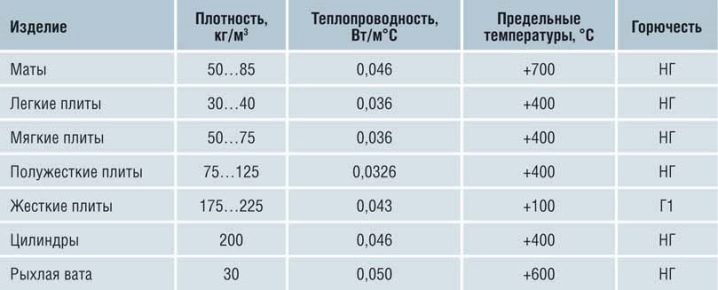

Specifications of stone wool are as follows:

- the coefficient of thermal conductivity of the material ranges from 0.032 to 0.048 W / m × K;

- moisture absorption - no more than 2% of the volume (or even less);

- Stone wool can be of different density, it depends on whether you use stone wool in slabs, mats or rolls;

- the material is not combustible, which is important when it is warming wooden walls.

External warming is usually made by semi-rigid basalt mats with a density of 80 to 150 kg / m3. These mats can be of different sizes, so you can choose the one that you need. Experts do not recommend the use of basalt wool in rolls for wall insulation, because over time the rolled material sags.

The thickness of the heat insulator depends on the region in which the house is located. The harsher the winter, the thicker the insulation layer should be. In Central Russia, this layer is 150 mm, while the insulation is mounted in two layers (100 mm and 50 mm). If you need to increase the thickness of the insulation, you will have to mount another row of sheathing.

How to warm?

The technology of wall insulation involves some preparatory work. The walls are cleaned of dust and dirt, at the same time noting all the gaps and cracks - it is convenient to make a white marker, so you definitely will not miss even the smallest gaps during further work. Next, the walls are treated with wood preservative. After drying, the gaps are sealed with a special latex sealant for wood, which will prevent “cold bridges” - paths of cold air entering the house. If there are too many cracks, then sealing them with a sealant will be expensive, in this case tow, moss and any natural materials are used for sealing.

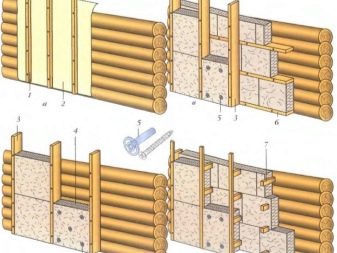

Before starting installation of mineral wool and siding, it is necessary to install the frame (crate). To do this, suitable timber or galvanized profile, and experts prefer wood. The fact is that when the temperature drops in the street, condensate may form on the metal elements.

You can not forget about the installation of guides and constant monitoring of surfaces by the water level, since all the elements of the batten should be in the same plane. Guides fasten not only at the corners of the building, but also around the doors and windows.

Before starting work on fixing the timber to the wall, it must be treated with wood preservative. While it dries, on the surface of the walls mark with a white marker the places of future fixings of the guides.

The distance between the elements of the batten is usually made 5 centimeters less than the width of the insulation mats, which is necessary to install the mats tightly, “unstack”.

If the walls of the house are very uneven, then in some places under the crate will need to strengthen the wooden lining. The vertical or horizontal fastening of the guides depends on how you plan to fix the siding in the future. If vertically (standard method), the guides should be mounted horizontally. The crate can be fixed with both self-tapping screws and nails, it can also be fixed with metal corners for additional strengthening. When mounting the guides, consider the clearance (up to 5 cm) for ventilation.

After the installation of the frame, you can proceed to the installation of mineral wool. Mats put between the guides of the frame, starting at the bottom. It is important to stack them tightly, without gaps and cracks. If the layers of mineral wool are two, then the first one is laid which is thicker. If the heater needs more than two layers, then the second crate is fixed to the first one. For example, on the horizontal - vertical.

In general, it is quite easy to stack material. Difficulties can arise only with the space around the doors and windows. In order that there are no cracks left, you need to cut strips of mineral wool of the desired width and fix them in the remaining free space. The layers of mineral wool should not be bent out.

After laying the layers of insulation, the walls are covered with a windproof membrane. Her pieces are connected with building tape or fastened on the elements of the sheathing with the help of a construction stapler.

After all the work, the construction must be “stitched” with special plastic fastenings - “fungi”. They will press the insulation against the wall and will not allow it to "slip".

The next step is the installation of a counterbracket for siding. This is done directly on top of the windproof membrane, screwing the bars, which will subsequently be fixed siding.

Works on mounting siding under the force even home craftsmen. It should start with the installation of ebbs, if the building has a protruding basement. If it is not necessary to install the reflux, then you can begin to fix the siding with reinforcement of the “starting strips” at the bottom of the structure. The “starting lanes” of different manufacturers can vary greatly and look different, and they can be distinguished by the locking connection, which allows the panels to be installed later to snap into place.

Siding is fixed with screws in the central part of the slit-like holes in the slats. After fixing the vertical and horizontal planks, you can proceed to fixing the corner profile, with all the details checked level - they are always strictly vertical or horizontal.

Special finishing strips are also located around the frames and doorways - they are then fixed elements-platbands, allowing you to hide the end of the siding elements.

If you are still inclined to install a metal frame, then do not forget to lay insulation in all the slots of the profile.In general, the installation of a metal structure is not very different from the installation of wood, but additional elements are required - direct hangers (profiles will be installed on them). Direct suspensions can also be used when fixing the wooden structure of the batten.

Tips and tricks

- Domestic mineral wool is heavier than its imported counterparts, so if you need to take care of the weight of the structure, you should choose an import manufacturer.

- It is impossible to carry out works on warming, if the wood is wet. It is necessary to let the tree dry out, otherwise fungus will inevitably form.

- Always leave a gap between the siding and the insulating material - it will allow air to circulate and evaporate excess moisture.

- Experienced craftsmen when choosing the thickness of insulation recommend to focus on the region where the building is located. So, houses built in Central Russia, the North-West and the Urals require a layer of insulation of 20 cm. For the southern regions of our country, 10-15 cm will be enough, but for Siberia - at least 35.

- According to the recommendations of experts, one of the best insulators is Beltep Facade 12 (“basalt wool”).

- Vapor barrier film is not suitable for protecting wooden walls, as it does not allow the house to "breathe." As a result, under insulation, the building will begin to rot and collapse.

- All siding elements are fastened with screws, while they can not be tightened too tightly.

- Lay out the siding panels before starting work and mark up the attachment points. So all fasteners will be on the same level, and the design itself will be more robust and even.

- No need to try to fit the panels to each other as closely as possible - between them there should be a small gap (5 mm). So siding will not suffer from temperature fluctuations, freely expanding or tapering.

On how to warm the house mineral wool under siding, see below.