Making and installing do-it-yourself lifting gates

When purchasing a car, the owners first of all think about a cozy, warm, comfortable and spacious dwelling for their steel friend. This individual space is called a garage. It can be attached to the house, or it can be a separate small building.

In any case, the garage simply must be equipped with a personal car entrance. Garage doors - the very first option in search queries for those who want to create this miracle of mechanics and technology with their own hands.

Types of designs

It would seem that what is simpler: choose a standard gate for your opening - and not have an additional headache. But craftsmen, proving to themselves and the world that they are not sewn, continue to look for new ways of saving and applying their own creative forces and technical skills.

Among the wide variety of garage doors, there are basic designs that delight even the most demanding car owners with their functionality every day.

The simplest ones are classic swing models.. They usually consist of two wings, one of which is the entrance door. As a rule, swing gates are very massive and take up quite a lot of space. Since their plowing requires a rather large amplitude. They are mounted on a metal frame, to which they are attached with strong canopies. Such gates require increased attention: control lubrication of mounted mechanisms. Due to the lack of care for swinging gates, it is sometimes possible to detect their sagging.

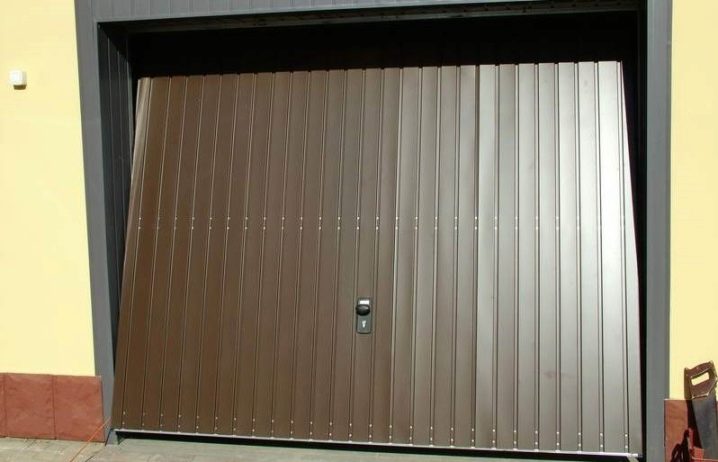

Sectional gates for the garage are a few metal moving canvases connected by loops. The edges of each part are equipped with special rollers that move along special guides installed in the doorway. They go under the ceiling, thanks to which the sectional doors smoothly go up, saving space in the room.

There is a convenient variation of this view when the gate slides off to the side.

Folding garage designs also consist of vertical sections. But more often they are swinging gates, folding along the sides of an accordion. Can be installed in the opening of any width (the number of sections - canvases will depend on this).

They can be installed in such a way that they will fold both inwards and outwards - depending on the size of the room and the need to save it. The main load falls on the walls and ceiling, thus, the space remains free and unused.

One of the most common and easy in the device types of garage doors are lifting structures. Like others, they can be automatic, but also have their own unique mechanism on the levers.

Mechanical model of the lifting gate opens and closes with a flick of the wristand by setting an additional bar with a motor, you can get excellent automatic gates on the remote control.

Materials

Any garage doors are made of the following basic materials:

- metal (profiled);

- tree;

- steel.

Structures made of corrugated board have a rather long life. and have high strength. Processed with special anti-corrosion agents, such doors will be resistant to moisture and temperature changes. In addition, the care of metal structures is much easier than for any other materials.

Decking is very easy to cut and is divided into the necessary sections / sections, removing the additional weight load on the rails. but when working independently on a garage door, it should be borne in mind that it is very easy to cut deeply about the cut edges of the metal. Elementary safety rules will save you from getting unpleasantly injured.

Wooden garage doors are less in demand on the marketbut also have their functional value. Along with metal, they have a low price. Wood is always beautiful and natural. Perhaps this is where all the advantages of the material end.

Wooden gates are fire hazardous, less durable and have very low strength. They are subject to decay even after treatment with antiseptic and other impregnations.

Steel structures are somewhat more expensive than wood and metal, but as durable and strong as the latter.

The main horse, which puts the majority of modern car enthusiasts and professionals in their field - sandwich panels. Practical and economical, such gates are good heat and sound insulators. They are very easy to install, warm and wash.. Excellent fire protection property will ensure your car stays safely in the garage with such a gate.

Profiled sheets are also excellent material for the manufacture of garage doors.. With such an entrance structure, you are not afraid of weather conditions and mechanical damage. This is a very durable, beautiful and economical material.

Dimensions

Modern manufacturers of garage doors offer a huge number of dimensional varieties of their designs. Some can even make them to order. Make the necessary measurements in your garage you will not be difficult.

There is also an opportunity to make an independent calculation using preliminary drawings and diagrams. Be sure to take into account the specifics of the room, the material from which your gates will be made, the weather conditions waiting for them at different times of the year..

Professionals insist that the overhead door can be installed exclusively in rectangular openings. The lifting mechanism is also impossible to do otherwise than inherent in the classical models.

A good option is to take ready-made standard drawings of a lifting garage door and substitute your own values there in order not to be mistaken. In this case, the scheme must take into account not only the size, but also the location of the whole structure as a whole. Particular attention should be paid to both the door leaf and the lifting mechanism.

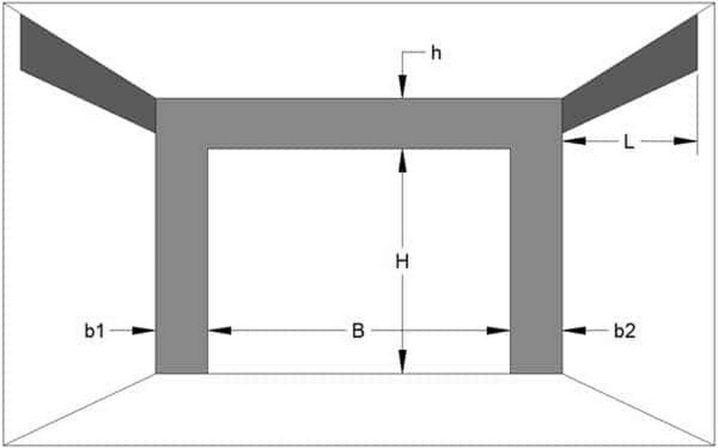

The drawing details what measurements and where to do it.

The decryption is pretty simple:

- H - the height of the opening in which the door frame and the structure itself will be installed. It is very important to understand that the total height of the opening and the maximum height of the car that can drive into the garage after installing the gate are two completely different things. This distance is measured in order to understand what kind of clearance is left on the gate to the ceiling.

- L - the lintel or the depth of the garage and b1, b2 - the shoulder pads are necessarily located in the same plane, but must always have different values. Moreover, L is always greater.

- B - the width of the opening should be measured with gaps of approximately 2 cm on each side.

- L - the depth of the garage is necessarily greater than the height of the whole structure of the door, otherwise the canvas simply has no place to "leave."

How to do?

Independent manufacture of lifting gates takes from two to five days. Depending on the desired result.

For example, there are two kinds of lifting mechanisms:

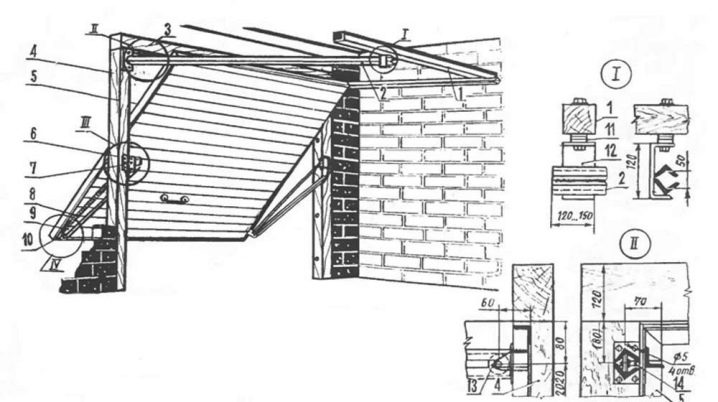

- Levers + springs. Not the easiest, but the most common and safest way to raise and lower the garage doors of small mass. Special attention during installation will have to be paid to the fixing and adjustment of the springs and the high quality of the guides for the rollers.

- Counterbalances. As a rule, it is used in the manufacture of improvised folding gates of great weight. The cable is tensioned from the lower corners of the canvas, passes through a special block and is attached to the counterweights on the other end of the winch.

The identification of lifting mechanisms provides a clear picture of what tools and materials you may need during the production and installation process.

Consider the main steps in the manufacture of garage doors lifting type:

First stage - creation of a layout and drawing of the future gate.This has already been a little said. But when describing the stages of production directly, it should begin with this.

The second stage involves the acquisition of the necessary tools and materials for the manufacture of the gate:

- Rectangular pipe profiles 40 * 20 mm and 20 * 20 mm. It is very important that they have sufficiently dense walls: at least two millimeters. The first are well suited for the manufacture of the frame of the canvas, and the second - for the longitudinal and transverse bridges and guides.

- Cloth gate. Here, the owner must decide for himself how he wants to see entry into his garage: profile sheet, sandwich panel, wood, metal.

- Wooden beam or metal corner. If you decide to use a lever-spring mechanism, such tools are ideal for you to mount it.

- Basic and retractable rollers and directly the mechanism of raising the gate.

- Insulation, if you decide to make your garage warm even in the cold season.

- A set of sophisticated tools: Bulgarian, welding machine, screwdriver.

- Among the simple ones, only that can be found in the arsenal of any master master: level, screwdriver, tape measure, pencil, hammer, wrenches.

When preparing the opening should take into account the fact that it should be in the same plane with the walls of the garage itself. This will improve the functionality and simplify the operation of the structure.

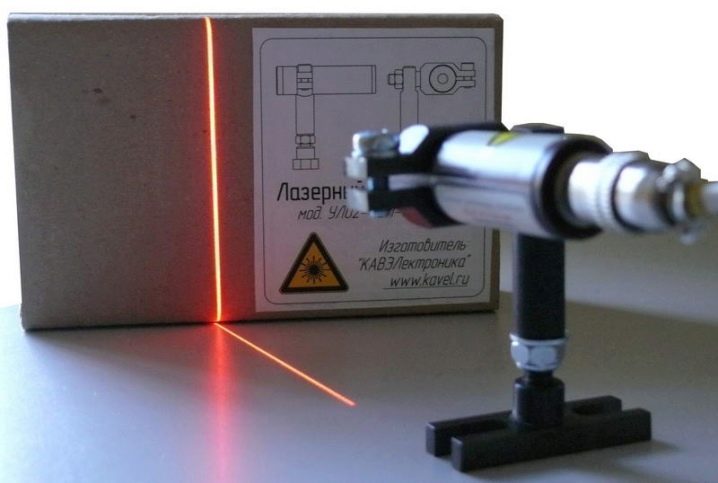

We proceed to the alignment of the walls, to adequately assess which will help the construction of water or infrared level. But also prerequisite is the strength and horizontal flooring.

So, all the preparatory activities have been carried out, we proceed directly to the manufacture and assembly of the garage garage doors with our own hands. And this will be the third stage of work.

Making a frame. This is the main element on which the greatest responsibility and the biggest burden falls. First, we collect the box, which will be made of wooden bars or a metal corner, as indicated in the required materials. The main feature of the manufacture and installation of the box-frame is that its lower part should go under the floor level by 2 cm. This is an additional means of fixing the structure.

It is important to remember that it can not be adjusted with the use of wooden wedges and foam.In order to "fit" the frame under the opening, you must use special metal inserts.

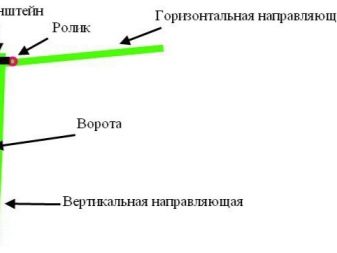

The next step is the installation of roller bearings.. First you need to install guides. They are sometimes called rails for rollers. This moment is important because the entire installation process must be accompanied by a thorough level measurementotherwise, the structure simply cannot function.

The picture shows the green rails and their proper installation to make it work.

It is time to proceed directly to the door curtain. Production options are simple and not very diverse.

There are three main types of installation directly gate shield:

- wooden frame of bars, sheathed with sheets of metal;

- one-piece metal shield;

- metal-profile base, which is also mounted solid sheet.

This is the other side of the coin, that is, what will be inside the garage. It's over, I want to add more insulation to our incredibly cold winters. As for the external processing, here everything depends on your financial capabilities and aesthetic preferences.

The fourth stage in the manufacture of overhead doors is to install the gate. If there is an urgent need for it, the production of the entrance door and its installation are carried out with greater ease. To do this, fit simple doors cut from the gate and installed on the hinges.. After the readiness of all basic structural elements, a complete check of the mechanisms, tightness, level and functionality is carried out.

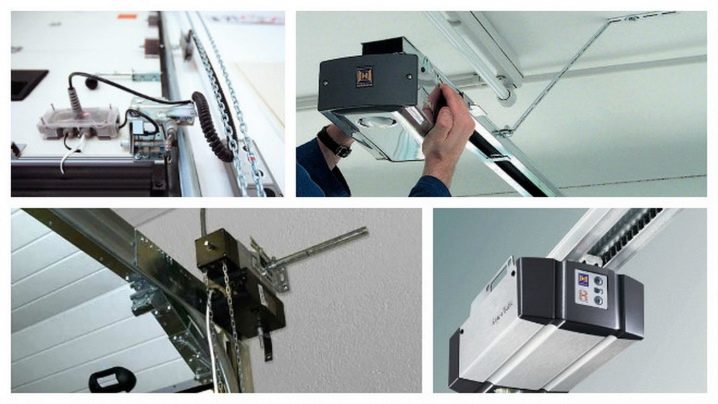

Many craftsmen in their video blogs talk about the possibility of automation of lifting gates. This is also the strength to make yourself the owner of the garage. There are three main components: an electronic drive unit (the brain of automatic opening and closing of the gate), a radio signal receiver, and a remote control.

For the installation of the first professionals advise to use almost improvised means, such as a reverse winch or electric window mechanism.

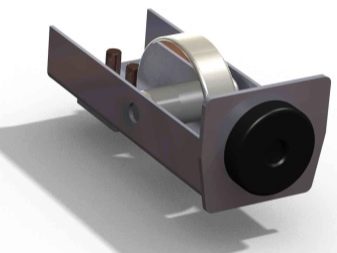

Another important point is the installation of a lock on the gate. Since such a construction can often be opened with one flick of the wrist, it is not difficult for attackers to deal with the gate and the contents of your garage.

Among the optional accessories that can be installed during the manufacturing process of a do-it-yourself garage door are more decorative tips: installing windows that increase the amount of sunlight and save energy.

As can be seen from the step-by-step instructions for the independent manufacture of a lifting gate, this process is rather laborious and sometimes even complicated. But thanks to the personal participation of the owner of the garage, it becomes noticeably more economical. For example, the average price of a lifting gate of a domestic manufacturer can reach up to 70,000 rubles. When doing all the work with your own hands, you save about 60,000 rubles, taking into account the installation options.

Observing all the rules and steps in the manufacture of garage doors with a lifting mechanism, you get a universal and unique design that will protect your car at any time of the year.

Operation Tips

Basic tips and recommendations for the operation of the garage doors of the lifting type are reduced to the maintenance, adjustment and repair of all components in particular, and the system as a whole. For example, all rubber seals require additional periodic lubrication with silicone.This will help avoid cracking or frosting in the frosty season.

The lever system requires constant lubrication so that it does not rust, creak and work as long as possible. Rollers, by the way, have the same uncovered need. The tension of the springs needs constant adjustment so that the operation of the garage doors of the lifting type is as comfortable and durable as possible.

If the tension weakens, the gate can simply not open. And if, on the contrary, the spring is overtightened, then the sash can be tilted, and damage to the canvas.

In case of mechanical damage to the door leaf, it is no longer possible to fix it. Since it is installed as a single sheet, it will be necessary to replace the entire main door cover.

After all the basic work on the fabrication and installation is done, you should worry about security systems. So, it is best to install the feet on the rails so that the sheet does not go off the guide during operation.

One of the main advice of professionals and amateurs of their business is the timely diagnosis of the state of the whole structure as a whole. As well as constant monitoring of the state of its components.

Hand-made manufacturing of overhead doors for the garage is a very complicated process. It requires constant monitoring, increased accuracy and responsibility. Getting to work, you need to weigh the pros and cons of this process, and already with confidence to take it. Taking into account all the nuances, tips and recommendations, any car owner will be able to make exactly what he really wanted, but it was scary to imagine. All people are blacksmiths of their happiness and their surroundings.

If you have already decided on the design, made all the necessary measurements, half the work has already been done. The most laborious and the one in which there is no way to make a mistake. A welding machine and Bulgarian - not the worst animals of the construction world. Go for it - and you get the perfect result for a very modest cost.

See how to make a do-it-yourself lift gate in the next video.