Tilting gate: do-it-yourself protection for the house

A practical, reliable and convenient garage construction of the fence is called an overhead gate. When opening, such a gate installation takes a horizontal position with an extension slightly forward, forming a sort of small overhang above the exit.

Main characteristics

The tilt-up installation is distinguished by obvious advantages that other types of gate installations do not have:

- the strength of the whole web will ensure reliability, protect against unwanted break-ins, and prevent extraneous penetration;

- if during the assembly of the door structure to comply with the existing technological recommendations, the surface of the structure will be resistant to corrosion for a long time;

- such gates will not require a separate free space when opening;

- open gates do not occupy useful space;

- a garage installation is made with various finishes, decorated with various panels, diluted with inserts;

- garage doors are insulated with expanded polystyrene - this makes it possible to insulate the box and thereby prevent the appearance of condensation;

- the structure can be opened manually or automatically by equipping the flaps with an automated opening system;

- establish similar designs and in double garages, and single.

Tilt and turn door systems also have disadvantages. They are associated with the existence of restrictions, certain features of the installation:

- the gate structure is installed only in a garage opening of a rectangular appearance;

- open gates reduce the height of the garage opening;

- the integrity of the paintings will not allow repair of small individual areas - with the appearance of defects, it will be necessary to completely replace this element;

- the gate must be equipped with a spring mechanism. This mechanical installation is usually designed only for a certain weight of the gate. Consequently, it is necessary to take into account the severity of the insulation during the construction of insulation.Insulated gates add weight, respectively, need to install counterweights;

- between the canvas and the frame itself may appear crevices. Thanks to the rubber sealant, these slots can be blocked.

This design is recommended to choose for garages without heating.

Operating principle

In terms of their design, a tilt-up or shield gate is fairly simple. The whole structure is made up of the frame, the panel itself, the guides, due to which the gate can be rotated, taking up a vertical and horizontal position.

The basis of the entire system is steel welded frame. It is installed in the garage opening for moving the door installation. In the production of such a frame, pipes with a rectangular section will be needed.

When opening, a roller mechanical device is used and reinforced lifts - levers, thanks to which the door leaf moves along the guide, fixing itself under the garage roof. Forms a kind of canopy. When closing, the compensation springs stretch and, conversely, remain free when opened.

There are two types of opening mechanisms:

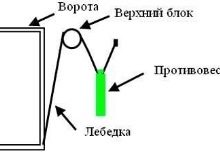

- Counterbalanced Device. This type of mechanical device consists of a powerful cable attached to the welded frame in the bottom corner. The cable passes through the blocks and counterweights mounted on the winch. This device is recommended to be used when assembling massive heavy gate structures.

- Pivot arm. This mechanism is very simple. Maybe that's why he is so popular. The reliability of the mechanism in ensuring the simplest movements that prevent blocking the device.

An indispensable requirement for the installation of such a mechanism is considered to be a well-thought-out adjustment for tensioning the springs, and high-precision mounting of the guides.

You can control the shield gates manually or using an electric drive, that is, to automate the control process.

Selection of building materials

Pick up building materials for the production of tilt-up door installation with your own hands you need based on the used mechanical device and fabric.

To make the simplest design will need:

- wooden bars used in the assembly of the box. Section - 12x8, ceiling - 10x10;

- iron pin;

- corners necessary for the production of the frame - product size - 3.5x3.5x0.4. In the manufacture of rail, corners are needed - 4x4x0.4 cm;

- channel bracket - 8x4, 3x0.5;

- spring with a 3-centimeter diameter of the inner hole;

- iron rod used in the assembly of the voltage regulator with a cross section - 0.8;

- electric drive - it is necessary at arrangement of the automated system;

- the canvas itself.

The gate leaves, by the way, are either immediately solid or made from sandwich panels. As the canvas can be used conventional shield, assembled independently from simple boards or upholstered with sheet metal.

When assembling the canvas such a homemade board board will be the best solution. It is not difficult to make it with your own hands, the main thing is to beat it up with galvanized metal, and then cover it with a special protective compound.

Polystyrene foam or foam can be used as a heat-insulating material. To improve the external parameters, it is better to veneer the finished product with plastic; you can also use wood panels.

Instruments

In the manufacture of the gate will need tools:

- screwdrivers and hammer;

- drill and drill;

- level pencil;

- welding machine;

- Bulgarian and wrenches.

Installation

The initial stage of mounting the door installation is the design of a future design. It is necessary to remove the dimensions from the opening and draw up a sketch or take an already prepared drawing with calculations and diagrams.

Next, you need to purchase building materials and find tools to proceed directly to the fabrication of the portal structure:

- Assemble a box of individual bars, fastened together with iron plates or corners.

- The box is fixed directly in the opening, fastened with pins, the bottom of the box is approximately 2-3 cm deep into the floor.

- Collect leaf sash. The frame is covered with a shield, and then closed with sheets of metal.

- The support of the mechanical device is made of a corner. Two holes with a diameter of 1 cm are drilled in the shelf. Such holes are needed when fixing a mechanical fixture to the support posts. In the next shelf 3 holes are drilled, they are needed when installing the spring bracket. The bracket attached to the shelf will support the springs.

- The installed bracket together with a spring is connected with an adjustment plate,Such a plate is made from a metal strip. Extreme spring twigs are used as a hook, at the bottom they attach a tension regulator. The ring will turn out from one edge, from another it is necessary to cut a thread.

- The hinge knot at the bottom is made of a corner in which there should be a 0.85-centimeter hole. The corner is welded to the frame at the distance between the edge and the center of the hole. This type of hole is needed to assemble the lever of the lifting mechanical device.

- A plate in which there is a necessary hole for the assembly of a tension regulator is welded to the end part of the lever.

- To move the shield you need to make rails. The edges of the two corners are welded so that the space inside between the peaks of the peaks is 5 cm.

- The edge of this rails is welded to an iron plate with drilled holes. A gap of 8 cm is left between the axial line and the lowest part transversely. The pieces of the channel are welded on the edges of the rails at a 15-centimeter distance. Bolt channel attached to the beam on the ceiling.

Ready installation color, giving an esthetic look. Immediately before assembling the structure, it is better to paint all hard-to-reach areas.

There are several recommendations that should be followed when arranging the tilt-up structures:

- It is recommended to use welding for high-quality reliable assembly of parts. So you can reduce the need for fasteners, drilling extra holes;

- the height of the garage door can not be less than 2.2 m;

- it is better to place the drum in the back with a sufficiently low rise;

- the bottom profile of the garage leaf must have a groove where the seal is installed;

- the main parameter is the mass of the canvas, an acceptable weight of 100 kg;

- reverse self-locking winch can be installed as a drive;

- To install the automation is better to use car alarms.

For convenient operation, the shield is made of translucent facing materials. Up-and-over doors are equipped with a security system, as well as a necessary locking device. This will help protect the garage from hacking and crushing.

How to make a lift-and-turn gate with your own hands, see the following video.