Folding gates: types of structures and principle of operation

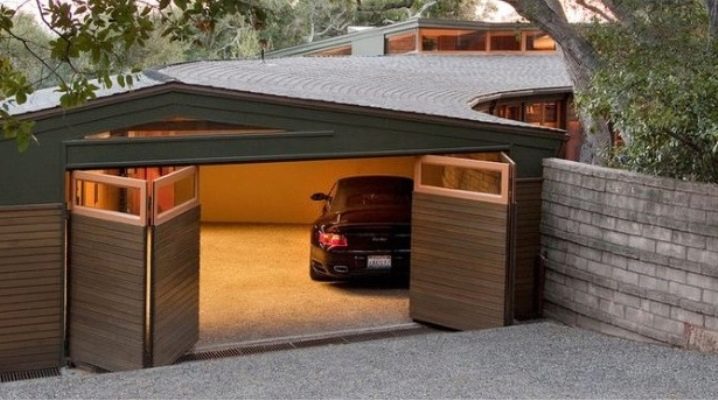

Gates, installed on the garage, hangars or production warehouses, initially carried one main function - protection of everything inside the room from theft. Modern gates are considered an architectural element. The installation must fully comply with the general style of the building.

Folding gate

Folding type of products is considered the best for installation on private buildings and objects of large industry. Basically, entrance structures are installed on objects with fairly wide openings, since in the open form folding gates do not take up much space.

Folding installation of the gate are found in warehouses for the storage of large-sized equipment. An example is the tram depot or aircraft hangars. Such gate are used in cottages or at the dacha.

Merits

The advantages of folded structures include:

- Compactness. Folding gates even when opening occupy a small area. The actual problem for large openings is space saving.

- Convenience of operation. Folding gates of various sizes can be opened manually.

- Load. All she goes to the walls of the room. Such products will not load ceilings. If necessary, install an additional power mechanism.

- Reliability, long operational life. Folding products have a relatively simple mechanism.

The connection of the vertical sash is the finished product - the door-accordion. Transport rollers that allow the web to move along a special transport beam and close the opening are installed on the upper end. On heavy industrial throughput facility used transport carts. The bottom guide defines the movement of the flaps.

Benefits:

- no extra space is required when opening;

- the installation of a pass-through structure may be performed on both sides of the opening;

- the construction of its weight will not load the roof, the entire load will fall fully on the walls of the room;

- if necessary, the sash is sheathed with polyurethane: at the warmed gates, the crevices are tightly closed with a compactor, thus ensuring the low thermal conductivity of the web;

- ease of maintenance does not require specialized knowledge;

- ease of opening.

Vertical structures are equipped with three types of drives:

- Trackless - mechanism, located in the rack structure, bolted to the powerful plates of steel - this product is used only in small-scale profile;

- The bottom one - when the controlling type of the mechanism is absent in the upper part of the installation, that is, the height dimensions are completely unlimited - in this situation a foundation base is required

- The upper one - at the top of the folding gate is installed a drive type of mechanism - the foundation is not needed here, only the height of the product is limited - no more than 4.5 m.

Sectional gates

The most productive is the lifting-section device. Such a system is distinguished by reliability and convenience. Sectional doors are installed for industrial buildings and garages. This type of bandwidth will satisfy aesthetic requirements, will be combined with architectural style.

Design features will provide:

- reliable protective functions;

- excellent sealing;

- safe use;

- compact placement;

- easy operation

To open this design does not need free space and this is attributed to another equally important advantage.

All factors were able to provide sectional goal popularity.

In the process of opening, the sheet of an automatic sectioned product rises up vertically, moving along a rail located under the ceiling itself. In the process of opening the canvas is folded, goes up, taking a horizontal position. The closing process is performed in the same way, but already in the reverse mode. This system will not require extra space, will allow to leave the car closely pressed to the wings.

A set of sandwich panels connected by loops, and called the canvas. Their thickness reaches 45 mm. Polyurethane-insulated panels have low thermal conductivity, excellent sound insulation.

The rollers mounted on the edges of the webbing are equipped with pressed bearings. This ensures that the gate moves along the track.

For the manufacture of automatic sectional installations using the drive in two groups:

- Bulk. This type of drive is usually used in enterprises where constant excessive load. The chain drive will provide opening of a cloth with the maximum area of 45 sq. M. This design of the gate can be used in buildings without heating with high humidity;

- Ceiling. This type of drive is usually used for garages without significant loads. The design differs in functionality and low cost.

The drive is controlled by means of magnetic cards, keyfobs, a remote keyboard, special buttons that are installed next to the access control.

This type of products is used to close the entrance opening at such facilities as a garage, a storage room, an administrative building, a hangar, an industrial building.

Typically, rolling doors installed in the absence of technical capabilities for the installation of sectional doors.

Reliability of parts and related components with a zinc coating provides long-term safety.

Products of rolled type are a design from assembled lamels in a uniform cloth.Lamels are profiled steel plates. In the folded or flat form of the closing unit, the plate is locked into a lock with the previous one. Such a canvas will be assembled only at a certain location of the lamellae.

When opening such a cloth is wound on a special shaft, which is fixed on the consoles. Rotation for winding the web is created by an electric motor. It is also possible manual control using spring-inertia devices. This product has a highly reliable and durable mechanism.

Roll installations are equipped with an automated system. The electric door is equipped with a complex of remote start and control, the workflow of such control is controlled by a variety of blockers.

The weight of the cloths determines the selection of automatic electric drive:

- Valny - with a rather impressive weight;

- Vnutrivalny - with a weight below 180 kg.

Swing gates

Products with two swing-out flaps are called double-leaf or double-leaf flaps. Oar systems consist of the cloths fastening and rotating on a vertical axis. This design is used quite often.Gates are installed in factories, garages, courtyards and in the country.

The type of opening of swing gates can be internal or external, that is, to the courtyard or to the street. The disadvantages include the need to clean the trajectory from the snow, so that the sash can easily and completely open. Today also automatic opening mechanisms are used.

According to the type of installation and the principle of operation, the drive of the swing construction can be divided into three separate classes:

- for underground type installations;

- linear;

- and lever.

To reduce the load, the construction sashes are equipped with hinges with hinges.

Sliding gates

This type of product is a self-supporting exit structure. The frame of the gate moves on a roller construction. This mechanism is set on the foundation. A bolt is used to lock the structure.

The lower edge of one of the valves is fixed on the carrier bar. This also attach the monorail, which acts as the main guide part. In addition, a roller mechanism is also attached. It provides gate displacement and adjustment. The length of the sash will determine the number of rollers required.

In the process of opening one of the valves is moved. Simple design is quite popular.

Installation of rolling systems has many advantages:

- noiselessness;

- simple construction;

- strength and durability;

- reliability.

Silent work is caused by the use of special roller bearings, which are usually made of glass-filled polyamide.

The surface of the product is treated with an anti-corrosion compound that ensures long service life. Paint on the gate is applied by powder, this allows the installation to be more resistant to temperature changes.

Lifting gates

A design with an upwardly lifting web at the time of opening is called a lifting product. Establish such a gate in the hangars or ordinary garages. This type of opening is equipped with automatic. Opening the gate with your hands is difficult and uncomfortable.

Sectional lifting installations are becoming increasingly popular. The canvas consists of connected sections, which at the time of raising the gate go behind each other. This type of opening saves a lot of space. Management is automatic or manual. The canvas is usually made of aluminum.

Benefits:

- resistance to hacking;

- reliability;

- safety and tightness;

- excellent noise isolation.

The system of levers required associated springs provide the movement of the blade. The door frame is made of rectangular pipes. The design is quite simple. All this speaks to the convenience and reliability of the product when opening or closing.

About the mechanism of lifting and folding gate, see the following video.