Gates made of corrugated board: options for some models and step-by-step assembly instructions

Home and cottage need a gate to enter the car, even in its absence. From time to time it is necessary to bring something into the yard: building materials, large household appliances and even manure, bringing it all through the gate is not very convenient.

With the current variety of goods and services, the gate can be bought, but not everyone can afford it. It will be more interesting to build a structure yourself.

Materials for production

The gate can be made of profiled flooring (metal profile), shaped pipe, metal, wood.

To choose a material it is necessary to compare its disadvantages and merits.Previously, such structures were made of sheet metal, but it is heavy, it needs to be painted and hired professional welders for installation. This increases the cost of such a product.

The construction of a profile pipe can also be made only by a professional welder, and if you want to hide the yard from prying eyes, you will have to close the gaps with pipes, using boards or other components.

Wooden gates are beautiful, but less durable and difficult to maintain. In order for them to be stronger, you need to choose at least oak boards, and this is not cheap. You can of course make them from reiki, bar, picket, because it is a fairly cheap material. In any case, wooden parts must be treated from wood parasites, mold and fire using antiseptic, primer and moisture protection. Then they should be painted or varnished in two layers.

The combined doors made of metal and wood or wood polymeric composite look good, the buildings with wrought inserts look even more beautiful, but their cost increases.

Now there are modern materials: profiled flooring (metal profiles) and professional sheet that is light, relatively inexpensive, easy to use and durable (manufacturer gives a guarantee of 20 years). It has a variety of shades. Flooring differs from the sheet in that it is more protected from corrosion, reduces noise more and has greater reliability.

When working with flooring or sheet you do not need to buy additional tools and accessories. It will not be difficult to make the gates by yourself from a profiled flooring, such gates can also be decorated with various decorations. Choosing the material, you need to decide what design will be at your future gate.

What are the types?

Structures are divided according to the method of opening: swing, sliding, sliding, forged, lifting. They are also different in the method of manufacture and form, for example, you can meet the welded and arched gates. Wickets are built-in and standing separately.

Special features

Swing gates are simple to manufacture and easy to maintain, even an inexperienced welder can make them even from profiled flooring, since only a small number of simple seams are present in the structure.This reduces the risk of breakage and increases the service time of the gate.

To do this, the products must leave a lot of space for opening and take into account the possible load from the wind. It will be necessary to clean a large area from the snow in winter (unless of course there is a lot of snow in your climate zone). Unusual gate models have a variety of styles and décor, but easier to install automation, which can be purchased at a low price.

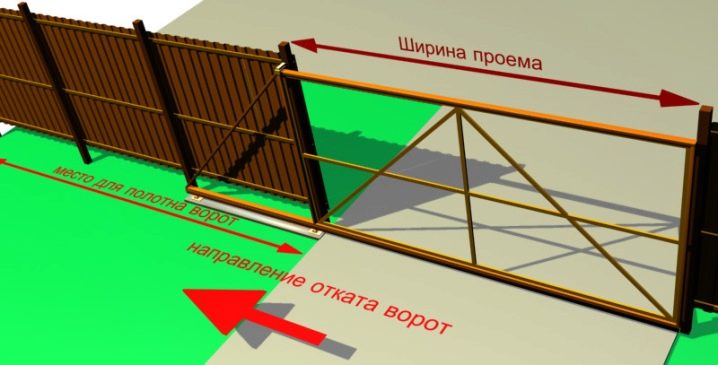

Sliding (cantilever) gates save space for opening, are convenient for dense building. They have a complex structure, but there is no need to clear the place for their opening. Requires a counterweight and a place along the fence to install rails. Making such structures and caring for them is quite complicated, additional materials are needed that increase the total cost.

Sliding gates similar to sliding, the only difference is in the number of doors. Sliding has two boards, therefore place for installation must be on both sides of them. Therefore, the amount of material is increasing, but at one side of the fence there is less space.

Forged gatesundoubtedly stronger, have a beautiful appearance and give luxury and individuality to housing. But the price of such products is less democratic.You can buy and assemble the finished parts by welding them yourself, but you need to be proficient in the welding machine: know how to prepare the metal and be able to clean the seams.

If you do not want to see the house territory, you can fill the voids with profiled flooring or boards (do not forget to process them).

Lifting gateswhich are used at the entrance to the garage, more expensive and more difficult to manufacture. But how nice it is in bad weather to open the gate without leaving the car.

Arched gate can be made from the materials listed above (wood, metal, forging, brick, stone, profiled flooring), and their combinations. Also, they are different in configuration and method of opening, with the exception of lifting.

Advantages and disadvantages

The advantages of products include:

- ease of manufacture;

- ease of care and operation;

- ease of installation;

- the ability to make facilities at any time of the year, including winter;

- low weight of the product, reducing the pressure on the support;

- high technical performance;

- no need for painting;

- resistance to fading;

- resistance to frost, snow and other weather conditions;

- variety of shapes and colors;

- affordable price.

Due to these qualities, the gate retains its excellent appearance for a long time.

Products are also inherent cons. Thin sheet can be easily cut, deformed, scratched, which can lead to corrosion processes. There is no insulation, there is a large wind load.

Colors

They produce profiled flooring of various configurations, colors and shades: from white to brown. The choice of the desired tone depends only on your taste and the features of the surrounding objects.

Design and style

The fence can be very diverse in color and shape, among the options you can find a design that fits any site and building. This allows you to create different compositions using forged patterns and finishes, combinations with wood, brick, stone, and even mesh. The choice depends only on the imagination and desires of the owner.

How to do it yourself?

It is believed that the creation of swing gates can be carried out by a person who does not possess professional skills. The installation site and the type of gate must be planned, taking into account various features and nuances.

Dimensions depend on:

- car size (measuring the width, do not forget about mirrors + 1 meter);

- parameters and number of pillars;

- widths of openings, frames and other structural elements.

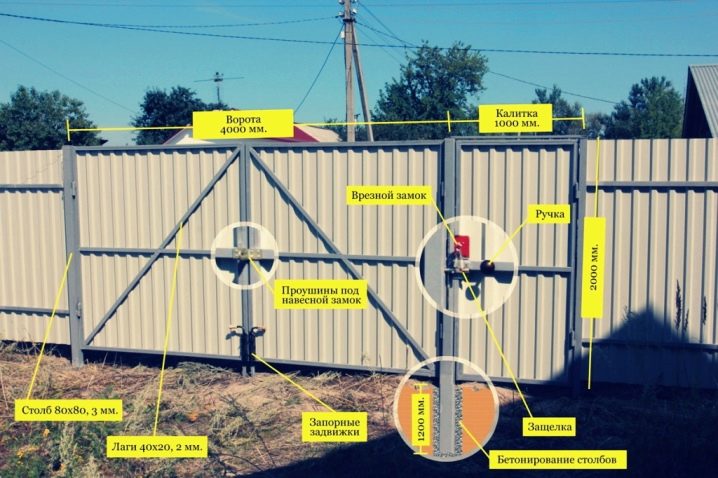

Most often, the width of the gap in the gate exceeds 4.5 m, and in the gate - 1.2 m. In height, they are often equal to the size of the sheet and depend on the height of the car. Do not forget to take into account the distance below, it depends on the climatic zone of this area (the amount of solid deposits in winter), to open the gate freely, and is from 0.15 to 0.3 m. From above it is possible to decorate a design with a decor.

It will be easier to calculate the right amount of raw materials and evaluate the rigidity of the parts if you prepare a schematic drawing and plan the work. From the size will depend on the exact amount of material required, which will prevent unnecessary costs.

Swing gates come with one or two doors, here it is necessary to make the correct calculation. The advantage of single-leaf designs is to save raw materials, but they take up more space when opened.that is not always convenient, have a large sail and warp. Therefore, the structure must be strongly strengthened.

Do double-wing models these problems are excluded, but due to the increase in details such models are more expensive. One part of the gate is allowed to be made larger, and a smaller half can be used for the gate. Consequently, single-leaf options can be made with a small opening.

To build a structure correctly, you need to carefully study the scheme of its structure. It is important to consider:

- the width of the entire opening;

- size of each door;

- the number of racks;

- the size of the racks and the depth of their instillation;

- product design and dimensions of all its elements;

- the location and size of the gate;

- location of the loop;

- configuration of constipation and their place of installation;

- location and details of the gain.

Gain options:

- welding of corners to strengthen the doors no more than one and a half meters;

- frame grabs at intervals of 0.2-0.3 m;

- in the doors of more than one and a half meters are installed various jumpers.

Materials

Now, having a schematic drawing, you can proceed to the calculation of the necessary raw materials. Should be considered:

- wall decking (it is wider);

- screws (preferably roofing);

- metal pipes of different diameters for support columns;

- blanks for the frame and its amplification;

- metal sheet, if you need to make kerchiefs for reinforcement;

- hinges;

- locks;

- shutters, latches (you can do it yourself);

- metal paint (applied even to rust) of the desired color;

- tassels;

- details of the decor;

- meter, level, plummet, grinder for cutting pipes, drill, apparatus for manual arc welding, protective mask for welding, screwdriver, consumables, scissors for cutting metal, gloves.

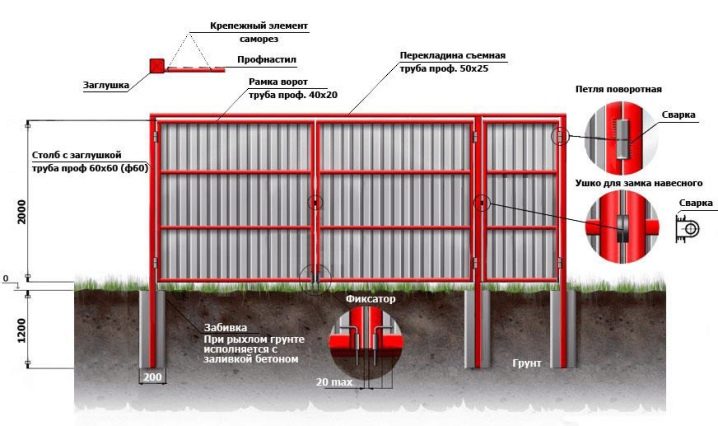

Cooking pillars

For them, there must be an equal depth of space - 1/3 of the height of the rack. It is simpler and more economical to do this with a garden drill; it should be twice the diameter of the pillars. A mixture of rubble and sand 0.15-0.3 m deep is poured into the hole.

If necessary (depending on the material of manufacture), the posts are treated for corrosion damage, we install the columns vertically with a plumb-line and concrete. From the top of the support close (in any way possible) to prevent ingress of precipitation. The posts closed by any facing material will look beautifuldown to the tree.

Cooking frame

The frame is also made of material available to you. Of course, it is preferable to use a metal pipe with a cross section of not less than 60x40, but it is possible to use wooden material (do not forget to process it), it all depends on your capabilities, imagination and preferences.

For the manufacture requires a fairly flat surface on which to lay the sash. We start welding parts, reinforcing them with steel corners or crossbeams for greater stability. Wooden frame fastened with screws or bolts.

Manufacturing sash

Once again we make measurements to eliminate errors, if necessary, strengthen the workpiece in the right way for you. If the gate is inside, it is necessary to make additional space for it.. We clean everything thoroughly in order to avoid corrosion processes, we bait the parts together, only after accurate measurements we cook them without gaps.

We clean the places where the welding took place very high quality, degrease them, coat everything with primer, paint the welded seams. Instead of a primer, you can use paint applied directly to rust. After drying the surface, paint everything again.

The hinges are welded initially to the support pole, then to the frame, retreating from the end of the frame by 0.2 m. The location of the hinges depends on how the doors open.. If you attach them directly to the frame, the door opens to one side. And if you attach them to the support close, they will open and out and in. Then, so that the structures do not hang out and do not spoil the fence, put limiters. Three loops are welded to each side on each side, otherwise two are enough.

For mounting profiled flooring on the door, it is safer to use roofing screws of the same color.

If the roof of your house is covered with metal flooring, then gates of the same color will look good.. Sheets can be fastened through a single wave both to the frame itself and to the reinforcements. If one sheet on the door is not enough, then the sheets must be fixed overlap each other by one wave. Doors are closed if desired by laying on both sides - from the street and from the courtyard.

Fastening and manufacturing of accessories

It is expensive to install constipation and pens, purchased in good quality stores, and cheap alternatives are usually short-lived. They can be made from the remaining pieces of reinforcement and tubes by welding, they will work exactly with different weather conditions.

From above we put the constipation on the screws from the inside of the door, fasten the two lower ones to the posts.In the ground, we drill small holes and concrete pieces of tubes into them (the inner hole should be wider than that of the rod). We also attach locks to the wicket door if necessary, but we also install a lock (it will be more convenient to build in a mortise design).

Options, advantages and disadvantages of manufacturing wickets, built-in sash, are different:

- You can make sashes of different sizes, for the gate select a smaller sash. This option will significantly reduce the complexity of manufacturing and reduce costs.

- The option inside the sash provides for the installation of two loops - above and below. This will not only make the structure stronger, but also reduce the wind load.

- Placing the gate closer to one of the supports, we will increase the pressure on this support. May need more reinforcement for the other door.

- The location closer to the center weakens the structure, allowing for a skew. A door gain adjustment is also required.

On how to make the gate of the flooring with your own hands, see the following video.

Tips and tricks

In order to make the doors of corrugated flooring quality and durable, you need to follow a number of proven tips:

- It is easier to make the sash in size corresponding to the size of the sheet.

- If you find the gap below too wide, you can close it with a removable strip for the summer.

- To fabricate a wider door, more material is needed for reinforcement.

- Nonprofessionals are better to buy pipes with a thickness of 3 mm - they are easier to cook.

- Cutting the workpiece for the manufacture of corners, preferably at an angle of 45 degrees, especially for welding the upper joints.

- Accuracy is required. Let the frame wings be a little smaller, it is easier to fix by welding a patch according to the size of the slit to one of the wings. Otherwise, you have to cut the parts and digest them again.

- It is better to purchase galvanized profiled flooring for the manufacture of gates and wickets with the No. 8 or 10 marks “C”, but the “best choice” would be the “National Assembly”. He has a greater margin of safety.

- The edges of the flooring are quite sharp, and in the manufacture of the product, note that the edge of the sheet ends with a “hollow”. Otherwise, during operation, you can cut yourself and spoil the clothes, and the product will not look aesthetically pleasing.

The gate with a wicket complete with details of forging will look very beautiful and original.You can buy it in major construction stores. It is permissible to make parts to order, but it is much more expensive. The composition should be collected to your liking.

Beautiful examples and options

To decorate the gates of a summer house and a private house the following ideas can be implemented:

- visual variety of colors, materials and types;

- combination of forms and materials at sliding gates;

- interesting combination of materials and colors;

- a great combination (forging from blanks and lining with profiled flooring) with a separate wicket;

- minimalist sliding designs with block racks.