Forged gates: all the details of the choice of material and installation steps

Forged gates made of high-quality materials are a solid construction that can serve its owner for many years. They become the business card of the owner of the house and create a positive impression, adding more value to the site.

Special features

Forged products have remained popular for many years, thanks to which manufacturers can present a rich assortment of iron products, which are distinguished not only by the design of the structure, but also by the material for manufacturing, as well as the type of movement of the valves. Such products are the perfect complement to any land and guarantee its reliability. But in addition to the guarantee of protection, it should not be overlooked that the forged gates are also responsible for the solid appearance that the structure acquires due to the various patterns that can give an ordinary metal grille an original look.

The most unique feature of wrought iron gates is their original design.which becomes unique as the drawings are developed directly by the customer. And already on the basis of samples of patterns and additional details, the main scheme of the gate design is created, which becomes the direct embodiment of originality and individuality of the future owner.

Forged products are perfectly combined with wood and brick, and even with stone fencing. It does not affect the beauty of the product and the landscape - it harmoniously fits into any landscape.

The features of the forged gate are not only in their appearance, but also in the production technology. Computer technologies make it possible to easily develop a product design in the form of a three-dimensional image, which allows the customer to evaluate the design and in case of anything, make corrections to the sketch together with the designer. The design of the door can be created entirely by hand or using stamped blanks.

Stainless steel is used for forging, but other parts can be made of metal. Each detail of the design must be processed by three types of compositions: primerincreases the service life of the product; nitro-paint ensures the imperceptibility of the joints of forged elements; the anti-corrosion coating makes the material more resistant to environmental influences.

Taken together, the performance characteristics and aesthetics of the structure give the wrought gate a considerable value, which is reflected in practical ways in a number of advantages of these products.

Advantages and disadvantages

Forged gate designs may have different characteristics, but in general, all of these products have similar advantages and disadvantages.

The advantages of forged products:

- Versatility. They are easily combined with any materials and exteriors of buildings.

- Such gates are easy to maintain and do not require much attention and care.

- A wide range of products represents a large number of finished products of various styles and designs. Ready-made gates can be easily selected for the landscape of the site, its style and characteristics, the required type of entry or entry into the territory, the degree of protection and reliability are also taken into account.

- Also, you can always order a design according to individual requirements.Hence the third advantage of wrought iron gates - their exclusivity.

- High operational life is perhaps one of the main advantages of these structures. Due to the strength and reliability of the metal, the quality of the forging of the gate can last for a long time without losing its operational and aesthetic characteristics.

- Independence from weather conditions often becomes a priority when choosing a gate, especially in areas with harsh climatic conditions. Even in the manufacture of the structure is treated with special anti-corrosion compounds that protect the material from the adverse effects of the environment. Also, when self-treating a product with anti-corrosion agents, it is possible to extend the service life by several decades.

- When the gate is equipped with additional security systems, the level of their reliability increases. They can be video cameras, motion sensors, automatic shutters and locks of electrical or mechanical devices.

- Forged products are entirely from environmentally friendly materials.They can be not only street, but also be used in houses, being reflected not only in doorways, but also on pieces of furniture, decor and architectural elements.

Disadvantages of wrought iron gates:

- High price. But it is impossible not to take into account the fact that their service life significantly exceeds the service life of other types of gates.

- Forged products are difficult to manufacture and install.

The design characteristics will depend on the owners themselves. We must not forget that the regular processing of loops and their lubrication, as well as the application of means of protection against the influence of environmental factors, will only help to prolong the service life and preserve their original appearance. As for cleaning from dirt and dust, even with a large number of openwork forging elements, you can easily clean the gate with the help of water from a hose.

What are the types?

There are many items for the classification of wrought iron gates.

They differ in their purpose:

- for closing arches;

- to close the road;

- for use as a passage through the fence;

- to protect entry and exit paths.

By the type of movement of the sash gates are:

- swing;

- retractable, consisting of one movable sash;

- sliding or double sliding gates, consisting of several leaves, which are moved apart in opposite directions;

- lifting

Swing gates are the most popular and frequently chosen options. They are easy to use and do not require additional costs for the mechanism of movement of the valves and the subsequent care of them. All that may be required is to periodically lubricate the hinges in order to prolong their service life. As the name implies, the doors at these gates in the classical scheme simply diverge to the sides when opened.

Retractable structures have a different type of movement of the valves, which is the movement of the gate along the fence, which saves space due to the release of a certain area from the open doors. Similarly, working and sliding gates.

Lifting gates are equipped with a special mechanism of movement of the bolls, when using which the leaf of the gate rises and enters the room, making way for the passage. Such a mechanism is rarely seen at a wrought-iron gate, but it still comes across.

Each type of sash can be equipped with an automatic movement system, which greatly simplifies the operation of the structure. The automatic sash movement system allows you to remotely open or close the gate, which is convenient for motorists who do not need to leave the car anymore in order to leave the yard or enter the site. The automatic system is controlled by a remote or application on the device.

The shape of the valves design are of the following types:

- Deaf This type of gate is a combination of openwork forging and inserts of other materials, which together gives a reliable protection of the territory from prying eyes.

- Transparent. The most common type of wrought iron gate, which consists of openwork forging and metal rods for the base.

- Solid. At the heart of solid wrought-iron gates lies a canvas, which, in turn, is decorated with a wrought ornament or bas-relief. This type is an analogy of a dead gate, but has a greater degree of protection.

- Wrought iron gate with a wicket.

As a basis for solid gates, not only a sheet of metal, but also wood can be used.It has also become popular to use polycarbonate and professional sheet. Wooden gates look luxurious and are a solid addition to the site, and iron forgings made on the background of them in the form of various patterns and bas-reliefs become a wonderful addition. Metal sheets are also not inferior in wooden characteristics, and in many respects even surpass them.

Materials

Basically, forged gates are stainless steel, metal sheets and profile pipes.

The construction of the gate itself consists of several elements:

- product frame;

- leaf shutters (if provided design);

- decorative elements forging.

In fact, the components of the forged gate are utterly simple and available for purchase at any hardware store, but the whole difficulty lies in the manufacturing technology of the forged pattern itself, its design, creation and welding of all elements.

Of the additional materials that can also be a direct part of the wrought iron gate, can be:

- wood;

- brick;

- concrete;

- a rock;

- professional flooring;

- polycarbonate;

- imitation of all the above materials.

Materials can be processed both by cold and hot forging, if they are not stamped during production, but welded.

Style and design

Initially, wrought-iron gates were used solely for the sake of protection and only in rich estates, as previously products of this type were rather expensive. But so that the massive gates did not look alien and did not spoil the overall impression of the appearance of the property, the blacksmiths began to complement the forging with various patterns formed under the influence of the era and its style.

Today, the technology of manufacturing wrought iron gates differs little from the traditions of the ancestors: the craftsmen also use blacksmith tools and, according to the customer’s sketch, create exclusive masterpieces. The style of the gate is always designed with a bias in the classic design directions, or it is created entirely individually for the customer.

Various images and drawings of representatives of the flora and fauna, the initials of the owner of the site, the family motto and all the artistic elements that the customer could wish for can be woven into the main patterned ornament.In the same style as the gate doors, wickets, fences and various exterior elements are developed.

In fact, there are several style trends that are reflected in the manufacture of wrought iron gates:

- Gothic;

- classicism;

- Roman style;

- baroque;

- modern;

- rococo;

- minimalism.

Regardless of the style of the gate itself and whether they will look simple, elegant or exclusive, it is important that they are combined with the fence, all the architectural elements of the site and its design. Landscape designers recommend to owners when choosing a wrought iron gate to be careful with the design, especially if the main style of the house is more inclined to the modern technospheric directions in the design, as there is a risk to create a tasteless fence against the background of a certain structure.

Colors

The choice of the main colors of the gate and their color design is a very important step in the design of the entrance group. Here it is necessary to combine the color scheme of architectural structures, fencing, exterior and correspond to the design of the site. The most common color forged gates - black with gold.The old dark color fences also look impressive. White color also looks good, especially if the main stylist of the landscape is close to or corresponds to modernist trends.

Landscape design professionals have developed several basic canons for choosing fencing colors and their components.

Following them, you can easily determine the colors:

- the color of gates and fences is chosen to match the roof of the main architectural structures;

- if the supporting pillars have a stone finish, then the forging color is limited to brown or beige tones;

- gray and other light shades, including white, can visually increase the area of the site;

- dark shades repel - these colors can create an effect of inaccessibility, which is suitable for an owner who loves privacy and wants to hide from prying eyes;

- should choose a color that contrasts the facade of the building, if it is light tones;

- black color is in harmony with any landscape;

- If you want to create the effect of merging the fence with the environment, you should not choose green colors, it is better to give preference to blue sky tones;

- you need to experiment and follow your own taste.

Installation

Installing a wrought iron gate is a rather painstaking task that requires certain knowledge and professional skills, because trusting the installation of such an expensive product is better for professionals, because only they can guarantee high-quality work and subsequent operation without marriage.

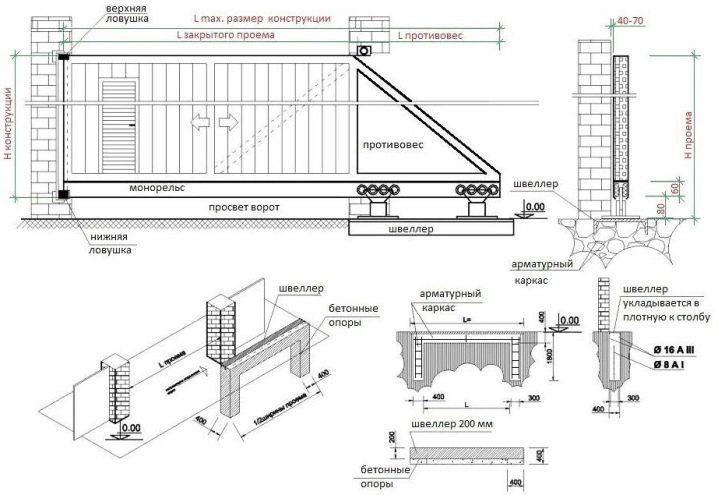

One of the very first steps in the installation of the gate - preparation of the opening. If it is designed without errors and omissions, then the gate will stand straight, free of defects, and the locks will work properly and not jam. The basis of the forged construction is bearing pillars, which also need to be covered with brickwork to increase their strength.

We must not forget that forged products have a decent weight. At the base of the bearing pillars there is a metal tube, which must be inserted into the recess and fixed, if possible, with brick or rubble.

It is also important to install the carrier columns at the required distance with millimeter accuracy. The depth of the pit for the pipe should be 1 meter or more, depending on the mass of the structure: the heavier it is, the deeper the hole.The pipe itself must be thick-walled, otherwise it will simply not sustain the weight of the structure and will begin to deform under pressure. After fixing the pipes, they can be concreted with a liquid solution in the ratio of sand, cement and water one to three.

After drying, it is required to prepare a thicker mortar and start laying bricks using a trowel. It is also important to stretch the metal tire at the gates, between the brickwork. Then you must install the fasteners and the gate structure itself.

It is difficult and rather dangerous for the future technical characteristics of the gate to establish the construction with its own hands. But if you still decide to install yourself, then you will need a certain set of tools, skills to use them and a willingness to conduct accurate work with the miscalculation of each movement, because all actions must be performed step by step so as not to be mistaken with the size.

From the tools you will need:

- "Bulgarian";

- drill;

- welding machine;

- fasteners;

- measuring instruments.

After completion of work with support beams, you can assemble the main structure and product frame.The structure is hung on supports, then the doors are adjusted and fastened to the structure. In this work, it is necessary to observe maximum accuracy, because the slightest flaw can lead to deformation of the structure and reduce its operational life.

Tips and tricks

Although the development of a sketch for the future construction of the gate is one of the most important steps, but before proceeding with it, it is necessary to decide which of the various types of construction will be the most suitable for the site.

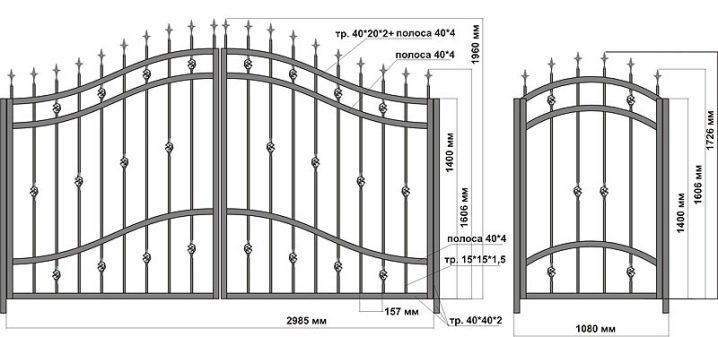

This will require calculations and take into account some parameters:

- Level of construction. Depending on the purpose, the height of the structure can vary from 1.5 to 3 m: a small one is suitable for decorative items, and a three-meter-high gate provides the highest level of security.

- Width. It depends on the width of the access road, as well as on the total width of the section: the larger it is, the wider the gate.

- Parameters and design of the fence.

- Functional design. This is the most important point for calculations, which determines the distance between the sections, the presence of a wicket inside the gate, the mechanism of movement of the valves and their type.

And only after taking into account all these parameters, you can begin to develop a sketch or a choice of ready-made gates from the manufacturer.

Another important aspect is the combination of a wrought-iron gate with a hedge.

A nice bonus is that the forged structures look great with different types of fences:

- A hedge in combination with a wrought iron gate gives mystery and originality to the entrance group of the site, especially if this fence is molded. But the simple interweaving of the loaches can also give the site a unique look of a fabulous manor.

- The combination of a wrought-iron gate with a wrought-iron fence is not uncommon, but this type of entrance group cannot provide an adequate level of privacy, and if it is spent on a continuous type of fence, it will be a rather expensive acquisition.

- The way out of this situation in terms of financial savings is the use of profiled sheeting. But a significant disadvantage is that often this material, along with forged patterns, looks out of place and alien.

- A brick wall in combination with wrought iron elements is one of the best solutions in terms of a combination of forging and fence.

- Stone fencing along with brickwork extremely elegantly complements the wrought-iron gates, but this type of fence is quite expensive. The way out of this situation is the acquisition of imitation stone.

- It is also a very elegant way to decorate the gate and fence in the same style - it is to combine elements of forging on the gate and the fence itself with another type of material, be it a stone or its imitation, wood, brick or profile.

Not everyone who plans to purchase a wrought iron gate, has the ability or desire to order a design according to individual designs, it is sometimes easier to buy a finished product, observing the required parameters. But even the purchase of these structures is not an easy process: it is also important to consider a large number of factors for the purchase of the product.

Here are some tips that can be useful to everyone when buying a wrought iron gate:

- The functionality of the product is one of the most important factors that must be considered, paying attention to the individual operating needs of the owner.

- Products with a low price are very attractive, but it is better to abandon the temptation to acquire them, since forged structures with the proper level of quality cannot have such a low cost.

- If the goal of purchasing a forged gate is not only reliability, but also a desire to pay attention to the entrance group and what lies behind it, then the best solution would be to purchase bright products with an unusual design.

- For those who live in harsh climatic zones, where the air temperature may be below -30 degrees or above +30, it is recommended to purchase galvanized structures.

- For those who want to save on wrought iron gates, you can search for products made of aluminum. But you should not rely on the reliability and durability of this design - it will rather become a decorative element than an obstacle to private property.

Forged structures are unpretentious in maintenance, but concern for their technical condition will only have a positive effect on the performance properties of the product.

Here are some tips for the care and maintenance of wrought iron gates:

- If rust stains, cobwebs of paint and other defects appear, which often happens with the negative impact of climatic conditions on the metal, additional painting may be required. Rust stains, chips and defects are treated with sandpaper until they are completely cleaned, and then become coated with paint.

- It is necessary to check the condition of the gate once a year and get rid of the defects, so that they do not have to be fully painted or replaced in the future.

- To prevent metal from rust, it is necessary to process it with specialized compounds.

- The mechanism of movement also requires care, especially if it is equipped with automation.

- Periodically it is required to clean the door from dust and dirt.

It is these few simple steps to care for the structure that can increase their lifespan by a significant amount of time, and thus save money and time of the owner.

Reviews

With proper installation of the structure and the acquisition of a quality product, virtually all the reviews about this type of entrance group, such as a wrought iron gate, are positive. None of the owners could not remain indifferent to the forging pattern of forging, especially if he makes a single composition with other architectural products.

Wrought iron gates allow you to create a certain image of the site. They become a worthy characteristic of the owner himself, indicating his taste and concern for his own home. But besides the aesthetic side, wrought-iron gates look like reliable protection against the penetration of not only alien views and animals, but also against uninvited guests.

Especially strongly inspired by a sense of security designs in the Gothic style, equipped with a large number of sharp spiers that can relieve detractors from bad intentions.

Sliding gates equipped with an automatic sash movement system deserve special attention. For owners, they are a symbol of convenience and functionality, despite the money spent. According to buyers, such an input system is really worth its cost.

People who have become owners of forged entrance groups sometimes tend to think that more types of these structures are intended for decoration when it comes to transparent products, which they cannot say about solid or deaf models. In any case, wrought-iron gates perfectly complement the overall exterior of the site only in cases when the design of the structure coincides with the style of the site, but not every house, for example, in the modern youth style can harmoniously look with wrought-iron gates.

The same applies to unequipped areas, small tasteless houses. You should not acquire forging to such architectural structures, as they will look comical and inappropriate.Wrought iron gates are solid, elegant and expensive.

Modern examples and best options

Wrought iron gates can look like a work of art - they rivet attention and fascinate. This work feels the work of the master, because it is truly a fantastic dragon.

Designs with wood inserts look very elegant and beautiful, and such gates will not only please the eye, but also serve as reliable protection from prying eyes.

Many believe that the only profitable color solution for wrought iron gates is the execution in black. But the example of this image becomes clear: even loudly-red designs look solid and respectable.

Gates with lions have been for centuries one of the most popular versions of forging, because these magnificent animals add luxury and grandeur to the designs of the entrance groups.

Each gate is a subtle and elegant work of the master, who from rough and unyielding material creates an ephemeral masterpiece consisting of thousands of bends of metal rods.

The first part of the video on how to make the gate with your own hands, see below.

The second part of the video on making wrought iron gates with your own hands.