Installation of fence posts

Without such an important component as the fence, it is impossible to imagine an ensemble of any private territory. The type of fencing, which can be temporary and easy or erected for many years, depends on the preferences and financial possibilities of its owner. However, in any embodiment, no fence can do without support columns. Therefore, the technology of installation of pole supports of various designs plays a very important role in the process of installing any type of hedge.

Process features

The specificity of installation of pole supports for the fence is that they must have the necessary resistance to dynamic and static loads created by the intake sections, to withstand both individual mechanical shocks, and significant wind loads.The latter property is especially important for solid fences, since the air pressure in strong wind often exceeds the mass of the entire fence.

In addition to lateral, vertical loads and the total windage of the entire fence, it is necessary to take into account the condition of the soil in which the pole supports are installed. Under this should be understood the degree of flowability and viscosity of the soil, its freezing in winter and moisture saturation index.

Hence the choice of the way in which, in fact, the pillars themselves must be erected. They all boil down to four points, that is, a simple driving of the pillars into the ground, their filling, partial concreting and full concrete pouring of the underground part of the pole support, and sometimes with the installation of a tape type foundation.

In the case of simple driving of pillars into the ground, the process of building a fence is significantly accelerated and cheapened, but in loose, soft ground, sandy, black earth or clay, the stand is easily loosened and tilted under the action of the wind due to the high windage of continuous intake sections, which may consist of corrugated board, polycarbonate or wooden slats and slabs.

Also, if the height of the fence is more than 2 m, the clogged poles will be twisted by the wind, even if the fence consists of a net-air permeable to air flow. The same will occur when such pillars are driven into moist clayey soil, which tends to swell at low temperatures in winter. Therefore, this method of installing intake columns is suitable only when they do not experience large mass loads or become clogged in solid or rocky soil.

In soft soils, fence posts can be hammered only in cases where the height of the fence is not higher than 1.5 m, and the intake sections consist of a net. It is also quite acceptable when creating decorative fences for front gardens and flower beds, but it is extremely undesirable to fix to the metalwork posts or the slate fence that is buried in the ground.

Installation of intake supports by the method of concreting is more time consuming and costly and time consuming, since it takes about 3 weeks to cure the concrete. However, the service life of the fence on concrete supports will be several decades, and the use of concrete mix to strengthen the fence posts is suitable for absolutely any type of fence and for all types of soil.

The only exception is wetland swampy soils. For them, it is impossible not only to concreting the pillars, but also to block them, and the exit is the installation of a pile-screw foundation.

Thus, the choice of installation method for the intake pillars depends on the specific conditions in each individual case. The use of driving may be attractive in terms of saving time and money, but is not a universal option. Concrete is reliable and durable, applicable to any soils and types of intake structures, but is much more expensive. In the case of stable dry soils, it is possible to somewhat reduce the cost of manufacturing a fence through the method of partial concreting of intake supports.

Manufacturing materials

In the construction of fences the most common materials for the manufacture of pillars are metal, wood, asbestos cement, concrete or brick.

Steel

Metal supports from hot-rolled angle or channel, shaped round, rectangular or square pipes in cross section are one of the most reliable options for installing any intake sections from welded and forged intake sections to slate,sheeting and mesh-rabbits and perfectly in harmony with any building materials and taking on significant dynamic and static loads.

In comparison with wood, iron is many times longer than its life. The poles belonging to one of the above types are reliable, versatile and functional to the point that they allow for quick and technologically simple installation of intake structures. The only drawbacks of such supports are the high cost of metal and the need for systematic painting for the purpose of anti-corrosion treatment.

Tree

The construction of wooden fences from slabs or unedged boards with an abundance of other materials in our time is, rather, the old fashioned way. For such fences can be used pillars of timber or logs of pine, oak or shares. In addition to them, supports of larch and mulberry can be used. These tree species are most resistant to adverse external factors such as moisture, temperature extremes and mold fungus. This also includes coniferous wood of spruce and fir.

The advantages of wood are its affordability and ease of installation,and the disadvantage is relatively short, about 5 - 10 years for light structures, the term of operation. To protect the wood from pests of bark beetles, impregnation with an antiseptic and painting or varnishing the upper part is required. The lower part of the pillars, installed in the ground, it is necessary to twice with an interval of 24 hours to process bitumen mastic and close the roofing material.

Asbestos cement pipes and concrete

These types of supports can serve as a kind of alternative, but they have serious drawbacks. Asbestos-cement pipe is not combined with all materials, which creates inconvenience in the construction of fencing. If you do not protect it with a plug from moisture from rain or snow, then in the cold this water will freeze, which will lead to cracking of the support.

Concrete pillars are excellent for the construction of massive structures, but they require the creation of a reinforced skeleton and formwork for them. After pouring the concrete mixture into it, you have to wait for the concrete to set for about 3 weeks.

Brick or stone

Such supports require the arrangement of the foundation and the installation of a steel rod, which is fixed at the base.Around him are brick or stonework.

The advantage of supporting pillars of building or facing bricks, natural or artificial stone is their aesthetics, capital and resistance to any loads, and the disadvantage is the complexity of construction, which does not do without the help of an experienced builder, as well as the high cost of the material. The durability of the fence with brick or stone pillars depends on the correctness of the laying.

Device designs

The choice of the shape of the fence posts depends on what type of fence sections will be mounted on them. Thus, it is advisable to mount welded, cast or forged structures, profiles, slate or mesh on metal supports. Their section is selected for fences from the grid of about 60x40 mm, and for professional sheet - about 80x60 mm.

The supports made of brick or stone are used for fencing of metal profiles, forged fence designs, brick and stone fences, or for concrete sections. To lay out such columns, skills in a bricklaying are required.

Wooden pole supports are used for the construction of wooden rails or fence fence.

Concrete racks with considerable strength and reliability are very heavy. With a fence height of more than 2 meters, an assistant will be required for their installation. In order not to engage in the independent manufacture of such supports, you can buy them. Concrete pillars are suitable for installation of all types of fences from the glitter mesh or chain-link to slate, profiled sheet and concrete sections.

Markup

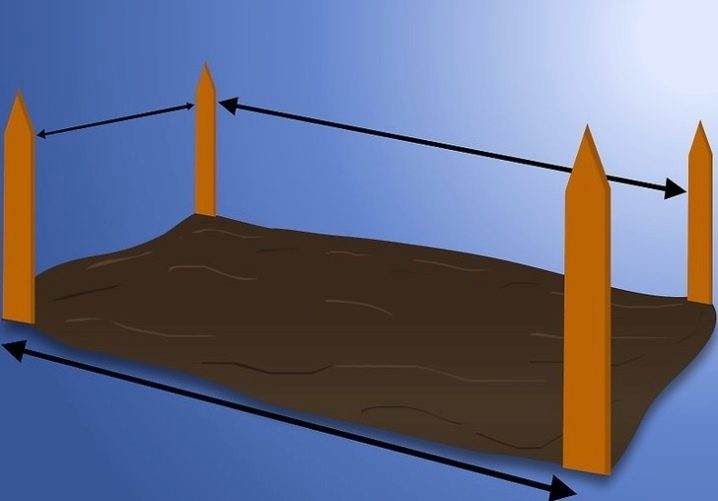

Planning and marking the territory of the site under the pole supports should begin with the definition of its corner points, which are marked by clogging stakes in them. Between these pegs, the cord is then pulled. Each such peg should in this case be placed clearly against the next. At the corners of the perimeter, it is necessary to put pillars of a greater thickness in order to withstand high loads.

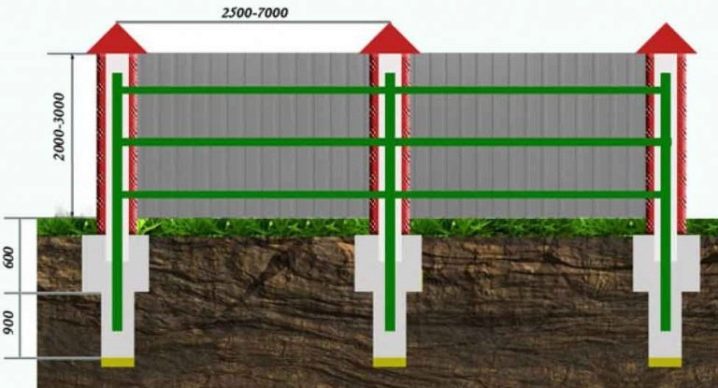

The most optimal distance between two adjacent supports, or, in other words, the length of one intake section, is a distance of 3 m. If the construction of a large mass fence is planned, in order to avoid sagging, the length of the span is reduced to 2.5 m.

After the final installation of the first corner support, the second one is the same, the height of which is aligned with the height of the first one.Between these two pillars two cords are pulled from below and above. They will serve as markers for placing intermediate stanchions.

The installation points of the pillars with the corresponding spacing between them are outlined with the help of a measuring device such as a tape measure, with which they pass along the cord. The standard distance here is a distance equal to 2.5 m. You can do a little differently, using alternation over the entire length of the future hedge of 2 m sections with intervals of 2.5 m. This method is used when the preliminary calculation shows the possibility of obtaining one short span in the end.

Then, without removing the cords, at the points outlined in this way, they drill holes to a depth of 1 m.

If you plan to build a high fence - about 2.5-3 m, then you should definitely take into account the increase in its windage and wind load. To do this, the length of the segment between the support pillars should be reduced to 2 meters, and they should be deepened into the ground by 1.2-1.4 m.

Then you should install four support pillars at the corners of the site, fixing them in the ground in one of the ways, which will be discussed in the next section.These columns, as well as all the others, should be leveled in height and set exactly in the vertical plane with the help of the building level. Between these pillars, the cord should be re-tensioned and the intermediate pillars should be aligned on it, which will be installed in the holes prepared in advance with the above dimensions.

Installation methods

If the owner of the site decided to install pillar fence supports with his own hands, then he should take into account such factors as the type of soil on this site, the material from which such supports are made and the mass of the future fencing.

When installing fence pillars made of wood in the corners of the territory, it is better to dig up pillars ø 15 cm, and for intermediate supports, a diameter of about 10 cm is admitted. They are set to the top down so that moisture does not rise up through the microcapillaries of the column and does not accumulate inside it. Before installation in the pit or after it, the columns are painted with oil paint.

As already mentioned, wooden poles are used for the most part for light intake structures, therefore, their mounting is a fairly simple matter. Drilling of a pit under a wooden support is carried out to a depth of about 0.5 m, if the height of the support part rising above the ground does not exceed 1.5 m. With a greater height of the enclosure, the depth of the underground part increases according to the principle that the lower part deepened into the ground should be 1 / 3 of the total length of the pole support.

The diameter of the recess should be twice the diameter of a wooden post. The drill is required to be kept strictly upright in order to obtain a straight hole with smooth edges.

Further, its bottom is lined with a layer of expanded clay or gravel for drainage of rainwater or subsoil water. Install the pole should be strictly in a vertical plane, adjusting it to the level. After that, the support should be loosened from the sides with crushed stone, or a rubble stone or broken brick, which are systematically tamped in as far as the bucking and filling of the pit with scrap occurs. The verticality of the pillar is verified by the level in the process of such a booting after each tamping.

For greater durability, wooden supports can be placed in steel sleeves. Subsequently, they will serve as a casing for the underground part of these supports.

The mechanical strength of steel fence supports successfully withstand the load from very heavy fences with significant windage, so they require rigid fixation. For their installation, concreting and clogging into the soil layer is used.

Concreting is used when installing the pillars in sandy soils that do not have a tendency to bulge and with normal water permeability.

Hammering a pole with a sledgehammer is a simpler method, requiring, however, considerable physical effort. The support with the purpose of its more dense fixation in the ground should be driven into the hole with a smaller diameter than the column itself. This method is suitable for light type fences and can only be used on heavy, dense or rocky soils.

In the case of skew, such supports are leveled with the same sledge hammer, which makes it possible to quickly reconstruct the entire fence.

Metal pillar supports with a spiral in the base can serve as a useful option. They are screwed into the ground, compacting it.After that, it remains only to concrete these supports using conventional technology.

Asbestos-cement pillars ø 12 cm are the most common. Such supports are not considered to be strong, therefore they are used for light intake structures, although with proper compliance with the installation technology, their service life may exceed 50 years.

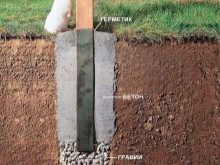

The depth of the pits for such supports should be about 80 cm in the event that the height of the column exceeds 2 m with the extension below. This expansion is made for the sake of its further pouring with concrete. The walls of the pit are covered with roofing material in the form of a tube. Its upper part should protrude 15 cm above the ground surface. A wooden formwork is placed around this elevated part of the ruberoid tube.

The inside of the pit is filled with concrete, but not the entire volume. While the concrete mixture is not seized, an iron bar is placed a little shorter than the column itself.

After waiting for the solution around the rod to harden, an asbestos-cement column is put on it and the entire remaining volume is poured with concrete to the very edge of the formwork. To protect the pipe from bursting in winter due to freezing water, the internal cavity of the pole supports is filled with concrete to the very top, forming a convex cap from it to prevent accumulation of water in the support.

There is also a less labor-intensive method, similar to the installation of a steel profile, when the pillars are buried in the soil and poured with concrete, but its implementation is permissible only for sandy types of soil.

Before the construction of brick pillars will need to pour a strip foundation for them. To this end, a trench comes off, which is laid with broken bricks and poured with concrete. In the place where the brick pillar support will be erected, the frame is made of durable reinforcement for several metal rods. The armature can be replaced with a wide pipe.

The surface of the foundation is covered with a layer of waterproofing. Before you start laying, make sure that the markings are correct. By folding the first row, the accuracy of the masonry is checked at the building level. Frame made of reinforcement or pipes are lined with bricks, filling the cavity with concrete mixture.

Useful recommendations

After making the final decision on the choice of material for the pole supports and the method of their installation, they proceed to the preparation of all the necessary tools and materials. Be sure to need a garden gas or electric drill, bayonet and shovels, crowbars, tape measure and other measuring tools, cord, levels and a sledgehammer.For the manufacture of concrete it will be necessary to have a concrete mixer or to weld a box from a corner and sheet steel for mixing it manually. Zabutovki require a stone or broken brick, and for the preparation of the concrete mix - sand, gravel and cement.

It is quite natural that all work on the installation of pole supports of any type should be carried out in strict accordance with the above described technology for each of them, in order to avoid unnecessary pulling out of these supports and repair of intake sections.

It is necessary to observe the level of burial in the ground of the fence posts, which directly depends on the weight of the fence structure. The larger it is, the more deeply these columns should be buried.

If the height of the fence above the ground exceeds 2–3 meters, then the depth of penetration of the supports should be 1 meter. The same rule applies to heavy hedges. Light fence designs can be mounted on poles, the lower part of which is recessed by 50 cm.

This should also include the depth at which the soil freezes through and the level at which the soil waters lie. The average indicator will serve as the deepening of the pillars into the ground at 1/3 of the height of the support.The installation of the fence as a whole and the installation of pole supports in particular hardly makes sense to carry out in winter, unless, of course, we are not talking about the southern regions of Russia with a relatively mild climate. This is especially true of concrete work.

With a significant (over 25 cm) elevation difference in the uneven area, additional pillars will be required and the construction of a step-type fence. Additional supports with high mechanical strength are installed in places where there will be gates and gates.

An important point is not only checking the verticality of the column at the time of its fixation, but also respecting the level position and the same height of all the supports.

Assembling a fence on a private plot can be carried out on its own, when one of the previously described universal methods is selected for it. With its competent implementation, the fence will last for many years and without additional maintenance.

In recent years, steel columns with a gitter or chain-link mesh have gained considerable popularity, and fences from a profile are often encountered. To build wooden fences in the budget version is not quite practical.More complex fences on asbestos-cement and brick supports require the involvement of specialists for their construction.

For how to install the fence post, see the next video.