Ways and features of attic warming

There are many people who seek to create high-quality and comfortable attic. But to accomplish this task without reliable insulation is impossible. And because of the various options for insulating materials, the features of their use should be given special attention.

Special features

At the cottage and in the country house always try to provide maximum comfort and convenience. Therefore, quite often rooms for winter living are equipped in the attic floor, which was not originally intended for people to live at all. And this creates a number of differences from the usual wooden house with a cold attic.

Unlike any other rooms in a private frame house, the attic is very hot in summer and cooled in winter. Not a single room, even with a large glass area, has such a problem. The geometry of the walls duplicates the outer contours of the roof roof with all its slopes, and therefore it is necessary to abandon the use of any bulk insulation.Yes, and soft roll options, prone to fast rolling, also not suitable. It is very important to use the most effective insulating material so that a relatively thin and light layer of it performs its task without pressing excessively on rafters and walls.

In the case of unheated premises there are additional nuances. The draft floor is attached to the lags from below, and you will have to agree with this circumstance - after all, the front surface of the floor will be fixed on top. Next comes the vapor barrier and, in fact, the insulating material. Whether to put waterproofing, even experts can not finally come to a common opinion. Floor boards thinner than 4 cm simply do not make sense, even under the most slender and lightweight people they will sag.

How to choose a heater?

There is a huge variety of heaters on the market, and if not everyone is suitable for protecting the walls of the attic from the inside, almost everyone can be put in the floor “cake”. But it is necessary to take into account the properties of a particular substance and the structures created from it, first of all, the level of thermal protection.

The choice of insulation for the attic is very difficult, and with the slightest difficulty with it should be consulted with professionals.However, given the well-known properties, pros and cons of each option, you can decide in most cases on your own.

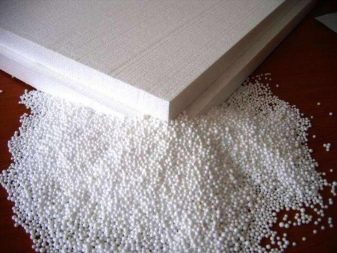

For decades now, foam has been widely used for insulating various structures. Under normal conditions, this component:

- does not saturate the air with toxic substances;

- excludes infection by microorganisms and their biological decomposition;

- along the way it performs the function of vapor barrier in the room;

- has a very low mass;

- differs affordable cost and serves as much as insulated buildings.

But it is impossible not to mention the weaknesses of such heat protection. So, low density turns into an insufficient mechanical strength. If nitrokraska gets on the surface of the foam plastic, it quickly collapses. This material is not ventilated, which can create a number of problems in the attic. And there may be mice or other rodents; to resist their invasion helps only reliable outer layer, but it aggravates the structure and makes it thicker.

A large number of people use polyurethane foam (PUF), which is better than regular foam in a number of indicators.But the use of this insulation will be correct only if you abandon a number of harmful myths. The experience of its use in this capacity has been around for more than half a century, and during all this time, residents of houses with polyurethane insulation have no reason to be angry. Any person, if only he does not have an extremely large complex, will quietly walk along the floor, warmed with foam. The main thing is that the shoes should be soft and not have sharp spikes and other protruding elements.

Do not confuse polyurethane foam, laid in the "pies" of flooring, with mounting foam. Their chemical composition is close, but this is where the similarities end. When a hard material is polymerized, closed cells are formed in it, which allows to achieve a phenomenally high level of thermal insulation. Providing the same with the materials at hand or even with any other factory-made products will fail. There are, however, factors due to which polyurethane foam has not yet supplanted (and will never displace) other types of insulation:

- it should not be placed where ultraviolet light can act;

- It is unacceptable to use even the best varieties of polyurethane foam in contact with highly heated surfaces or near an open flame;

- The heat loss figures promised by the manufacturers are an ideal product of the highest density (and it is very hard to create one)

- over time, the effectiveness of thermal protection due to the replacement of the gas filler with air decreases;

- the highest adhesion is guaranteed, but not for surfaces that are absolutely not prepared.

For the attic are often used, and other heaters. If polyurethane foam is the result of progress, then warming of sawdust has been practiced for many centuries. Obvious advantages of this method are its availability to people, low cost of material and the ability to independently control the quality of the finished layer.

To improve the quality of the material, it is treated with boric acid or copper sulfate solution, mixed with lime, gypsum and cement. Then no harmful animals will start inside, and the risk of fire will be eliminated.

The natural origin of sawdust insulation allows us to consider them as safe as the “ancestor” - wood. Prior exposure is required for 12 months and thorough drying of the material.If wiring passes in heat-insulated walls, floors, or ceilings, it is placed in fireproof enclosures. The big problem is that even properly processed sawdust will crumble over time. Therefore, they are not very suitable for warming walls and other vertical surfaces.

The use of mineral wool for residential attic is attractive only because this method of thermal protection simultaneously reduces the penetration of extraneous sounds from the outside. Such a heater does not burn, does not change its configuration when the temperature changes sharply. The mineral wool is not prone to destruction under the influence of caustic substances, it is not eaten by animals and bacteria.

At contact of a heater with metals there is no corrosion. It is relatively easy to process the material, but if condensate forms, it will fall all into the layer of insulation.

The competition of mineral (basaltic) wool is also ecowool. It is produced from waste of the pulp industry and secondary raw materials, so according to its environmental characteristics, this method of thermal protection is quite acceptable. Fresh ecowool keeps warm well, but after a short time its quality deteriorates.This is caused by the mechanical settling of the material, so it is advisable to lay it in excess. Such a deficiency is completely devoid of extruded polystyrene foam.

In the overwhelming majority of cases, it is combined with plasterboard plating. Outside, this material is protected by:

- siding;

- brick;

- aluminum or steel profiles;

- ceramic tile laid in the joint.

Use polystyrene with caution - it can easily catch fire when in contact with an open flame or at high temperature. It is advisable to choose those options that are processed in production with special components that effectively suppress ignition. But when using the penoplex, as the manufacturer promises, water absorption is excluded, maintenance of comfortable conditions in the room is guaranteed.

The strength and uniformity of the coating allows it to not crumble and not to collapse even with a strong mechanical effect. Builders can forget about the use of protective masks and gloves (which is unthinkable when working with the same glass wool).

Returning again from the latest technological advances to traditional materials, it is impossible not to say about the insulation of expanded clay.According to its composition, it is represented by oval-shaped granules obtained from baked clay or expanded clay sand. Depending on the production technology, expanded clay with a density of 250-600 kg per 1 cu. m. It perfectly retains heat and, in addition, prevents the development of microorganisms, rodents settle.

U-shaped piercing mats are made mainly on the basis of stone wool. They inherit its positive properties: zero fire hazard, resistance to harmful substances, excellent heat retention and resistance to strong heat. Thanks to the adaptation to the surface of the surface, this rolled material is perfectly combined with shingles. Even glass wool is not capable of holding the same amount of air per unit of volume as piercing mats. Its reliability is evidenced by at least constant use in nuclear power plants.

Continuing the review, it is impossible not to mention the different types of foil insulants. Most often in practice, you can meet with polyethylene foam - this self-adhesive coating will help protect chimneys, smoke pipes and ventilation pipes in the attic from heat leakage.Mineral wool is sometimes combined with foil, it is also intended for insulation of smoke channels and roofing.

If such a shell is used for expanded polystyrene (necessarily double-sided), it will be able to transfer heating to 170 degrees. Mostly it is designed to reduce heat loss in warm floors.

Another type of foil insulation is penofol. With it, it is easy to stop heat loss through the floor, walls and roof. Reflective insulation works effectively only when reserving free space, and there must be at least five layers of air. But beware of using polynor. This material is essentially no different from foam, although some manufacturers say that it corresponds in quality to the foiled versions.

Paroizolyatsionnye and waterproofing properties are equal to zero. It is much more practical to use fiberglass. It should be borne in mind that its panels should not move under their own weight or under the influence of other factors, therefore it will be necessary to install the thermal protection very carefully.

If you go back to the foiled materials, it is difficult to get past the folgoisolone.It allows you to leave 95% of the heat inside, does not freeze through itself in winter, and is not inclined to crack in the summer. If the installation is done correctly, the service life of the material is very long.

Its features have a selection of insulation under the metal. To solve this problem is widely used:

- mineral wool;

- Styrofoam;

- glass wool.

It is advisable to work just at the time of construction of the roof. After all, stuff and attach material to the inside. An alternative to the three means listed is an insulating plate, also known as soft fiberboard. This coating will provide reliable sound insulation (in addition to the basic function). On the air accounts for up to 4/5 of the total volume of heat protection.

How to calculate?

Having chosen one or another material, it is required to calculate the thickness of the heat insulation layer. The standards for such a calculation are defined in SNiP 23-02-2003. The smallest value of thermal resistance set for a specific territory is reduced by the amount of thermal resistance of the material. You can calculate it by taking the coefficient of the table and the desired thickness. When the walls are formed of several materials, then what should be the insulation, count, summing up their performance.

Ways

Seamless insulation involves the use of sprayed materials.Most often in this technique used polyurethane foam. It is necessary to combat the appearance of dampness. Spraying foam near an open flame or heat source can be life threatening! These disadvantages are overlapped by resistance to chemicals, extreme cold and mechanical stress. The combined warming of a penthouse can be carried out with use of both the sprayed, and slab and rolled materials.

Additional double insulation is a variety of combined, it is used if you need to strengthen protection against heat loss. Then the existing plating turns into a base, after it a ventilation gap is left, and then a membrane, a warming material, is put. Then comes the turn of the new options for vapor barrier and plating. Alternatively, you can make a warm film floor under the skin.

It is important to check that the “pie” of the roof does not have cold bridges and other deviations from the norm.

How to warm?

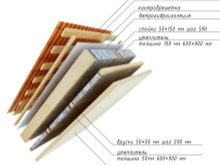

For external insulation of the attic (strengthening the thermal protection of its roof) it is allowed to use only dense materials of slab execution. Most masters recommend using penoplex in this case, since it is very well manifested in this capacity.Arriving at the rafter board, equal to the width of the insulation, you can avoid it sliding down. Laying plates should be made in a staggered manner. To create crates used bars, their thickness can not be less than 4 cm.

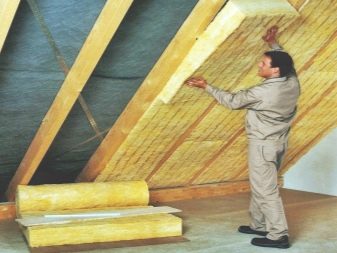

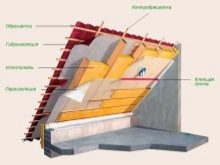

Experienced repairmen have long ago developed the attic insulation technology from the inside and strictly follow it. To the top of the insulation was covered from moisture, you need to bypass all the wooden beams and attach, using a stapler or vertically directed slats, a special film. She lay in layers with overlap, the fastening is made with special tape. Then a lathing is made, which is made of rails 80-100 mm wide parallel to each other, which are stuffed onto rafters.

When working, it is recommended to monitor whether the rafters sag under load and whether the surface is flat. Deformations are detected during inspections at the building level, and if they exist, you need to take a plane. When the crate is ready, you can insulate it with your own hands, bringing basalt mats inside. The width of the individual mat should correspond to the gap between the rafters, and the thickness - their width. If the mat is very thick, heat insulation is placed in several layers.

Next comes the turn of the ceiling vapor barrier - it is ensured by plastic films, glassine or roofing felt. When attaching such materials to rafters, glue is applied or rails are packed with a step of 0.4-0.5 m.

It is recommended to glue each joint of the film with construction tape. Where the climate is very cold, it will be right to put a vapor barrier in the gaps of the insulation itself. When all these works are done, it is the turn of installation of decorative panels, becoming the front wall decoration.

Sometimes crate neglected. In such cases, it is necessary to fasten to the bars themselves or to the steel profile stuffed from the inside onto the rafters:

- plywood;

- siding;

- drywall;

- other selected material.

In those cases when the walls of the attic at the same time are parts of its roof, there is no special need to warm them. The difference between wall insulation and work on the ceiling is the need to always crate. The heat protection scheme of the floor overlap forms a whole “pie”: the vapor barrier is below, the insulation is higher. To do without waterproofing in this case will not come out in any way, it is located above the insulation, occupying the space between the beams.Finishes mounting chipboard or high-quality boards.

Protecting the attic from heat loss is required, even when it is used only during the warmer months. Since even the most reliable structures can fail, you need to take care of the selection of waterproof material. Then suddenly leaky fragments of the roof will cease to be a serious danger to the house and property in it. Not less significant circumstance - resistance to fire, especially for insulation on heated attic and near chimneys. According to experts, the best solution in a warm attic room is glass wool.

Plasticity allows it to lie in the gaps between the rafters, without leaving the slightest free areas. Accordingly, the cold air streams will not rush down, depriving the residents of the house so much deserved heat. In the middle zone of the Russian Federation, wadded materials should be laid with a layer of 15 cm, and the rules of construction in cold climates require double this value. Any type of "wool" according to the informal order developed among developers should be installed only with vapor barrier.

The first step in the work will be tightening the waterproofing membrane, which is held on the rafters with the help of rails. The gap of the tensioned films and roofing materials is at least 30 mm, any wrinkles and folds are unacceptable on the membrane. Particular mention should be made of the installation of thermal insulation of the gable in the attic of the attic type. It is desirable to produce not inside, but outside. With internal insulation, the dew point will be shifted into the internal space, and the whole point of the work is lost - the wall will freeze through more deeply and more than before.

Preparation of the walls of the gables step by step begins with cleaning them from dust and dirt, then the base must be primed. Special primer improves adhesion of the adhesive to the surface. Experts recommend applying it in a couple of layers.

It is impossible to do without a contra-grille in any residential attic - if builders start saying that it is possible to refuse it, this immediately speaks negatively of their professionalism. Both in the gables, and in the main part of the attic, you need to warm the windows, their junction points with the walls.

Every homeowner should know the peculiarities of this work, because so many performers violate the sequence of actions and get a bad result.

In the slopes (upper and lower) there is very little space for laying insulation material. It is advisable to order windows, deeply seated in the roof. The best way out, many experts believe stone wool and other insulation with the highest level of thermal protection. Regardless of the specific choice, it is required to mount waterproofing.

Another problem place on the second floor is the corners. At oblique angles, the heat insulator is attached, giving it the necessary shape in advance. When the work is finished, the heat-insulated surface is thoroughly checked in order to notice the appearance of cracks. Upon detection of their strip of insulation, which is 10 mm wider than the identified defect, it should be placed in the problem area. Thermal insulation between the ground floor and the attic with bulk materials implies that they fill the free space between the beams or the bars to the very top. A film is attached on top attached to the structural elements.

Instructions for effective attic insulation allows you to mount all the necessary materials and structures to the owner of the house.It is possible to work outside only in warm and cloudless weather, because the slightest moisture caught on the roofing elements and portions of the “cake” can lead to unpleasant consequences. If roll materials are selected, it makes sense to wait for the summer and begin repairs. To mount them from below is very inconvenient and impractical, the number of errors inevitably grows.

It is categorically unacceptable to block the gaps of insulation with foam, for this you need to use only the same material.

Insulation of complex structures

Insulation of a broken attic roof has its own characteristics. 100% wood is required to be impregnated with special antiseptics and fire retardants. Every detail that is on the street side should be treated only with compositions for exterior work. But these mixtures are not suitable for impregnating wood indoors - if applied, it will be possible to fight the bad smell for many years. The space under the roof must be equipped with ventilation gaps to prevent moisture stagnation.

Waterproofing under the broken roofs in many cases, put without stretching to a flat state, but on the contrary, allowing it to sag by 30-50 mm.The choice between such approaches is the business of professionals who know when it will provide water flow and when it will not.

When working independently, you need to do everything in the usual way and not try to reinvent the original schemes. Care should be taken to ensure that all insulation materials are correctly placed in several planes at once.

Common mistakes

Even qualified builders are not insured for 100% of the blunders, and if a particular team has only positive reviews, you still need to carefully monitor its work. If, however, mistakes were made, very soon there will appear characteristic signs of improper insulation of the attic, and condensate is the first enemy of any homeowner. It is unacceptable to interrupt the vapor barrier line on the entire outer surface of the attic, and each section of the junction of its fragments must be glued with masking tape. A gross error in the appearance of condensate - to seal all the cracks.

If you do this, it will stop dripping and begin to flow in full-fledged streams. To deal with the problem of leaking roof and accumulating fluid, blocking the path of water, it is useless.

You need to seek help from professionals and not just consult, but call them to inspect the attic, preferably with a thermal imager in their hands. If on an unheated attic the reverse pipe of the heating system is laid, to insulate and create waterproofing, the vapor barrier should be exactly the same as in the heated space.

Useful tips

Warming is a complex problem. It would be naive to try to solve it by simply picking up the “miraculous” insulators promised by advertising. Even if their properties are real, to eliminate the shortcomings of engineering solutions and structural materials will not work. From the first minutes of design and construction, you need to think about how to provide warmth and comfort - only then you will get the optimal result. In the absence of experience and knowledge, it is more correct to order the services of masters, they will select the best materials and in a few hours will bring your idea to life.

But for those who still decided to warm the attic on their own, a set of recommendations and tips, presented in the next video, will help.