How to insulate the attic from the inside, if the roof is already covered?

Many owners of old houses are thinking of expanding living space through the attic. However, they immediately wonder how to be if the roof is already covered, but it is still necessary to warm the attic. In this case, to the rescue comes the decision to conduct insulation work from the inside.

Special features

The process of warming the attic from the inside can not be called easy. To do this, you need to know the specifics of the roofing device, as well as find out if your existing roof is suitable for insulation. Indeed, not every attic can be altered under the attic, especially if the roof is already covered.

There are three situations how a roof can be performed:

- There is only a ventilation gap between the rafters and the crate.In this case, the roof is considered absolutely unsuitable for insulation. We'll have to completely disassemble the roofing structure to warm it.

- Between the crate and the rafters polyethylene film is laid, which serves as a vapor barrier. Such solutions can be considered optimal, and the roof - fully prepared for subsequent work on its insulation.

- Between the rafters and crate laid diffusion membrane. Option similar to the previous one. The presence of a waterproofing layer is evidence that the roof is prepared for insulation from the inside.

Thus, the main feature is the preparedness of the roof for further insulation.

Heaters

Thermal insulation of the roof of a private house, cottage, cottage can be done by various means. Here there are liquid materials, and elastic, and even those that have a relatively high density.

Before proceeding to the selection, be sure to pay attention to the roof structure. It often happens that not every material is universal, so it is better to be safe. The simplest example is the insulation of duo-pitch and sloping roofs: if practically any heaters are suitable for a simple duo-pitch design, for a sloping one, by no means all.

If you do not consider liquid insulation, then the rest are sold in two forms - in slabs and in rolls. As you might guess, thick insulation is presented in the plates, fibrous in rolls.

It should be noted that not all options available on the market are suitable for insulating from the inside. This is due to the fact that insulate the attic from the inside is much more difficult due to the existing rafters. This increases the need for leveling cold bridges.

Consideration should be given to materials for internal insulation in more detail.

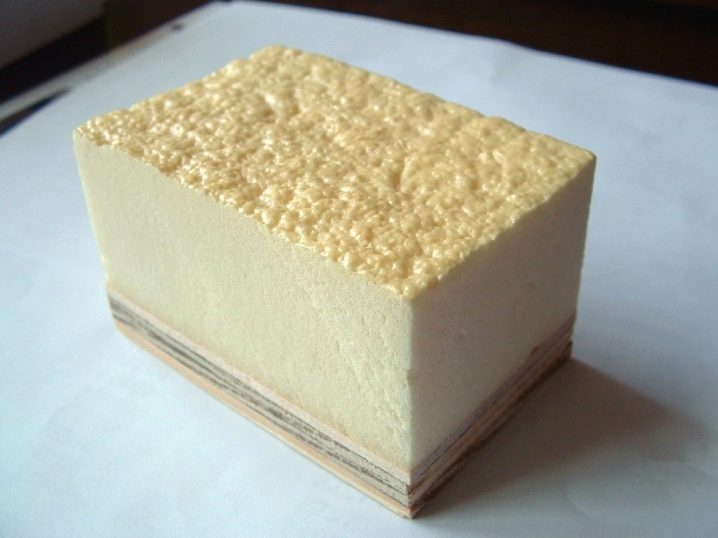

Styrofoam

Ordinary foam refers to the cheapest materials. It is sold with finished slabs, which makes it easy to use. Despite the fact that the foam belongs to the budgetary insulation solutions, it has many advantages.

So, the foam is not hygroscopic - it absolutely does not absorb water and moisture. To improve the water-repellent characteristics, it is enough to treat it with a special tool., which will clog pores on the surface, and water will simply flow down on the foam plates.

It should be borne in mind that the foam has a very low weight due to the presence of a large number of voids between the granules, its components.This contributes to the fact that it will be possible to cope with the works on warming alone. Ease gives another advantage to relieve the load on the roof structure.

The foam conducts heat poorly, with the result that we can safely say that it perfectly isolates the attic. The simplicity of working with it is another significant advantage of the material: cutting the material, cutting out pieces of the right size can be done with an ordinary stationery knife.

However, there are some drawbacks. Firstly, the foam does not “breathe” at all, which can cause condensation. Secondly, the foam is susceptible to damage by pests, in particular, rodents. Thirdly, the foam can not make out wooden floors, as over time, the wood will shrink and gaps will appear between the foam plates.

How to insulate the attic with foam plastic, described in the next video.

Penoizol

Penoizol, or urea-formaldehyde foam, is a liquid version of the foam. Warming solution is prepared immediately before use. Its difference from many other installation compositions, for example, foam polyurethane foam, is that it does not expand in the process of solidification, retaining its original appearance and state.

The mass resembles white foam, similar in appearance to shaving foam.

Liquid foam is often used to insulate roofs and mansards at the construction stage, but it can also be used after the roof has been laid. Among other things, it can be used to further insulate the walls and floor of the attic.

The vapor permeability of the material, like that of a dense analogue, is almost zero, which makes it imperative to take care of decent roof ventilation. However, the material does not conduct heat, so with its main function - insulating - copes perfectly well. So if you do all the work should be the way, insulation with penoizol will be a worthy and budget solution.

Extruded polystyrene or penoplex

Despite the fact that the foam and polystyrene belong to the same group, the second is more practical. This is largely due to the specifics of installation. So, polystyrene closes the rafters, because of which the best tightness is achieved. Styrofoam plates are easily fixed to each other with glue. Due to low weight, installation can be done independently.

The material has a long service life, while it does not rot and is not exposed to attacks from rodents. The only serious drawback is the flammability of the material. Will have to take care of additional insulation wiring, because one spark can lead to a strong fire.

If the conduct of any communications in the attic is not provided, polystyrene foam will be an excellent choice, especially if you consider that it can be covered with any finishing material. It is also compatible with wood, and with metal, and with any roofing.

Minwat

Mineral wool often acts as an alternative to penoplex. This material refers to the roll, which is caused by the ease of laying insulators, supplied in this way. Minvat has a fibrous structure that fundamentally affects some of its properties.

So, mineral wool is an elastic material that is attached between the rafters. In this additional attachment is not required, it is enough to cut the slabs of wool 2-3 cm wider than the portal into which the insulation will be inserted.

Rodents do not attempt on cotton wool, so you can not worry about the integrity of the insulating layer. Mineral wool, however, belongs to the category of eco-friendly insulation.Among other things, it guarantees excellent thermal insulation, despite the fact that it does not absorb moisture, and even if it gets wet, it dries in record time. Also, fibrous material is better to use if you need to additionally soundproof the attic from the surrounding street noise.

More information about warming attic mineral wool in the next video.

Glass wool

Glass wool is one of the varieties of mineral wool, but there is a difference. First of all, it is worth noting that the materials are made from different fibers. Fiberglass is used here. Due to this material is more elastic and durable. In addition, glass wool has the best noise absorption characteristics. At the same time, it is hydrophobic - it absorbs moisture well, but dries poorly, as a result, when wet it quickly loses its operational properties.

Many fear that the use of glass wool for thermal insulation purposes in a residential area will lead to disastrous consequences. In fact, it is not. If you correctly carry out all the finishing work, then no harm to health will be caused. On the contrary, glass wool is even safer than penoplex, because it does not burn.

However, the material requires care when laying it.It will be necessary to take all safety measures, protecting organs of vision, respiratory tract and skin from glass dust.

Stone wool

Among all insulating wat stone is more expensive than analogs, and all thanks to its special properties. Compared to others, it is itself safe and practically free from the drawbacks of other samples. It is the most environmentally friendly of all, not afraid of elevated temperatures, as it does not ignite, and also does not deform under the influence of heat.

Stone wool perfectly retains all other sounds, while its sound-absorbing characteristics are an order of magnitude higher than that of other wat. Another advantage is a good vapor permeability of the material. It “breathes”, therefore, condensation on it cannot form.

Stone wool can last for a long time. Such good performance properties are due not only to the strength properties of the material, but also to its ability to resist mechanical stress. Even if it is compressed, it is not deformed.

Cotton wool is sold in the form of soft plates, which are easy to cut into the required formats if necessary.The only drawback is the high price, but the material is worth the money.

Ecowool

Ecowool is very different from other wat form of sale. If the remaining analogues are delivered in rolls or plates, then ecowool is first crushed, and then applied by spreading the material with the help of special equipment. It is believed that in this way it is better to plug all existing gaps, forming a monolithic insulating coating.

Ecowool is a completely natural material. Without going into details, it can be said that it is a specially processed paper. Also included is a borax, which is a natural antiseptic. Its addition ensures that parasites, bacteria, mold fungi will not start in ecowool. Due to this ecowool has a long service life.

There are two disadvantages here. First, ecowool should be applied using special tools. Secondly, the cost of the material also can not be called democratic.

Polyurethane foam

Polyurethane foam must also be applied using special devices, which are quite expensive.

To avoid unprofitable expenses for the purchase, it is easier to lease the equipment - to rent.

The use of equipment and the application technology itself is quite complex, so when working with the material, you must have at least some experience and knowledge on this issue.

Polyurethane foam is most of all similar to polyurethane foam as it has the similar principle of work. It expands in the same way when it freezes, completely closing all the gaps and gaps through which a cold wind can penetrate or leave the precious warmth. After solidification, the material becomes monolithic and smooth. This feature suggests that it does not absorb moisture, so you can do without the construction of additional waterproofing and vapor barrier layers.

All this makes foamed polyurethane foam an ideal choice, regardless of what material is made of roofing and floors. The best solution when working with him is to invite a team of specialists.who will perform the installation in a few hours on their equipment, doing everything with the observance of technology.

Penofol

Penofol is a unique foil insulation.It is produced in the form of plates of polyethylene foam, coated with an aluminum layer on one or both sides. Aluminum reflects heat, returning it back to the premises, so heat loss is minimized.

However, it is important to make sure that the foil side is turned inside the room and not out.

Penofol is absolutely safe for humans and animals, although it is not a natural material. Due to the aluminum coating, it does not conduct heat, which gives reason to argue about the excellent thermal insulation properties of the material. Among other things It may not be necessary to make a vapor barrier for this material, since with proper installation it will do an excellent job with vapor barrier itself. due to the special texture.

This method of insulation - one of the most expensive, but also one of the most effective.

If you plan to use the attic for permanent residence, then choosing penofol, you will not regret it.

Room preparation

Having decided to warm the attic from the inside, you first need to properly prepare the room itself for the work. Keep in mind that not every attic is suitable for insulation. Check if the ceiling height is 2.5 m for more than 50% of the entire attic. If not, then we should not engage in warming. - it will be impossible to live here anyway.

Next, remove all existing cladding material, exposing the rafters. Installation of insulation will be made either on top of or between them. Check the condition of the roof, as well as the presence of steam and waterproofing layers. Keep in mind that the roof, which has smudges, must first be corrected, and only after that it is possible to proceed to the insulation work.

Check the joints carefully - places adjoining the roof to the wall. It requires special care, because it is these spaces that cause the most problems.

It is important that they are in good condition, do not have gaps, except for ventilation.

Vapor barrier

When creating an attic floor for winter living, especially if the winters are harsh in your area, you must first check for the presence of a vapor barrier. As a rule, it is made immediately when the roof is mounted, even if they do not plan to use the space under it as an additional room in the future. If there is no vapor barrier, then the roof will have to be redone outside, disassembling roofing materials. Alas, it is impossible to build a vapor barrier inside, because it must lie between the rafters and the counter grill.

Various materials can be used to create a vapor barrier. All of them have their advantages and disadvantages, as well as the specificity of combinations with insulating materials. All this needs to be borne in mind when moving to insulation work, so it makes sense to dwell on the materials for the vapor barrier in more detail.

In addition, it will help you to make a choice if the roof of your house does not yet have a vapor barrier.

Polyethylene film

Despite the cheapness of the material, many builders strongly discourage its use. This is due to the fact that it is unsuitable for creating a vapor barrier in Russian realities. The material absolutely does not "breathe": it does not let in not only moisture, but also air, and this creates problems with circulation and, accordingly, the greenhouse effect. So, the condensate can not evaporate and, draining, falls on the insulation.

Therefore, if in your house the vapor barrier is still made with the use of polyethylene film, refuse to buy absorbent water insulants, such as glass wool.

Over time, the film tends to collapse and crack, so after a short period of time, you still have to completely disassemble everything to replace your fragile material.

Pergamin

Asphamine is suitable for steam and waterproofing, so he received universal recognition. However, there will have to act in two directions. Firstly, a layer of glassine will need to be laid between the roof and the counter grill, and secondly - on the insulation from the side of the room. If all work is done correctly, it guarantees reliable protection and an optimal microclimate in the attic. From above, a double layer of glassine should be laid between the roof covering and the counter-grid.. Only then can the optimum effect be achieved.

Glassine is more needed to protect the insulation from moisture, so any one can be chosen as a warming material. Try to choose such options that are not deformed under the influence of temperature drops, and are not susceptible to attack by rodents.. Both wadded options, and penoplex perfectly will approach.

Ruberoid

Roofing material is used as a vapor barrier since the days of the USSR, so in old houses you can find just such material between the roof and the rafters. However, if possible, such a layer will need to be dismantled. This is due to the fact that the ruberoid is rotting material, and in accordance with the norms it cannot be used for hydro- and vapor barrier in buildings with a long service life.

If it is decided to leave the ruberoid, then you should not expect good vapor barrier properties from it. For this it is better to lay an extra layer of special vapor barrier material, at least the same plastic film.

It should be borne in mind that on the inside of the ruberoid condensate may accumulate, which will lead to wetting of the insulation. So, if the insulation is temporary (for example, it is carried out in winter, and it is planned to redo everything in the spring), then polystyrene can be combined with roofing material.

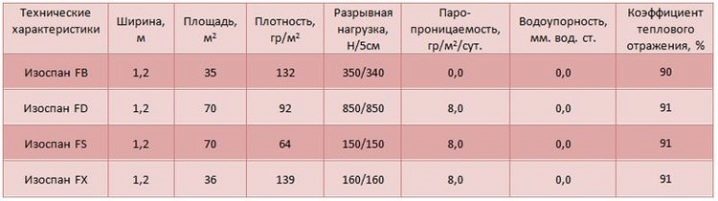

Izospan

Material izospan consists of polypropylene. It is among the most recommended for the construction of vapor barrier due to the fact that it was developed only for these purposes.

Izospan collects condensate and in the future does not allow it to fall on the insulation. For this is responsible the two-sided texture of the material.On the one hand, it is smooth, but on the other - a little rough. On the rough side, condensate droplets are trapped and evaporated. With the help of izospana, not only the roof but also the walls of the attic are being vaporized.

Depending on the properties of isospan, the markings differ. The most expensive, but also effective materials are considered with the effect of energy saving FB, FS, FD, FX. They have a foil coating that reflects the heat back into the room, thereby reducing heat loss to almost no. At the same time, the special texture still does not allow condensate to slide down and spoil the insulation.

Waterproofing membrane

It should not be attributed to waterproofing membranes all the same properties that are inherent in specialized vapor barrier films. Indeed, both those and others collect and evaporate condensate, but the main task of waterproofing membranes is to protect the house from moisture, and not from steam. In addition, waterproofing membranes have a wider range of applications: from insulation of attics and basements to the protection of swimming pools.

Waterproofing membranes are available in various forms. There is a diffusion, superdiffusion, as well as anti-condensate, which is more suitable for the vapor-insulating role.If you find, having disassembled the cladding material, one of such membranes, consider yourself lucky.

You can stack any insulation without fear that it will get wet and quickly lose its qualities. In addition, the microclimate in the attic will be excellent.

Penofol

Penofol is at the same time both warming, and paroizolyatsionny material. but it can be laid only when a waterproofing membrane is found between the roof and the rafters.

Reflective foil surface itself will collect condensate and help its evaporation, but the second “bare” side should be well protected from moisture. Only in this case, the variety will cope with both steam and heat insulation.

Material consumption

The calculation of the material is made at the stage of inspecting the roof for damage. Here it is important to consider the step between the rafters and the distance between the vapor barrier and the internal space. The quantity and thickness of the plates depends on the internal space: will the heat insulation be laid in one layer or in several layers? The size of the plates depends on the distance between the rafters.

Notice that if the step between the rafters is more than 60 cm, then it will be necessary to independently prepare an additional crateto make fixing insulation possible.

As for the sprayed heaters, in this case, you will need to calculate the volume. You will first need to clarify data such as the estimated thickness of the insulation layer, the perimeter of the rooms and the height of the walls, as well as the density of the insulation. We must not forget about the presence of windows and doors. It is best to use a special calculator.

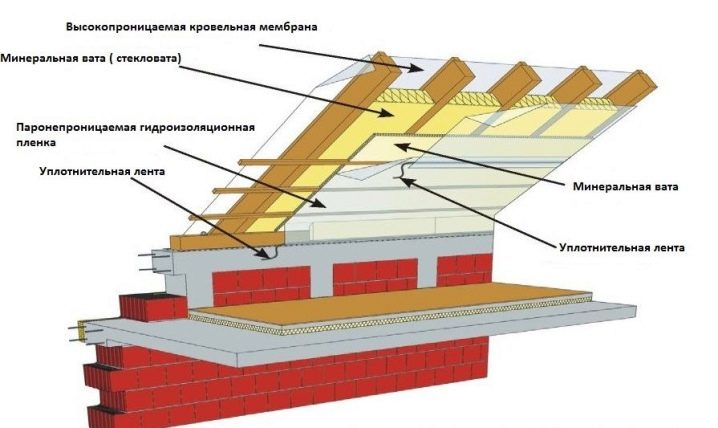

Warming scheme

Since during the attic insulation the roof is mainly insulated, it makes sense to consider the scheme of laying layers only for it.

If you start outside, the cake will look like this:

- Above is a roofing material that does not touch. Under it are crate and counterbattice, serving as a frame.

- Next comes a layer of hydro- and vapor barrier, which is also the source.

- Under waterproofing layer of insulation is laid. Depending on the width of the step between the rafters, additional lathing can be constructed here.

- From the side of the room is attached vapor barrier layer that protects the insulation.

- In conclusion, perform the finishing finish.

How to warm your own hands?

To insulate the attic with your own hands from the inside, you need to keep in mind the layout of the layers behind each other, as well as follow the following step-by-step instructions:

- It is necessary to retreat a little from the existing waterproofing layer, leaving an air opening. This will allow the heater to "breathe."

- After that the heater is mounted. Depending on the material, it can be placed between the rafters or on them, as well as sprayed. The way in which it is necessary to handle this or that insulation material is written in its instructions.

- Next, install a vapor barrier film. If the gap between it and the insulation is possible, then the junction to the walls, the ceiling and in the case of the attic to the floor should be airtight. Otherwise, condensate will form on the side of the film that is deployed to the insulation, and so should not be.

- At the last stage, finishing is done. You can choose from a variety of options, but usually get drywall, wall paneling or MDF.

Tips and tricks

Experienced builders give the following recommendations regarding attic insulation from the inside:

- wadded insulation is better to buy not in rolls, but in mats, so they do not need time for “tracing”;

- to insulate the floor you need to choose foam or other inexpensive material;

- insulation does not need additional fixing, but if that, for this you can use nails, adhesive tape or construction stapler.