Features of wood flooring

In any structure, the floor, as a rule, is the most problematic part, since the penetration of cold air masses through it with well-warmed walls is quite probable. Neither an excellent heating system nor carpeting will help solve the problem. Most other vulnerable wooden floors.

The most logical solution is to properly warm the floor using special materials, but first of all it is worth exploring the structural features of wooden flooring.

Special features

Even the correct laying of floorboards without gaps and gaps over time comes to naught due to the nature of the wood structure. Boards can crack and heat loss is inevitable. Through the floor, which has not been reconstructed, up to 30% of heat is lost, therefore to warm the wooden floor is necessary, but it is worth remembering about the features of this work.

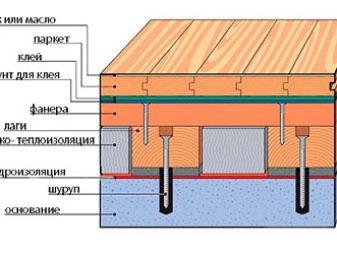

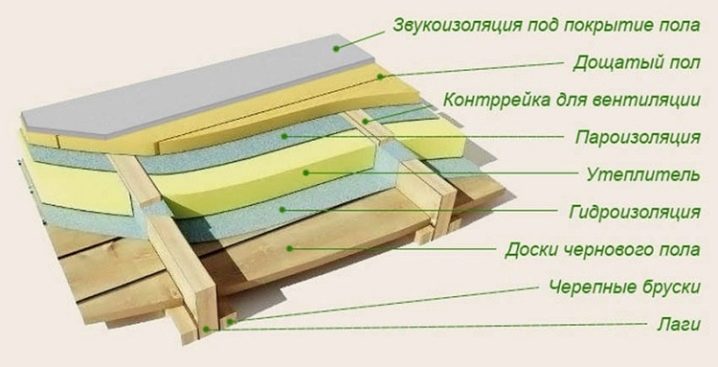

The wooden floor does not consist of only boards, it has a more complex structure. The basis of the floor is logs, which are wooden blocks. They are attached to either a rough floor, consisting of raw boards, plywood, chipboard, and which is the basis for finishing coatings (laminate, parquet), or finishing floor, the basis of which is made by milled boards.

In order for the floor to be comfortable, different types of insulation are used, but for normal operation of one insulation is not enough - it is necessary to use layers of waterproofing.

Their presence is necessary because the excessive humidity of the space contributes to the formation of fungus and the development of insects that destroy the wooden structure.

Warm rooms

Most often, wooden floors are present in private buildings, and therefore it is important to know how to warm the wooden floor in a country house. And it depends on many factors. In the first place - this is the time of construction of the structure. If the house is new, then you need to wait for the time that is necessary for the shrinkage of the wood structure (6-7 months). If the house is old, then after the dismantling of old coatings it is necessary to pay attention to the wear of the lag, removing rotted, even partially, logs.

When choosing a material for thermal insulation in a country house, it is necessary to consider the area of the room and the height of the ceiling, the type of surface, the option of placing the floor structure, the temperature and humidity of the room, the load, and, of course, the purpose of the house. Each of these factors directly affects the choice of material.

The height of the ceiling in a country house for efficient and economical heating should be within 2.35-2.50 m. The height of the room after laying the insulation should not be less than 2.35 m, otherwise the space will not be very comfortable, and above 2.5 m to avoid an increase in heating costs.

The thickness of the insulation also depends on the purpose of the house. For houses used in the summer, you can do with a heater with a thickness of 5 cm, and for a house that will be operated continuously, it is better to purchase material with a thickness of at least 20 cm.

The choice of material is directly dependent on the floor design, as this affects the installation method. There are several types of flooring:

- Laying flooring made either at a short distance from the ground, or on a special bedding. Both that and other flooring are laid without airing.

- The flooring is located above the basement or cellar with high humidity.

- The flooring is located on the logs, below there is a pile foundation with a grid.

- Laying the flooring on the logs, located below the ventilated basement with good ventilation due to the presence of airways.

When choosing a material for a country house, it is necessary to take into account the characteristics of the insulation itself. In addition to thickness, characteristics such as environmental safety, resistance to fire, insulation service life.

To warm the floor in the toilet, located in a private wooden building, you should not only take into account the above characteristics of the insulation, but also take care of waterproofing the underground space of this room, as well as consider the ventilation system.

It is possible to warm wooden floors and apartment. The choice of material and method of installation will depend on the floor of the apartment. For the first floor, where there is a ground or a basement nearby, the insulation will be from both the apartment and the basement if there is one. To warm the floor on the 2nd, 3rd, 4th or 5th floor, the material is laid only on the apartment side.

In a private house, it makes sense to insulate the floor on the 2nd floor only if one or the other floor is not heated, or warmer materials are used in the construction of the first floor compared to the second floor, as a result of which a temperature difference occurs.

Floor device

Floor insulation can be done by different methods. The choice of method depends on the initial state of the coatings, the location or lack of utility rooms.

The simplest, most reliable and most often used is the method of warming by logs. It is suitable for warming floors for both private wooden structures and for floors located in apartments located on the 1st floor. In this case, the principle is that the coating is divided into finishing and draft.

Warming of a wooden floor occurs due to consecutive laying of various materials.

The draft layer consists of wooden boards docked with lags. Below the planks are the cranial bars that run along each lag. The logs themselves are bars that are laid over the entire surface of the floor at a certain distance from each other, as a rule, from 0.6 to 1 meter.They can be mounted on the foundation of the building, be embedded in the basement of the building, mounted on load-bearing beams or mounted on erected posts of durable material (brick, concrete, stone).

The vapor barrier layer is laid on the subfloor and on top of the lag. It is needed only when using a certain type of insulation, and the insulation itself is placed between the lag. The gap between the insulation and the vapor barrier must be at least 4-5 cm. This value ensures proper ventilation of the space. With a lack of height, the laths fill the counter rails.

If the building is located on the territory where high groundwater is present, then instead of the vapor barrier layer, a waterproofing layer should be laid that will not allow the insulation to get wet. In addition, some types of insulation do not need the presence of a vapor barrier.

Installation of special products outside the house, installed in 4-5 m increments and a chimney, will also help to get rid of high humidity. The presence of these elements contributes to good air circulation and increases the efficiency of floor insulation work.

It is possible to warm a wooden floor without dismantling the old covering with the help of linoleum on a jute or felt basis, but it is better to use it not as an independent kind of insulation, but as an addition to a warm floor. This durable and easy to install coating performs the function of waterproofing.

Another method of insulation without dismantling is liquid foam, which is driven under the floor through the holes with a special device. But using this method, it is worth remembering that the space is filled unevenly, and therefore this option is not perfect.

How to choose insulation

All kinds of materials of natural or artificial origin, used for insulation of wooden floor, are divided into:

- fibrous;

- foamed;

- backfill;

- cellular stone.

Any insulation has both advantages and disadvantages.

The most common and affordable material is mineral wool. Warming floor mineral floor has a lot of advantages. This material, in addition to its direct purpose, has very high noise insulation properties, has good fire resistance, and has a low thermal conductivity.This eco-friendly material is simple in arrangement and has different forms of release (rolls, mats), which is important to consider when choosing.

A variety of mineral wool is insulation brand "Izover"manufactured by Finnish manufacturers for over 20 years. The basis of this material is fiberglass. Warming "Isoverom" will protect the wooden structure from the development of fungi, bacteria, invasions of rodents and insects.

But this material has its drawbacks. First of all, they are characterized by poor moisture resistance, therefore it is better to use mineral wool in combination with a waterproofing layer.

Unlike mineral wool, polyfoam badly passes water. This light non-toxic material is not susceptible to deformation due to exposure to temperature fluctuations. Having even a small thickness, it does not lose its good insulating properties. But he also has some drawbacks. In the first place is the fragility of the material, so the fit of the material should be made as accurately as possible.

Durable polystyrene foam has improved characteristics. In addition to high levels of noise insulation and low thermal conductivity, the material features increased strength.Installation of extruded polystyrene, in addition to insulation, protects the house from the invasion of rodents and the development of mold fungi.

Isolon or penofol vapor-tight rolled materials have a small thickness and therefore cannot provide the necessary degree of insulation. Most often these materials are used together with others. Penofol or Izolon pave a rough surface of the floor, using it as a waterproofing layer, which is laid insulation.

Bulk materials used as insulation, such as expanded clay and sawdust, are used for structures without basements.

Warming of the floor with sawdust makes it possible to save, since sawdust has a low cost. In addition, the shape of this heater allows you to fall asleep even the most inaccessible places. Very often, sawdust is combined with other substances to enhance thermal insulation, antiseptic and other properties.

Expanded clay floor insulated in the case of the immediate vicinity of the soil. This lightweight material has a porous structure, due to which, in addition to thermal insulation, good sound insulation is ensured. He is not afraid of temperature drops, and even an inexperienced person can handle installation.

Insulation technology

After analyzing the floor structure, it is necessary to consider the best solutions for a particular room. There is a certain sequence of floor warming, suitable for both warming in logs and without them.

First, it is necessary to dismantle the old coating, if the process of warming occurs in the old room, and lay down or replace the logs. Then proceed to the laying of a rough coating, which is laid waterproofing or vapor barrier layer. Its edges should go on the wall at 15-20 cm, and the joints should be taped.

Then you can start laying insulation, which is placed either between the lags, or directly on the lined layer. It is necessary to lay insulation between lags without gaps, otherwise the effectiveness of these works will be reduced to zero. The resulting gaps can be sealed with foam or sealant.

After installation of the insulation, you can proceed to laying a vapor barrier layer, which is fixed on the logs, and the joints of the material are glued with tape.The final stage is the installation of boards and finishing flooring.

Insulating cheap does not mean bad, the main thing is to choose the right heat-insulating material after analyzing the floor structure.

How to warm a floor on logs, look in the following video.

Successful examples and options

There are many examples and options for warming a wooden floor in the most diverse areas. It is possible to warm the floor not only in the apartment, in a private building, but also on the balcony, in the summer house, veranda and bath.

By the successful options include the decision to use two types of insulation, especially if the use of the same material does not give the proper result. For example, to warm the floor in a bath, a layer of expanded clay is placed on the ground, on which, in turn, a waterproofing layer is laid. Between the lags placed another insulation, which is covered on top with a layer of vapor barrier, and only then after the roughing boards the main covering spreads.