The rules and subtleties of the alignment of the wooden floor

Wooden floors can look very attractive and beautiful, they save heat well. However, a significant drawback is the frequent and easy subsidence, the formation of cracks on it. Only special processing methods help to cope with these problems and prevent their occurrence in the future.

Special features

The need to level the wooden floor is often caused not only by the desire to make it more aesthetic, but also to improve the comfort of life. It is very inconvenient, and sometimes it is not safe to walk in rooms, different parts of the floor of which have different heights. Also, do not forget that Improving the properties of the floor extends its service life and allows for less frequent overhaul, less spend money to replace damaged boards and slats. All hard floors have a clear design scheme, and if it is broken, it will not perform its functions.Wear deteriorates dramatically, and in the near future you will need to re-solve the problem of arranging a new flooring.

It is possible to level the floor in various ways, but they should not be chosen for simplicity or convenience, but for practicality in specific circumstances. Plywood is often practiced, but similar results can be achieved with the help of putty based on PVA glue, self-leveling compounds. Very strong distortions in the geometry of the floor in a house or apartment will have to be eliminated, creating lags.

It so happens that the removal of the previous coating is very difficult or even impossible without complete destruction of the structure. Then you need to leave them in place and level the floor with a plane or grinders. This situation most often occurs in a private dwelling, because in apartments, if they make wooden floors, they are much more perfect.

When grinding, a huge amount of dust inevitably appears, therefore, it is necessary to take special measures so that it does not get into the adjacent premises, does not damage furniture and other valuable property.

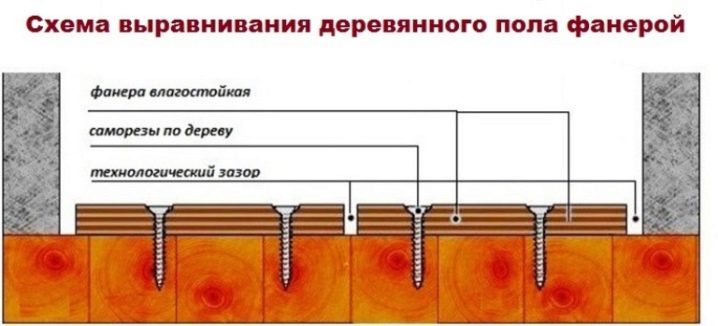

Laying sheet materials

The curved floor can be adjusted using plywood sheets, and with the simplest method, no lags are needed at all.The perimeter of the walls is framed by bosses (they will allow to maintain a gap of 20 mm, without taking the tape measure all the time). Between sheets of plywood should be left at intervals of 0.3-0.8 cm, so that at the first slight shift or increase in temperature, the draft layer is not deformed. Laying the sheets should be with a run-up, all the following are half shifted compared to their predecessors.

Be sure to fasten the sheets with screws, and it is best to immediately make holes in the right places. In another method, the perimeter of the room is filled with lags, with the result that a tape base appears. Rascheku and intervals do the same principles, but be sure to first lay out the sheets, not fixing them, and just look at the result. So it becomes clear whether there is enough material and whether its dimensions are correct. All those blocks that should be applied in the next step are numbered.

The cross bars must be fixed with self-tapping screws, then the leveling of the lag and the supports are checked, after which the frame is fixed to the base. Now you can put and fix plywood, and on top of it - laminate or linoleum.Plywood can also be laid over the sabashek point supports.

The size of each shabashki is determined by how uneven the floor in this room. Laying lining need more often, as their reliability is less than that of lags. The basic scheme of action is the same, the difference is expressed only in geometry. When an equalizer (grinding machine) is used to correct individual defects Always wear gloves and a respirator for maximum protection.

If parquet will be laid on top and lags creak, professionals often recommend pouring them with expanded clay. This solution is suitable no matter how warm your home is. Alternatively, you can make a screed for sheet materials on top of the insulating or noise insulation layer. As a lining under the main layer of the floor there is nothing better than plywood, and chipboard, and even the OSB inevitably lose to it. Using a slab, it is impossible to use it as plywood as a face coating in a pinch.

Wood chipboards have a very important advantage - they are noticeably cheaper and make it possible, with all the efficiency of the structure, to make it as comfortable and as high-quality as possible.Work begins with fastening products to beams, the cross section of which may not be significant, only 30 mm. Each beam is leveled horizontally and fixed on old bases. After 800 mm they are attached to the boards with screws. If you make the interval longer, the coating may arch.

For chipboard the mandatory compensation distance from the walls is 20 - 30 mm. Lay the panels with a takeoff run, shifting them by 0.4 m (not strictly), and adjacent sheets can be shifted only in the middle of the beam, otherwise sagging will occur.

If you use a tongue-and-groove type of slab, you can make no gaps and form a monolithic layer.

Screed

Alignment using screeds is a very old technique, but still quite effective. Professionals believe that expanded clay is suitable for this no less than the cement-sand mortar. Moreover, this solution is easier and reduces the unit load on the floor. Even in private houses it is very important, but there is no question about apartments. To prepare the solution, take part of Portland cement category M400 into three parts of sand and eight parts of expanded clay. Lighthouses are placed 0.5–0.6 m apart, and the solution is poured over it so much that a coupler of 80–100 mm is obtained.

To make an even base, you have to cut it to start with polyethylene, wrapping the ends of the film on the wall just above the intended layer thickness. The material is laid with overlap, and all its borders are covered with construction tape for highest strength. Be sure to use reinforcing masonry mesh (raised to 30 - 40 mm above the base). There should be two layers, the solution must be compacted and its external surface leveled. If you do not want to cook the screed yourself, use one of standard claydite mixes, which are not very difficult to find on sale.

Punching and putty are better than pouring, they will help to cope with minor deformations, but if you want to eliminate solid defects, you will have to use sheet materials.

Always first analyze the real state of the floor and its base, and only then choose the method of forming the tightening structure.

Mixtures

Self-leveling compounds are better than ordinary screeds in that they spread out by themselves and form a layer of uniform thickness. No effort is needed, it is only necessary to strictly adhere to the technology.The slightest irregularities and depressions will be blocked. But a very uneven floor cannot be adjusted in this way, because the greatest height of filling of mix - 20 mm. If the defects are larger, you will have to use lags.

Floor leveling agents are divided into two key groups: the first is designed for rough finishing, and the second is for finishing, which allows you to put any kind of coating. The basic properties are given by gypsum or cement, to which mineral and polymer components are added, in order to guarantee an increased mechanical resistance. It is easy to recognize a coarse leveling agent, it is always a mixture with a large grain, and the fraction determines how thick a layer of the mixture can be applied to a sagging floor without fear of cracking.

The final mixture in contact with water become more plastic, they are easy to distinguish by accelerated spreading. First, the surface is cleaned and polished, then a primer is applied to the subfloor (preferably non-water-resistant compounds that can penetrate deeply). Then put waterproofing (polyethylene), overlapping hardening mesh (fixed as carefully as possible), and only then pour the final mixture.To smooth out differences, to eliminate air from a layer, use studded rollers. How long to wait for the result depends on the specific composition used.

Alignment using self-leveling mixtures allows you to abandon the use of beacons and save enough time.

But on the other hand, the problem may be a lack of experience or poor knowledge about a particular drug. After all, if you violate the basic rules of its use, an expensive tool will be spent meaninglessly.

Mastic (rubber, bitumen or polymer) is most often used if there is no need for finishing coating. In addition to leveling the tree, it allows you to focus on its color and relief, brilliance. Protection against penetration of moisture and sunlight, from mechanical defects is improved. An alternative is often the use of putty, which is made in the artisanal way of PVA and sawdust. The resulting composition is very cheap and at the same time very durable, able to fill absolutely all the cracks and unnecessary gaps of old floors.

Consider that when laying laminate a similar solution does not guarantee the necessary strength, therefore it is necessary to lay sheet materials over it. Most often, the fill is made several times, but they wait until the previous layer dries.

It is advisable to lay the front sheet over the draft cover, screwing it to the base with screws. They will help to strengthen the areas that are not tight enough to the lags.

Prepare the tool before you start pouring any mixture. Be sure to need a container for the preparation of the required composition, as well as a punch or drill with mixing nozzles. A notched trowel with a length of up to 100 mm rolls the layer to an even thin state. The size of the teeth of the spatula should correspond to the size of the treated layer. Single large gaps will correctly fill the foam, and not to resort to other methods of alignment, do not refuse to fill.

Scraping

Putty helps to cope with minor irregularities, the composition of the mixture - just sawdust and polyvinyl acetate glue. The cost of the work will be relatively small, and the base created is quite possible to put on top laminate, linoleum and even the best varieties of parquet.There is no need for logs and other auxiliary constructions, therefore the progress of work is considerably simplified.

Begin by removing the existing coating and thoroughly cleaning all impurities. Next, the surface will need to oshkurit, and all those boards that bend under load or creak, you need to strengthen the screws. The same is done with lags; then they pin the slats, which will act as lighthouses. Only after all these actions can putty putty and align it using the rule.

The applied composition will dry in approximately 48 hours; after making sure, you can start the following work.

Using the plane, it is easy to remove the croaker, the hollow, which appeared somewhere locally. If the board is concave, instead of tooling apply elastic putties, sealants or paste based on a combination of PVA with wood flour. Please note that machined bases must be protected with varnishes or enamels from further destruction.

The scraping works well only if the floor has not cracked, is not expanded, has not been subjected to the invasion of gnawing wood beetles.If there is at least one of these problems, you need to either replace or repair the damaged areas. Not only surface grinders, but also drum parquet-grinding machines help to carry out the processing quickly. But in hard-to-reach places it is more correct to use manual cycles or angle grinders, their characteristics in such cases are invaluable.

Liquid separator, sometimes used instead of films, should not form an oily peel. Therefore, choosing it when preparing for a scraping or other method of leveling the floor, you need to make sure that the substance will be well absorbed.

Professional Tips

Preparation for leveling the floor begin, examining the lags; they look for traces of insects, evaluate the hardness and dryness. If everything is in order with these moments, you can immediately proceed to the main work.

You can choose to work any type of plywood, but provided that its humidity coincides with the humidity in the room. Most often, purchased sheets are sprayed with a spray bottle and kept for at least 40 hours in the right room. Before the reconstruction of flooring is also recommended check the condition of the pipes laid below, otherwise, after processing, it will be possible to investigate them only with great difficulty.

When using standard plywood, self-tapping screws with a pitch of 300-350 mm are used, and if it is thicker, the distance can be increased.

Laying plywood strips (updated logs), they are fixed using the same screws or glue; they are also recommended to coat small plywood fragments embedded in the emerging slots. The optimum size of the blocks is considered to be a square of 0.6 by 0.6 m. They should be put strictly after the final drying of adhesive preparations applied to the lags. It is preferable to use hardware, equipped with hidden heads. When working with their own hands, experts also recommend drilling and countersink the holes. So the fastener becomes invisible.

Removing the old layer of wood during scraping, do it carefully, moving "snake". Before starting work, you need to remove all things and furniture, and cover what you need to leave, with plastic wrap. Remove any nails and other fasteners, because in contact with them, even the most reliable machines for scraping fail. Having eliminated the defects, deal with the dust that appears (first with a powerful vacuum cleaner,and then wiping the floor with a lint-free cloth). Only then can varnish be applied to wooden substrates.

Among all the fillers pay attention to acrylic: even if the floor will be after some time with a deflection, a layer of such material will not be deformed when walking. Acrylic sealants also have high plastic properties.

How to level a wooden floor in the old house, look further.