How to lay plywood on wooden floor?

The floor of the boards is durable, environmentally friendly, resistant to abrasion. However, after several decades, the boards begin to creak, crack or rot from the increased humidity in the room. If you lay linoleum or carpet on an unprepared wooden floor, lay laminate or parquet, the surface will not be perfectly flat. All defects of the draft base will be visible through the finishing finishing coating, and in the case of locking systems, installation with irregularities will not be possible.

To make the floor quality and durable, under the floor covering you need to lay the substrate. For this fit sheets of plywood, which will hide all the irregularities and shortcomings of a wooden floor.

Special features

To choose plywood for leveling the floor, you need to understand the features and classification of the material on the market. Plywood varies in grade, thickness, moisture resistance and production material.

Key features will help you choose the right sheets.

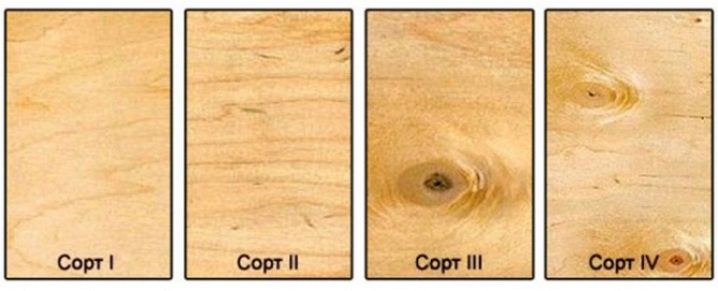

There are 4 types of plywood, which can be distinguished visually:

- The fourth grade with defects on the surface, rough, there are holes from the knots, because the production is the lowest quality raw materials.

- The third grade is better than the previous one and is less on the surface.

- Class II has slight cracks, smooth.

- The highest quality and expensive first grade is well polished, all sides without defects.

When choosing a variety are guided by price and quality. For the construction of the sub floor suitable plywood of the second and third grades. According to the method of processing emit:

- Unpolished plywood.

- Ground (one or both sides).

For mounting on the floor, one-sided polished material is taken, laying the smooth side on top.

Plywood is made of hardwood and coniferous wood (usually from pine and birch). Wooden veneer is sealed together with natural and synthetic resins. The top layer can be treated with a lacquered water-repellent compound.

By resistance to moisture in residential areas distinguish brands:

- Fba

- FSF.

- FC.

In the bedrooms and other living rooms with low humidity, FC and FAA brands based on carbamide and albumin caseinic glue are laid. They are environmentally friendly and moderately resistant to moisture.

Brand FSF laid in the hallway and in the kitchen, where a large moisture resistance.

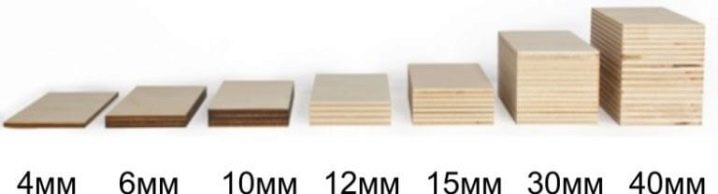

The thickness of the canvas determines the number of layers of veneer. An odd number of them stacks perpendicular to the previous one, creating a durable building material. For the flooring of the sub floor take plywood with a thickness of 10 mm and above.

Plywood lends itself to mounting screws, does not crumble and does not crack.

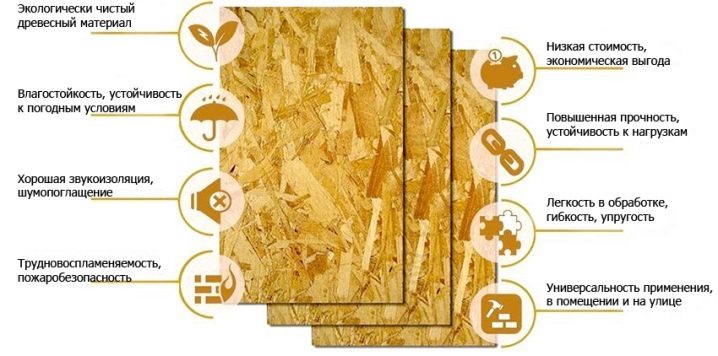

Analogue of plywood in the construction market is OSB - oriented strand board. Such materials have similar properties, and differ only in production. Wood veneer is used as raw material for plywood, and wood chips are processed for OSB with natural resins.

RSD is divided into different categories:

- The first is suitable with minimum load and dryness.

- The second is made for impassable living spaces.

- The third one is distinguished by high moisture resistance and durability.

- The fourth is used in the construction of walls.

- Varnished or laminated - covered with a protective layer of varnish or laminate.

- Grooved - at the joints has a connecting groove.

The best solution for the subfloor will be OSB 3, grooved and convenient to install. Such sheets are produced with a thickness of 0.5 cm to 4 cm.

Advantages and disadvantages

When it is difficult to determine which substrate is better: plywood or chip, the advantages and disadvantages of each material should be considered. Plywood flooring has such advantages:

- Withstands heavy loads.

- Low weight.

- It is flexible, has high bending strength and deformation.

- There is no foreign smell.

- High leveling ability.

- Easy to handle, saw.

- Easy to operate.

- Smooth beautiful exterior.

- Keeps heat indoors.

Pros of using oriented strand board:

- Available at a price.

- Do not stratify.

- Surface free of defects.

- Various sizes.

- The panels are light.

- Resistant to harmful insects.

But all wood-based materials have a common drawback - moisture has a great effect on them. Humidity will quickly destroy the raw wood, so it is better to lay moisture-resistant brand coatings. The reverse negative side of moisture resistant panels - environmental friendliness.They release formaldehyde, which is harmful to health, but it helps to fight moisture.

Both leveling materials have a high degree of ignition from an open fire, so before laying the material, you need to take care of increasing the flame retardant properties.

If you lay the flooring on the logs, it disappears up to 10 cm in the height of the room. This is not always acceptable in certain situations. To lay sheets, it is necessary to make a clear calculation so that there is no waste and unnecessary work on the alteration. It is recommended to fasten these materials with self-tapping screws with an average step of 20 cm.

Such sheets are well tolerated fasteners and tightly attracted.

The differences in price between plywood and OSB of the same brand are not the most significant, but OSB is cheaper. In suitable and unpretentious conditions, OSB can be laid, but plywood is suitable for durable wear-resistant coating.

Materials and tools

Plywood and OSB are similar in laying technology. To lay the floor with wood sheets, use the same tools for installation. Mounting materials are also the same. To quickly and efficiently carry out the flooring of plywood sheets on a rough plank floor, you need to stock up on basic building fixtures. The work will need:

- Level to measure floor flatness.

- Screwdriver or screwdriver for fastening screws.

- Drill for drilling holes for dowels.

- Measuring tape to measure the required length.

- Jigsaw or hacksaw for cutting off sheets of plywood to the desired size.

- Grinding nozzle on a drill or grinding machine for grinding joints between sheets.

- Roller or paint brush for applying a primer.

- Broom or vacuum cleaner for garbage collection.

- Spatula for applying glue.

- Hammer for nailing.

To improve the moisture-resistant and flame-retardant properties of the material, it is advisable to use special anti-inflammatory compounds and primers.

Putting plywood or OSB is better for water dispersion adhesive bustilat, PVA. These grades are suitable for gluing woody surfaces. They are safe for health, have no smell and dry during the day. Glue is easily applied with a spatula or brush (depending on the consistency).

Attach plywood sheets can be on screws and nails. If the laying of materials is carried out in the apartment, it is preferable to use screws with dowels, because working with a drill and a screwdriver is simpler and quieter than with a hammer with nails.

Preparatory work

Before starting installation of plywood on a wooden floor, basic preparatory work is carried out. First, an assessment of the initial draft wooden base is carried out. Visually assess the status of floorboards, the presence of poorly fitted and creaky floorboards.

Check on the construction level drops and surface irregularities.

Then make dismantle plinths. All loosened boards need to be additionally fastened with nails or screws to the lower beam. The floorboards affected by the fungus are replaced or cleaned, impregnating with an anti-fungal compound. Deformed and damaged boards need to be changed. The protrusions on the surface are scaled with a plane and ground. Cracks and cracks are filled with sealant or glue.

After repair, they are cleaning garbage, sawdust and dust with a broom or vacuum cleaner. Untreated wooden floor is treated with an antiseptic. As insulation of noise and insulation under the plywood floor, you can lay rolled material.

Penoplex or Isolon of small thickness is suitable for the substrate. Connect the strip of the substrate between the building tape.

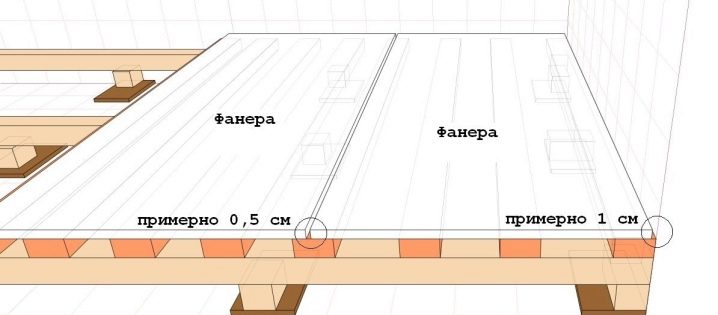

Fastening of plywood occurs after drying to avoid deformation.For this material is entered into the room and leave for 2-4 days. The best solution to protect against moisture and fire is to treat both sides of the panel with a primer or acrylic lacquer. The technology of laying wood sheets requires a distance of 1-1.5 cm from the wall between sheets up to 0.5 cm.

This must be taken into account when cutting and laying plywood blanks on the floor.

To relieve tension from the material during operation and ease of installation, the sheet is cut into 4 parts using an electric jigsaw. Pre-place and fit all the parts, draw the layout and number the blanks. It is necessary to lay sheets with offset to reduce the number of joints and to avoid crossing.

If you follow all the rules when laying plywood, it will serve as a quality, durable basis for any floor covering. Finishing decorative material can be altered, and the plywood base will remain the same.

Alignment methods

The leveling method depends on the flatness of the subfloor. Differences in height of more than 1.5 cm suggest plywood flooring on logs. Minor irregularities are covered with plywood directly on the wooden floor.

Boards with a drop of less than 1 cm are aligned with the supports in the right places. Thin squares, wooden or plywood blocks are used as a support.

Laying plywood on the floor can be done using the substrate or without it. The lining roll is rolled over the entire surface and sealed with tape. Plywood is spread from above in accordance with the scheme, evenness is checked and fixed with self-tapping screws. In this case, sheets with a thickness of 1 cm are needed.

Without the use of cushioning material used adhesive method of attachment. A small area of the room is covered with glue for 2-3 mm, starting from the corner. A sheet of plywood blank is laid on top and pressed tightly. Additionally, you can fasten several screws for better fixation. This method is the installation of the remaining part of the room.

Laying birch plywood does not require special skills and can be done by hand.

When the sheet of plywood does not lie flat, it bends, there are small differences in height with other blanks, supports are used. The pivot points are placed in poorly adjacent places and are fixed through with self-tapping screws.

If the wooden base is covered with fiberboard, then dismantling is performed if the material is old, crushed from moisture, crumbles and exfoliates along the edges. Fiberboard is not recommended to lay on the floor, because the sheets deteriorate from moisture and have poor leveling properties due to the small thickness.

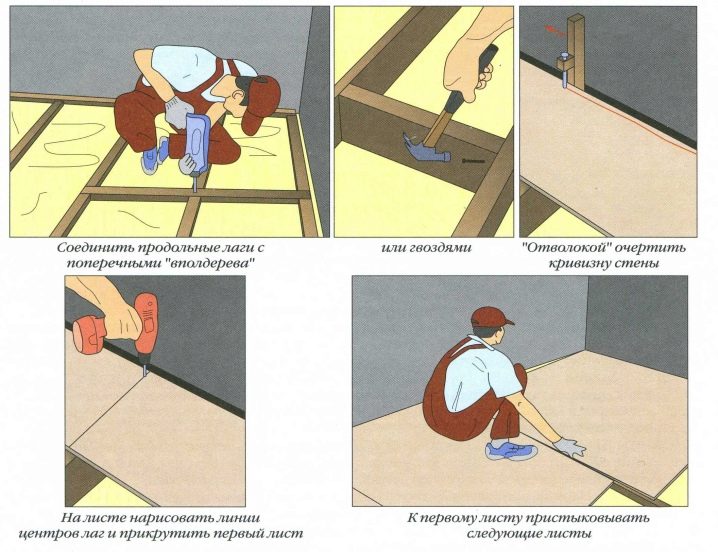

To neutralize significant differences in height, use lags. As the lag used boards of the required length with a cross section of 3-5 cm by 7-10 cm or coniferous plywood slats of the same size. The location of the lag depends on the thickness of the plywood and the load during operation. Small thickness requires less distance between the lags, ranging from 40 cm. It is not necessary to use sheets less than 1.5 cm in height. The installation log is designed in accordance with the layout of the plywood in the room so that the joints are placed in the middle of the timber.

Horizontal installation lag is measured by water or laser level. From the accuracy of the installation depends on the evenness of the entire floor. Lags are attached to the glue and screwed with screws. Between them perpendicularly place the bars, getting a reliable crate, on which the plywood blanks are spread.

All panels are laid out on the crate, adjusting the size, not forgetting the damper gaps. Fix the plywood flooring, screwing screws to the logs in increments of 20 cm.

Expert advice

It is necessary to responsibly treat the repair of the old wooden floor, without neglecting this important event. The durability and strength of the plywood flooring depends on the condition of the rough base. The length of screws, screws and nails depends on the thickness of the panel. As a rule, take the length of the screw, three times the original material.

So that the caps do not protrude above the surface of the plywood floor, it is necessary to drill out the recess by 2 mm in advance, drown the screw head into the material.

The main advice of professionals, subject to which you can qualitatively put flooring and achieve acceptable quality:

- If the house provides for the placement of a floor heating system, then it should not be laid under plywood, but only on top, since heat will not pass through the plywood.

- Do not lay the plywood floor in an unheated room.

- Operating humidity should be no more than 65%, the temperature should be 18-25 degrees.

- Thin plywood is not laid on uneven boards, or installation is carried out in two layers with offset joints.

- Communication engineering structures as well as additional heat-insulating and sound-absorbing layers of material can be placed between the lags.

- At the preparatory stage when laying plywood on a wooden base, you should carefully clean up the garbage, since its presence will lead to unevenness and poor attachment to the base.

- After laying and strengthening the plywood flooring, the surfaces are polished, which will exclude minimal differences in height between the various parts.

Instead of plywood cloth, you can put sheets OSB or DSP. Cement-bonded chipboards are distinguished by fire and moisture resistant properties, as well as good covering ability. DSP boards are difficult to install and transport, as they are heavy. With the observance of the technology of flooring, you can make high-quality clean floors in the apartment with your own hands.

For more information on how to lay plywood on a wooden floor, see the following video.