The subtleties of the choice of a warm electric floor

Recently it is decided to install additional heating systems in the house. This role is often performed by heated floors. They allow you to beat the room more effectively and make your stay in the room more comfortable. But the choice of a particular type of underfloor heating is quite difficult, because manufacturers represent different types of heating systems, including electric underfloor heating. Each such design provides a certain way of heating and has a number of differences. Therefore, it is important to know the advantages and disadvantages of all these types and the rules for their selection.

Device

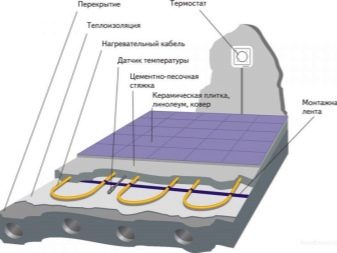

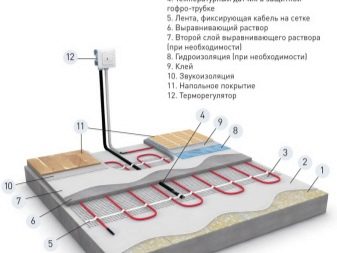

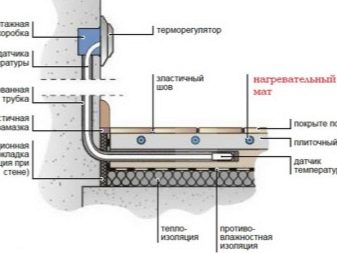

Electric floor heating has many features of the device design. So, this whole system includes several main parts.For film models, you need to make a special rough floor. In this case, electrical elements, such as cable, mats, film heaters, are laid on a flat, smooth surface.

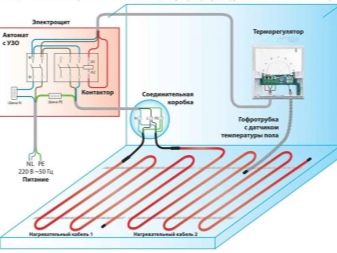

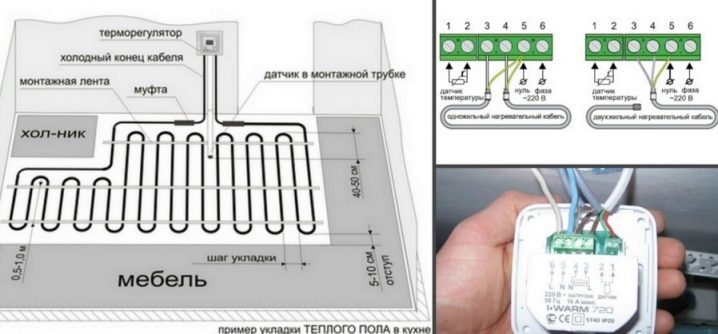

A separate element of the device of such a system is a thermostat. It allows you to control the parameters of heating, independently enable and disable heating. All heating elements and cables, including the ends of temperature sensors are connected to it. Electric floor heating is laid under the flooring, but some designs can be laid on the screed, or you can do without using it, but on a solid base.

Not all models of a warm electric floor include thermostats and sensors in their device. But this option can overheat and fail. That is why the most good is the model, the device which includes two thermal sensors and a thermostat. The device of each specific type of a heat-insulated floor differs, as well as its characteristics and cost.

The system also includes a safety device. This is a device that is designed to protect against electrical shock. Electric floor warms due to the formation of heat in the heating wires. Heating elements have a special insulation layer, which makes the system safer and more stable.

Advantages and disadvantages

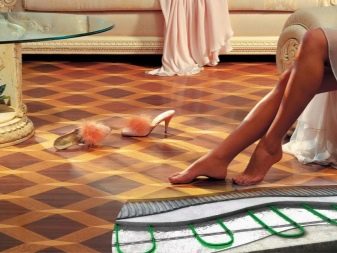

All electric underfloor heating in general have a number of advantages. So, in comparison with other types of warm floors, they have a rather long service life and at the same time provide high-quality and reliable floor heating. The floor temperature is about 25 - 27 degrees. This indicator is comfortable for the legs.

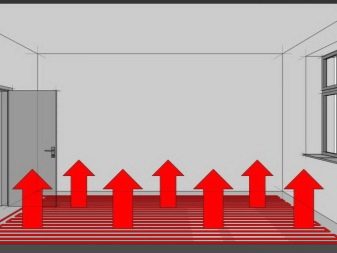

Heat from electric floors is understood up slowly and lowly, uniformly heating the entire floor area. So in no drafts are formed at all, the temperature is evenly distributed. One more big advantage of electric heat-insulated floors is that they do not overdry air. In a room with warm floors, air humidity is normal and permissible for human health.

Electric flooring is much easier to install compared to other varieties. This applies especially to water-heated floors, the installation of which is very difficult and not allowed in all rooms. In addition, this floor perfectly copes with the function of an additional source of heating in large rooms when there is not enough battery power.

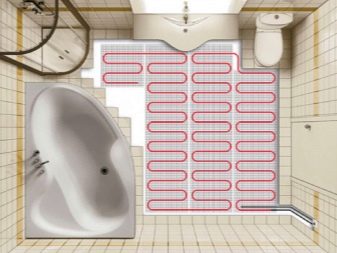

But in small rooms it can also be used as the main method of heating, for example, in a bathroom, in a small kitchen, on a balcony or a loggia. Such a floor can evenly warm the air in the whole room with a small area. Another big advantage of electric warm floors is that they do not interfere with the planning of the interior and take up very little space. Floor coverings securely close such a system.

The system of warm floors in general is not cumbersome and quite compact. Electric underfloor heating does not adversely affect the flooring. They smoothly transfer heat to it, allowing it to warm up evenly. Thanks to this, it is possible not only to heat the entire floor covering, but also to maintain the necessary temperature of the floor and the air in the room.

But now not all warm floors are ideal. A number of electrical models have flaws. So, they are not suitable for installation under the furniture, because they can overheat it. Wooden furniture without legs with a solid facade can crack and lose its former gloss. Therefore, it should be laid only after you decide where the furniture will stand.

After that, you will not be able to make a permutation, since the covering will already be spread out and a place will already be allocated where it is possible and where furniture cannot be put. But in this case, carbon fiber floors are not core-based. Another disadvantage is that the installation of a thermostat is required in each room. On the one hand, this is convenient, since you can regulate the temperature for each room individually, but on the other hand, this is an extra cash cost.

Another negative quality is that electric floors spend a lot of electricity. It can get up to a fairly large amount of money, especially if you consider that they will not replace the main heating in many rooms and thus you will not be able to save.

How much electricity is consumed?

When choosing a floor heating system, it is important to consider the purpose of the room in which it will be installed. For a kitchen or corridor, models with a capacity of about 110-130 W per square meter are suitable. m. For a private house, especially for its first floor, fit more powerful models - about 40 watts per square meter. mFor the bathroom as a source of heating is better to choose models with a capacity of 150 watts per square meter. On the balcony you need to choose even more powerful warm floors - 180 W per square. m and above. Thus, the consumption of electricity depends on which room you install underfloor heating.

Coatings differ in energy consumption depending on the type of their structures. In equal conditions, cable warm floors require a power of 120 watts per square meter. m and matt - 160 watts per square meter. m, so the first - more profitable.

If such a heating system is installed in wet rooms, you will see an even greater difference between these figures. Carbon floor is considered the most economical, but this applies only when it is used as an additional source of heating. This is due to the fact that it has a system of self-regulation, which does not allow electricity to overspend.

Kinds

According to the type of heating of the room and the floor, there are two main types:

- Convection warm floor. They can be:

- ordinary cable;

- in the form of mats.

- Infrared warm floor. They are:

- film;

- rod (carbon) mats.

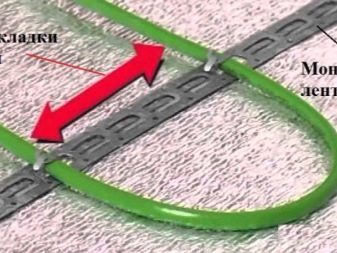

As for convection floors, they have a constant heating cable. It is laid in a zigzag method or in the form of a spiral under the cement screed. Moreover, between each turn of the cable leave a distance of about 10 cm. There are resistive and self-regulating convection floors.

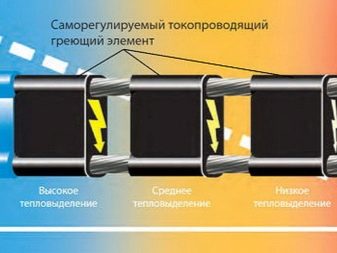

Self-regulating models have a rather complicated device. They can independently determine where exactly the overheating occurs in the floor heating system, automatically lower the power supply and turn off the power in this area.

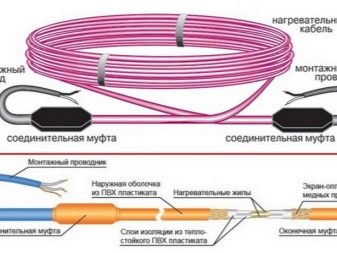

A simpler device has conventional heating cable. Such systems are easier to install. They are presented in the form of the following options:

- single resist;

- strong.

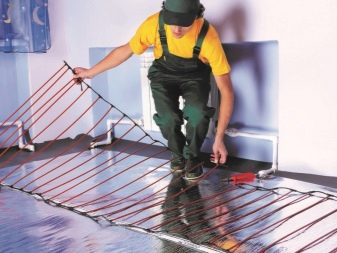

Such floors create electromagnetic radiation, and the two-core version makes it several times weaker. The installation of the cable floor is quite complicated, since the cables do not have to intersect with each other and between them must be maintained at an equal distance. In addition, all transitions should be smooth, no bends are allowed. Floor coverings can be installed on them only 3 days after laying the floor.

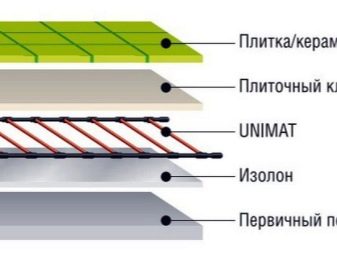

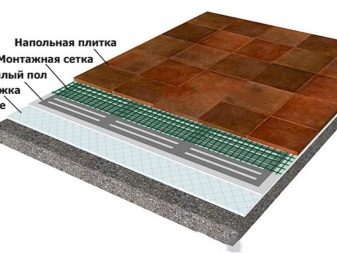

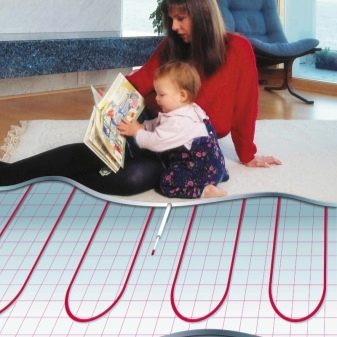

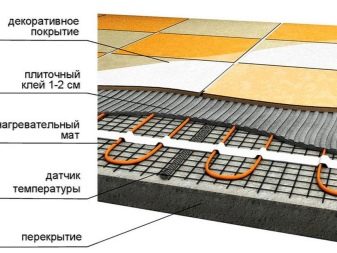

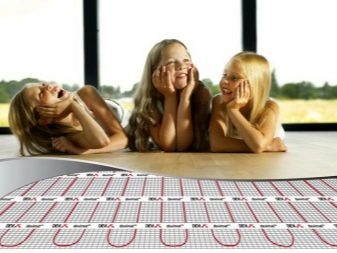

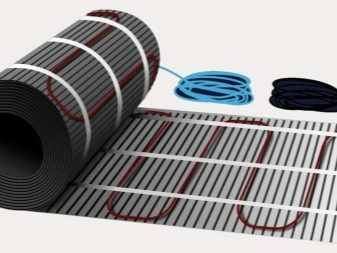

More convenient option are mini mats with cable included. They are already ready and laid out in the right kind of cable, mounted on thin mats, which is a fiberglass mesh, resembling a thin carpet. This cable is ideally located and does not form kinks. That is why such a system is easy to do it yourself.

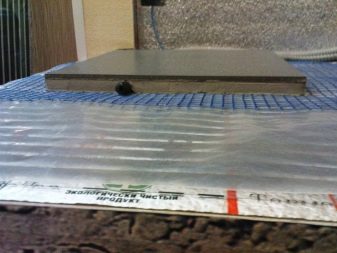

The mat is rolled onto the finished cement screed under the floor covering. Especially it should be noted that such mats are very thin. Their thickness does not exceed 4-5 mm, so they are not bulky and do not conceal the size of the room. Manufacturers are models in rolls of different widths from 50 cm to a meter and even more. Moreover, the mats have a special base, which can be glued by pressing, you do not have to use any adhesives.

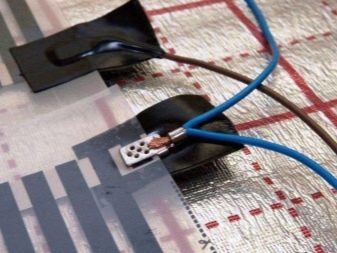

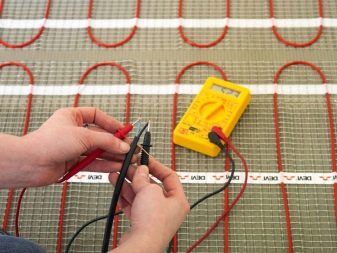

When laying the thermostat, temperature sensors and a device for automatic shutdown of the system are connected to the cable warm floor. But when laying such mats there can be some problems. So, in some places, the grid will still have to cut and carefully lay the cable so that you can put a second sheet without interrupting it.It is important not to damage the cable and put it at a safe distance of about 5 cm.

The next large group of warm floors - infrared electric floors. They heat the floor exclusively, not the air. That is why they retain the required level of humidity and uniform heating of flooring without harming it. This effect is achieved through infrared radiation. But in connection with this, a number of buyers are wondering whether such radiation is safe. Many experts claim that it is completely safe for human health, even useful - infrared radiation is used even in medicine.

In addition, experts indicate that infrared heated floors ionize the air and make it even more useful. In addition, they do not cause an allergic reaction, as the manufacturers claim.

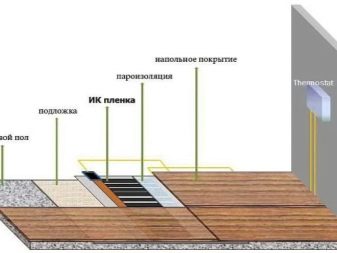

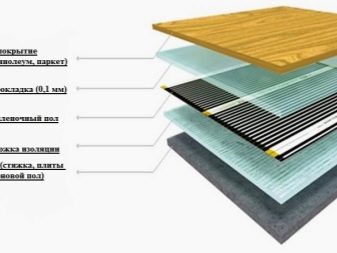

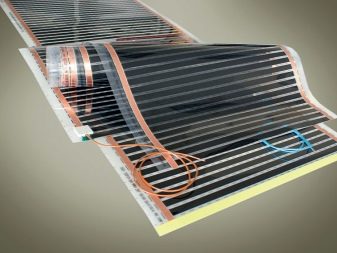

As for the film models, they are thin insulating polyester films of small thickness. They are almost invisible. In thickness, they are only about 1 mm. The infrared floor heating film includes two main layers, between which there is a heating element in the form of carbon paste, applied by strips.But there are better and more expensive models in which the paste is applied in a continuous layer.

Carbon paste conducts heat well and therefore quickly converts electricity into infrared waves. Along the edges of the film are copper conductors that allow you to evenly distribute the electric current in the heating elements. The bottom layer is a reflective heating substrate that allows heat to be directed upwards to heat the floor, not the ceiling of the neighbors.

On top of this floor is covered with polyethylene, which allows for the greenhouse effect. Due to this heat is distributed as evenly as possible. Such a thin version of a warm floor is perfect for thicker flooring, such as laminate or board. But when such a system is installed under thinner coatings, for example, under linoleum, manufacturers recommend installing an additional plywood layer.

The infrared floor has the following principle of operation: electricity comes from the thermostat through wires that are connected to special terminals with sheets. An important and challenging task will be correct docking of contacts.which will allow to achieve perfect warming up of floors. Contacts at the edges of the infrared film are tightly clamped and fed to the right side.

If during the installation you pinch this wire or deploy it incorrectly, the system will quickly burn out and will last no more than a year. That is why when installing such a floor is better to contact an electrician or follow his instructions.

The infrared heat-insulated floor is the most universal of all options of an electric and heat-insulated floor. It is perfectly suitable for installation under any floor covering, starting from natural parquet and ending with a warm shag carpet, you can put any rugs on it.

The thickness of the infrared floor heating is the thinnest, compared with other types of floors. Huge The advantage of this type is that the installation of such a floor does not require a concrete screed. It can be safely laid out under the finishing material for the floor. In addition, it is now planned to install an infrared heated floor, even on the walls and ceiling. That is, this option can even replace the main heating.

Separately noted is the flexibility of such a system, which opens up wider opportunities for planning and interior design of the room. Film infrared floors can be installed independently, especially since manufacturers present models with special markings. It is in this place that you can cut the coating for its further docking.

But this type of warm floor has some negative qualities. So, when installing it in concrete, you have to wait a long time, sometimes this period reaches a month, since it is necessary to wait for the completion of all chemical processes occurring in the screed.

Infrared floors have not the highest temperature of heating. This is because they are designed to be installed under natural surfaces, such as wood. That is why they do not overheat above 28 degrees. If overheated, many coatings can deteriorate or deform.

In addition, the peculiarity of installing such warm floors is that they require a smooth and even surface. This is due to the small thickness of infrared heating systems.

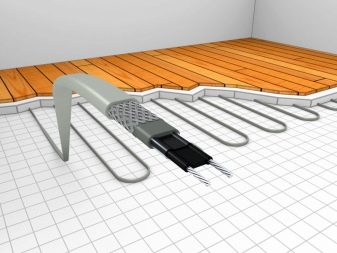

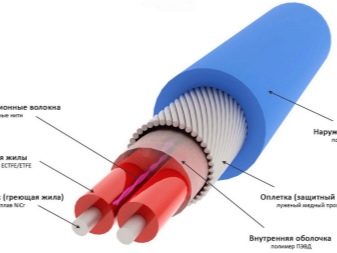

Rod carbon Floors are no less interesting design. Their bases are made of carbon fiber, which has a high level of heat transfer. It converts electricity to infrared heat. The rods are connected parallel to each other. And this is one of the most reliable floor heating systems, because if one of the rods is damaged, the rest will not be affected.

It is believed that the carbon rod floor is the most durable and able to serve more than 50 years. The great advantage of this variety is the core self-control system, through which ideal temperature control can be achieved. The system itself increases the heating temperature in those parts of the room where there may be drafts, for example, at the entrance, or vice versa, reduces the power around batteries and other sources of primary heating.

On such systems, you can easily put any pieces of furniture, not worrying that they will eventually be spoiled. Beneath it is also a creeping reflective material that allows heat to be directed upwards. They can fill almost the entire area of the room.

Some relate to electric heating systems water models,who work using electric boiler. The boiler is often installed directly on the heating system pipe.

Which to choose?

When choosing a heated floor, it is necessary to take into account its characteristics, since different floor coverings are suitable only for a certain type of such systems. So, the laminate has a low thermal conductivity, but it quickly heats up. A film is often installed under it, but at the same time a lot of electricity is spent on such heating, since the floor will need to be kept on always so that it does not cool down.

As for the tile, it heats up longer, but it also keeps the heat well after turning off the heating system. Therefore, a film heat system is perfect for it, which can first heat up this coating and then turn it off, saving considerable energy costs. But laying any warm floor under ceramic tile is quite complicated, because if it cracks in the future, the heating system can be damaged. Under it is better to put a reinforcing mesh of fiberglass.

For new premises more suitable cable warm electrical system, because in them,As a rule, only a rough finish has been completed before settling, and therefore you can set the foundation yourself and save a lot, for example, on the purchase of mats. Thus, you will be able to make a cement screed yourself, but at the same time it will hide several centimeters from the height of the room. But it will be better to keep warm and evenly distribute it over the surface. So the floor will be slower to give off heat.

Characteristics and method of installation of a warm electric floor is suitable only for a specific coating. So, the cable system is mounted in a wet cement screed and is perfect for ceramic tiles, porcelain tiles, natural stone and laminate. Valid for it is also the installation under linoleum, wood and textile flooring.

The cable with heat-insulating plates keeps within under a dry coupler. The choice in favor of such a warm system should be made in case you want to put ceramic tiles, porcelain tiles, natural stone, laminate or wood. A valid, but not ideal option is linoleum.

As for the film floor, the carbon models are great for laminate and parquet, it is also permissible to install electric slatted floor under carpet and linoleum.They are mounted on a dry screed. Foil floor in the form of mats is placed under the tile adhesive. Such a system is perfect for installing ceramic tiles, porcelain tiles and mineral stone. Valid for it is laminate flooring, linoleum and textile coatings, and in some cases, wood coatings.

Rod film floor is laid on a wet cement screed. You can choose it if you want to make a porcelain stoneware, ceramic tile, natural stone or laminate flooring.

For different rooms

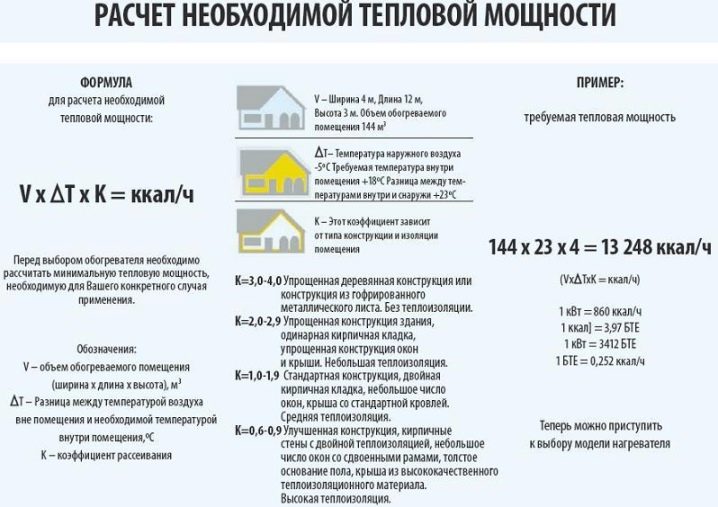

Different premises require the installation of different types of warm floors. It is necessary to calculate the thermal power required for each specific room. It is better to purchase models with a power reserve. It is necessary to take into account the height of the ceilings. If indoors they are higher than 3 m, then it is necessary to select heating elements with a capacity of more than 150 W per square meter. m

For the most ordinary rooms, for example, for living rooms, if you install a screed on the floor, it is better to select a cable or rod electric heated floor. For bathrooms, it is better to select models with a higher heating capacity.And most often the flooring in the form of porcelain stoneware is installed in the bathroom, so the core heating system is most suitable for it. Cable floor heating is also acceptable. If you do not plan to install a concrete screed in the room, then the floors can be chosen for laminate, linoleum or carpet, which are most often used in the bedroom or nursery. For such rooms most suitable film heating system.

Calculation and installation

Before installing a warm electric floor, it is necessary to calculate the area and power of the floor system. First of all, it is necessary to determine the necessary heating capacity, depending on the role you play for the floor heating. If it is necessary for ensuring comfort and walking barefoot, then for this purpose a floor with a capacity of 150 W per 1 square meter is perfect. m, but if this is not an additional, but the main heating system, then you need to select models with a capacity of about 200-220 W per square meter. m. Depending on the purpose of the room, the calculation will also differ.

In the bedroom you need to make heating about 180 watts per square. m, and in the bathroom - at least 200 watts.The heating rate for the living room is 150 W per m2, but if it has at least two exterior walls, then select the options for a warm floor with high rates.

When calculating It is important to consider where you install such a warm floor. If there is another apartment in the panel house below you, then the minimum permissible indicators will suffice, but if there is a cellar, basement or other unheated room or ground below, then you need to select models with powerful heating. Even greater power should have a floor installed on the balcony or on the veranda, especially if these rooms are not heated.

The power of the electric floor is also calculated from the area of the heated room. But the calculation should be made by subtracting from the total area of the room those areas where the furniture will be located. That is why before installing underfloor heating, it is necessary to plan and calculate where the furniture will stand and subtract this area from the total. It is also better to move a few centimeters from all walls, and this should be taken into account when calculating the area.

After that, it is necessary to calculate the total power for heating the floor of all rooms.It is necessary to multiply the resulting area by the necessary power for this place. But with such calculations, the figures will be quite impressive, do not worry, this does not mean that you will spend that much electricity. You will periodically turn off the heated floors, especially with self-regulating models, which, when automatically switched off, allow you to save electricity.

If the main heating system works well in the room and thermostats are installed along with the floor heating, then the floor will consume about a third of the power calculated by you earlier. That is why when installing a warm floor at home, it is important to pay great attention to thermal insulation, which later saves energy consumption.

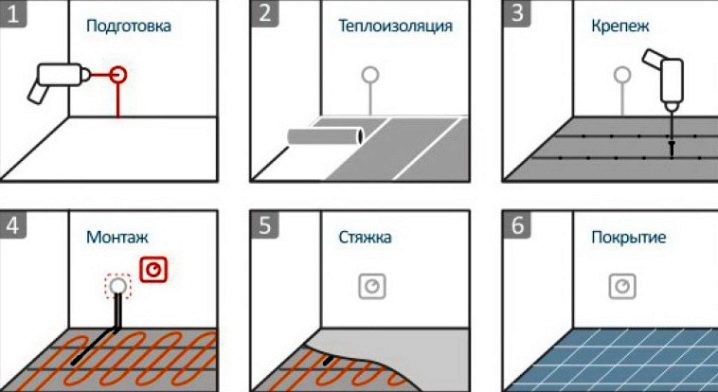

Laying underfloor heating varies depending on some features. So, for some systems, you must first mount the screed and install it there “on wet”, and place floor coverings on top. This installation option is suitable for cable warm floors, which have an additional layer of waterproofing and insulation.

The next option is to install an electrical floor on top of the screed.Thus prepare the floors for the further laying of porcelain. This is a great installation option for apartments that are located on the second floor and above. The simplest option for installing an electric floor heating system is to install the system directly under the floor. This method is only suitable for film electric floors. This is the fastest and easiest option, which saves time and saves you from capital work on the creation of concrete screed. This method is suitable for laying under linoleum or laminate. The layer of foamed polyethylene is covered on the existing screed, and then it is covered with foil. You can also install a layer of waterproofing on it, and then install electric film floors. All these methods have their own specifics and features.

But before carrying out installation work, it is necessary to clearly plan the placement of furniture in the room, plan where the heating elements and controls will be located. When installing, try to retreat from sources of primary heating, such as radiators, fireplaces, and batteries. It is important to correctly determine the installation method and carry out all the necessary calculations before proceeding to the direct installation of a heated floor system.

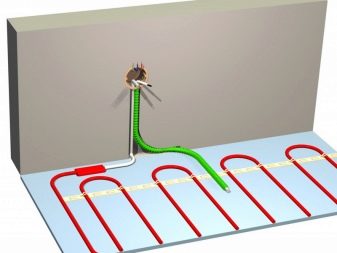

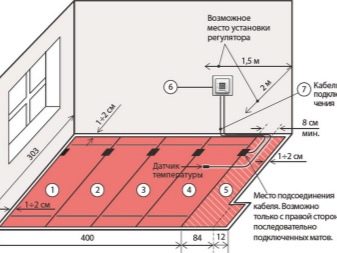

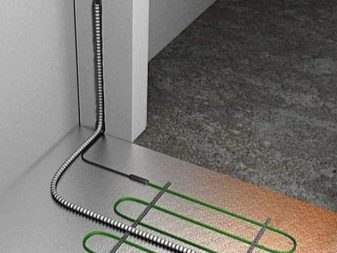

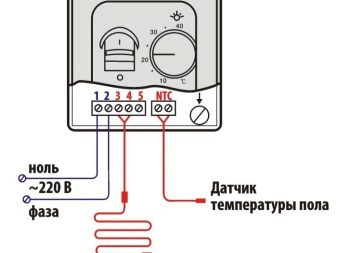

First you need to choose a place for a thermostat. It is better to place it closer to the outlet on the wall. The thermostat can be expensive. Its installation is very simple, but at the same time it will be clearly noticeable. More difficult and reliable is the installation of a mortise thermostat. It is embedded in a special mounting box in order to hide from prying eyes. So you can hide it from pets and small children who may accidentally press a button.

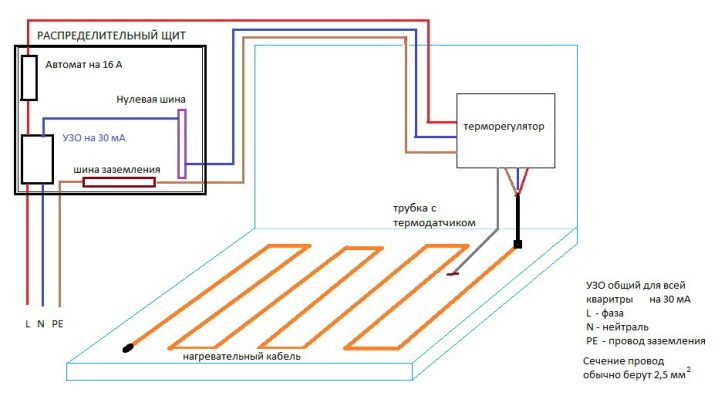

For the mortise thermostat model, special holes are made in the wall and first of all they mount the box where it will be placed. There you need to bring the power supply and isolate the ends. After that, you need to lay the strobe down to the floor and place the wires there for further installation of the electric floor. Temperature sensors are carried out using a corrugated pipe. The gate must be located not only on the wall, but also on the floor, not less than 50 cm in length from the wall. The sensor is located in this place, and the corrugated pipe makes it safe and simplifies the process of its subsequent replacement. In this place is installed the sensor attached to the wire through the wiring box.The edge of the corrugated pipe must be closed with a foam stopper or sealed with tape to prevent the solution from getting into it.

Sensor installation is complete. After that, you need to connect the wires to the terminals on the thermostat in accordance with the instructions on the back of the thermostat. Then you can proceed to connect the electric floor heaters - cables. They connect to the terminals on the back of the thermostat. After that you should connect the wires responsible for the power supply. This part of the work should be done by an electrician who knows his business, because this way you can avoid mistakes and protect yourself.

Upon completion of all these works, it is necessary to check the system for operability and stability and enable it for a certain period of time. After that, you can pour the screed, lay the tiles or even lay the laminate or the floorboard right away in case you use heat-insulated flooring.

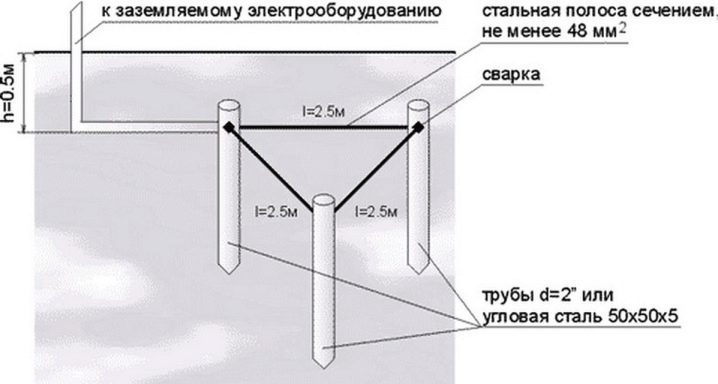

How to ground?

Grounding an electrical floor is an important process, as each electrical device presents some danger that must be disposed of.In addition, water can often spread on the floor, so electric heated floors must be grounded. This is especially true of wet rooms, such as a loggia, bathroom, kitchen. For this, it is necessary to select heating elements that will be enclosed in a high-quality protective sheath. In addition, you must additionally connect the ground to protect the electrical coating.

It is better to carry out this procedure in all rooms, since not all heating elements have a protective sheath made of metal. So, for grounding over the heating elements, a metal grid is placed on the electric floor. It must be connected with wires and connected to a special protective bus. Such a grid, in addition to the protection function, will additionally make the floor more rigid and reliable, especially since electrical systems have a small thickness. Metal mesh also allows you to evenly distribute the load on the floor.

At installation of heat-insulated floors in the private house it is necessary to do additional contours. It is necessary to install grounding with a depth of 1.5 - 2 m. Between them there should be jumpers at an equal distance of about 1 m.So you can protect yourself and your household from an accident and make home heating safer.

Control

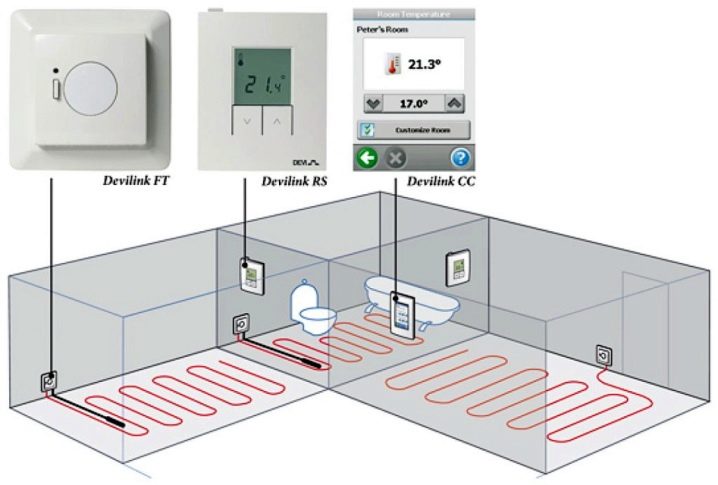

Electric floors can be controlled using a special device called a thermostat. It causes the system to be connected to the electricity grid. With it, you can control the temperature of the floor and the air in the room.

The main role in the management of internal sensors play. They are installed in the screed or, in case of its absence, under the topmost coating in the process of laying. Other sensors determine the air temperature in the room. They are not installed on the floor, but most often on the wall.

Manufacturers offer different electrical floor control panels and simplify the complex process of interaction with this system. So, the simplest is electronic mechanical regulator, which involves only the adjustment of the heating temperature and has a button to turn off the electric floor. It is possible to add and decrease the temperature with the help of a rotating wheel. Such a thermostat simplifies management at times, any person can handle it.In addition, there are far fewer breakdowns of such a system.

Digital thermostat implies a more complex and total control of the system. It is a panel with buttons or touch controls. In addition, it has a special control unit with electrical sensors that collects all the necessary information about the temperature of the air and the floor and transmits it to the thermostat.

The next type of control is programmable heat controller. It is the newest among such systems. It allows not only to exhibit different temperature regimes for all rooms, but also to change the temperature of different sections within the same room. They can be controlled not only manually, but also remotely using a smartphone, leaving home. So you can control the heat, even leaving the house.

All of these electric floor control panels can fit into different interiors, some of which are more and some less noticeable, everything will depend only on your decision.

Among the control systems are also distinguished simple thermostatsthat allow you to constantly maintain a predetermined temperature in the rooms.When the values you specify decrease or increase, it turns on or off electricity, thus maintaining the desired temperature in the room on its own.

Some models of thermostats involve the installation of one of the programs that can take into account the time of day, as well as whether it is a holiday or a working day. Such smart control systems can turn on the heating at the right time before the owners return home and turn it off when no one is at home. But the modes are easily customized and manually, if you have changed plans. Thus, control systems of a warm electric floor are interesting and diverse. They allow you to make its use more convenient and simple.

Reviews

Customer reviews show that many types of electric flooring and the brands that produce them have shown themselves to be exceptionally good. So the floors Rehau have a number of positive customer reviews and serve flawlessly for decades. Although they bought noted the high price of these models, they indicate that the systems still justify their cost.

Another high-quality and popular option among buyers is a warm floor cable type RehauSolelec. Its design consists of two-core high-quality cables.Buyers write that such floors do an excellent job with floor heating in even very wet areas. Manufacturers are models that are shielded with a layer of Kevlar under a teflon sheath, the quality of which is particularly noted by buyers.

Manufacturers also offer to purchase electric cable floors in the form of mats with a thickness of only 3 mm. Buyers write that such a warm floor is perfect for installation under the tile.

A Danish company representing electric floor heating is very popular among buyers. Brand name - Devi. He has been on the market for about 30 years. This manufacturer is a cable floor heating systems with different power, including models in the form of mats. Bought write that they can easily pick up the desired thermostat and sensors that will qualitatively reflect the change in temperature.

In addition, many customers like the fact that this manufacturer provides all the information about the quality characteristics of this heated floor and its compatibility with different floor coverings. In addition, the manufacturer guarantees a long life of its products.

Another popular electric flooring manufacturer - "Heatlux". The warm floor from this brand is pleasant to buyers that it represents an excellent ratio of the price and quality. The manufacturer offers both cable and film types of electric floors. You can pick up from him and various accessories, including comfortable and modern thermostats.

The rating of popular manufacturers includes brand floors. T-technologiesthat are being created in Russia. This manufacturer is a film and core heating systems, which have a low price. This quality, as well as additional services, is highly appreciated by buyers.

Customers generally positively appreciate the work of the Korean electric floor heating type. They write that when installing such a system in the bathroom, they instantly forgot about such a problem as the appearance and spread of fungus and mold. At the same time, they began to air the bathroom less often and leave the doors open as the water evaporates on its own. In addition, the floor quickly ceases to be emergency wet.

Many people write that the installation of an electric floor heating on the balcony made this room more functional, the clothes here began to dry faster.In addition, many on the balcony equipped a full storage system. Infrared floor heating is the most favored, especially models made of carbon rods. In the second place in the ranking of cable warm floor. But, of course, more convenient is the option in the form of mats, according to buyers, as it perfectly replaces convectors.

Successful examples and options

The most practical option when installing a warm system is the installation of thermal insulation coatings. This is a great way to increase the heat transfer of any finishing material, even if it has low values that reflect heat retention. In addition, the installation of an additional safety system is important. A great option would be to hold a separate power line for the floor heating.

A successful option is the preparation of a preliminary layout of all heating elements. In addition, it is better to additionally calculate the cable pitch so that there are no cold areas and the heating is the most uniform. Do not install underfloor heating under large furniture, especially for some electrical appliances, such as a refrigerator, or plumbing fixtures.

In wet areas, it is necessary to install more powerful warm electric floors. This is a great option that will allow you to create a comfortable and warm microclimate in the room. Great attention during the installation of electric floor heating should be paid to the installation of the screed. It insures the system against various breakdowns and external influences and accumulates heat well. But at the same time, if the floor heating system is damaged, you will have to break the screed and re-do an economical repair.

Installing a system of warm floors, it is important to take seriously the choice of flooring. It will be correct to purchase a laminate or other coating, on the packaging of which there is a special marking, which means that it can be installed on a heated floor.

Having made the decision to purchase this system, it is also important to consider the manufacturing company that produces these floors. Try not to save on the purchase, so that the system works as best as possible and lasts a long time. During installation, you must follow all the rules and recommendations, or additionally use the help of an electrician.

For information on which electric floor heating is better, see the following video.