Substrate for underfloor heating: advantages and disadvantages

The warm floor from the moment of its appearance has become very popular. Such a floor covering has a lot of advantages and advantages in comparison with ordinary floors, but only on condition of the correct choice and installation of all its parts, and in particular the substrate. That it is one of the main components of the floor heating system.

Features and Purpose

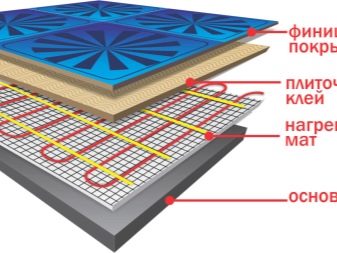

People who want to install a warm floor in their home often wonder if they need some kind of special lining material for the system, or in this case, the lining is just a waste of money. In fact, lining at the bottom of the floor is really necessary. It allows not only to level the floor before laying the final cover, but also performs other useful functions. Substrate under the warm floor is designed to retain heat and prevent its leakage into the lower layers of the system. Simply put, This layer has thermal insulation properties.

In addition, high-quality and properly mounted substrate allows to increase noise insulation in the room.

In order for the lining for the warm floor to cope well with its purpose, it must be chosen and put correctly, focusing on the material manufacturing as the substrate itself, and the final coating. Only in this case, the system of warm floors will work correctly.

Types of warm floors

Today, warm floor manufacturers supply them for sale in several varieties. For each specific type of floor, you must use the appropriate version of the lining - only in this case will it fully cope with its functions:

- Laminate flooring coating can be warm, however, the installation process is quite time consuming and responsible. A distinctive feature of such floors is the need to use two substrates at the same time. When arranging a warm laminate floor lining is needed to protect against overheating and prevent further deformation of the final coating - lamella panels.

- Under electric floor heating in some cases it is necessary to lay a two-tier lining.The first level is laid during the roughing, and the second - with the final installation. The use of insulation allows to increase the thermal conductivity of the cable, protect it from overheating, and also save on electricity costs.

- Infrared film underfloor heating also requires mandatory pre-laying the substrate. That it will allow to redirect all the heat from the infrared heating inside the room, and not inside the floor. In addition, walking barefoot on such a floor is much more pleasant. It is worth noting that infrared floor heating is often called film. As a heater various materials can be used.

- Water the floor may have a heating function, in which case the choice of substrate must be taken very seriously. Not only the quality of the heating, but also the safety of walking on the floor covering will depend on the right choice. It is the lining that can significantly reduce heat loss when hot water passes through the pipes and concrete crossbars.

The substrate is a significant, integral part of the floor heating system, regardless of its type.

That is why preference should be given not just affordable and suitable.to types of this heater - it is important to choose from all range really high quality and safe lining.

Types of insulation and their characteristics

Today, insulation for the floor, which is used as a substrate, is available in various forms. All of them are divided into three large groups depending on the composition.

Natural insulation

Such substrates are made from organic materials and are extremely vulnerable to various harmful microorganisms. For this reason, such a substrate must have a special impregnation. Its service life is less than that of heaters from other groups. This category includes substrates made from:

- Jute or flax. The fibers are small, the insulation itself absorbs moisture, dries quickly and does not change its original size and appearance. The downside is low insulation.

- Cork insulation is characterized by versatility of use, it has one of the best indicators of noise absorption and thermal insulation, does not deteriorate over time, has reliable protection against harmful microorganisms. Sold in rolls at an affordable cost. It has good elasticity, poorly amenable to burning.

- Felt insulation is made from sheep wool. This material has a thickness of up to 5 mm, it does not burn well, absorbs and passes moisture well, and also applies to breathable materials. This lining is only suitable for soft flooring. It has high thermal insulation.

Despite these quality characteristics, natural heaters are used quite rarely because of their short life, the tendency to accumulate condensate and change their size.

The most popular are synthetic linings.

Synthetic substrates

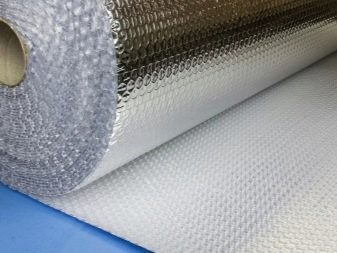

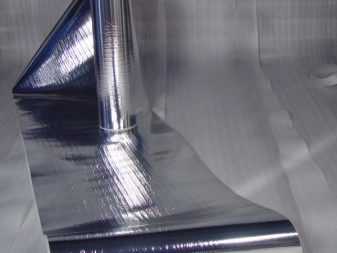

Synthetic lining can be foil or conventional. Synthetic insulation with foil have a greater ability to heat. They are not recommended to be laid on the concrete floor, otherwise the reflective surface of the foil quickly collapses. It is also worth knowing that there are heaters on sale both with a regular foil in the composition, and those with a reflective coating - a multifoil. It is a more modern, reliable and improved material.

Any metallized pole from the discharge of synthetic has two big advantages: increased thermal conductivity and complete immunity to any pathogens and bacteria.

Currently, such insulation is made from the following materials:

- PE foam stitched use as a substrate for any warm floors. It has low flammability, excellent noise absorbing and heat-insulating properties, does not crumple and easily returns to its original form. Available in sheets and rolls.

- Polyvinyl chloride it is hard and soft. As a heater is rarely used and only in a rigid modification. It is easy to ignite, and in the process of burning many harmful chemical compounds are released, therefore, currently polyvinyl chloride is used very rarely. It is realized in rolls and sheets from 3 to 20 mm thick.

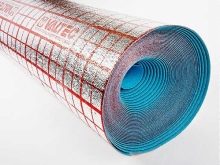

- Styrofoam - it is a foamed synthetic material with good flexibility. It is immune to fire, perfect for laying under any warm floors. It is realized both in sheets, and in rolls. On sale can be found as a smooth substrate, and with special bosses. The second option is intended only for laying under a water-heated floor.

- Polystyrene backing more simple when compared with the previous version. It is often used because of its availability and good thermal insulation qualities. Usually implemented in the form of sheets. The substrate of this synthetic material may be ribbed or smooth. Ribbed quencher is used when installing a water heated floor.

- Lavsan substrate is a kind of hybrid foamed polystyrene foam. The fact is that the sheets of this material are covered with a thin layer of foil, so the heat-reflecting ability of Dacron is simply amazing. The surface of such sheets is usually smooth, but sometimes there is a ribbed lining made of it. It is worth noting that a perforated lining of any kind in most cases is designed for laying under a water-heated floor. Pimples and allow you to firmly seal the insulation.

Some manufacturers produce substrates with markup, thanks to which you can easily understand how and where exactly the sheets or pieces of insulation should be interconnected. In the process of installation such information must be taken into account.

Mineral insulation

This group includes only one type of substrate - fiberglass or glass wool, as it is called by the people. The material is not subject to burning, does not absorb and does not conduct moisture, but at the same time it does not possess any thermal insulation properties. From the foregoing, it can be concluded that it is better to acquire synthetic substrates for a heated floor, as they have a longer service life and have better heat absorption than mineral or natural insulation.

Laying technology

Immediately it should be noted that the laying of the substrate of each type must be carried out according to individual technology, selected depending on the type of heated floor and insulation material. There is a general list of technological works that are consistently performed in all cases:

- Dismantling of the old flooring or screed of the new floor. If you plan to install a warm floor in a new house, you must first complete all the rough work, make the floor screed in any convenient way, wait until it is completely dry and then proceed to the next step. If there is a need to dismantle the old floor,the coating is completely removed with the help of tools, all the garbage is collected and disposed of in a landfill, and the work surface is thoroughly cleaned.

- You must carefully examine the concrete base for the presence of defects such as chips and cracks. They must be eliminated with the help of cement mixture.

- It is necessary to make sure that the floors are perfectly flat, have no flaws. In the case of strong elevation differences, it is strongly recommended to fill the entire floor space with a self-leveling mixture, the layer of which should not exceed 3 cm.

- In order to level the temperature drops, a special tape is fastened around the perimeter of the lower part of the walls.

- A solid polyethylene film is laid along the entire perimeter of the base, with a mandatory overlap on the walls.

- The substrate is laid in an even layer on top. Pay attention to the laying of all parts carried out joint to the joint. Lay the substrate should be so that the density of the material was not less than 150 g / sq. m

- Then the remaining parts of the underfloor heating system are alternately mounted.

Despite the seeming difficulty, the laying of both the substrate and the entire floor heating system is not so difficult.This work requires patience and care, and with the right skills, it does not take long.

Manufacturers

Today, even the most sophisticated buyer may be lost in the assortment of substrates. In order not to get lost in the most crucial moment and purchase a really high-quality and reliable insulation, it is recommended, first of all, to pay attention to the products of the following manufacturers. Among them are both domestic and Korean, and even Portuguese companies.

All of them are engaged in the production and manufacture of high quality insulation for underfloor heating, and customer reviews only confirm this:

- Foam rolled insulation firm "Stenofon" considered one of the best for today. It has excellent thermal insulation and noise absorbing characteristics. During operation, the substrate does not emit harmful substances and does not change the technical characteristics.

- The largest domestic company "Euroisolation" Offers its customers a truly wide range of underfloor heating substrates made from various materials.The quality and safety of each heater is confirmed not only by the reviews, but also by the corresponding quality certificates.

- Izokom - it is a series of heat-insulating materials for heat-insulated floors of different types. In the company's assortment, every customer will be able to find a substrate that perfectly meets all requirements. So, more than 4 types of various heaters are presented here.

- Valtec - is a joint Italian-Russian brand, which is engaged in the production of thermal insulation products, including substrates for floor heating. Today, the range of the brand has more than 6 varieties. Distinctive features of the products of this company are affordable cost, the highest quality and individual approach to each customer.

- Premium cork - This is a Portuguese manufacturer, which produces natural substrates of excellent quality at an affordable price. The range is not so great, but the goods are really high quality.

Reviews of substrates for warm floors of these manufacturers are the most positive, so it is reasonable to study their products first and then decide on the purchase of a specific insulation.

Successful examples and options

Underfloor heating is not only beneficial and practical, but also very beautiful, and photos only once again confirm this:

- Plain at first glance tiled floor in the kitchen is actually very warm. Now the owners do not have to worry about the fact that the child will freeze while sitting on it. This flooring does not just look harmonious and modern, it is also extremely practical.

- Thanks to the correctly installed warm floor and the use of an optimal substrate, walking barefoot on the tile will be comfortable and convenient even in the bathroom, and the floors themselves will look as stylish as possible.

- Electric floor heating is most relevant in the nursery. It’s no secret that babies most often play on the floor, and in the cold season it’s simply impossible to do without such a warm and safe floor.

Properly mounted warm floor ensures not only comfort, but also gives comfort, beauty and safety.

How to choose a substrate for the floor, see below.