Volma hard putty: features and scope of application

Today, putty is a versatile material with a lot of possibilities. A variety of compounds used for surface treatment, leveling walls, sealing seams. Without the use of this consumable material it is impossible to carry out a complete overhaul. Hard putty presented in the modern market differs not only in components in structure.

The material has individual technical characteristics and other features. Among the huge variety of assortment Volma putty is very popular. Products of this brand has gained popularity due to a number of advantages.

Special features

The putty of the above brand is made on natural plaster base. This is the main component that plays an important role in the final result.Gypsum has a high viscosity index, firmly connecting the other elements. On the shelves of stores and in the catalog of the brand products are presented in a dry form. This putty is used for repair work manually.

Additional components of the compositions are chemical, as well as mineral trace elements. Additives are responsible for various performance characteristics, including wear resistance, adhesion.

Benefits

After analyzing the products of the brand "Volma", the experts have made a number of advantages. Positive aspects of the products were confirmed by professional craftsmen and ordinary customers.

- The mixture has elasticity and plasticity. This is a light, airy composition.

- Volma hard putty is an environmentally friendly and safe for health material.

- This material has no shrinkage.

- Thermoregulation is inherent in this putty.

- It differs in convenient use and high quality.

- With its help effective alignment, and also reliable seal of seams is possible.

- The maximum layer of material (in the process of leveling the base with one layer) is about 6 cm.

We have identified the main advantages of choice.The above advantages have only certified, original product.

Range

Under the brand "Volma" produced a number of putty compounds. Pay attention to the most popular and widely used positions.

"Aquastandard"

At the heart of this product is a cement base, or rather, Portland cement. A distinctive feature of this putty are reinforced fibers, providing excellent reliability, durability and wear resistance. The product "Aquastandard" boasts increased moisture resistance and non-shrinkage.

The technical data are as follows:

- material color - gray;

- The optimum temperature for work is from +5 to +30 degrees;

- maximum layer of putty - 8 mm;

- the minimum drying period is one day. Maximum - 36 hours.

- the middle layer varies from 1 to 3 mm;

- after dilution, the composition must be used for two hours.

- 1 kg of the composition must be spent about 0.3 liters of liquid.

Using

This type of putty is suitable for processing surfaces that will be further processed using paint or plaster.Proper use will provide an even and smooth layer. Experts say that the maximum layer of the composition "Aquastandart" is 3 mm.

Putty is ideal for sealing cracks, chips, sealing sinks.

With it, you can close up the grooves to a depth of 6 mm. A large layer of material with a thickness of 8 mm is used to seal large defects. The material can be used for exterior and interior processing. To use the composition can be at low temperature conditions or in a room with high humidity. Apply consumable material on a variety of concrete surfaces, for example:

- slag concrete.

- aerated concrete.

- foam concrete.

- claydite.

Work with coatings that have been pre-treated with cement-sand and lime mortar is allowed.

"Layer"

At the heart of this product, the manufacturer uses gypsum. The component is distinguished by viscosity and reliable bonding. Additional organic and chemical elements give the product such positive qualities as wear resistance, practicality, adhesion, water-holding capacity.

Application

This putty is designed for leveling surfaces, further decorating with wallpaper, paint or ceramic tiles. If in the process of work all the recommendations were fully taken into account, after drying a smooth glossy surface with a pleasant gloss is formed. Additional putty is not required. The optimum temperature for work is from +5 to +30 degrees. High humidity is not a problem for the composition.

This plaster can be applied to:

- brick;

- concrete (foam and aerated concrete);

- blocks of plaster;

- cement-lime plaster;

- GVL, GKL.

How to cook?

On one kilogram of the mixture in dry form will need about 0.6 liters of plain water. Mix the putty with liquid in a plastic container. The bucket must be clean. Stir the powder with the liquid until a uniform, lump-free liquid is formed.

For dilution, it is advisable to use warm water at room temperature. Use a special construction mixer, which will help to carry out the procedure as quickly, efficiently and conveniently. After it is necessary to leave the composition for a couple of minutes so that it is present.

Follow the manufacturer's recommendation during the dilution, which is usually indicated on the package.

If necessary, add powder or liquid to the resulting solution until the consistency is optimal.

How to apply?

Professionals recommend applying putty to the surface within 20 minutes after preparation. Use a plaster falcon or trowel. The optimum layer thickness should be between 5 and 6 mm.

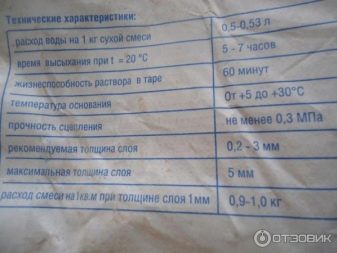

"The finish"

The composition in a dry format based on gypsum components, providing viscosity. These particles have a size of about 0.2 mm. Manufacturers have added various modified components and mineral impurities. The material has a high adhesion index and prevents the formation of new cracks.

The characteristic of this material is as follows:

- temperature conditions for repairs: from +5 to +30 degrees;

- the complete drying of the material takes 5 to 7 hours at a room temperature of +20 degrees;

- the thickest layer is 5 mm;

- the optimum layer varies from 0.02 to 0.3 cm;

- 1 kg of the mixture need half a liter of water;

- ready solution is suitable for work within an hour.

The product is used for finishing the surface. After drying, you can coat the paint or glue the wallpaper. The mix "Finish" can be used for work with such surfaces:

- gypsum;

- concreted;

- sheets of giprok;

- gypsum fiber sheet;

- gypsum boards.

Apply the mixture to dry surfaces. Make sure that they do not have particles of dirt and traces of old paint coatings.

If the base material has high absorbent properties, an additional primer treatment should be carried out. It is recommended to mix the material for at least three minutes. After a break of several minutes, the mixture must be mixed again. For drawing it is better to use a metal spatula.

"The seam"

This material is made on the basis of gypsum binders. To give it excellent technical characteristics, the manufacturer added organic and inorganic elements to the composition. A distinctive feature is increased adhesion and ability to retain fluid.

Consider the technical characteristics of this putty:

- a full day of drying is required;

- temperature conditions for facing surfaces range from +5 to +30 degrees;

- standard layer thickness is from 0.02 to 0.3 mm;

- the application should be done in 40 minutes;

- on 1 square. m surface needs to spend 250 g of the composition.

The “Seam” putty is ideal for covering surface flaws. Proper use will ensure even coverage without defects. The composition is ideal for sealing cracks, small holes and potholes. This is a reliable and durable sealing of joints between the plates. The composition is ideal for decoration of the glossy surface and work with irregularities of 5 mm. Use with such surfaces is allowed:

- concrete;

- brick;

- GVL;

- foam concrete;

- aerated concrete;

- giprok;

- gypsum or cement bases.

"Standard"

One of the most popular products of the Volma brand is the Standard putty. The material is highly resistant to cracking. High adhesion is also worth noting.

Consider the technical aspects of this composition:

- if the air temperature is about 20 degrees, the material will completely dry in 24 hours;

- to dissolve 1 kg of dry laughter, you need half a liter of water;

- strength indicator is 0.3 MPa;

- optimum thickness is 1-3 mm, maximum index is 8 mm.

- maximum pot life in a tank is 2 hours.

This putty is suitable for use as a base (starting) finish for leveling walls. This is a good treatment before the subsequent decoration (it can be used for wallpaper, paint and other finishes).

Putty can be applied on concrete and gypsum bases, gypsum-fiber sheets, drywall.

Expert advice

Before purchasing a putty, accurately calculate the amount of material required. It is recommended to buy it with a margin if you are working with such finishing material for the first time and do not have adequate experience. Standard packaging weighs 25 kg. Read the quality certificates before purchase. Relevant documentation confirms the quality of the product.

When purchasing, look at the shelf life of the composition: after it expires, the material loses its properties. In addition, buy products based on the type of surface.

Reviews

The network has collected a huge number of opinions of professional craftsmen from the field of repair and ordinary customers.Users note that the purchase of putty from the above brand is a reasonable purchase. Most reviews are positive feedback. Users focused on the excellent results, reliability and practicality of these compositions.

In the video below, see the process of applying the gypsum plaster "Volma Layer".