Putty and the nuances of the formation of angles

Putty is the preparatory procedure of the surface before the final final finish. This type of cladding easily aligns the walls, making the coating more smooth. Plastering corners has its characteristic details.

Putty

During the restoration of each building builders are faced with the alignment of corners, both internal and external. To align the corners, first you need to choose the best solution and apply it in the future.

The solution differs according to the existing criteria:

- The degree of preparation. Solutions are dry and, accordingly, have a low cost. It is easy to use such solution in work, it is only necessary to part it independently. In addition, there are ready-made mixtures on sale that do not require preparation.

- The proportion of binding components. The composition can be made of gypsum or cement. For example, cement mortar has excellent moisture resistance, which allows it to be used for filling the corners of a kitchen or bathroom. The only disadvantage is the possible cracking of the finished coating after the complete drying of such a mixture. Gypsum cladding is used only to cover the inner walls of the room - this is because it does not have a high degree of protection against moisture.

- Purpose Solutions are universal and decorative. In addition, there is a special leveling material.

The variety of existing species should not be scary, because you can always consult with a specialist before purchasing.

Selecting the desired composition that will be used when leveling the corners, you need to pay attention to the number of grains in the solution. This indicator affects the quality of the future facing coating: the smaller the indicator, the thinner and better the finishing layer will be.

Before starting work on the alignment of the corners, it is worth preparing the tools that may be needed during the facing work:

- Corner trowel.This special tool is used in aligning the outside corner of the building, including the inside corners. It differs from other options by special fastening of the handle, which is fixed on the sides of the corner.

- Construction level.

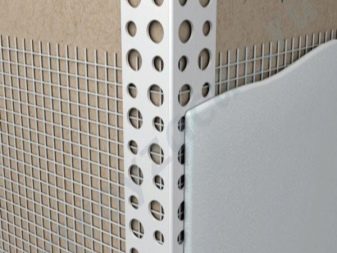

- Perforated plastic or metal corners.

- Metal spatulas of various sizes.

Principle of operation

Puttying outer corners. Filling is carried out using the design of the surface joints at right angles. At the edges of the wall you need to install nozzles to get the right putty putty on the outer areas.

Specialized nozzles can be different:

- Metallic. By production of nozzles the galvanized steel material or aluminum metal can be used. To reduce the weight of the structure, so that the product can be drowned in the putty, perforations are made on the sides. The disadvantages of this type of instrument include the possible appearance of corrosion in galvanized areas.

- Plastic. In form, such plastic products are very similar to metal nozzles, only plastic material has the highest operational period.This design is often used in the treatment of uneven wall surface with significant protrusions or other various defects.

- Flexible. Such nozzles are used for cladding angles that are in openings with arched geometry. Also, flexible nozzles are used if it is necessary to plaster curvilinear sections on a plasterboard surface. The special design of the corner will allow to bend this product at the right angles without damaging the edges. These linings are used only when processing rectangular surfaces, but the filling of the remaining concrete planes is performed without the use of auxiliary structures.

Putting the outside corners in the room should be done in the following order:

- A small amount of the solution is applied over the entire surface in a uniform layer. Processed the area that needs it.

- Then perforated corners are mounted to drown them in the mixture itself.

- Products set by level, putty added if necessary.

- After complete drying, proceed to the final finishing process.

- On the trowel impose a little mixture to handle the surface with only one side.

- Then this procedure is repeated - the work is being done on the other untreated side, along with this it is necessary to remove the excess solution.

- It is necessary to level the composition with uniform movements, the furrows should not be left.

- The procedure is repeated until complete treatment of the entire area, which is subject to lining.

- The site begins to grind and primed with a special penetrating solution only after complete drying of the putty coating. If necessary, then carry out the final putty.

- Then you should re-grinding. The procedure should be carried out carefully so as not to erase the first layer of putty.

Internal corner filler. Work should be done in the following order:

- To begin with, determine the curvature of the processed corners. There are cases when it is necessary to pre-lay the plaster.

- Flat areas of the wall begin to level - such areas will have to be brought close to the joints.

- Along the entire angle you need to apply the prepared mixture, and remove the remaining surplus by the rule.Such a tool must be used alternately on each wall.

- To simplify the hard work, experts recommend using an angular trowel - the design of this spatula will help to complete the processing faster, you will not need to perform any additional procedures.

- The resulting coating on the slopes can be checked for evenness with the help of a square and a level. If there are any deviations, then the procedure will have to be repeated, but this time you need to use a reduced amount of solution.

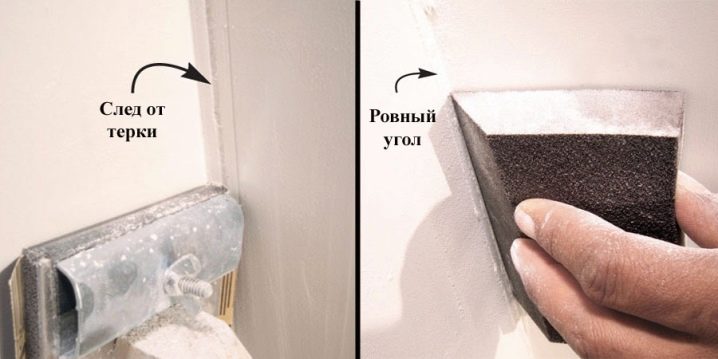

Grouting and grinding corners. Small protrusions may form at the end of the inner lining. Derive such unwanted defects by grinding. To do this, follow these simple steps:

- On the pre-cooked hand grater you need to install an emery cloth so that it protrudes 20 mm beyond the edge of the tool.

- Such a device is first treated on one side of the corner, then on the other. During processing, all movements performed must be carried out quickly and abruptly.

- Due to its plasticity, sandpaper easily removes rounding, thereby creating a flat surface.

Putty plasterboard angle.Often in work with walls covered with plasterboard, difficulties may arise: cracks begin to appear at the junction points. To prevent this from happening, you need to follow the following instructions:

- The first step is to cut the seams, create grooves, and then clean them.

- Then you need to handle the already cleaned seams with glue - this should be done with a spatula.

- After that set the 60-mm grid.

- Then you should do the processing according to the method described in the instructions.

Mounting the mesh must be done carefully. The building should be the same temperature - so the solution will not spread after application.

Possible mistakes

During work, inexperienced specialists make various mistakes: with a fairly strong pressure, using a grater or with uneven tool movements, small dents may appear. Such defects are easily aligned, the main thing is to pre-prime these problem areas.

After priming, you can apply a small amount of putty, allow this layer to dry, and then begin to gently clean the coating, periodically replacing the granular sandpaper with a new one.

The correction layer should be thin - more effort should be applied during grinding. Movement during operation should be light, smooth and smooth.

Putting corners is not difficult, you can easily handle the internal corner joints with external elements. The main rule in this work is to wait for drying, because only after that you can proceed to the next stage.. Thus, the finished facing surface will be better and better. It is impossible to work with raw material that has not dried out, since it is simply impossible to achieve the desired result with this approach.

In order not to lose time when the putty layer dries, you should do some other work, for example: you can begin to level the walls or finish the ceiling.

The process of filling corners and bringing out irregular shapes is not laborious and quite interesting, since it opens up space for creativity. Even putty complex grooves and beveled corners of any master a great pleasure. However, when working with your own hands, you must clearly follow all the instructions that are written in this article.After all, then the result can please not only the performer of works, but also all others.

How to putty angles, see in the video below.