How to choose a putty for the floor?

Sometimes over time or due to active use, defects appear on the floor surface: holes, hollows, cracks. But not always the owner has the opportunity to completely change the entire floor. What to do in this situation?

There is a solution: you can prime and putty the floor, and then paint it again or use another type of coating - laminate or linoleum.

Special features

Putty is called repair mortar, the purpose of which is to seal holes and cracks, as well as the elimination of minor defects in the floor, walls and ceiling. In the case of floor treatment, its layer is intermediate between the primer and the application of the finish - paint, laminate, linoleum. The better the mixture conceals surface irregularities, the longer the floor will serve.

Puttying the floor is somewhat different from a similar procedure on the walls or ceiling. For the floor putty is not kneaded so thickly as for the ceiling or walls. The ratio of composition and water is 1: 5. Pre-ground surface.

In the case when the floor surface is moisture-proof, the putty should be made even thicker, in a 1: 3 ratio.

In addition to the above, the surface of the floor requires the application of more layers. Coatings that are put on top of putty are also different: substances such as linseed oil or wood stain are not used to cover wall and ceiling surfaces.

In addition, it has its own characteristics of puttying of different types of floor - wooden, concrete, polystyrene foam.

The main thing is to get as a result a flat area on which you can lay parquet, laminate, linoleum, or simply apply a layer of paint.

Kinds

Putty is used to eliminate minor imperfections and level the floor surface. Modern manufacturers offer a large number of putty materials.

For wooden surfaces will suit various options:

- Acrylic - this type of putty mix will eliminate irregularities and disadvantages of the floor surface. Putty is no less good at grouting. The composition of acrylic moisture resistant, fireproof, elastic and durable. The main requirement when working with acrylic putty is a thoroughly prepared, clean and dry surface. After the floor is dry, it will get a smooth and shiny texture.

- Fillers based on various solvents, which include dust from wood. Indispensable when working with arrays, even rare. Suitable for puttying parquet. Solvent-based blends are good for treating surfaces equipped with underfloor heating systems. Dry very quickly.

- Oily - The basis is oil, chalk and water. High strength and durable composition. The oil composition dries for a very long time. If this is not critical, then you can be sure that the coating will be of high quality and durable.

- Polymer - The basis is water, good for filling holes and smoothing irregularities. Dries quickly, eco-friendly, durable. The advantage of polymer putty is that the treated surface does not accumulate dust and the treated edges of wooden boards do not clog.But it can not be used for puttying cork floors.

It is forbidden to work it directly on the floorboards.

Regardless of the type of putty, it must have a number of qualities:

- be uniform in texture;

- have good adhesion (adhesion with the surface);

- dry quickly;

- have no impurities and additives in the composition;

- quality floor covering.

Before starting any putty work, it is better to check the quality of the mixture in a small area.

Putty mix - the best tool for leveling the floor of concrete. The best is the putty compound based on PVA glue., and you can both buy and make it yourself. In the second case, it will cost at times cheaper.

The advantage of working with this type of putty is that the mixture is ready immediately, it is not necessary to pre-mix it. The solution is very plastic, so it is quite easy to apply. It has excellent adhesion, so it is good to “grab” with the floor surface.

After that as the floor dries, there will be no cracks, dimples, irregularities or baldness. Also this type is not subject to shrinkage. The surface will turn out smooth, beautiful, with the absence of air bubbles, delamination and other troubles.

Very often, when faced with the rather high cost of putty mixtures, people prefer make it yourself from materials such as PVA, linseed, cement, sand and other components. In the presence of some skills and everyday wit, you can make a composition not worse than the factory.

There is another type of putty mix - waterproofing. It consists of a three-component polyurethane compound consisting of a semi-finished product, a hardener and a dry mixture. It can be used either alone or with other putty materials. It is very durable and resistant to all kinds of mechanical stress.

It is used, as a rule, to isolate a concrete floor or a protective layer of a self-leveling floor from moisture, to seal holes and holes. Used for processing structures such as swimming pools.

Application area

Apply the composition for filling the floor very widely. They are needed both for those who install parquet or laminate flooring, as well as for those who need to update the flooring and redecorating.In both cases, the composition and sequence of actions will be almost the same.

There are also mixtures that are equally suitable for plastering ceilings, walls and floors. The difference is only in the density of the solution.

Puttying of a concrete floor can be carried out both under linoleum, and under laminate, and as a basis for a self-leveling floor. True, in the latter case, it is desirable that the concrete be relatively smooth in itself, without additional tweaks. Basically, mixtures for it are sold in dry form. Therefore, before starting work, the composition must first be diluted and kneaded. There are also pasty mixtures that are immediately ready for use.

Also for this floor often used self-leveling putty. It is more liquid, therefore it is leveled better. The finished solution is placed evenly and thinly, in a single layer. Thick mixture can not be applied, cracks may appear. When the putty has dried slightly, the spatula can be removed unnecessarily applied composition. Next, the surface is leveled using sandpaper.

If the putty should serve as the basis for the self-leveling floor, the polymer mixture is best suited.We must remember that the surface itself must contain a minimum of cracks and irregularities.

Using a properly chosen putty for a wooden floor will level it, hide irregularities and cracks in plywood or boards, prolong the life of the surface. The floor of polystyrene foam can also be repaired with the help of putty compounds.

If gypsum-fiber sheets (GFL) are laid on the floor, as well as fiberboard or chipboard, putty irregularities and rub the seams again need exactly putty mixture for the floor. Only then can you achieve perfect joints, invisible to the eye.

How to apply?

On the floor, putty is applied in several stages.

- Close up deep holes. To do this, apply several layers. Each subsequent layer can be applied after complete drying of the previous one. The finishing layer is placed on one level with the coating.

- After all the gaps are sealed, all layers are dried, the upper layer is smoothed with sandpaper with a fine notch.

- The thicker the layer of putty, the tighter the color of the future floor should be.

A layer of putty is always visible through the paint, stain and varnish.Therefore, with the choice of color should be determined with the given features.

- If you need a specific shade, putty can tint (before work started or after drying all layers).

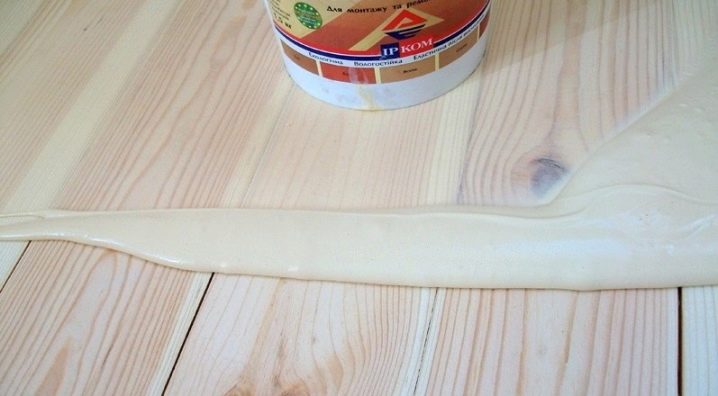

- The gaps on a wooden surface are filled with the help of a spatula made of metal or wood in the direction perpendicular to the boards in the floor.

- Putty mixture is applied with a thin and even layer. In order to maximize the level of the floor surface, stretched gauze is put on the first layer, after which they are puttied on another layer.

- After drying all the applied layers, the surface is primed with oxol or linseed oil. When the floor is dry, you can put parquet, laminate or just paint the surface.

Putty is chosen, guided by both the type of surface and the result I would like to get.

There are the following types of putty:

- basic;

- finish;

- universal.

The base is always put the first layer. It evens out the main roughness, and also overwrites the seams. The finish, as its name implies, is placed last. Universal can be used in any quality.

Tips and tricks

Repair professionals recommend sticking to the following:

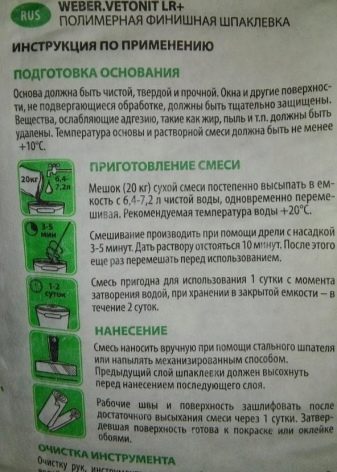

- Be sure to read the instructions on the package or packaging of the mixture prior to purchase or at least before use.

- It is necessary to mix the solution only in the amount that is required for 4 hours of continuous work. If you make more quantity of the mixture, you will have to throw it out, since after this time it loses its properties.

- In order to choose the right type of composition for puttying, you need to take into account the properties of the room in which the work will be carried out, as well as humidity. Some formulations are suitable for use only in rooms with low humidity levels. It is better to find out before the work began.

- After all the layers of putty are applied, you need to wait for them to dry completely - it will take about a day (maybe more). And only then you can start the next type of work.

- Before you apply the first layer of putty, you need to clean the surface. After this, the potholes, pits and cracks are first primed, then the holes and cracks should be treated with PVA glue diluted with water 1: 5.

- After that, finally, you can proceed directly to puttying.

If you follow these tips, you get a beautiful and even floor with a minimum of financial costs. Otherwise, there is a possibility that everything will have to be redone, possibly with the involvement of specialists and, of course, additional expenses.

To learn how to properly putty wooden floor homemade putty learn from the video below.