Decorative travertine plaster: advantages and application technology

Among the variety of finishing materials, decorative plasters are very popular. Plaster mixes allow you to create a fairly accurate imitation of various surfaces. One of the most spectacular coatings is the imitation of natural stone travertine. This article will discuss in detail the advantages, disadvantages, features and technology of applying decorative travertine plaster.

Special features

Natural stone travertine is in second place after marble in popularity of use for interior decoration. However, the appearance of this material is in no way inferior to a marble stone. The cost of natural minerals is quite high and not everyone can afford this finishing option. With the help of textured plaster "Travertino" you can create an artificial imitation of stone, which visually practically will not differ from the natural natural coating.

Decorative plaster perfectly repeats the texture of the stone. In addition, using special application techniques, interesting patterns and patterns can be created on the surface of the material. A decorative mixture under a wild stone is often restored old buildings. This material perfectly eliminates minor defects in the form of chips or cracks.

Since the mortar is applied to the walls in a rather thick layer, with such a plaster it is possible to correct small surface irregularities.

Advantages and disadvantages

Decorative plaster with the effect of travertine is a unique material due to not only the appearance of the resulting coating, but also high technical characteristics. The advantages of this composition include several properties:

- Health safety. There are no harmful components in these mixtures.

- High strength. The created coating is resistant to mechanical stress, and also protects the walls from damage.

- Fire resistance.

- Good adhesion with most types of surfaces.

- Moisture resistance. This material is perfect for finishing rooms with a high level of humidity.

- Resistance to the formation and spread of fungi and mold.

- Resistant to aggressive chemicals.

- Variety of options for creating original coverage. Numerous methods of applying plaster can create interesting patterns on the surface, as well as form the topography of the coating.

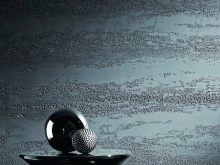

- A wide range of shades.

- The mixture copes with the task of eliminating small defects in the form of minor irregularities or chips. Also, the solution penetrates well even into small gaps, sealing them.

- Ease of care. The coating is resistant to various contaminants. If necessary, the finishing layer can be wiped with a damp cloth.

However, this material has some drawbacks. The main disadvantage is the complexity of finishing works. Without experience, it may not be possible to create a high-quality decorative coating.

Therefore, for finishing such plaster, many resort to the services of professionals, which, in turn, increases the cost of repairs.

Kinds

Decorative mixtures with imitation of travertine have some differences in the composition, as well as in the texture and color of the created coating. The basis of the solution includes components such as:

- ground marble particles;

- sand or lime;

- binders (synthetic acrylic resins or other polymers).

The composition for internal and external works differs in some components. To finish the facades, a mixture based on white cement is made. For work indoors, formulations with marble chips and quartz sand are made. The composition can be divided into several types of plaster under travertine:

- Silicate mixtures based on aqueous alkaline solutions of sodium silicates. This coating has a high level of vapor permeability and resistance to the formation of fungus and mold.

- Mineral solutions based on hydrate of lime with elements of light minerals and the addition of Portland cement. Plaster is resistant to moisture and high strength, which makes it possible to use this material for facade cladding. The solution is characterized by economical consumption and good adhesion to most surfaces: gypsum and cement bases, wood-laminated boards, concrete, gypsum plasterboards.

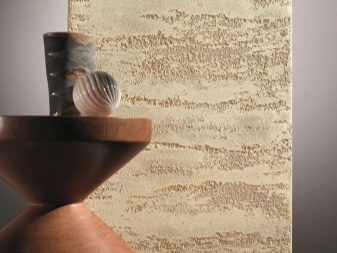

Design options

Due to the large number of different techniques of applying plaster with the effect of travertine, you can create many original coatings. In addition to existing techniques, you can implement your own ideas and experiment with coating. Most often, white or beige plaster is used to finish the walls. To create interesting effects, you can independently change the shade of the surface in one of the following ways:

- add color to the ready for application solution;

- apply a certain shade of finish to the dried coating, without waiting for it to dry, you can walk on the surface with a sponge soaked in water, which will emphasize its relief;

- You can use special decorative varnishes for plaster;

- cover the finish layer with wax.

You can create interesting textures using the tools used to apply the mixture. In addition to the usual tools such as the trowel and trowel, coarse bristled brushes, plaster trowel and paint brushes are often used to apply the mortar. To imitate the old surface, the coating is pierced and scratched with a needle roller,and also use a combination of dark and light areas.

You can form a ragged pattern on the coating by using solutions that differ in color. Layers are applied in coarse strokes, randomly and in different directions.

How to apply?

The process of finishing works with decorative plaster "Travertino" consists of standard stages of surface preparation and application of the mixture. The difficulty of working with this material is the need to use special techniques to create an effective coating.

It is possible to work with plaster at an air temperature of ten to thirty-five degrees and a humidity of no more than seventy-five percent. Most types of decorative mixtures under travertine can be operated at temperatures no higher than fifty degrees. For this reason It is not recommended to apply the solution too close to the heating equipment.

Many masters recommend to process the finishing plaster covering with a lessizing compound. Formed on the surface of the film protects the plaster from negative external influences and increases the life of the finishing finish.

Surface preparation

A mandatory step before the finishing of any type of lining is the preparation of the base. The walls are cleaned from the old coating, dirt and grease. In the presence of strong irregularities, it is recommended to level the surface. It is not required to bring the walls into a perfectly smooth defect-free state, since the plaster will hide minor imperfections.

Despite the fact that decorative mixtures "Travertino" have good adhesion, it is recommended to treat the base with a primer.

Smooth surfaces without roughness, for example, gypsum panels, fiberboard and particleboard are subject to mandatory priming.

Material consumption

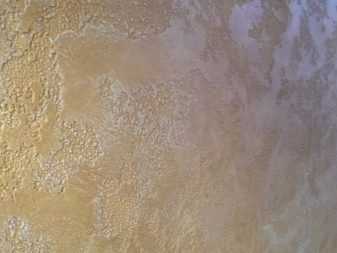

The consumption of plaster will depend on the chosen technique of applying the solution, as well as on the thickness of the layers. It should be borne in mind that when applying the mixture in broad strokes of small thickness, the resulting coating will visually resemble a weathered stone. Material consumption in this case will be relatively small: about one and a half kilograms per square meter with a layer thickness of just over one millimeter.

To create a relief coating it is necessary to apply the plaster in several layers of large thickness.In this case, the flow rate of the mixture can increase to three and a half kilograms per square meter.

Basic technology

There are two main ways of applying the composition "Travertino": solid and partial. The method of continuous finishing involves the formation of a uniform layer, which is decorated after the coating dries out a bit. Partial application consists of combining plastered areas with an intact wall surface.

The direction of brush strokes may also vary. In addition to the standard options for horizontal and vertical distribution of the mixture, you can use the chess method and chaotic distribution.

Finishing work

After surface preparation, the solution should be prepared for application according to the package instructions. If you have purchased a ready-to-apply mixture, then before starting the plaster, it is recommended that you mix well. The first layer of material will be the base. No need to make it too fat.

The mortar is spread over the surface using a paint roller or a special trowel with rounded edges for Venetian plaster. The layer should be thin (no more than a millimeter) and uniform.. Repeated application of the solution should be carried out no earlier than twelve hours.

The second layer is overlaid with chaotic relief strokes so that irregularities form on the wall. The plaster is allowed to dry a little for fifteen minutes.

Next, the surface must be slightly smoothed, giving a more uniform structure. Thus, the coating will be combined flat and slightly bumpy areas.

At home, apply the plaster on the wall by the method indicated in the video below.

Examples in the interior

With the travertine effect plaster you can not only revet the walls, but also decorate some interior elements. The decorative coating applied to the stairs is perfectly combined with metal wrought iron railings.

At the finish coating, you can manually form the joints, thereby creating the effect of a stone wall.

The travertine coating looks great in both classic and modern interiors.

Decorative mixtures "Travertino" allow you to create an atmosphere of antiquity, especially in combination with other elements of decor.

With the help of Italian plaster under travertine, it is possible to form not only relief surfaces, but also smooth glossy coatings. To create such an effect, the finishing layer after drying must be well polished.