Marble plaster: varieties and methods of application

In construction today, very often applied plaster. This is a universal tool for interior and exterior decoration, which allows you to even the walls, repair cracks, hide unsightly seams. A large variety of this building material makes it possible to perform repairs quickly, simply and with an individual approach.

Special features

Marble plaster is made of acrylic or mineral polymers with the addition of natural stone crumbs. Acrylic version, as a rule, has a translucent and completely transparent structure. Mineral supplements in combination with marble chips give a wide variety of colors. Depending on the purpose in construction stores, today you can choose moisture resistant, antibacterial, highly plastic and especially resistant to mechanical damage plaster.In addition, the decorative function of such a coating is achieved by adding spangles, mother-of-pearl and other additional impurities to the composition.

Among the advantages of this coverage are the following positions:

- Resistance to sudden temperature changes and atmospheric phenomena. Very actively marble plaster is used for exterior decoration.

- Steam resistance allows to lay a covering in saunas and baths.

- Increased moisture resistance is found in the names recommended for application in swimming pools, bathrooms and also for outdoor work.

- Having available a natural marble crumb, such plaster is eco-friendly and steady against mechanical damages.

- Full fire safety with such a coating is also provided.

- It is possible to apply marble plaster on any surface - this is manifested in its versatility.

Disadvantages of coverage:

- high price;

- Laying material requires experience and skill;

- it is necessary to use finishing agents: varnish or paint.

However, these drawbacks also attract an even greater number of people who want to use marble plaster.To choose the right texture, you need to understand the variety of types of this finishing material.

Kinds

There are several options for the classification of textured plaster with marble chips:

- According to the main substance. Marble plaster can be made of lime, acrylic or cement-sand mixture.

- By the size of a marble crumb. This classification also divides the finishing material into 3 types: fine-grained (0.2-1 mm), medium-grained (1-3 mm) and coarse-grained (3-5 mm).

- As a mixture. Marble plaster is sold both in finished and in dry form.

The decorative component in different mixtures also varies:

- marble chips gives maximum adhesion to any surface;

- granite grains provide the composition with the highest strength and durability;

- granite-marble component increases the practicality of the material and wear resistance.

Most often for interior work choose marble plaster of small and medium fractions. Compositions based on marble are suitable for decorating walls of plasterboard, brick, gas and foam concrete blocks. Textured marble plaster for walls is a very beautiful and durable finishing material. It serves for a long time and is almost not subject to mechanical damage.Ease of use is also associated with the care of her. Since the material is practically not afraid of moisture, it can be wiped with a damp cloth.

Professionals are advised not to start applying the stucco with marble chips on their own, since this process is rather complicated and requires certain professional skills.

Application technology

Plastering of the surface is always done with tools and the main substance for processing. Below is a list of tools you may need:

- Two spatulas. Ideally, these should be stainless steel products. You can also use a rubber narrow and wide tool.

- Trowel - it is a steel shovel with a curved handle, ground on both sides. With its help, the laying of marble plaster takes place directly.

- Trowel and grater. The first tool smoothes the applied solution, the second - produces grout.

- Capacity for kneading. As a rule, a plastic or metal bucket is used. It is necessary to ensure that it is clean in order to avoid non-uniform consistency and loss of ductility of marble plaster.

- Electric drill with a nozzle mixer (if you buy a dry mix that will need to be kneaded - it is very difficult to do it manually).

- Building level - to determine the evenness of the application of a layer of plaster.

- Master OK. This small tool is needed to apply the solution to the trowel.

Check the availability of all necessary, you can proceed to the preparation of the treated surface. Since marble mixtures are applied with the final layer, the surface under them should be even and dry. Therefore, first of all, the wall is cleared of dust and dirt, it is examined for cracks, pits, protuberances. When they are detected, a special cement-sand mortar is prepared, with which it is all sealed. The old layer of plaster is better to remove in those places where it is especially visually noticeable.

If there are areas with mold or fungus, they must first be cleaned, then treated with an agent with a high chlorine content. The entire wall is entirely better treated with antiseptic solutions in order to reduce the risk of such growths in the future. With the help of the level you need to check how flat the wall is. If necessary, apply a layer of starter filler or plaster. After drying, the entire surface should be primed. If a clear acrylic blend is chosen for the finish, the primer should be selected as a covering. Before applying it must be painted in the base color of marble plaster.

It should be noted that the soil dries for at least 12 hours. It is necessary to leave the surface at this time alone. In the meantime, you can begin to knead the marble plaster. Even ready-made mixtures sometimes have too thick consistency, therefore, in accordance with the recommendations on the packaging, it is diluted with water or solvent.

After drying the primer on the wall proceed to the application of plaster. To do this, you must perform a number of actions:

- A small amount of the solution is typed trowel in the tank.

- From the trowel, the mixture is transferred to the trowel - it already carries out the application of plaster on the wall. The tool must be kept at an angle of 60 degrees relative to the surface of the application. The mixture is laid in a uniform layer in one direction. Usually processing takes place in squares.In the process of applying should not allow the drying of the extreme lines of plaster.

- After processing the entire surface, you must wait 30 minutes until the layer dries, then you can begin to grout. Grater stainless steel must be very tightly pressed to the treated wall and smooth in a circle, applying the same force. In this process, there is no need to do strong pressure or to concentrate on one site for a long time.

- Finally, the marble plaster dries a day after application. This time is ideal for coating with varnish or a product with hydrophobic additives, which will give the surface a glossy shine and provide additional protection against damage. After that, the wall dries for another 12 hours.

In total, the process of applying and surface treatment takes a little more than two days. To speed up this process, professionals use a mechanical crumbing machine - this is a small container with a nozzle at the bottom, a nozzle, a special nozzle, which is connected to a compressor. The hole from which the marble solution is sprayed has a diameter of about 6 mm.

After the preparatory measures in the tank pnevmokovsha pour the plaster mixture and proceed to the application. The nozzle should be at a distance of about 50 cm.Processing is done from top to bottom, carefully observing the same layer on the entire surface. The mechanical process ends in the same way as the manual one.

In order to finish the process of finishing the room as comfortably and correctly as possible, you should follow the basic tips provided by repair professionals.

Tips and tricks

The above is the most commonly used method for applying marble plaster. There are still some nuances related to the result that must be obtained at the end of the process:

- Plaster with a large marble crumb is applied with a grater of stainless steel. It uses the effect of "wet on wet": not letting one layer dry, the second is applied on top. Only half an hour later you can begin to grout, as in the standard application scheme.

- You can lay the plaster with some intervals between the processed pieces, and you can do a little overlap. However, it should be remembered that a greater number of strokes and layers will make the result more refined and close to the appearance of a natural stone. Between coats, grout periods must also be observed.

- Sometimes it is customary to use wax as a finishing layer - it gives the surface a silky shine. Possessing protective properties, the wax layer will eliminate the ingress of dust particles inside the marble coating.

- The use of proven and well-known manufacturers will save from buying poor-quality material.

In the issue of care marble plaster is completely unpretentious material, but only if it was covered with a finishing layer: varnish or wax. If the finishing material itself turned out to be finite, then such a coating will require proper treatment, just like natural marble, and this material is afraid of harsh cleaning products and coloring liquids. To wash the surface treated with marble plaster, you can use a mild soap solution.

Environmental conditions are very important when applying this material to walls. It is necessary to observe air temperature from +5 to +20 degrees, as well as humidity - not higher than 65%. These indicators are required even during the drying of the surface.

When performing work on a sunny day, it is necessary to do everything possible to cover the wall where the marble plaster will be applied,since the sun's rays will lead to rapid drying and, as a result, cracking of the coating. All the tools and the container in which the solution was mixed, must be washed immediately, otherwise after drying, they will just have to be thrown away.

As for the material consumption, it directly depends on the size of the marble chips in the composition of the plaster. For example, a fine-grained mixture is consumed in the amount of 1.5-2 kg per 1 m2. Material with medium grains of marble consumes from 2.5 to 3 kg per 1 square meter. m. And finally, large inclusions of the noble stone increase the coating consumption to 5 kg per unit of measurement. The layer at the same time should always be 2-2.5 times the size of marble chips.

Style and design

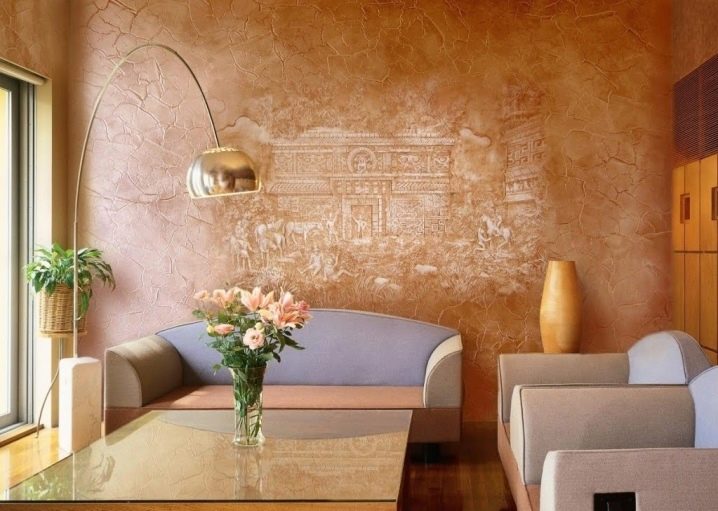

Imitation masonry is used in the interior quite often. You can find many options for finishing the basement and facade of the building. Marble plaster is used to transform a bathroom, living room, kitchen, dining room or terrace. Much less often such a finishing material is applied in living rooms.

The colors that are currently available on the building materials market delight the eye with their diversity. Marble drawing is a mixture of three shades, the most saturated is taken as a basis, to which colors in the same range are mixed, but already paler.Mixtures of all possible colors are on sale, including white, emerald, red, brown and other shades.

A separate topic is the original technique of applying marble plaster in two or three different colors. The most difficult, but also the most exciting is the process of laying material in the form of a certain pattern. Step by step it can be described as follows:

- The picture prepared in advance is pasted on the wall. This can be done with masking tape, which is a very important companion of surface treatment with marble plaster.

- The first layer of background material is applied around the image.

- After 30 minutes, the layer is smoothed, the picture is taken.

- The contour is pasted - stencil of the picture on the background.

- Apply a layer of plaster of a different color to the stencil where the picture was located before.

- The layer is aligned again after half an hour, and the stencil is removed.

Oracal self-adhesive film can also be used as a stencil, which can be easily removed and leaves no traces on the surface.

Famous manufacturers and reviews

The leaders in the production of marble plaster are Bayramix, Granulum and Ceresit. There is unanimity among buyers: any mixture with the use of stone chips costs quite a lot, and the application requires the hands of a professional or his support. This is the biggest drawback that is constantly under discussion. Among the advantages distinguish strength, durability, beautiful and noble appearance.

One of the best manufacturers users call "Bayramiks", in second place "Granulum" and on the third honorary - "Ceresite".

For how to apply marbled plaster, see the following video.