Knauf gypsum plaster: properties and applications

The manufacturer from Germany Knauf has long been producing high-quality plaster. Particularly popular among consumers are gypsum plaster compositions from this company. Knauf materials vary in sensitivity to moisture, density, and other parameters that need to be paid attention to when choosing a suitable gypsum plaster.

Advantages and disadvantages

In the plaster plaster compositions Knauf is mineral additives, significantly increasing the service life of the coating. Due to the composition of such materials on coatings, there are usually no even minor defects (depressions, roughness). Knauf plaster is very easy to use: even people who have never had to deal with this kind of work can finish. However, you will need to first understand its intricacies.

There are also other important advantages of such plaster compositions:

- Versatility. Knauf gypsum plaster can be used for plasterboard, cement, brick, concrete foundations. However, before using such a material, in any case, you will need to make sure that the surface is sufficiently strong. Using the plaster composition from this manufacturer, you can create a finishing layer, draft screed. You can significantly simplify the construction process. The coating can be quite thick - about 5 cm.

- This plaster can be used before pasting wallpaper. The base should be as smooth as possible. There should not be any defects and textures. Knauf plaster composition allows to achieve just such a result.

However, these plasters have some disadvantages:

- Pretty high price. However, this deficiency is compensated by the excellent quality of Knauf products.

- Shrinkage. Sometimes it has almost no effect on the coating, but in some cases it begins to crack, deform. Some consumers believe that the manufacturer is to blame, but it should be borne in mind that such defects often arise due to ignoring the rules of preparation and application of the material.Knauf plaster shrinkage is usually minimal. In some cases, external factors affect the condition of the coating: when using a plaster composition, a variety of nuances should be taken into account.

Species

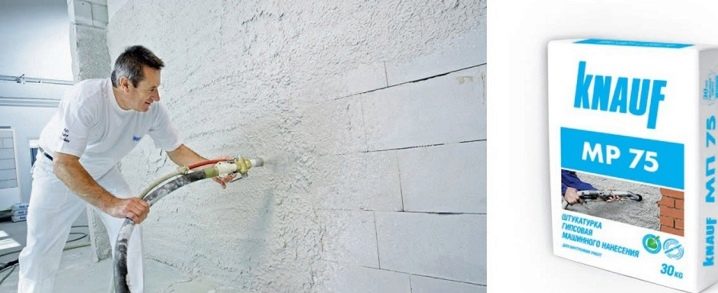

Knauf gypsum-based plasters differ in the method of application. Plaster material can be designed for machine or manual use. If to use machine, then it differs in the minimum expense and speed of putting plaster. The layer in such cases most often turns out to be quite thin (from 1 to 2 cm). Some put the machine plaster compositions by hand, but usually it is not very convenient: under the spatula such material begins to spread and gutter.

Knauf MP75 is a plastering material for machine use. The coating is very smooth, it is characterized by increased resistance to fluid. Such a composition can be used for application to old plaster, wood, plasterboard surfaces. Other Knauf plasters are applied manually.

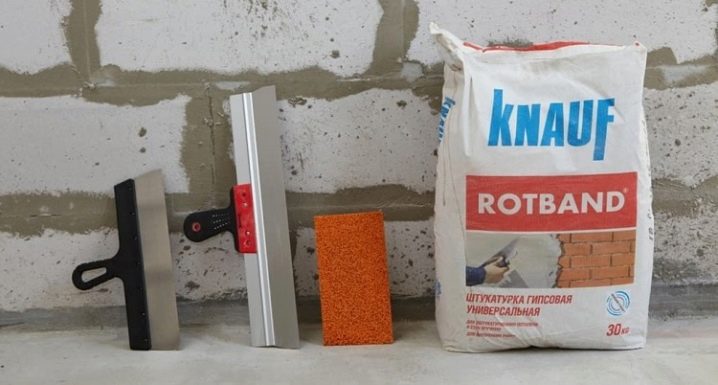

Rotband is Knauf’s most popular gypsum plaster. This composition is universal, it is applied to the ceilings and walls.It can be used in rooms where the humidity is quite high, for example, in kitchens, in bathrooms. Such coatings are intended only for interior decorating.

The main advantages of Rotband plasters are fire safety, environmental friendliness, vapor permeability. This material is actually a putty and plaster at the same time. Rotband plaster coatings are pink, gray, white. The shelf life of such materials is six months in undamaged packaging (as with many plaster plasters).

Goldband is a plastering compound that is also in high demand, but it is not universal. Goldband plaster can be applied only on surfaces that are hard, for example, on brick, concrete. It is suitable exclusively for walls. With this coating you can make a smooth surface on which there are quite significant irregularities. However, it is not recommended to apply a layer thicker than 5 cm, otherwise defects may appear on the coating. The color of this plaster can also be pink, gray or white. Goldband compounds are cheaper than Rotband.

Start - this plaster is used to make the bases more even before further processing.. Finishing work is carried out manually, but there is a kind of plaster composition, which is intended for machine use. This is MP75 plaster.

Surface preparation

First, determine the temperature in the room. In the implementation of finishing work, the temperature should be no more than +30 degrees and no less than +5 degrees, otherwise the coating is deformed. In this case, finishing work will need to be done again.

To make the coating as durable and durable as possible, it is necessary to remove dirt and dust from the base in advance. If there is an old plaster layer, it is also better to pre-clean it.

It will be necessary to remove metal elements from the surface (for example, screws, nails). On the wall can only be chipped and cracked, they should be filled with plaster.

The surface can be treated with a primer, which will allow the plaster to adhere better to the substrate. This is especially true for brick and foam concrete surfaces.

Solution

To prepare the solution, you must perform the following steps:

- pour the plaster into the prepared container, pour in the same liquid (approximately 0.5 l of water per 1 kg of dry plaster material);

- you must first examine the information specified in the instructions, because the proportions are sometimes indicated different;

- then it will be necessary to mix the material until it becomes homogeneous. This can be done with a drill with a nozzle or a construction mixer;

- then wait a few minutes, the plaster should stand for a while;

- mix the material again - and it will be ready for use.

It will be necessary to use the plaster for half an hour, then it will become unusable.

In order not to harm the plaster, do not mix it with any additional ingredients. If everything is done correctly, the quality of the mixture will be very high, even without various improvements.

How to apply?

Knauf plaster should be applied to the substrate in a single layer. So that a rather heavy material does not fall from the surface downwards, it will be necessary to carry out reinforcement. Applied plaster composition level using a rule. The plaster will begin to set in approximately 40 minutes. Then, using the trapezoidal rule, you need to remove excess plaster.

The rule may leave traces on the surface.To remove them, it is recommended to use a wide spatula.

Then the base will need to prepare for the final finish. It should be wet and wait: it should be matte. Then, in a circular motion, wipe the surface using a sponge grater. Then using a wide trowel to smooth out the coating. If the surface should be as flat as possible, then you should wait about 24 hours after finishing work and wet the coating. Then level it using a spatula.

Drying

In the room where the plaster dries, there should be no drafts, sudden temperature changes. Avoid direct sunlight. In order not to harm him, should not be accelerated drying. It is possible to ventilate the room approximately 24 hours after the finishing works. This will remove the fluid that is on the plaster. Knauf gypsum plaster usually dries for about seven days, in some cases it takes two weeks. This coating can dry for a long time in high humidity conditions.

For peculiarities of plaster on beacons using Knauf HP Start, see below.