Features of the gypsum mix

Dry gypsum mixes are quite popular type of finishing materials and are widely represented in the construction market. The popularity is due to the ideal ratio of price and quality, ease of preparation and use, as well as the wide availability of formulations.

Special features

Dry gypsum mixes are presented in the form of homogeneous bulk materials consisting of gypsum binder, fractionated filler, modification additives and pigments. In the role of a binder component is building gypsum, which is based on calcium sulfate hemihydrate.

For the manufacture of very strong mixtures to high-quality plaster add anhydrite. These two components are responsible for the working qualities of the composition, ensuring fast setting and high strength of the material. The brand of gypsum used for the manufacture of dry mixes is regulated by GOST 125 79, which allows changing the strength range of the component from 3 to 7 MPa.

Limestone and dolomite flour, ash, chalk or quartz sand are used as fractionated aggregate. These components significantly reduce the cost of composition and help prevent cracking of the frozen mixture during its operation. In the production of lightweight plaster, perlite is often used, and mica is added to the putty. The particle size of the dispersion components depends on the type of mixture, and ranges from 0.1 to 1.0 mm.

Modification additives are introduced into the material to improve its performance and ease of use. Thus, the addition of hydrated lime Ca (OH) 2, as well as the use of cellulose fibers, significantly increases the plastic properties and mobility of mixtures, provides good adhesion, and also significantly reduces shrinkage deformation and the risk of cracking.

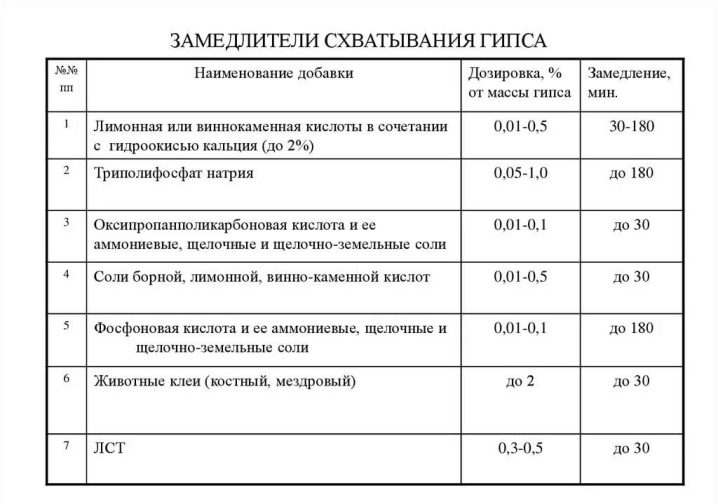

An important role is played by retarders. Their use significantly increases the survivability of the mixture, contributes to convenient application and makes it possible to adjust the formed layer.

If, despite the presence of additives, the gypsum mortar sets too quickly, add 10 to 20 grams of citric acid per 1 kg of dry mix. This will slow down the freezing composition for 30 minutes.

Advantages and disadvantages

High consumer demand for dry gypsum mixes is due to a number of positive properties of these compounds:

- A characteristic feature of gypsum mixtures is a large yield of the finished solution from a unit mass of dry product. This allows you to reduce the consumption of material by more than two times, in comparison, for example, with cement mortars. Thus, for plastering one square meter of surface, only 9 kg of gypsum plaster is required, while the consumption of cement for finishing the same section will be about 18 kg.

- The high plasticity of the solutions makes the process less complicated and time consuming, in comparison, for example, with cement compositions.

- The uniformity and smoothness of the formed layer allows you to immediately start applying a decorative coating.

- No shrinkage deformation.

- Excellent adhesive properties allow to perform plastering work without the use of reinforcing mesh. The exceptions are the walls of new buildings, in which shifts are possible, arising from the shrinkage of the new building.

- High sound and thermal insulation properties of dry mixes guarantee reliable protection of premises from cold and extraneous noise.

- The small weight of the walls covered with plaster, significantly reduces the load on the supporting structures of the building.

- The rapid speed of the initial setting and complete drying can be attributed to both the advantages and disadvantages of gypsum mixtures. The assessment of this quality depends on how professionally plastering or puttying works are done, as well as on how quickly it is necessary to complete the installation.

- Dry mixtures are environmentally safe and non-flammable, which allows them to be used in residential and public buildings without restriction.

- Gypsum materials are well ventilated and quite hygroscopic. This gives them the opportunity to release the accumulated moisture and reduces the risk of mold and fungus on the walls.

The disadvantages of dry gypsum mixtures include the impossibility of their use during outdoor work., as well as in rooms with humidity above 60%. Rapid setting of the composition can also be attributed to the disadvantages. To avoid premature hardening, it is necessary to dilute the mixture in small portions and use retarders, for example, a mixture of citric acid with polyphosphates and gelatin.Another disadvantage is the low strength of the plaster layer, which can be easily scratched or chipped. The price of gypsum mixtures is usually 15–20% higher than the cost of cement-sand compositions.

Kinds

Dry gypsum mixes are available in several versions, and differ in composition, purpose, location and cost.

On the modern market there is a huge selection of plastering, putty, mounting, troweling, as well as self-leveling compounds and adhesives.

- Plaster mixes are a very common type of dry formulations and are used in interior decoration. Gypsum-based plaster is very easy to use: the formed layer is not prone to slipping and cracking, the installation process is very simple and is possible for any person. The average daily output can reach 40 square meters of surface, which is a very good indicator and provides a significant reduction in repair time. Among the minuses of plaster there is a low resistance to moisture, which does not allow for work on the street.The disadvantages can be added and low frost-resistant properties of the material, as well as the rapid setting of the finished solution.

- Mounting mixes are used in the construction of internal partitions, during the lining of gypsum plasterboard or gypsum-fiber boards, as well as for the installation of the base when laying the floor of GFL. The material also does not tolerate high humidity and is not recommended for use when conducting outdoor work.

- Putty mixes are non-water-resistant dispersed compositions and are intended for finishing and leveling bases, for preparing plastered or concrete walls for painting, for facing and restoring household items, and for eliminating joints when finishing with GCL and GFL sheets. This light finishing putty has excellent adhesion, does not shrink and dries quickly.

- Gypsum-based glue is indispensable if gypsum plasterboard, tongue-and-groove slabs and gypsum plasterboard are used for installation. The material has low waterproof performance, so its scope is also limited to dry and warm rooms. To ensure high adhesion and increase the bonding strength, 12 hours before applying the adhesive, the surface should be thoroughly dust-free and primed.Only in this case, you can count on the reliability of the connection and its durability.

- Self-leveling mixtures are used as self-leveling floors and are characterized by high strength and a smooth surface. The material is easy to prepare and install, does not shrink and dries quickly.

- Zatirochny mixes are presented by fine dispersive structures and are intended for elimination of small defects of the working bases. The material has good adhesion, high ductility and low cost.

Scope of application

Dry gypsum mixes are widely used in construction and repair. With their help, leveling of floors and walls, gluing of tiles, elimination of gaps, chips and other base defects are made. Almost any surface can be plastered with plaster compositions: brickwork and clay walls, concrete bases and cellular foam concrete, gas and claydite concrete, and an old plastered wall. In addition to repair and construction works, gypsum compositions can also perform decorative fuction.

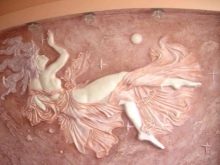

They are actively used in the manufacture of artificial stone, for the design of bottles and cans, interior decoration, the creation of stucco and bas-reliefs. The mixtures are irreplaceable in the construction of internal partitions, for the construction of which metal profiles and drywall are used.

With the help of mounting and troweling mixtures, it is possible to completely hide the inter-leaf gaps and achieve a perfectly flat and uniform surface.

Manufacturers

Dry gypsum mixtures are produced in many countries of the world.

The most famous and recognizable manufacturers are German concern. Knauf and the Russian companies "Volma" and "Miners". Knauf products account for about a third of the total dry mixes on the domestic market. The company is known to the Russian consumer since 1993 and produces the entire line of gypsum compounds, including plaster, grout, masonry mixes and adhesives. Every year the company's sales increase by 35%, which indicates the high quality and demand for German products. Production facilities of the company are located in more than 250 countries of the world, the production of mixtures is carried out on high-tech equipment with strict control over the quality of the trains.

Volma Company occupies an honorable second place in the construction market after Knauf, and is engaged in the production of putties, plasters, leveling, tile adhesives, assembly and self-leveling compounds.The company operates in 5 factories and owns three gypsum quarries. The "miners" are also well known to the Russian buyer. The company has four branches, 15 production lines, and is considered the largest producer of dry mixes in our country. No less popular are the products of the companies Gipsopolimer and Perel. Enterprises produce the entire range of gypsum mixes, characterized by high quality and low price.

Tips and tricks

Gypsum mixes are very easy to make. To do this, you need to take a container with a capacity of 20 liters and pour into it a powdered composition. Then pour the amount of water specified in the preparation recipe and mix the solution with the help of a construction mixer. If a small amount of the mixture is diluted, then mixing can be done by hand, using a trowel or trowel.

After the mixture has acquired a uniform consistency without lumps and clots, the solution should be left for 5 minutes and then re-mixed.

Before starting work surface should be carefully prepared. To do this, remove the mechanical debris from the base, clean it from dust, and, if necessary, degrease it.Then you want to cover the base of the primer and leave for some time. After complete drying of the primer, you can begin to work with a plaster composition.

Dry gypsum mixes are a versatile finishing material that allows you to quickly and efficiently repair the premises, eliminate defects in finishes and creatively decorate the interior.

For details on plastering the plaster mix, see below.