Stone-sand mixture: features and application

Construction of buildings and roads can not do without building mixtures. They can be natural or artificial, large or small, and contain various materials. Today we are interested in crushed stone-sand mixture, which has a natural origin and can be represented in various fractions. Further we will use the abbreviated name of this mixture - ShchPS.

What it is?

Under the abbreviation ShchPS implied mortar, which includes sand and gravel. Do not confuse it with rubble, which is produced from natural materials. These are two different building materials, unable to fully replace each other. Such a mixture is obtained in the process of mining granite / limestone, as well as as a result of their processing.

When natural material is being mined (granite, limestone), large elements are exported. The remaining fine material is transported to the crushing plant. At such factories, the material is cleared of dirt and impurities. The building mass is sorted and goes through the crushing stage. It is then passed through a sieve. The result is several varieties of the mixture.

The final product in its characteristics, composition and fractions must comply with the standards prescribed in GOST.

Fractions and their use

The mixture is obtained in the process of crushing the ore. Accordingly, the size of the components of thyroid trap can be different. Also in the mixture may contain different amounts of sand and rubble.

All these characteristics are very important, they determine the characteristics of the mixture and its purpose.

- A mixture of C1 corresponds to a fraction of from 0 to 40 mm. Used to create pillows in the field of construction of automotive paintings. Allows you to achieve the perfect surface.

- C2 is sieving 0–20 mm. The scope of use corresponds to that described for the previous version.

- By C3 is meant a large fractional sieving (0–120 mm). Used for arranging an additional layer during the construction of roads.

- C4 and C5 are the most sought after mixtures. Fractions are between 0–80 mm and 0–40 mm, respectively. Such ZHPS are used to strengthen the roadsides, are used in the construction of roads, regardless of their destination. Also used in the process of creating concrete slabs and panels.

- C6 is a mixture of rubble and sand, the maximum particle size is 20 mm. Required when creating pillows for the future road.

- C7 is crushed stone from 0 to 10 mm. Also used for decorating pillows.

- C8 is a very fine mixture obtained from rubble and screenings, which are formed in the process of crushing. The largest fraction of 5 mm. Such material is needed for the arrangement of the lower layer of the future highway.

- By C9 is meant a stone (maximum size 80 mm), diluted with sand. For the laying of such material is chosen the lowest layer of the road. Also used for the arrangement of roadsides.

- C10 consists of a stone of an average fraction (up to 40 mm). Used in the early stages of road construction.

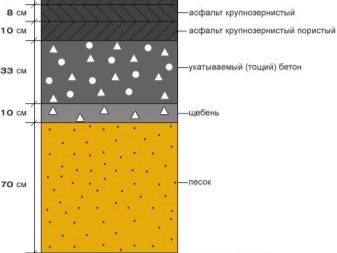

For the upper layer, a mixture of fine fraction is selected, and large crushed stone is relevant for laying the lower layers, which are also called pillows.There are mixtures in which crushed stone of different fraction is present. Such materials are called intermittent granulometry; they allow for dense tamping of stones in concrete.

Other important features

Not only the fraction and the ratio of the content of rubble and sand are characterized by schPS.

There are a number of other characteristics that must be considered when choosing a material.

Drainage properties are responsible for the ability to pass moisture. For example, for the curb and the arrangement of the inner layers, you need to choose a composition with good throughput. For the main and additional layers there are special requirements for the coefficient, which reflects the ability of the material to pass water. This indicator varies depending on the type of coating:

- for roads of various purposes, the coefficient is 1 m / day;

- layers with frost protection properties, which are part of the bases, require a coefficient of 0.2 m / day;

- for bases that are being built for airfields, the coefficient is 7 m / day.

- Plasticity is taken into account when laying the road and during its further operation.During installation, the composition should be well leveled as a result of the use of a mechanized method or manual exposure. When operating the road, the mixture should fit well to the base and not spread around the sides.

- Water resistance reflects the ability of a compound to absorb water and give it away. The main criterion is the minimum moisture saturation. Excessive moisture content in the composition will lead to base fluidity, a decrease in adhesion, a loss of stiffness and a decrease in strength.

- Volumetric indicators consist of two parameters: bulk density and bulk density. This information about SchPS makes it possible to make calculations regarding the volume shrinkage and the weight index of the material that will need to be used for the entire scope of work.

Common mistakes

The use of crushed-sand material is governed by a number of rules and requirements. If they are not respected, the end result will not live up to expectations.

Consider the most common mistakes that need to be avoided when working with XPS:

- laying is carried out on fertile soil, which is also called turf;

- dumping is done on loose soil that was not pre-compacted;

- laying of the composition is carried out on the soil with a high degree of humidity;

- the thickness of the coating varies over the entire working area;

- a small thickness of the rubble-sand layer, which is not enough to provide the object with the necessary strength;

- the absence on the slopes of braking special barriers that will hold the mixture;

- cement strengthening is carried out without compaction of the embankment and foundation;

- the use of crushed-sand composition with a high content of clay, dirt and other impurities.

If you do not allow such errors in the process of using SCHBS and choose a mixture of the correct fraction, then the resulting base will be strong, reliable and durable.

You will learn about how the gravelly-sandy foundation for the construction of the road is prepared from the video.