How to choose masonry mix for bricks?

In the process of building brick and stone walls or interior floors, a special masonry mix is always used to join individual elements into a monolith. For a structure to be reliable and durable, such a mixture must meet certain requirements, which are different for each type of material. The solution should not only be mixed, but also laid according to a certain technology.

Special features

Brick remains the most popular material for the construction of residential buildings for decades, so the most common type of masonry mix is brick. This is a special composition of dry substances, which when added to water form an elastic thick solution. Such a solution perfectly adheres to the surface of brick blocks and when dried it turns into a very hard and high-strength material.

Most often, the composition of most brick mixes includes the following components:

- the main component in the form of large grains of sand or expanded clay concrete;

- the solvent is almost always ordinary water;

- binder - cement or clay;

- various additional minerals that perform protective functions or added to increase the service life.

Sometimes pigments and dyes are added to dry mixes so that the color of the frozen composition matches the color of the brick from which the masonry is made. This increases the cost of the mixture itself, but allows you to exclude the subsequent decorative decoration of the erected house.

Kinds

Whatever the finished masonry solution, it always includes a dry mix and water. The main secret of high-quality masonry is their proper ratio and preparation. However, dry mixes may differ in their components and properties.

Dry

Conventionally, this type of mixture can be divided into general construction and special. The first are used for the construction of walls and partitions, the most commonly used types are M150 and M200, which one depends on the brand of cement included in their composition.Special dry mixes are used for the construction of objects with special conditions, for example, with high humidity (pools, baths) or high temperature (furnaces, pipes).

White

Such solutions are used for laying facing bricks or stones or for the restoration and restoration of old masonry joints. Such mixtures, in addition to traditional sand, cement and water, include lime milk and special additives to impart greater elasticity (plasticizers). The white mortar is stronger than usual and it retains water better, which is especially important for facing walls.

Cement sand

The most popular type of masonry mix used for work with both conventional silicate and ceramic bricks.

Cement

Cheaper composition, which is used both in private construction, and for the construction of multi-storey urban houses.

Cement-clay

Such compositions are used for low-rise construction. Clay should be thoroughly cleaned from various impurities and well crushed. Such a solution is used not too often due to its low ability to protect against water and the impossibility of building multi-storey structures.

Cement-lime

Like cement-sand, such a mixture is used with any kind of brick due to the high degree of adhesion and strength of the finished material.

Limescale

Such a solution in its properties resembles compositions with clay. It becomes brittle after drying, retains heat poorly and retains water. Such an inexpensive mixture is used only for one-story construction, most often of various outbuildings and garages.

You can add a separately purchased dye to any of these types of dry masonry mixtures or purchase an initially colored mixture. When laying the facing elements, the mixture that matches in color will be perfectly masked, and decorative grouting can be done with a contrast solution.

The most common compositions on the domestic market are masonry mixes of the brands PEREL, VK Plus. A and Linker Standard. In addition, there are many of their Asian and European counterparts. To choose the right manufacturer, it is enough to get acquainted with reviews in the network and price range of various products.

To choose the right kind of dry ready-made mixture, you need to consider some of the nuances.

- Masonry brick or stone in the summer and winter is carried out with different solutions.

- Carrying out underground work has a certain difference with the ground, and as a result requires different types of mixture.

- For a clinker brick, a separate special solution is needed, the usual ones in this case will not work.

- For the construction of the hearth or furnace in the composition of the masonry mixture in any case should not contain cement.

Consumption

To calculate the minimum amount of mortar required for laying walls and facing the finished structure, it is necessary to calculate the surface area minus all openings. After that, at the rate of a third of 1 m3 of solution per 1 m2 of the working area, the required amount is calculated.

Most often, the solution is kneaded using 1 part of cement, 3 parts of sifted sand and 1⁄2 parts of ordinary water. For different grades of cement, the amount of water may vary. For self-production of the M25 mix, you need to mix cement and sand in a ratio of 1 to 5, for M50 - 1 to 4, and for M75 - 1 to 3.

For beginners, it is most convenient to use standard mix consumption standards for different types of bricks, depending on the thickness of the masonry.

Masonry thickness | The amount of mortar for laying in one brick | The amount of mortar for laying a half bricks | The amount of mortar for laying in two bricks |

12 cm | 30 kg | 24 kg | 18 kg |

25 cm | 78 kg | 66 kg | 54 kg |

38 cm | 126 kg | 108 kg | 90 kg |

For beginners, it is most convenient to use standard mix consumption standards for different types of bricks, depending on the thickness of the masonry.

Scope of application

Depending on the type of brick masonry mixture, and its components, it can be used with various building materials and in various fields. Conventionally, they can be divided depending on the type and purpose of the finished structure. Compositions with cement are practically universal for both private and industrial construction. They are used for any masonry - in half brick, in one or two bricks.

Mixes with crushed clay will not withstand high-rise masonry, and therefore are used only in low-rise buildings, as well as a mixture with lime. Nevertheless, cement-lime composition can be used with both silicate brick and ceramic, which expands the scope of their application.

In addition to the usual mixtures used for the construction of walls and floors, there are solutions designed for certain works.In order to brick a furnace, or a chimney pipe for a large fireplace in a private house you cannot use ordinary cement mixtures or mixtures for lining, you need a special solution for high temperatures.

For example, thermal insulation compounds are required for special porous blocks of concrete and ceramics.. The composition of such a mixture includes aggregates of perlite or vermiculite, which reduce the density, thereby increasing the insulating properties of the composition. Thin-layer adhesives are used for the installation and lamination of foam concrete or gas silicate blocks.

The seam made with this solution prevents the formation of cold air bridges and protects the interior from heat loss.

Tips and tricks

Much depends on choosing the right mixture, but it is equally important to properly prepare and lay the solution itself.

First you need to prepare all the necessary tools:

- trowel (special paddle) for applying and equalizing the composition;

- level or plumb to check the horizontal and vertical walls;

- pickaxe;

- lacing to indicate horizontal masonry;

- piercing for finished seams;

- measuring tape;

- order, which is needed to control the height of the superimposed solution.

After the necessary tools have been acquired or rented, all the rubbish can be removed from the working site and the solution can be mixed. With a ready-made mixture, this is easy to do - you just need to strictly follow the manufacturer’s instructions on the package.

The very sequence of laying bricks is made according to the following algorithm.

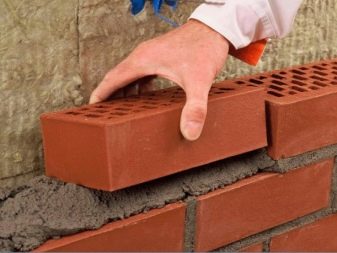

- Two bricks are placed in a triangle on the base of the foundation, the angle should be strictly equal to 90 degrees. The solution is applied on the bottom surface of the bricks and on the surface on which they are laid. It is good to lower the brick for a few seconds into the heated water before applying the mixture - this will increase the strength of the masonry and facilitate its construction. On the foundation or the previous brick row, the mortar is equal to the fingers, and on the brick a trowel. To minimize the thickness of the seams, the brick laid on the mortar is well pressed, moving on and away from itself.

- Repeat the operation with two more elements, then install two bricks of the second row on those that are in the bottom. The upper bricks must overlap the lower ones by one half.Excess mortar is immediately removed with a spatula and used for application to the following bricks.

- As soon as the corner section is raised to the height of the three elements, it is necessary to carry out similar actions on all the remaining corners. Be sure to stretch the lacing every five meters and apply the ordering to control the strict horizontal rows.

- Brick is laid out in rows in one or two, depending on the type of masonry, connecting with erected corner structures. If the masonry works are carried out for the first time, it is necessary to check the correctness of laying literally every brick. For professional builders, it is enough to check the horizontal and vertical of one or two stacked rows. Since the laying process itself is not very fast, and time for quality testing is added to it, you should not dilute a large amount of the solution at once. It will begin to harden and seize already in the container, and it is not recommended to dilute it again by adding water.

Summing up, it can be noted: whatever solution is used for laying bricks - commercial mix or cement with sand mixed independently - it is important to follow all recommendations for its dilution and use.Qualitatively prepared composition will provide the brickwork with high strength and durability even in the hands of a novice builder.

How to prepare a masonry mix for bricks, see the following video.