How to choose the attic hatch?

Attic space is a convenient and necessary element of any private house. It is an excellent place to store work tools, various building and household materials, long-term storage products, as well as space for arranging a cozy living room.

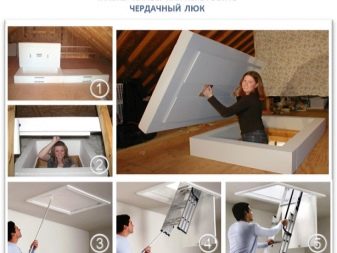

If there is an attic, there must be an attic hatch. Its construction is a business that requires investments and certain knowledge.

Special features

The design of the attic hatch must be reliable, simple and safe to use. When installing the hatch, it is important to consider a number of important nuances: the slope of the roof, the location of the floors and beams, the joints of the ceiling concrete slabs.

It is best to install the door inside the dwelling.. It is cheaper and safer, since this option does not require the construction of a large capital stairs,which can be used by unauthorized persons when attempting to get inside the house from the street. It is also an element of security, because the access hatch at the same time fulfills the fire protection role.

The attic hatch should provide a vapor barrier of residential premises (the property of protecting elements of the house and roof construction from ingress of moisture and preventing condensation, in the form of water vapor inside the insulation) and protecting the residential area from the penetration of rodents, large insects and other inhabitants of attics. Also the staircase leading from the attic should go out into the free space of the living space of the house, not blocking the passage inside.

If the attic is not heated, the insulation seems to be quite useful. Separately, it is necessary to designate fire prevention functions - the ability to prevent the spread of fire and smoke from the lower floors of the house in case of a fire. And finally, the last important detail that should be paid attention to is the appearance design.

Kinds

Attic hatches differ in the production material and in the type of opening (upper and lower).The main materials used in the manufacture of hatches are wood and metal. Metal hatches are reliable and durable, but require additional thermal insulation, and are quite heavy, which makes them potentially more traumatic when opening or closing.

Wooden - light, well-preserving heat and attractive from an aesthetic point of view. In addition, wooden hatches are easier to manufacture.

Therefore, it is most preferable to use wood.

When planning the design of the hatch, the choice of the type of ladder also occupies an important place.

Stairs are of the following types:

- addi - these are the simplest and cheapest;

- retractable ladders fold like an accordion;

- folding - presented in the form of a book;

- telescopic - are the most compact and ergonomic, their structural elements tend to fold into each other (like a “stepladder”).

In preparation for the installation and assembly of the elements of the attic hatch it is necessary to take into account that the weight of the stairs must be maintained by an attic door. Otherwise it is fraught with breakdowns and injury. Also, a quality attic ladder should be equipped with a framing device that serves as an additional support, reducing the likelihood of accidental fall and serious injury. Sliding hatch can be mounted on the surface of the drywall.

Folding attic stairs consist of several elements or sections. When folded, the staircase has the appearance of a compact unit built into the hatch door. Ladders must be provided with anti-skid pads or notches.which are designed to ensure safety in use. It is best to choose insulated lifting attic hatch concealed installation.

To exit the ceiling cold option is not suitable, because it will lose a lot of heat.

Materials and tools

Attic door consists of two main parts - the box (box) and door (cover). The main supporting element is the box. It is made of the most durable wood species: oak, birch, larch, aspen.

When making a box yourself, the easiest way is to use a wooden bar.Working with him does not require a high level of skill of the performer and the use of complex tools. But also for the manufacture of the frame suitable boards size 25-30 mm. It is this thickness that can be considered optimal for providing the required strength.

Standard box size is 120x60 cm. The options are square execution. In general, the choice of geometric shapes and sizes is based on the individual preferences of the owners of the house.

The box consists of four parts, fastened together at a 90-degree angle with wood glue, self-tapping screws or nails.

Some experts recommend making a notch in the upper part of the timber for planting the cover, while others indicate the advisability of installing additional support boards.

The choice remains for the performer of work.

Similar rules apply to the manufacture of the door. The simplest model of the design of the manhole cover is a frame, lined with boards and made of timber with a section of 20x40 mm, with an insulating material located inside. The assembled lid is reinforced with a cross barand then sheathed on the reverse side with plywood or fiberboard. As a heater can be used vapor barrier film with polystyrene foam or mineral wool.

Additionally, a door handle and an adjusting device can be installed. The lid is attached to the box with the most common hinges and screws, and at the junction of the door and the box around the perimeter is glued rubber sealing material.

The list of basic tools required includes the following:

- scrap;

- sledgehammer;

- perforator;

- electric drill;

- angle grinder ("grinder");

- set of screwdrivers;

- hacksaw for wood;

- measuring instruments (building ruler, measuring tape).

How to do it yourself?

Any construction work begins with drawings and careful measurements. The next step is to choose the installation site. Rules for the location of the attic hatch in wooden and concrete structures are different.

In the wooden house, the doorway is made between the beams, in the concrete - at the joining of the plates.

Arrangement of the opening in a concrete house is more difficult and in several stages:

- First, a diagram is drawn on the floor, in the place of the intended placement of the hatch (it is important to consider that the size of the opening must exceed the dimensions of the hatch by a distance of at least 5 cm).

- Through holes are drilled in the corners of the outlined square or rectangle.

- Further, an angle grinder along the intended perimeter cuts are made.

- Then at a distance of 15–20 cm from each other, additional holes are drilled at the cut points.

- The blows of the sledgehammer remove concrete and reinforcement with obligatory cleaning of uneven surfaces and drilling in the front part of the technological holes opening (for fixing the box).

- The installation process of the attic hatch begins with the installation and mounting box. Fastening is performed using driven anchors. In a wooden house, the use of anchors is optional; instead, you can use large screws or nails.

- After installing the box installation of the door hinges. Of all the known types when installing heavy and massive doors use straight hinges of the surface type - these are the most reliable and inexpensive of all. The installation process is the same as on ordinary doors. The choice of locking side loops is private.

- The final stage is the simplest - it is the installation of the hatch cover, which is made using self-tapping screws.

Special mention deserves the need for laying vapor barrier materials. This type of work is necessary if the attic is not heated. This is very important, because if the temperature difference between the residential and attic zones exceeds 5 degrees, then all the moisture contained in the warm air and blown up will fall out in the form of condensate, accumulating on the inner walls of the intra roofing rooms and insulation materials. Besides, the use of heaters and steam insulators contributes to the improvement of the sound insulation properties of the room.

As a vapor barrier material used conventional polyethylene or polypropylene films. After installation, the material is fixed (with strips or “sits down” on the glue) on both sides of the body of the manhole cover — the lower and upper.

The most common thermal insulation materials are mineral wool and polystyrene foam.

Mineral wool consists of fibers obtained from the deep processing of molten rock and metallurgical wastes. It is a quality, having good thermal insulation properties of insulation.

In addition, a very important advantage is its fire resistance. Mineral wool does not burn, because it is made of non-combustible alloys. It does not start rodents, fungus and insects. Its fibers are not subject to deformation, over time it does not decrease in volume. Mineral wool does not have moisture accumulation properties, the degree of absorption does not exceed 0.5%. It is characterized by good sound-absorbing properties, does not cause chemical destruction of metals (corrosion).

Mineral wool is transportable and environmentally friendly, has a long service life.

Expanded polystyrene or mineral wool is always placed on top of the vapor barrier film (also on both sides). In the process of working with insulating materials it is necessary to use respirators in order to avoid the smallest particles entering the airways. The overlap should be with warming. While raising the hatch, warm air should also not escape.

Among the "final touches" can be attributed to the installation of accessories, namely:

- door handles;

- closing mechanism (latches, latch, bolts, locks, bolt);

- an adjusting device (hydraulic, equipped with hydraulic cylinders or counterweight), designed for smooth and easy opening and closing of the hatch door and entrance.

Such a finish should be of high quality. As an alternative door handles can be replaced with a rope opening system. It is very convenient to use for people with disabilities, as well as for children and women. The rope should be tightly fixed with the wall ring, ensuring the fixed position of the hatch door.

Tips and tricks

The construction of the attic hatch in principle is not a complex type of construction work. But in order to save time and effort, as well as for people far from the construction business, it is more expedient to purchase finished products, entrusting the build quality to professionals.

Installation of finished hatches does not require special skills. In addition, factory products are more accurate fitting parts and structural elements, and is also more attractive (compared with many home-made samples).

Experts advise to adhere to the following recommendations:

- Manufacturer's warranty protects against unforeseen expenses;

- among all the available wood types, larch possesses the best strength characteristics;

- when building the attic hatch cover, it is most convenient to use the remnants of material left over from cutting out the opening, which will help to save;

- In the process of choosing the location of the opening, it is important to expect that in the future, when going up, do not hit your head against the internal elements of the roof;

- when working in a concrete room, the opening must be reinforced with metal corners;

- the treatment of wooden structures with an antiseptic (anti-putty agent) increases the service life of the attic hatch;

- if the attic hatch to perform the function of fire, then it is better to place the hinges on the reverse side so that the lid opens upwards;

- Fire hatches, as a rule, are made of high-strength metal, to which certain requirements are imposed. Wood can also be used, but with mandatory post-treatment of the surface with flame retardant varnishes (biopyrene and antiseptic);

- a fireproof attic hatch, which has an electric drive, must have a minimum number of gaps, and all existing ones must be filled with refractory materials.

You can learn how to make an attic door with your own hands by watching the video a little lower.