Features attic floor

The attic in the view of most people - an ordinary, secondary part of the house, causing only indirect interest. But in fact, this is a very important area of any home, and the comfort of people living in it depends on how it is made. Such an element is even more important if it is equipped with a residential attic.

Special features

Attic space is a predominantly infrastructure facility that completes the structure. There can be placed technological equipment, engineering networks of various types. Between the residential and auxiliary parts of the building, the temperature difference cannot be more than 4 degrees. It follows that the overlap must be thoroughly warmed and consist of many layers.

Materials

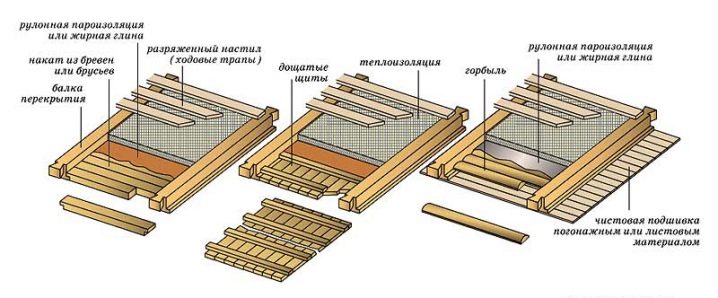

For laying the attic floor on wooden beams should be used:

- roll forward or board of boards;

- vapor barrier layer and the ventilation gap in front of the insulation;

- ventilation and vapor barrier after insulation;

- facial floor.

A large part of houses and other buildings are made of aerated concrete, since it effectively retains heat. The only problem is that the plates of this material are able to crack if an excessive load is applied to them. Therefore, in any aerated concrete house the optimal material for the attic floor is wood. A prerequisite for success will be a thorough impregnation of the material by means of preventing fire and soaking the wood.

Most often beams do not exceed 40 cm in height and 20 cm in width, their length varies from 5 to 15 m.

Beam structures are made of metal or wood, using boards, plywood or oriented plates. Occasionally, reinforced concrete slabs of various configurations and prefabricated elements with monolithic details are used. Choose a specific type of overlap should be given:

- seismic hazard;

- scale spans;

- number of floors;

- severity of load vertically.

In a brick house, the load carried by the walls will be higher. Therefore, a variety of permissible materials increases, provided that they support the stability and stability of the roof.Nevertheless, most developers prefer wooden structures, because they are the cheapest and do not require high professional knowledge. The basic requirements for the processing of material are similar. The most popular is with rectangular beams with a thickness of 150x100 mm.

Solid beam elements are limited to the length of the span; therefore, they cannot be longer than 500 cm. Glued laminated timber is sometimes three times longer, replacing it with boards that, when joined, are placed on an edge. Occasionally used rounded timber or I-beam construction. In brick buildings can be mounted metal beams based on:

- double tee;

- channel;

- corner.

This solution is very attractive, because the metal elements are relatively thin, while mechanically strong and serve for a very long time. In addition, the steel does not burn, and with proper processing will be immune to even corrosion.

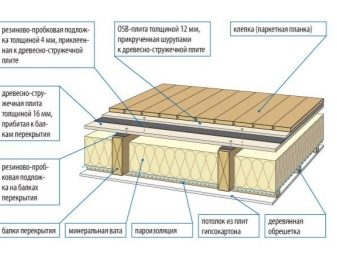

The frame house also has its own nuances of creating an attic floor. If a residential attic is equipped above it, there is no need for waterproofing, but it is required to prepare a high-quality vapor barrier.Under attics that are not heated, they use much more insulating coatings, arrange them in a special way and maximize thermal protection. Under the residential heated premises, the lags and the front floor are separated by a rubber or cork substrate to maximize sound insulation.

When using two layers of overlap, they also need to distinguish between sound insulation layer.

An unheated attic in a frame house is equipped with a waterproofing top. It is better to refuse ruberoid inside any dwelling, because it is a strong carcinogen.

Attic flooring in a house built of vulture panels can be made using the same technology or in the form of a familiar wooden frame. The second option is better in sound-insulating qualities, and panels - in keeping heat. Beams are produced from massive timber, dried in special chambers, which is then cut to the nominal size with modern equipment. It is desirable that parts of the ceiling should be delivered to the construction site already cut according to the project.

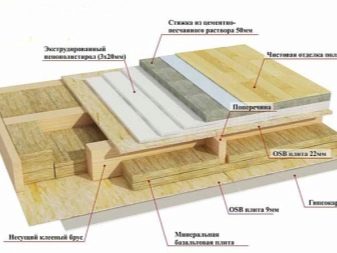

The overlaps are made of 22.4 cm thick vulture panels, although if desired, the client can use thinner ones — 17.4 cm. There are a number of subtleties in foam concrete houses, in which the attic can rest on the structures of:

- wood;

- concrete;

- metal;

- reinforced concrete.

Mandatory requirement is resilience to constant and periodic load, with no less significant retention of heat and ensuring dryness, maintaining an optimal level of sound insulation.

Foam blocks themselves can also be used to form the floor, as they are environmentally safe, well tolerate the effect of fire and are relatively inexpensive.

Part of the attic "cake" often includes a film that provides vapor insulation. But the most advanced solution is foiled materials, which simultaneously provide heat retention. Only on top of the vapor barrier can you attach the facial finish layer.

Device design

The overlap under the attic, which is at the same time the second floor in the house, necessarily has increased strength and must carry considerable loads. SNIP dictates a certain section of the beams used or the width of the panels, their pitch. The weight of the products themselves and the magnitude of the external load are taken into account.

Sometimes a vault is created from an I-beam supplemented with wooden shelves and a wall of oriented plate. In the attic floors the space between the beams is filled with insulation and vapor barrier from the ceiling of the room. Warming of the perimeter is usually made of polystyrene foam.

The truss system must be rigid, because shear and thrust forces cannot deform the structure. Under the scheme, this device resembles a triangle. From all types of wood coniferous breeds of the highest grades with a maximum moisture content of 17% are best. It is recommended to avoid blanks containing knots and cracks. Solid deciduous trees are used for:

- runs;

- pillows;

- Mauerlatov.

The most complex knot is considered to be naturally truss trusses, which, along with the rafters, contain struts, braces and stretch marks. It is required to mount all these parts so that the load does not fall on the walls. According to the rules, only external walls can take this load, but even there the vector of application of force should be strictly vertical. The distance between trusses shown in the diagrams and drawings should be exactly as follows from the calculations.

The easiest way is to equip the roof system under a single-sided roof, inclined at an angle of 14 - 26 degrees.

In small houses with a span of a maximum of 5 m, wall-mounted rafters are used. Such a construction simultaneously relies on both external and internal walls (if any).

Waterproofing and heat insulation

Thermal engineering calculation is reasonably recognized as one of the most difficult moments in the design of residential buildings. This necessarily takes into account the requirements of sanitary and hygienic nature, providing the most comfortable conditions for life. A typical example of a cold attic “cake” includes:

- roofing;

- external external walls (in the case of a gable roof equipped with gables);

- proper attic overlap.

Insulation must be made even on a wooden base, not to mention the metal or reinforced concrete.

The variety of permissible insulation materials is very large, among them there are plates, rolls and bulk options. Loose materials are considered the least practical, therefore it is better to use monolithic structures.

In order to properly make attic insulation, the need for insulation is determined according to the calculated winter temperature. You can find it in the SNIP section on building climatology, or in the climate map of a specific region of the country. Ventilated rooms are best insulated with soft or moderately hard heat insulators.

Waterproofing of a cold roof causes many problems, therefore, no professional will give a universal answer whether it is needed. In attention should be taken as the material and the level of the slope of the roof. It is advisable to place membranes with a high level of diffusion under the flat metal roof, which will reliably block the penetration of snow or raindrops.

Under the slate, the waterproofing layer is not always needed if the surface is intact, but it is better to mount it, in order to avoid flooding in the event of a leak in the coating.

Tips and tricks

Coniferous beams, which are significantly cheaper than concrete products, have the lowest weight. The ease of construction allows you to mount it without the use of construction cranes and formwork.The maximum permissible moisture content of a tree is 20%, and in the case of glued beams, this figure does not exceed 15%. But there is one more limitation: wooden beams are economically justified only with a span of 420 cm or less, that is, when elements are installed on transverse walls. If the length increases, the cross sections become too large.

The edges of the beams start deafly into the outer walls, the size of the recess - 150-180 mm. The gap from the inner walls to the beams should be 20-30 mm.

For information on how to calculate a hardwood floor, see the following video.