How to insulate the ceiling from the attic in a private house?

Projects of modern country houses often involve the use of premises under the roof (attic) as living rooms. In this case, a construction with the name “warm roof” is used, in which the slopes of the roof are insulated. Such insulation is thought out at the design stage, so in the future the attic room can be operated all year round. But if the country house was built ten or even twenty years ago, then high-quality thermal insulation may be absent. It also happens that a homeowner chose a “cold roof” for reasons of economy or construction features (for example,because of the need to install a lightweight roof structure).

Special features

So, first you need to decide on the side of ceiling ceilings, which you will insulate. At once, we say that there are no specific rules or strict instructions - you can insulate the ceiling from any side. There are even options for the insulation of ceilings from one side and the other. However, if the height of the rooms in the house is small, then it is better to carry out insulation work from the attic side. Correctly choose the finish from the attic also in the case when the house has already been renovated, and there is no desire to re-work the finish.

Of course, if the house is being renovated, in which it was decided to install a panel or slatted ceiling, it makes sense to simultaneously lay the most suitable insulation material between the base ceiling and the new ceiling. In all other cases, the owners of private homes prefer to arrange a thermal barrier in the attic.

The main advantages of warming houses with cold ramps are:

- almost all thermal insulation materials have a noise reduction effect, so the noise of rain, wind, or a nearby road will not be heard;

- insulation will protect the house not only from the cold, but also from the heat.

Materials

When comparing materials for warming cold-type floors, we are faced with the following problem - they are all very different in their characteristics, starting from the price and ending with the degree of environmental friendliness. Therefore, unequivocally call some kind of insulation "good", and some - "bad", we can not. In order to get the most complete picture of modern materials for thermal insulation, let us consider in detail each group.

So, the owner of a country house will have to make a choice between the following materials:

- Minvata or mineral wool refers to the group of fibrous insulation. Most often made of fiberglass or basalt fiber.

- Ecowool Modern cellulose based insulation material.

- Group of polymer insulation. Polyfoam, polyurethane, expanded polystyrene.

- Loose insulation - expanded clay, vermiculite.

- Natural traditional materials - chips, dry leaves and reeds, straw, sawdust, needles. Can be used together with clay.

Let's talk more about each group.

Mineral wool

The production method of mineral wool is the same for all the minerals from which it is made - melting, splitting into fibers and bonding fibers with a sticky substance.Melting glass will eventually give glass wool, slag - slag wool, basalt - basalt fiber. Basalt fiber in this group is the highest quality and safe for human health.

Slabs, mats and rolls of mineral wool are characterized by excellent technological characteristics. These are non-combustible and low-combustible porous materials with a density from 35 to 100 kg / m3. The most dense - mats, they can even plaster.

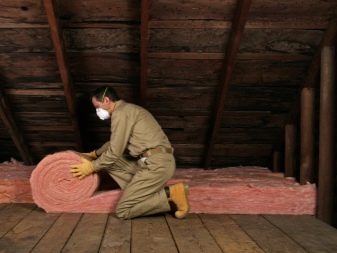

To insulate the attic space, it is sufficient to use mineral wool of medium and low density, sold in rolls.

The cost of this material is low, it is cheaper than most polymer insulators. In addition, the mineral wool is extremely rarely attacked by rodents, and the tree under the plates of the mineral wool does not rot. The drawbacks to pay attention to are the ability to pass moisture and health insecurity. Thus, even water vapors are able to deprive the mineral wool of its insulating qualities, however, after drying, the properties of the material will be restored.

By the way, the ability of mineral wool to retain heat depends on the density index. The average density is 0.045 W / ms, which is quite enough for high-quality insulation of the house, in which you can live in the winter time.

Fiberglass should be used exclusively for insulating ceilings from the attic, and stone fiber can be used inside the house.

Polymer insulation

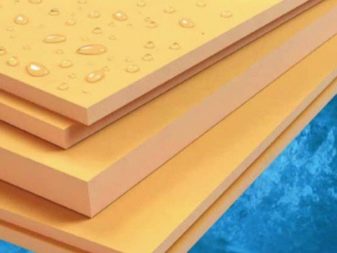

Traditional foam and modern foam (extruded polystyrene) are used as insulators very widely. Cost - affordable, insulating quality - good. The only serious drawback of polystyrene is its flammability and toxicity of the substance released during the fire, which is why in many countries it is forbidden to use foam plastic for thermal insulation.

Penoplex is a modern material, therefore it does not have such disadvantages as polystyrene. Even when burning, it is prone to self-extinguishing, which makes it particularly attractive when choosing insulation for wooden buildings. Moisture and bacteria also will not cause any damage to Penoplex - it is a durable and durable material that allows it to be used even when warming basement premises.

The more difficult (and colder) climatic conditions, the greater must be the layer of the foam complex. So, for cold regions the layer should not be less than 10 centimeters.

Sprayed insulation

Ecowool and polyurethane foam belong to a new type of insulation - sprayable. Both heat-insulating materials are placed on the heat-insulated surface by sputtering, but sometimes the ecowool is simply dropped between the lags of floors and tamped. Ecowool is made from cellulose, and polyurethane foam is a polymer and is similar to regular polyurethane foam.

Despite the fact that for the application of sprayed insulation requires special equipment (and the cost of its considerable and the acquisition for a single use will be unjustified), many owners of country houses choose it. Why? Certainly, because it is a seamless material, which means that the appearance of cracks or cavities, through which cold air can enter the room, is excluded.

By the way, the heat-insulating characteristics of sprayed insulants are about 1.5 times higher than those of foam plastic and mineral wool. The disadvantages of polyurethane foam include the need for protection from ultraviolet radiation, as it is destroyed under the influence of sunlight.

Loose insulation

Loose heat insulators remain popular for many decades, as they can fill a variety of spaces.Bulk materials are made from waste cellulose, glass and other post-industrial materials - vermiculite, perlite, polystyrene. Loose heat insulators are quite diverse, but the first place today, of course, expanded clay. Large, medium and small granules of expanded clay are made of ordinary clay, do not burn and have no smell. If you choose clay as a heater, give preference to large porous granules - they retain heat best.

In bulk insulators mass advantages:

- ecologically safe;

- fire resistant;

- unattractive to insects and rodents.

Loose insulators are not afraid of high humidity, granules do not crumble and do not split. Despite the fact that these insulation pass steam well, floors do not dampen, since the special structure of materials provides excellent ventilation. Bulk materials have one drawback, which needs to be mentioned - it is necessary to construct an additional partition to cover the insulation between the wall and the lining. With the floor and ceiling, the situation is somewhat simpler - the pellets can be filled into the space between the lags of the draft and the main floor,and when insulating from the attic, you can not close the loose insulation with nothing, if the room will not be used as residential.

Natural heat insulators

For centuries, our ancestors used natural materials such as sawdust and shavings, reeds, hay, fir branches, cones, leaves, and even dry algae to warm the home. The choice of insulation depended on what a suitable material was more in the area. By the way, if there are woodworking enterprises in your region of residence, you can get sawdust and shavings for just a penny or even for free, because such companies themselves often seek to get rid of waste products.

Unfortunately, all natural heat insulators (except for clay) can easily and quickly catch fire. In addition, rodents often settle in natural heat insulators.

Insulation thickness

Remember that whatever material for the insulation of the ceiling you choose, the effectiveness of the work will depend on the correct thickness of the insulation layer. Also, regardless of the type of insulation, it is recommended to remove all electrical cables in special insulation tubes. When building a new house, calculations are performed by designers and allow to take into account the thermal conductivity of all building materials. Such calculations will be the most accurate, but we use simpler methods for warming an ordinary country house.

So, it is known that the thickness of the interlayer of chips or sawdust for regions where the temperature in winter drops no more than -15 ° C is enough for a layer of 5-6 cm. If the temperature drops to -25 ° C, the layer thickness increases to 8-10 centimeters.

For other heaters, it is best to use the formula that allows you to determine its thickness with approximate accuracy. To do this, you need to know the thermal conductivity of the material (often it is indicated on the packaging of the material or certification documents and is indicated by the indicator W / ms). Next, find out the indicator of minimum overlap resistance for your region (m2С / W) - information about this indicator can be obtained on the Internet or in any large construction store from a specialist consultant. Now you can calculate the thickness of the insulation by multiplying this figure by the declared thermal conductivity of the insulation.

For example, for the Moscow region insulators should provide heat transfer resistance of 4.15 m2С / W. Suppose a foam was chosen as a heater, its thermal conductivity is 0.04 W / ms. Multiply the indicators: 4.15 x 0.04 = 0.166 m (or 170 mm). According to this formula, it is clear that the thinnest layer will be polyurethane, and the thickest - expanded clay.

Laying technology

Warming the ceiling from the outer (cold) side is also popular because you can avoid thinking about problems with condensate - steam does not get into the thickness of the insulation, which means it cannot condense and cause mold to appear.

So, for proper warming it is necessary to perform the work in the following order:

- We attach the films to the beams with brackets or battens. You can simply arrange the film on the floor of the attic.

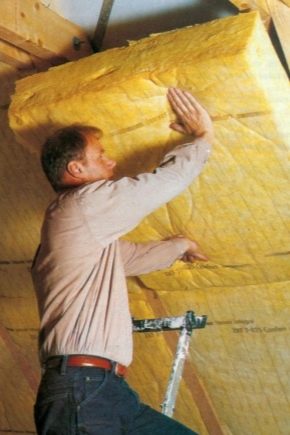

- We lay between the beams of the insulation plate or roll out the rolls. The insulation should not lie "waves" or puff up, so if it is wider than the rafters step, then the insulation should just be trimmed.

- The second and third layer are stacked as needed. The main thing when working with slabs is to stack them “in a hurry,” that is, with overlapping joints and beams.

- Soft roll materials do not need to be compacted, this can lead to a deterioration of thermal insulation properties.

- We cover with a diffuse membrane, and, if necessary, make a counter lattice.

Warming with claydite or sawdust is performed using a similar technology.

Useful tips

A lot of articles and even books have been written about the insulation of country houses. Before you begin to work, take advantage of the experience gained by the masters - read the special literature.

- The ceiling usually accounts for up to 15% of heat losses. If even after its warming the house remains cold, you should think about the correct warming of the walls and replacing the windows.

- Thermal insulation technologies suitable for country houses are also suitable for bath thermal insulation. Best of all have proven in this case, bulk insulation.

- Remember that if there are gaps in the ceiling, warm air will inevitably leave the room. Before starting the insulation work, evaluate the quality of the ceiling - perhaps it needs repair.

How to warm the attic with your own hands, see the following video: