Walls of plasterboard: the pros and cons

If it is necessary to build a wall, partition, arch or niche of plasterboard, then it is extremely important to know not only the technical aspects of the installation, but also the features of the material itself.

Special features

Drywall sheet is a light and flexible material with which you can quickly and easily transform an office, home or apartment. From this material it is possible both to build a wall, and to build an ornate interior construction.

The structure of the gypsum plasterboard (GCR) fully corresponds to the name: its core is made of gypsum with mineral pigments, to which the surface layer of cardboard is attached with glue.

The advantages of the material are well known to professional finishers. They are as follows:

- allow you to create a perfectly flat surface vertically and horizontally;

- allow to construct curvilinear structures, as well as individual elements of the most varied form and complexity;

- have good air permeability, promote air circulation and maintain a healthy microclimate in the room;

- soundproofed;

- characterized by high thermal insulation;

- made of environmentally friendly materials, do not cause allergies;

- fire-resistant, not prone to spontaneous combustion, do not sustain combustion and protect walls in the event of a fire;

- are lightweight;

- simple to install, do not require when facing professional skills and special equipment;

- the price of GCR and its consumables is affordable;

- the coating of this fiber is optimal for finishing any type (painting, plastering, wallpapering);

- leave little waste.

The use of gypsum board allows you to significantly reduce the time spent on finishing work, for example, you can build a plasterboard partition in a few hours, while the construction of a similar brick construction will require two or more days.

Like any building material, drywall has some drawbacks that significantly limit the scope of its use - panels do not have durability, they are destroyed by mechanical damage, and in addition, they absorb moisture.

Yes, and attach to such a coating something quite problematic - to keep on a picture or a bulky shelf can only dowels with screws. But even in this case it is undesirable to place anything heavy, it will at any time cause the collapse of the wall.

Types of designs

With the help of drywall, you can build structures that are diverse in their appearance and functionality, namely:

- walls that divide the room;

- partitions of any shape;

- complex interior installation.

Gypsum wall or partition has a practical functionality or performs a purely decorative function. With the use of sheets, you can divide the space into zones, build niches, change the location and shape of the doorway, create a false wall, achieve increased heat and sound insulation.

Partitions made of gypsum board are considered more appropriate than similar installations made of other materials: brick, wood, and foam blocks. Plasterboard fiber partitions are produced in a short time, their cost is much lower than the options of brick or wood. False wall inside remains hollow, which allows you to lay the necessary utilities and make additional insulation.

The material has a small weight and small dimensions, it is easily cut, so the installation can be carried out even by a person with minimal experience with the usual tools that are available in every home.

Options for partitions from the GKL great variety. There are the following:

- by type of profile: regular and arched;

- by function: temporary or capital;

- by type of design: deaf or with an opening for a door or window;

- by type of installation: sliding or stationary.

In addition, partitions and interior walls of the GCR differ in thickness and some other criteria.

Decorative plasterboard partitions, as a rule, are mounted in order to hide the flaws in the room and close the radiators. They do not require serious fasteners, often complemented by stylish elements: lighting, mosaics, inserts from materials of another type. Usually the same elements are fixed on glue or mounted on a frame. Models that have a practical purpose, mounted during internal repairs. They modify the general appearance of the room, contribute to its division into different zones and add additional functionality to the finishing elements.Such walls and partitions are installed in a frame way and are mounted on all the walls in the room.

Regardless of the type of partitions, each has the same structure, namely:

- the frame is made of wood or metal profiles;

- plasterboard sheets used for walls or partitions;

- wall filling - glass wool or mineral wool, which contribute to additional noise and heat insulation.

Depending on the technical characteristics, there are several types of drywall:

- Wall GKL it is characterized by a thickness of 12.5 mm, a width of 1.2 m, and the length of the sheet can be 2.3 or 2.5 m. It does not contain any additives, it is used for the installation of walls and partitions.

- Ceiling gypsum has a thickness of 9.5 mm, width is 1.2 m, length - 2 or 2.5 m. This lightweight modification has found wide application in the construction of niches and door arches, as well as in cladding ceilings. It differs from the first variant only in thickness.

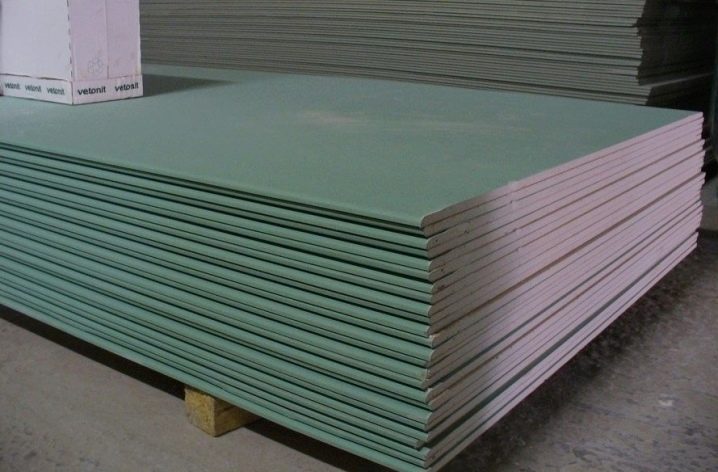

- GKLV - it is moisture resistant material. Its thickness is the same as that of the wall variant, the width is also standard (1.2 m), and the length is 2 or 2.3 m. A distinctive feature of the material is the introduction of moisture-resistant pigments and antifungal impregnations into the structure.Thanks to them, the material becomes hygroscopic, resists moisture and is used in rooms with high humidity (in bathrooms and shower rooms).

- GKLO - This is a drywall sheet with fire resistant parameters. It has standard parameters: thickness 12.5 mm, width 1.2 m, length 2.3 or 2.5 meters. The core of this type of fiber includes active components that are resistant to high temperatures and burning, all of which is enhanced by special fire-resistant impregnations. The material is widely used in those premises in which there are increased requirements for fire safety, as well as for lining fireplaces and chimneys.

It is worth paying attention to the fact that the cardboard coating in all types of GCR is resistant to fire. This material does not burn, and the maximum is only charred. But the core is opposed to the flame only in GKLO.

- GKLVO - it is a moisture-resistant material that combines all the advantages of G-CLP and GFCS.

- Arched GCR used to create exquisite wavy designs and rounded interior elements. Its width corresponds to the standards of 1.2 m, the length is presented in one version - 3 m. But the sheet thickness is small - only 6.5 mm.The small thickness, as well as the introduction of fiberglass fibers into the composition, leads to increased flexibility and ductility of the material. Such sheets have a rather high price, and the fact that they have to be mounted in several layers makes the finishing work more expensive.

Design

Drywall has found application in cladding and creating decorative elements in the room.

Ceiling

Today, drywall is one of the most popular materials for cladding ceilings and structures of multi-level suspended structures. Drywall is required for design in the following situations:

- with irregularities of the ceiling;

- if necessary, hide the utilities laid from above - pipes, a massive ventilation box, an unaesthetic cable and others;

- for the implementation of the original interior solutions.

Ceiling decoration using GCR can be carried out in rooms of any type and purpose.

Walls

Virtually any interior finishing work associated with the installation of drywall. That it is used to create a perfectly smooth coverage, arrangement of various niches and shelves,as well as the construction of other elements of the design structure. In addition to the decorative function, GKL also has a practical purpose - creates enhanced noise absorption and insulation of the room. Sheets of gypsum fiber are mounted directly on the wall with glue or on a pre-assembled frame, as a rule, sheets of 12.5 mm are used for this. Sometimes, to ensure greater structural strength, gypsum boards are laid in two or three layers.

Facing plasterboard is carried out in any premises, it is most effective for cold walls facing the street, which freeze through in winter.

A plasterboard wall with heat insulation contributes to the room warming, prevents the accumulation of dangerous condensate and the appearance of fungus. Finishing the drywall wall can be any.

Floor

Drywall can also be used for dry floors. Of course, only extremely durable sheets with high abrasion resistance and resistance to mechanical damage are used for this. This coating is applied in two layers, then covered with any standard topcoat - parquet, linoleum, carpet,tile or laminate. The advantages of this method are obvious - this is a high speed of work and their efficiency.

The design is often used GKL for the construction of multi-level compositions, for example, podiums and protrusions, which effectively mask unaesthetic pipes and other communications.

Bulkheads

To create partitions drywall is the material number 1. It is most often used to divide the room and create a stylish and functional zoning of space. Some constructions can be constructed on the basis of a metal profile frame, which is fixed to the walls and the ceiling, and then sheathed directly with gypsum fiber plates.

Built-in niches

Shelves with drawers in plasterboard constructions look very impressive in the interior, and they are simply irreplaceable in homes with small children, because the kid will not be able to hit the sharp edges of the hinged elements. Niches are used to place small elements of decor in them that make the room cozy. These can be photos, small souvenirs or books. The form of such niches can be very different.As a rule, they are mounted lights, which makes the interior unusual and spectacular.

Tip: when installing niches, special attention should be paid to the weight of products that are stored in the niche. Drywall can only carry light items.

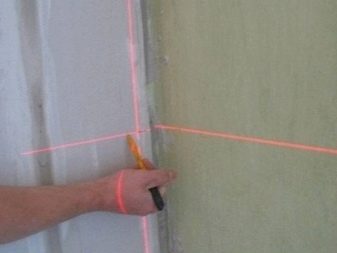

Frame

Most often, plasterboard surface cladding is performed in a frame manner; for this purpose, a wooden or metal crate is mounted. It is very important to apply the correct markings, as the strength and evenness of the future false walls largely depend on the accuracy of the calculations.

To do this, first mark the place on the floor from which the mounting of the carrier panel will begin, the resulting figure is projected on the ceiling - this is the length of the frame. The distance between the wall and the markup is its width. Perpendicular to the floor on a nearby wall, markings are applied for rack-mount metal profiles. The markings are presented in the form of vertical lines with a step of 50–60 cm, and later when fixing the drywall to the plank, the edges of the sheet will be located along them.

When facing walls, it is important to remember that one wall is first finished, starting with the installation of guides and ending with the installation of gypsum plasterboards, and only then is the transition to the next surface.

The works are carried out in several stages, namely:

- labels on the floor and walls need to be connected, and then guides are mounted along them;

- installation of suspensions is at a distance of 60–70 cm, their center must necessarily be located along the line;

- rack metal profiles are fixed in the guides so that their middle groove coincides with the upper and lower marks, and then they are connected to each other;

- the vertical level of the base and the shelves is controlled by the building level, after which it is necessary to make a finish fixation with self-tapping screws.

Application area

Drywall is used for various variants of performance, such as:

- ceiling finishes;

- installation of partitions;

- giving the walls a perfect evenness;

- the construction of interior compositions of various arches, shelves, baseboards;

- masking unaesthetic and damaged surfaces;

- repair of old coatings;

- giving to surfaces of a relief;

- creating multi-level structures;

- insulation, sound insulation of cavities and openings.

Drywall with high moisture resistance, as a rule, is used for finishing bathrooms and kitchens. Fire-resistant modifications are widespread when facing communication mines and air ducts,when telephone and Internet cables, plumbing and heating pipes, and ventilation devices are required. Drywall is used in both wooden and brick houses.

Drywall installation

Installation technology is quite simple. First, the sheet is cut. To do this, use the usual construction knife with a spare block interchangeable blades. The sequence of actions is described by the instruction, according to which it is necessary to perform the following actions:

- the sheet is laid on a clean, flat surface;

- pencil marking is applied;

- using a knife, the cardboard is incised from the outside;

- GCR is installed on the edge of the support, the sheet is gently cracked along the incision line;

- the gypsum board returns to its original position, is placed on the edge and bends;

- cardboard from the inside is also cut, and the blade should not go through;

- the sheet turns over on the inside, is placed on the support again and finally breaks.

After the sheet is prepared, you should proceed to the immediate assembly of the installation with your own hands in accordance with the step-by-step instructions.

You must perform the following steps:

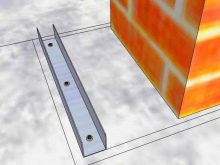

- along the lines drawn on the ceiling and floor lines, guides are attached;

- under the fixed profile is placed sealing tape;

- to the profile on the vertical markers mount strips, all works start from the corners and lead to the center;

- on screws fix stiffeners;

- further in the cavity conduct communications, wires and cables, also fill with mineral wool;

- on top of the frame, a sheet of drywall is attached directly;

- the edges of the sheets are smeared with a putty or a reinforcing mesh is applied, then grinded;

- A primer is applied over the panels and a finish is applied.

It is worth paying attention to the following points when mounting the plasterboard:

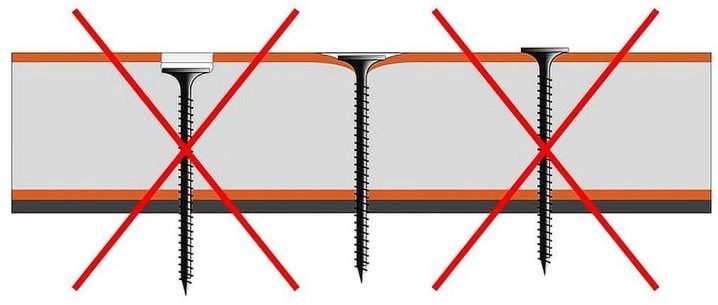

- the sheet is attached to metal profiles with self-tapping screws 3.5x35 mm;

- first of all, the edges of the panel are fastened, and then the central part. The screw has a step of 10-25 cm;

- screw the screw so that the cap slightly "drowned" in drywall, it should in no case stick out above the surface;

- if possible, before starting the lining it is worth seeing a master class on how to install drywall.

Tips and tricks

Drywall is a very popular material, so it is widely represented in hardware stores. At the same time, it absorbs moisture well, therefore, if it is not properly stored in the warehouse, its consumer parameters can be significantly damaged. To avoid problems and purchase the highest quality product, you should adhere to the following recommendations:

- try to buy the product only in large stores that have proven to be a reliable and stable seller, avoid questionable points of sale;

- to assess the conditions in which the GCR was stored, the cleanliness of the room and the level of humidity in it;

- personally inspect each sheet purchased GKL, it should not be chips and deformations. On a good quality product, no curved curves, dents or scratches are allowed. Any violation of integrity will entail breaking the entire sheet in a damaged place;

- Carefully follow the loading and unloading operations. Even if a drywall sheet was purchased in perfect condition, this does not guarantee that it will arrive in the same form. If the product was purchased and paid for, but the defects were discovered later, the warranty will not be valid;

- if possible, you should not immediately purchase the entire batch with the required quantity. To get started is to buy one sheet to test it. For example, you can cut a sheet into strips, a quality sheet must have a strictly uniform core, a cut without inclusions, and the knife must go smoothly and smoothly when cutting;

- if you decide to buy goods from a dubious supplier, but at a very attractive price, it is worth remembering that the stingy always pays twice. Handicraft products can not only fall apart and break, but also prove to be unsafe for health.

To protect yourself from fraud and marriage, you should give preference to products of famous brands.

About 70% of the Russian construction market is occupied by products of the German concern. Knauf. This giant has manufacturing facilities around the world. Only in Russia there are about 10 factories for the production of building materials. Knauf is associated by many with high quality, reliability and practicality. About 10% of the market is accounted for by other European brands - Lafarge, Gyproc, Rigips.

Gyproc - This is a Scandinavian brand, which has successfully established itself in the position of one of the leaders in the world drywall market.In terms of output in 2002, he won first place, leaving all major competitors far behind him. A distinctive feature of the GCR of this brand is a high environmental safety, confirmed by certificates "Leaf of Life", "Ecomaterial". In addition, Gyproc has released drywall, which is 20% lighter than products from other manufacturers. However, its price is slightly higher than the cost of Knauf products.

Lafarge - This is a Polish manufacturer, which has established the production of gypsum cardboard throughout the world. Even Knauf is inferior to this concern in the number of production workshops. This allows to reduce the cost of production, which is why Lafarge drywall has a very affordable price. It was this company that at the beginning of our century made a real revolution in the manufacture of drywall, bringing to the market sheets of semicircular shape, all the edges of which are covered with cardboard. Such processing panels became a kind of business card company.

About 20% of the market belongs to domestic companies. Among the leading Russian manufacturers are the following:

- Gypsum (Volgograd) - produces drywall under the well-known brand "Volma".The products of this brand has excellent performance and reasonable price.

- Gifas (Sverdlovsk) - manufactures products of exceptionally high quality, which in its operational parameters is not inferior even to popular European brands.

- Abdullingips (Kazan) - Established the issue of ordinary GCR and GKLV, has a low price relative to other Russian analogues.

- Golden Group Gips (Togliatti) - lets out sheets of gypsum cardboard on the equipment of the French concern Lafarge. Products differ in exclusive quality and favorable price.

For how to sheathe plasterboard walls, see the next video.