How to choose a profile for drywall?

Modern construction does not do without drywall. Cheapness, durability, ease of installation brought him to one level with the most common materials. But the use of drywall requires a certain level of awareness of the installation and materials used in this area of construction.

Special features

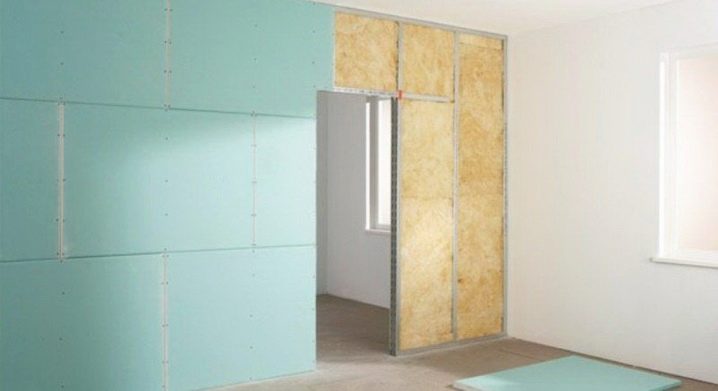

Drywall allows you to create a variety of designs. Figured walls, arches, niches, suspended ceilings and much more can be designed thanks to this material. For example, when creating a partition in a room, drywall has many advantages - a relatively low weight, lower installation costs and material compared to brick or plaster blocks make it almost indispensable.Also, drywall with proper installation and operation is not inferior in strength to many materials.

There are alternative ways to install drywall - such as, for example, gluing to the walls. But the most common - fastening GKL to the profile design. It is from the profile that various structures are formed - from the simplest to the complex, which more closely resemble a work of art.

Construction stores offer a large range of profiles. Each element is intended only for a specific function in the frame. If they are used improperly, the whole structure will not be strong and durable. Knowledge of the features and sizes of metal profiles allows you to pre-create projects and drawings for the design of an apartment or any other room.

Purpose

The main step in creating a drywall construction is the construction of the frame. Based on what is installed (arch, partition, and so on), there are certain requirements for the frame. For example, for curtain ceilings, the frame of the profile must withstand heavy weight loads.When mounting the partition, the frame must be resistant to deflection.

Before you build the frame, you need to decide on the type of the planned structure. If it is a figured design, then profiles intended for bends are applied. Here it is also necessary to take into account how the structure should be resistant to accidental impacts or heavy loads under external influence. The location of arches and ceilings is inaccessible during normal movement of people around the room. In the frame of such products there is no need for additional strength of the profile assembly. In contrast to these products, a curved wall must withstand occasional overloads.

For the implementation of specific design requirements, various forms of profiles are produced. Given the purpose of the product, the material is selected. Reliability, durability and functionality of interior parts strongly depends on the correct selection of the profile for its intended purpose. An important role is played by the selection of fasteners and fasteners. They, as well as profiles, have their own purpose. The connecting elements of the profile structures can not be neglected.This will affect the stability and evenness of the surface. Additional design details, as well as the profile, have a strictly defined purpose.

Each type of screws performs its role in the design. At this, too, should pay attention. Misuse of self-tapping screws may lead to structural fragility and even danger to human life, since a mounted product may fall. In the selection of screws and other fasteners plays the role of their length. For example, the use of screws more than the required length will cause inappropriate costs. Screws with shorter length will affect the strength of the frame and its stability.

Types and sizes

In the manufacture of the profile used cold rolled sheet metal. From above it is processed with zinc. Such production makes the metal profile reliable and durable. The galvanized surface protects against corrosion, which allows the profile to be in operation for a long time.

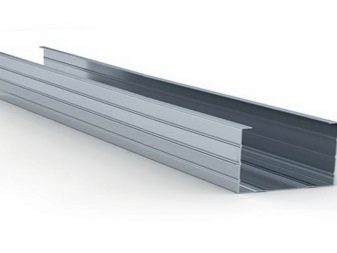

Designing a frame for a plasterboard product is not a very difficult task. The design contains perpendicularly directed parts located in a horizontal or wall vertical plane.These elements are called carrier and rack. In addition, there are guides and starting parts of the structure, which are located perpendicular to the carrier. Choosing the right material is also not a difficult task. This helps to get acquainted with all its possible types.

Rack profile is in great demand. In the label, adopted by Knauf, it is referred to as "CD". Profile "Giprok" is labeled "PP." The sizes of these elements are selected so that when using them there is almost no waste. In addition, their size allows you to optimally spend space on the constructed elements. This profile can be from 2.5 to 4 m long. Width - 60 mm. Shelf shelf - 2.7-2.8 cm.

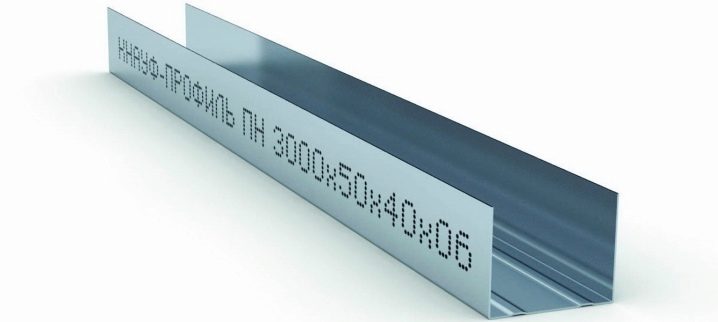

Profile guide "UD" or "PPN" is designed for mounting the supporting parts of the frame. During the collection of suspended ceilings or wall cladding guides are mounted around the perimeter. It is more convenient when they are perforated. Due to the fact that during installation drill through the profile, this process will be easier. They are produced in length of 3 m. Metal thickness is 0.55 mm, height is 2.8 cm, width is 2.7 cm.

Profiles "UW" or "Mon" refer to the guides and are used for the installation of partitions.Their purpose is to ensure that it is possible to make a different thickness of the partition, if necessary. These items are made in different widths. Dimensions: length - from 2 to 4 m, ledge of shelves - from 3.4 to 4 cm, width - 4.2, 5, 6.5, 7.5, 10, 12.5, 15 cm.

Profiles "CW" or "PS" are used for partition walls as a rack when forming walls. Their width should coincide with the starting one. In the profile of good quality there are openings for the possibility of laying communications. Giprok produces this element with a stiffener, which creates a curved edge. Length - from 3 to 4 m, ledge of shelves - 5 cm at Knauf, 4 cm at Giprok.

The arched profile is made curved. The surface may have different bends. When performing surfaces of a specific shape, it is such flexible profile views that are used. In places of bends and curvature of the plane installation of the frames are these elements. If necessary, they can be replaced with other profiles. At the same time make the slot at short intervals. Such a replacement complicates the installation process and can only be an exception in unforeseen circumstances.

In addition to profiles, other parts are used when mounting the frame. Accessories and accessories for drywall products are very diverse.But the free sale of them is much smaller, since the assembly of the structure can be conducted using a small amount from the entire range, the remaining parts remain unclaimed.

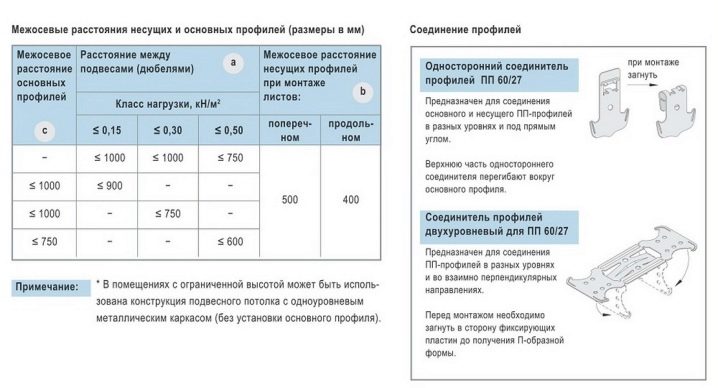

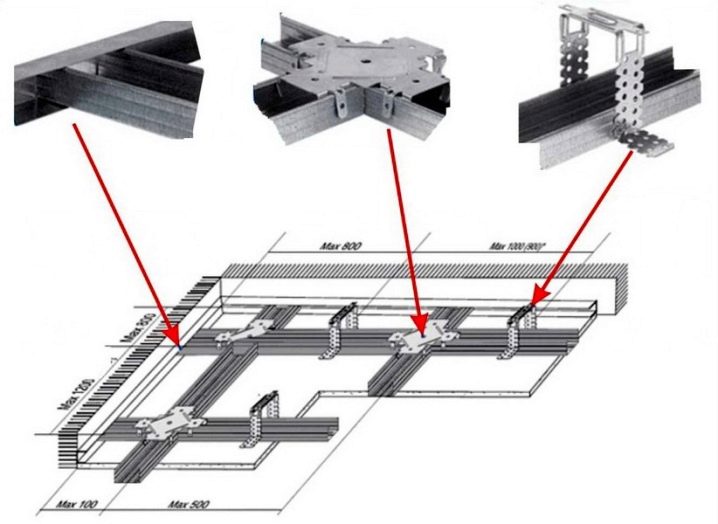

A two-level connector for a CD profile is used to connect two profiles at different levels. The need for this element is determined by the perpendicularity of the location of the profiles. Such connectors are sold even, but before installation they must be bent with the letter P.

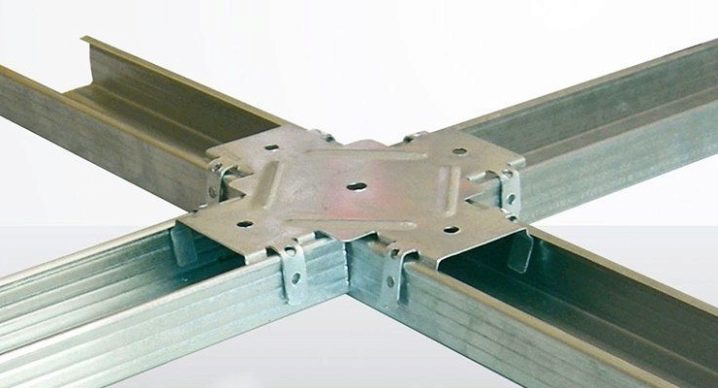

Connector single-level for CD-profile, or "crabs" - mount, which is necessary when the profiles are installed at the same level. As in the previously described case, the profiles are installed perpendicular to each other. Fixing them with screws is necessary only if the load per square meter is more than 20 kg. For a smaller load it will be enough for a self-tapping screw on both sides.

Direct suspension for CD profile used for the manufacture of the ceiling of plasterboard. It is mounted directly on the bearing surface. As well as the two-level connector, the suspension is sold direct, and during installation it is necessary to form the letter “P”. The standard suspension length is 12.5 cm.Suspensions and other lengths are made from 7.5 to 30 cm. The suspension is designed to hold a mass of up to 40 kg.

Anchor suspension is also called a suspension with a suspension. It is used in the same way as a straight line to attach a CD-profile to the bearing surface of the ceiling. The production of such a suspension is due to the fact that the suspended ceiling can be a level much lower than the length of the suspensions. When assembling the anchor suspension is installed inside the profile, then thrust is carried out into the hole made in the spring. The thrust has a length of 25, 50 and 100 cm. The weight that withstands such a mount is 25 kg.

An extension for a CD-profile, in a different way - a longitudinal connector, is necessary if the profile length is less than the required one and it needs to be increased by connecting an additional profile. The connector is inserted at the end of the profile, taking into account that its projections should be directed in the same way as the projections of the profile. After the junction of the two profiles at the location in order to stiffen the joint, a screw is screwed on each side.

The corner connector for the CD-profile is designed to connect profiles that are located T-shaped in the same plane.It completely replaces the crab connector. Also for assembling the frame and attaching drywall to it, various types of self-tapping screws are used.

The TN 25 self-tapping screw on metal which is necessary when fastening gypsum cardboard to a profile design. They come in different lengths with a small thread pitch. Self-tapping screws of the type TN 25 (length 25 mm) are also used in cases when several sheets are attached, while using screws 35-40 mm long. If for some reason, drywall is attached to the tree, use screws with a large thread pitch. They are called wood screws. For one layer of drywall take parts with a length of 35 mm.

Self-tapping screws LB 9, 11, 16 and LN 9, 11, 16 - drilling, which are used when attaching the profile to the connectors. Numbers in the marking indicate the length of the screw in millimeters. The shortest length of these screws is 9 mm. But they have disadvantages when installing drywall products. For example, a small length is inconvenient when twisting. A high bonnet prevents the drywall from tightly fitting the profile.

Screws with a press washer is more practical when fastening profiles with each other and with additional elements. Such screws are used on all surfaces. There are, like the previous ones, piercing and drilling type.They have a large range of length - 9-100 mm, if necessary, you can purchase even greater length. Screws of 16 and 14 mm are most demanded. Used in almost all designs, performed from drywall and profile.

Self-tapping screws with plastic dowels are used when installing profiles like "UW" or "UD" on the walls. Nylon dowels are optimal when using such fasteners.

Anchor wedge is used to attach the suspensions to the supporting structure to achieve a high quality connection. This mount has a very long service life, is not susceptible to drying out over time, resistant to corrosion. When mounting a suspended ceiling, saving on these elements is impractical, as strength and reliability are the conditions necessary for any fastening. Instead, you can use the ceiling dowel.

Dowel-nail is used when fastening the profile structure to the bearing surfacesuch as masonry, concrete wall or blocks. Pick up such mounts with heads in the form of fungi. A diameter of 6 mm and a length of 40-60 mm is sufficient. If necessary, when the structure needs a stronger connection with the bearing surface, a larger diameter or length is used.Convenience is that they are hammered, there is no need to twist them.

Getting started is best by purchasing the most diverse types of fasteners. This will allow the connection of all possible elements that are used in the work. When confronted with non-standard situations, for example, a void in the supporting structure or additional fastening to other parts of the structure, it is often necessary to resort to the most unexpected methods, complementing the already existing mounting schemes. This helps the presence of screws or anchors of greater or lesser length. It is also easier and more reliable to use anchors and their analogs when using any rods or extension elements instead of suspensions.

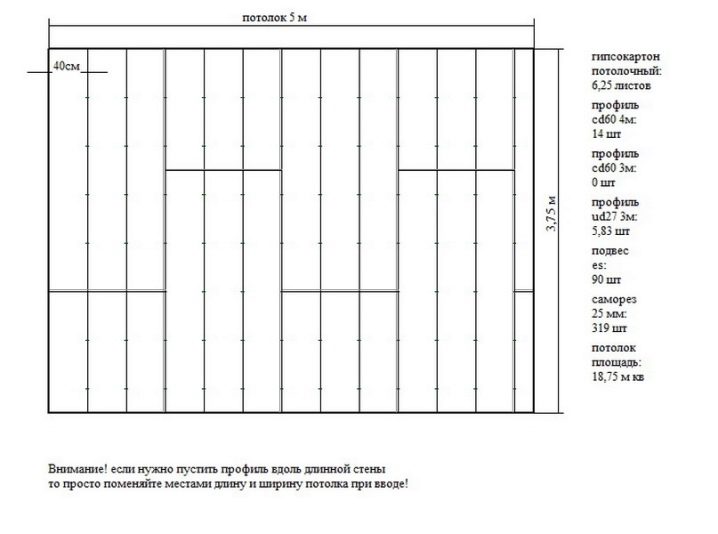

How to calculate the required amount?

GKL installation is carried out in two ways:

- fastening to the mounted frame;

- gluing to the bearing surface with adhesive solutions.

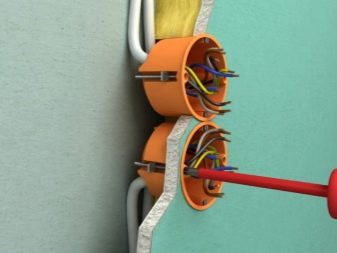

The first method is most common, despite the high costs of funds and usable space. The reason for this is that the voids left behind the drywall can accommodate what they are trying to remove from the field of view (sewage, water pipes, electrical wiring and the like).But the main task before the start of work in this case is the calculation of the required amount of material.

The calculation of the guide profile is reduced to the division of the entire perimeter, where it will be located, by the length. Then this number is rounded up so that the stock remains.

In this calculation, you should follow 2 recommendations:

- The calculation is based on the size of the room, trying to choose the length of the profile guides so as to minimize the length of the scraps.

- Calculate the amount and add 7-20% of the total material. Such an increase makes it possible to compensate for small scraps that would have to be fastened in separate pieces instead of a whole.

Calculation of the carrier profile - the most difficult of all calculations in the drywall construction. In this calculation it is necessary to take into account the design of the frame completely. For ceilings, the profile is calculated from the ratio X = (A / N + 1) * (B / 3) * K. The bearing profile for the wall facing frame is calculated according to the following formula: X = (P / N + 4) * K. In case of exceeding the 3-meter height of the wall, this formula is transformed into another form: X = ((P: W + 4) * H / 3) + P * K.

The letters in these formulas denote:

- X - the number of profiles with a length of 3 m;

- And - the length of the plane (m);

- B is the width of the plane (m);

- P - perimeter (m);

- H - wall height (m);

- K - correction factor (for an area of 10 square meters and less corresponds to 1.275; for an area from 10 to 20 square meters, it has a coefficient of 1.175; more than 20 square meters, the area has a coefficient of 1.075);

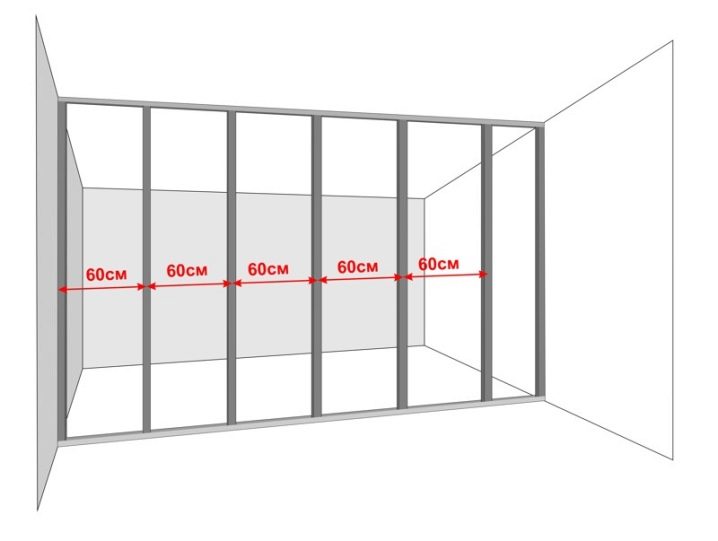

- W - the step through which the carrier profiles are installed, it is equal to 0.4 or 0.6 m and depends on how the structure will be subjected to the pressure of the drywall weight. For a sheet stacked in one layer, it has a pitch of 0.6 m. Two layers have a pitch of 0.4 m. The design in which moisture resistant gypsum board is used has a pitch of 0.4 m.

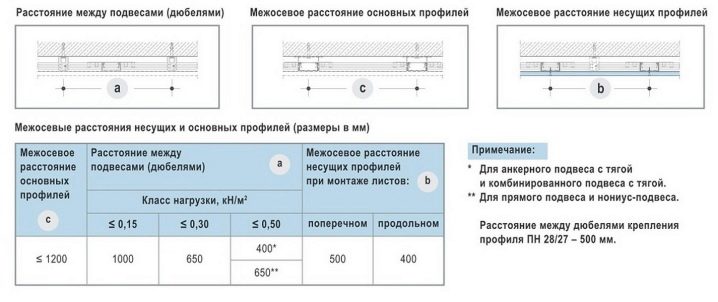

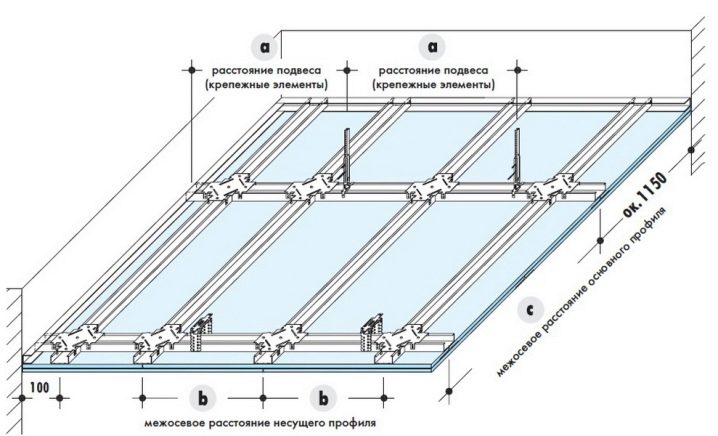

Calculate the number of suspensions simple action, based on the number of load-bearing profiles. Here they take into account the fact that they are located on the profile through a distance of 0.6 m. If the profile length is not divided by 0.6 m, then the number of suspensions is reduced in order to arrange it evenly along the entire plane and profile length. The approximate number of suspensions is calculated based on the total length of all profiles. According to the same principle, a suspension is attached every 0.6 m.

Calculate the amount of drywall for cladding the ceiling and wall is easy.

For this you need to take into account certain points:

- The calculation must be conducted on the assumption that the standard sizes of sheets of drywall are 1.2 by 2.5 m or 1.2 by 3 m.

- Before finishing the room is best to perform a sketch on which to determine the required surface area of drywall. It is necessary to distribute the sheets of drywall along it so that the material is used optimally and the amount of waste is reduced.

- For finishing surfaces that are complex shapes, the total area of all planes and bends is calculated, taking into account recesses and projections. To this area add 10-15%. Then it is divided into the area of one sheet of the selected size and rounded to a whole number.

The calculation of the required number of fasteners is the simplest task, which is produced from the material already calculated. The number of screws for fixing drywall is calculated based on the fact that about 100 pieces are spent on each sheet. "Crabs" are required for 1 piece for each connection of metal construction profiles. Screws with dowels are calculated from the fact that the guide profile requires 1 piece for every 0.4 m, and for attaching to the supporting structure of the suspensions 2 pieces are needed for one suspension.

In conclusion, you can add to the calculation that the purchase of materials should be done with a margin. This is due to the fact that during installation possible breakage of materials or loss of screws. In the calculations there may be small errors or unrecorded moments. Products purchased in the store may have an imperceptible deviation from the quality shown. For example, drywall may have cracks that are not visible under a sheet of paper. Some of the screws can be curved, which will not allow to screw them in by a screwdriver. Screws can come with blunt ends or with a missing slot in the head. These and many other nuances can cause a lack of material and, as a result, time costs for mounting the structure.

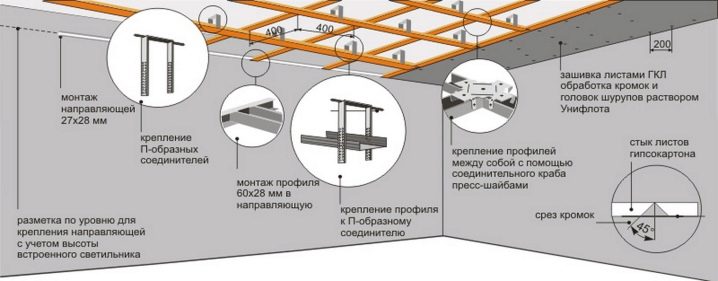

How to install?

The following tools will be required for the installation of the drywall construction: screwdriver, drill, building level, fasteners (dowel-nails, screws), metal shears and profile cutting, tape measure, screwdriver, knife for cutting drywall sheets. When facing works it is necessary to take into account the loss of usable area. Therefore, it is necessary to design, for example, wall covering as close as possible to the bearing surface. This rule is used in all possible cases when working with drywall.Begin work with markings on the walls adjacent to the place of covering. Do the markup, googling level.

Installation of the profile is very simple. By marking, where the bearing profile will be mounted, mount the guides. Next, suspensions are mounted according to the line of the planned installation of the profile that was previously drawn on the wall or ceiling. Performing this operation on the crate, you can not neglect the pitch profile. Otherwise, the place of joining the drywall sheets will not be located on the profile area, which is a gross violation of the installation technology.

The distance between the suspensions varies from 0.5 to 1 meter. It depends on the desired structural strength. If this is provided for by the project, then after the collection, the engineering communications, thermal insulation and sound insulation are laid in the profile structures and the box.

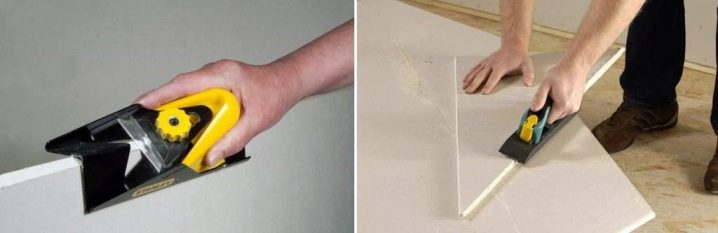

When installing drywall to the assembled frame using a screwdriver, thanks to which all the work will be faster and easier. The trimming process is nothing more than leveling the wall. Therefore, it should be sufficiently tight fixation of GCR on the profile. Great attention should be paid to the edges of the GCR cut, which should be done as evenly as possible.In those places where the cut sheets are joined, it is necessary to cut a chamfer whose angle is 45 degrees. When puttying chamfer makes it possible to make the joints invisible. Drywall is fixed with screws at a distance of 20 to 25 cm. Where windows or doors are installed, position the profile along the opening. This makes it possible to easily fix the drywall. It is advisable not to use wooden beams as an auxiliary element, as it may damage the drywall during drying.

For the erection of arches using curved drywall or make it personally from a direct sheet. A flat sheet can be soaked, creating a humid environment for a while, and put it on a pattern, on which to repeat the bend. Another option for bending sheets is to make incisions on the facing paper. In this case, take into account the radius at which the drywall will go. The steeper the bend, the more cuts are needed on the sheet.

These recommendations are enough for the construction of drywall structures of any shape and complexity. When creating a project, it is important to think about the shape and size of the desired product and calculate the necessary material as accurately as possible.

Tips

Doing work on the installation of gypsum for the first time, do not neglect the technology. It is necessary to strictly observe the distance between the profiles, especially when many whole sheets are mounted. You should always remember that the deviation from straight lines when mounting the frame will lead to a bulge or concavity. Great attention should be paid and fastening strength. Floor slabs have voids, so anchors are used for durable fastening. Foam concrete walls are not able to hold fasteners. Such compounds should be avoided or additional measures applied to the strength of attachment of suspensions.

For fastening any interior parts, special types of fasteners are used. This allows you to securely attach home appliances or other items to the drywall, such as wall lights, televisions, hangers, mirrors, and so on. In no case can not attach them to the drywall screws. This will not give a reliable connection, except in the event that the screw passes into the profile through the sheet.

You can also pay attention to the fact that the suspensions do not always satisfy the necessary stiffness in deflection.In this case, additional constructions are used. These could be reinforcements of own-made suspensions or the purchase of any additional parts from the store’s range. Self-mounting can be made from the supporting profile or guide. It all depends on your ingenuity.

It must be remembered that at the junction of drywall must necessarily be on the bearing profile. If we neglect this, then with a small effort the sheets can move relative to each other, which will cause the crack of the final putty. In those places where greater strength of deflection is needed, additional profiles are installed. Alternatively, you can use a double layer of drywall or moisture-resistant drywall, which has greater strength in comparison with the ceiling.

In order to use a minimum of usable floor space, place the sheets closer to the bearing surface. You can resort to the device strobe in the field of attachment profile. This option is possible, but it has drawbacks, such as more installation time is required and more effort is required from specialists.As a rule, in these cases, resorted to as adhesive compositions, which will not cause voiced deficiencies.

It should be noted that drywall is sensitive to the humidity of the room in which it is stored. To avoid bending sheets, they must be laid on a flat floor and only stored in this position.

In wet and damp rooms when installing drywall, you need to remember that it must be well protected from moisture. For example, in a bathroom, drywall protects tile. In this case, special attention should be paid to ensure that water does not get into the space between the bearing surface and the drywall. When performing plasterboard finishing work, it is necessary to prime the entire surface well. This will promote good adhesion of the putty and increase moisture resistance. When shpatlevanii also do not neglect the laying on the seams of the construction mesh, or in another way, serpyanka. This will give greater strength to the puttied joints.

When installing drywall on the profile, you must check the presence of protrusions or protruding parts. This may cause drywall damage. It is not recommended to use drywall in places where the temperature changes frequently (street, loggias, balconies, and so on).

Bearing guide profile does not necessarily cut completely in those places where you need a corner. In order to form it, it is enough to trim the edges of the profile to the corner and bend it to the desired shape. It also helps in the formation of a stable angle, if the clipped profile edges are fastened together with self-tapping screws. If the profile needs to be bent at an angle of less than 90 degrees, and the edges of the profile do not allow this, their excess parts are trimmed.

In complex structures, if high accuracy of drywall angles is needed, sheet milling technology is used. For this, a shape mill is used. With this tool you can cut grooves of any shape and hole (oval, circle, rhombus, and so on). Using shaped cutters, not only the installation of drywall itself, but also puttying is accelerated. Milling technology requires large financial costs for equipment, but is very profitable with large volumes of work.

For convenience, when installing drywall is better to use a magnetized screwdriver head, as the screwdriver takes different positions and the screw without support falls. In some situations, it is impossible to hold the screw with the other hand.In some cases, plasterboard products are fastened close to the wall, so it is not possible to fix the sheet. In order to solve the problem, the profile frame is assembled without fastening on a bearing surface. Then drywall is attached to it and already later in the assembly it is installed on the bearing surface where its location was planned.

If in the voids of drywall passes the wiring and goes on top of the sheet, then it needs to be fixed on it. This will avoid many difficulties after the assembly of the entire product due to sinking of the wire back into the cavity of the plasterboard construction. Sheets of drywall are sold in various thicknesses. Sheets 9.5 mm, designed for cladding the ceiling, it is not recommended to use on partitions. If, however, inflate the length between the profiles on the ceiling, there may be a deflection of 9.5 mm sheets down.

Drywall has a weak sound insulation, so if you want to make it reinforced under the guides before attaching the bearing surfaces enclose the damper tape.

How to choose a profile for drywall, see the following video.