Knauf Drywall: Material Features and Applications

When building their homes, each person should pay special attention to the choice of finishing materials. One of the most common types is drywall. Today we will talk about these building elements of the company Knauf.

What it is?

Drywall (gypsum plasterboard) is a popular finishing material. It is a sheet, which consists of two layers of special construction cardboard. Also in the composition of this design necessarily includes the core. As a rule, it is made from ordinary gypsum dough.

It is possible to use such a product in almost any room. Each individual drywall sample is distinguished by its specific characteristics (width, thickness, length, weight). Most often, this finishing material is used in the alignment of ceiling and wall coverings.

Special features

Currently, Knauf plasterboard products are becoming increasingly popular among consumers and repair specialists. This manufacturer can offer customers a wide range of different models of such structures. The choice of a suitable option will depend on the type of room in which the drywall will be installed.

One of the most important technical characteristics of Knauf drywall is its high moisture resistance. It is because of her that similar construction material can be used even when finishing bathrooms, pools and baths. It is achieved thanks to special water-repellent substances and mixtures, which are pre-processed material.

Many experts often separately note such important technical features as the presence of the semicircular edge of the Knauf drywall. Also, some speak of a special high-strength adhesive solution, due to which the sheets and core are bonded to each other, although not all manufacturers use glue as a connecting substance. In addition, plasterboard structures of this company are produced not only as the main frame, but also as a basis for any decoration.

It is important to note that the company Knauf today produces plasterboard sheets for decorative decoration, and for the main. In the first case, a bright ornament can be applied to the product. It may also have a different structural surface, which allows it to be used as a design element. Sometimes these sheets are even covered with a special stone to decorate and give it beauty.

It is worth noting that drywall must be chosen depending on the type of finish itself. For the ceiling, it is best to purchase sheets with a thickness of 9.5 mm. This variant of building structures will allow you to carry out all the necessary installation work on the installation of lighting. For the design of the walls it is possible to use materials a little thinner.

Knauf drywall firmly boasts a number of important advantages:

- Low price. Every person will be able to afford the purchase of Knauf drywall.

- Easy installation. Practically everyone can independently, without resorting to the help of experts, to carry out the finishing of the gypsum plasterboards of this company. In addition, it should be noted that when purchasing such a product, there is a special step-by-step installation instruction for it.

- High level of moisture resistance. With the help of special hydrophobic substances, the material becomes water resistant. Contact with moisture will not affect the quality of such a product.

- Light weight Knauf finishing gypsum board has a low weight, making it quite possible to attach it to light floors, which are not designed for heavy loads.

- High fire resistance. Since there is no air gap between the core and the outer cardboard coating, the part can only be charred by contact with fire.

- Easy care. Plasterboard constructions will not require special complex cleaning. You only need to periodically carry out the usual wet cleaning. Detergents for this you can use almost any.

- Beautiful appearance. Today, customers can find various types of decorative knauf plasterboard in hardware stores. This type of finishing material can be used for finishing coatings.

- Security. Such materials are made from environmentally friendly components that do not harm the person and his health.

Despite such an extensive list of positive qualities, Knauf plasterboard panels have certain disadvantages:

- Its hard to cut. Some models of these building materials are made with the addition of additional fillers. They make the material too dense, which is why it is often difficult to cut them into the right parts.

- Fragility of the structure. Due to the excessive fragility of drywall, it is rather difficult to transport and transport, therefore, some parts often break down during the loading process.

- Lack of elasticity. Many samples of drywall is quite hard to bend, which greatly complicates the creation of the desired surfaces and decoration coatings.

- Low level of sound insulation. Many experts strongly recommend that customers when covering rooms with drywall to cover the walls with an additional layer of mineral wool. This technique will significantly increase the noise insulation in the room.

- The possibility of the appearance of pests. Between drywall panels, as a rule, there is a considerable empty distance. It is in it that various rodents and insects often settle over time.

- It is difficult to mount additional items. If you want to hang a picture or a lamp on a plasterboard wall, then you will have to pre-finish the covering with a frame.It will be possible to attach other elements to it. After all, the usual drywall construction without a solid foundation can simply collapse when reinforcing decorative parts.

Kinds

Knauf drywall is currently represented by a considerable number of different models. Each of them is distinguished by its important characteristics and properties. Therefore, when choosing the right instance, you must definitely pay special attention to the quality of the material.

Today the most popular among buyers are moisture resistant types Knauf drywall. Even building of bathrooms can be finished with such building material. This type of construction is called GKLV.

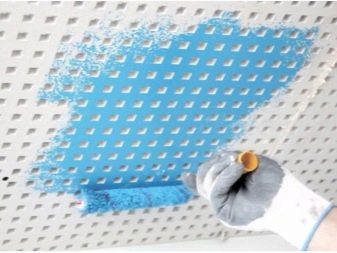

Such drywall in the manufacture of necessarily covered with a special anti-fungal composition. It is these substances that prevent the formation of mold on the surface of the panels. In addition, it should be said that hydroprotective mixtures do not allow moisture to penetrate into the material.

Another popular type is fire resistant drywall Sheets of this type are painted in pink. Under the outer layer of cardboard is the same standard plaster,but only with the addition of fiberglass and special reinforced clay. It is these additional elements that give the panels increased resistance to fire.

Currently, a considerable number of consumers choose acoustic Knauf drywall. This type of material does not need an additional sound insulation system at all. After all, this coating consists of perforated sound-absorbing plates. It is these panels that contribute to the absorption of unwanted sounds.

The special type is arched drywall He deservedly can be called the most flexible among all the other wall samples. With this material, you can easily give it any desired shape of the surface. In addition, it is worth noting that this type of plasterboard sheets is the most suitable option for decorating coatings in the room.

Dimensions

Each Knauf drywall model has its own standard sheet dimensions. For a simple universal type of these panels, they, as a rule, make up 2500х1200х9 mm. Such building materials are most often used in the decoration of living rooms in the house.

But it should be noted that the size of standard drywall sheets can vary considerably. This is especially true of thickness. After all, in some cases it can be 4-5 mm, and sometimes it can reach 14-16 mm.

The moisture and fire resistant Knauf drywall has dimensions of 3000x1200x12 mm. It should be noted that the width of the panel can also vary greatly. It may even be only 500-600 mm. The thickness, like that of universal plasterboard, can be from 5 to 12 mm.

Accessories

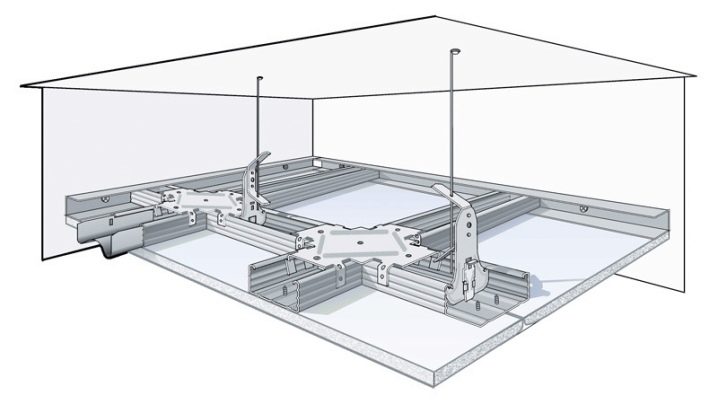

Often in the same set with the drywall sheets themselves are some of the components. They are required when installing the material. Such an important element is suspensions for the construction. They are only needed if there is no frame when installing the panels.

Most often when finishing use the direct extended suspensions for HL. According to many experts, they are the most simple and practical. Such parts have the form of a metal plate with several small holes. These elements are attached directly to the ceiling.

There are also wire hangers. As a rule, they are used in the case when the height of the ceiling is too high, and the coating must be installed much lower.Such a detail is a thin wire on which a place is fixed for a self-tapping screw fixing the suspension on the floor. The height of the base will be adjusted with this wire hanger.

The following important components are guides. They act as a solid frame. It is with the help of the profiles of the whole structure that the hardness and the desired shape are given. They are made most often from metal. Especially important are these elements when designing cassette ceilings.

Corners also are indispensable components of drywall. They are needed in order to accurately arrange the corner zone of the room and make the floor smooth. Strengthen similar parts at the junction of the walls, and then fix. Be sure to pay attention to these elements are not highlighted and not too bulged up, otherwise you may have problems with the subsequent installation.

When installing Knauf drywall special adhesive mixtures are used. They are necessary not only to connect the panels, but also to hide ugly seams (putty can not be used for this). Such ready-made substances you can easily buy at any hardware store.

Selection and application

The choice of suitable drywall depends on the type of room in which the material will be installed. In spaces with excessive moisture (swimming pools, saunas, baths) it is most advantageous to use moisture-proof sheets. In buildings with poor sound insulation should use acoustic elements. In ordinary living rooms, simple standard plasterboard panels are acceptable.

Later it is necessary to make several connecting parts. Fastening rules are most often written in the instructions. First you need one side to attach the metal profile on the ceiling. It will be the main frame. Installs such a design with screws and dowels.

Before installing the material, be sure to thoroughly clean the surface from dust and other contaminants. Then you need to dilute the adhesive solution and spread it on one of the sides of the panel. After construction should be mounted on the wall or ceiling. It is important to ensure that the parts are fixed exactly.

After completing these works, you need to strengthen the corners and remove all seams. This is done with the help of components in the set. At the same time you can not use putty.It is also worth making an additional alignment of the wall or ceiling covering.

Tips and tricks

Many experts offer consumers a number of recommendations for installing drywall. So, most people advise wiring electrical cables and plumbing pipes before covering the panels. Some carry out such procedures after installation, which may cause problems with further repairs.

Also, some experts advise when laying sheets to cover them with special construction mixtures. They contribute to greater strength, hardness of the product and increase its service life. But It is worth noting that this procedure is completely optional.

Many separately leave recommendations on the technology of installation of drywall parts. So, experts say that if you want to decorate the ceiling with such material, then you should use a horizontal adhesive tape. It is attached to the ceiling. We need this strip in order to clearly fix the level of the ceiling. Only after that it is necessary to mount the structure itself.

Separate stitching also deserves special attention.Most experts advise that this procedure be carried out using the same adhesive that was used to install drywall. In this case, the mixture should be applied in a thin layer. After coating, the substance should be slightly smeared with a spatula.

Reviews

Today, on the Internet, you can find a considerable amount of feedback on Knauf plasterboard sheets. Many consumers have left positive characteristics about this building product. So, the majority spoke about the high quality and durability of the material.

Also, many have left reviews about the beautiful appearance of the product. According to users, such a drywall is perfect even for finishing. A lot of people said about the convenient and simple installation, which can be done independently.

But some people also left reviews about the price of these panels being too high. In addition, you can find statements about the excessive fragility of the material, which greatly complicates the work. Many have said that it is too difficult to drive a nail or similar element into the drywall of this manufacturer, since the coating immediately begins to break down.

How to make a suspended ceiling from Knauf drywall, shown in the video.