Engineered flooring: flooring features

The variety of floor coverings is quite large, but completely new types of materials are periodically added. Relatively recently, an original solution such as engineering parquet appeared. It is important for any consumer to know what he is and how he is applied.

Special features

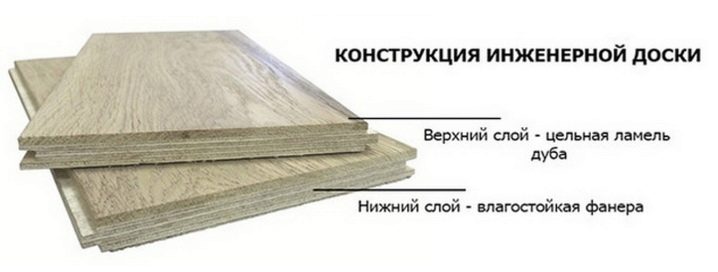

Engineering parquet of the simplest type consists of two layers connected by a special kind of glue. There is a tree on top, almost always of elite species, the thickness is from 0.4 to 0.65 cm. Below, 1.2-1.6 cm of FC plywood are located. In the more complex (three-layer) version, dense wood is used both from above and below, and the central part of the parquet is made of glued coniferous bars. The direction of the fibers in the middle is perpendicular to their direction on the surface. In most cases, tongue-and-groove locks are used, greatly simplifying and accelerating the layout.

Both types of engineering parquet are expensive materials.top quality category. The competing alternatives are massive parquet, block parquet, three-layer parquet product. With proper installation technology and operating rules, the risk of breakage (destruction) of individual boards is close to zero.

Advantages and disadvantages

The engineering board is made using toxic adhesives, which means its environmental and sanitary safety is a big question. Laying such a coating, however, is much cheaper than using block parquet, especially with a complex ornament or when selecting plates of different colors. It is also important to take into account the fact that engineering parquet is inferior in strength to a quality solid rock mass due to the use of soft layers.

Focus on the reviews should not be, because the actual experience of the use of engineering boards in reality is not there.

Piling

You should not be afraid of low durability, especially since in the modern world it is unlikely that you will have to live in one place for many years. However, it is important to know how to properly use an engineering board. Now there are three main options for its use:

- on the substrate;

- over concrete;

- on plywood.

Soft substrate made of polyethylene foam, cellulose mats and similar materials is created very easily. But this is a risky decision, because the slightest difference in humidity can cause swelling, bending of the board. Most often, this problem occurs on the border of the floor and walls.

It is possible to lay the engineering parquet on the glue strip only under the condition that the base is perfectly even.

Please note that only high-quality concrete should be used, since the entire load of the finishing layer will be transferred to it.

Concrete is required to be primed with primer (previously it should already be clean swept, you can use a vacuum cleaner), and then lay the board on the glue of two components (the main one is polyurethane). Please note that Apply this glue only on the base, not on the board itself.

To ensure that the coating is uniform, notched spatulas are used; at least a slight gap is necessarily provided around the perimeter.

Laying engineering flooring on waterproof plywood is considered the best method, since this automatically solves the problem of leveling the subfloor. Plywood blocks - squares of ¼ sheet,staggered out with the obligatory displacement of the seams. Glue holds them on the surface; for reliability, additional dowel screws are used. In order to correct the consequences of temperature and humidity expansion if necessary, intervals of 0.2-0.3 cm are maintained,

The use of coverage and its perspective subtype

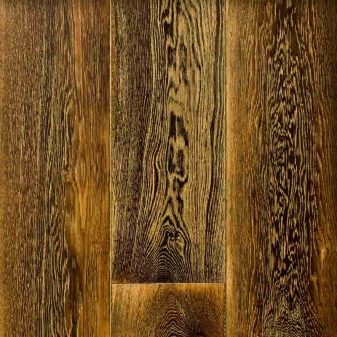

In the process of producing engineering parquet, hardwood can be used, for example, oak, beech. It is distinguished not only by its excellent resistance to various harmful factors, but also by impressive aesthetics. Important: for the entire service life, you can only grind engineering parquet twice, so that you strictly follow all the requirements for the use of the coating and care for it. We must not forget that the engineering board differs in length and width from coatings made of solid wood. It is good because it does not lose moisture in different situations.

The modular type of engineering parquet, featuring an unusually beautiful appearance, is gaining more and more popularity. From finished blocks, as if from a mosaic, you can construct a unique geometric pattern.A wooden tile resistant to water penetration is placed below; it is usually used for arranging garden paths. The main part of the coating is made of highly durable types of the array, they are selected very carefully for aesthetic properties. In the future, the wood is glued in the form of a bar. Glue mounting allows to increase flooring noise insulation when walking.

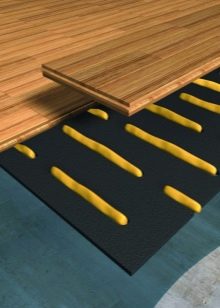

Any engineering board is a little subject to deformations, therefore it can be laid on top of a warm floor. Time and money for the installation of engineering parquet will require more than when using conventional floorboard. The procedure of its installation is difficult, and without the help of professionals it is difficult to do it properly. BUT already mounted coating can not be dismantled. Of course, it can be disassembled, but it will damage the blocks. Therefore, you should approach the choice of the appearance of such a flooring as carefully as possible, not to buy something that may cease to like in a short time.

The engineering board is allowed to be used both in living rooms, and in service rooms. It does not fade a little in the sun, and after high-quality grinding and coating with a layer of mastic, it instantly acquires its original beauty.Exact information about the use of coating, about the nuances of its installation and prices, check directly with the sellers, as the parameters vary depending on the manufacturer.

Review of engineering parquet in the next video.