Bulk floor: beautiful design ideas

Currently, the market for finishing materials is literally overflowing with a variety of floor coverings. One of the most durable and durable is considered to be unusual self-leveling floors. Let's get acquainted closer with these unique and high-tech materials.

What it is?

Before you begin to directly consider the characteristics of self-leveling floors, you should figure out what they are?

Many consumers have heard this name, but did not go into details and have little idea what it is. The self-leveling floor is a special finishing coating, characterized by solidity. In addition, there are no joints and seams, so it looks very aesthetic and neat.

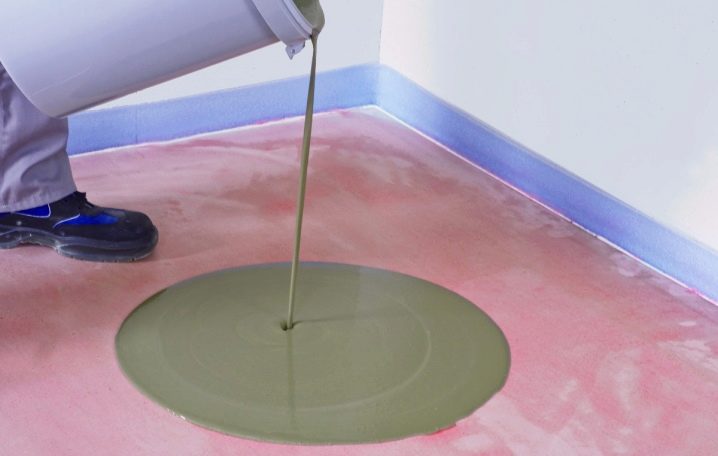

Initially, such a finishing material has a liquid appearance. As a rule, it takes about 1 hour to fully cure and dry. As for the thickness of this finishing layer, it can be from 1 to 5 mm.

The composition of the modern self-leveling floor most often includes polyurethane and epoxy resins, as well as a variety of mineral fillers and special decorative additives. All of these components allow you to form a high-quality and durable flooring in the room, which not only does not fear mechanical damage, but also looks beautiful and presentable.

Special features

Many buyers today are turning to high-quality self-leveling floor, because it is characterized by unsurpassed strength and durability. No wonder that such coatings are most often installed in rooms exposed to high mechanical loads. However, they can be safely used in ordinary residential areas.

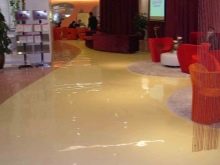

In living spaces, repairs are most often carried out using self-leveling floors that contain polyurethane. A distinctive feature of these coatings is the presence of a beautiful shine and the widest choice of colors. Thanks to these characteristics, it is possible to choose the optimal liquid floor for any interior.

In a different way bulk floor call self-leveled. He, by the principle of liquid wallpaper, can perfectly hide some irregularities and defects in the base of the floor, but this does not mean that it is not necessary to prepare it before laying the liquid mixture.

There is also a self-leveling floor screed necessary for the installation of decorative flooring. When it is laid, special mixtures are used. As a rule, such compositions are characterized by a special fluidity, which allows you to perfectly hide the unevenness of the base.

It has already been mentioned above that a beautiful and reliable floor has a liquid consistency. For its quality and proper preparation, water will definitely come in handy. However, not so long ago, more advanced anhydrous variants appeared, which included anhydrides. These are special gypsum screeds made using calcium sulfate. Today, not only European, but also Russian manufacturers produce similar products.

Also worth noting is the fact that high-quality self-leveling floors have minimal shrinkage. Not all floor coverings can boast of such a property. Of course, a lot depends on the company that produced the mixture. Here it is best to turn to proven and well-known brands in order not to run into a low-quality product, which will give a noticeable shrinkage or will have a heterogeneous consistency.

Installation of a self-leveling floor may seem like something “overly complex”, but in fact it can be done with your own hands. Of course, if you have any doubts in this matter or you are afraid to take on such work, then it is better to entrust it to specialists.

Kinds

There are several types of self-leveling floors. Each type of flooring has its own distinctive characteristics and nuances concerning its installation and operation.

Epoxy

Today the self-leveling floors, having in its composition epoxy resins, are very popular. Often these materials are used in the decoration of residential premises. The main advantage of epoxy floors is their resistance to the action of alkalis, acids and other aggressive mixtures.

However, it is not recommended to use them in rooms where they will be constantly subjected to shocks and other similar impacts. For a long time they will not last in such an environment, therefore in the production area they can not be installed, but for home furnishings it is a good solution. Also, epoxy floor has an attractive appearance, which can decorate the interior of any room and make it more original. It can be safely used to create amazing 3D floors.

Polyurethane

Polyurethane (one- and two-component) self-leveling floor is no less popular and in demand today. Its inherent performance characteristics make it quite possible to use it for the repair of an ordinary apartment building.

To the main positive feature of polyurethane flooring can be safely attributed to their reliability and durability. This high-strength material has a low weight, which does not affect its resistance to serious wear. Such coatings easily carry impressive mechanical loads. In addition, they are not afraid of aggressive chemicals.

Experts say that polyurethane floors can be laid without a doubt in rooms subject to regular temperature changes. Under these conditions, the coating will not be deformed and will not lose its attractive characteristics. Thanks to these qualities, polyurethane floor can often be found in workshops and other industrial premises.

High-quality polyurethane floor is not afraid of even abrasive substances, as it does not scratch from their impact and does not lose its original appearance. This once again confirms that for many years such material will delight its owners with a beautiful design.

High-tech polyurethane floors can boast resistance to radiation. They are also characterized by excellent antistatic qualities. They are allowed to be installed even in the situation of enterprises related to nuclear energy and in rooms where explosive substances are stored.

Methyl methacrylate

The primer, the special substance providing viscosity of structure and a varnish is a part of this bulk floor. It also contains a dry mix, which is responsible for the shade of the future floor covering.Quality floors of this type are even transparent. Their thickness can be as low as 0.5 cm.

It is worth considering that methyl methacrylate floor does not tolerate exposure to aggressive chemical compounds. Also, it is better not to subject it to excessive mechanical stress. However, it should be noted that such varieties of the floor of the floor dry quickly and harden. You can safely walk on it after a couple of hours after all installation work. The maximum strength characteristics he will find after 3 hours.

Experts say that the laying of such coatings can be done without fear, even in cold and harsh climates.

Acrylic cement

The acrylic look of a bulk floor can brag of fine operational characteristics. It turns out perfectly smooth and aesthetic, and for this it is not at all necessary to prepare the foundation.

As a rule, acrylic-cement floors are stacked at enterprises specializing in processing and processing food products. The thickness of such coatings rarely exceeds 2 cm. A high-quality self-leveling floor of this type provides good waterproofing in the room.

It is possible to use such floor material in spaces with the most different temperature conditions (from -60 to +110 degrees). The surface of the acrylic-cement floor does not become slippery, even if you spill water on it. However, at home, such instances are not used very often.

Polymer cement

Currently, this type of self-leveling floor is the most successful solution for home furnishings, in which it is important to maintain the ceiling height without the use of screeds consisting of several layers. These floors are waterproof and do not accumulate dust on their surface.

Advantages and disadvantages

As with any other finishing materials, self-leveling coatings have their pros and cons, which you need to be aware of when choosing such a floor. The positive properties of this product include:

- Ease of application. With this you can cope on your own without attracting specialists.

- Quick drying As mentioned above, some coatings dry out in just a couple of hours.

- Strength. Most types of self-leveling floors are characterized by high strength and durability.This is especially true of coatings designed for use in a production environment. Despite the listed characteristics, this material is a thin layer that does not “eat up” free space. He also applied a thin layer.

- Not flammable. Self-leveling floor is fireproof, which makes it more practical in comparison with laminate or solid wood.

- Not afraid of mold and mildew. On the surface or in the construction of the self-leveling floor does not form fungi or mold spots. Also, they are not afraid of various parasites and insects.

- Security. Even in conditions of high temperatures such floors do not emit dangerous and harmful substances that can harm the health of the household.

- Easy care. Some types of liquid floors are not at all afraid of aggressive household chemicals and even abrasive products. This suggests that you can safely remove dirt from their surface using conventional means, without fear of harming the floor.

- Does not accumulate dust. As a rule, dust does not accumulate on the floor, so it often looks well-groomed and aesthetic.

- Alignment effect High-quality self-leveling floor can easily hide some defects and unevenness of the sexual base.

As for the drawbacks, the self-leveling floors have not so many of them.These include:

- High cost.

- Increased requirements for the preparation of the base of the floor.

- The difficulty of removing defects and flaws in case of improper filling.

As you can see, there are still more positive qualities in self-leveling floors than negative ones. However, the choice is always up to the consumer.

How to choose a mixture?

Currently, various leveling compounds are sold in stores, which differ from each other in composition, drying time and layer thickness. Incorrectly chosen product can not meet the expectations of the buyer and will not help to achieve the desired effect, so you should get acquainted with the different types of mixtures and their distinctive characteristics.

Cement

Such compositions are made on the basis of cement. It is permissible to install them in almost any room, and it does not matter at all what temperature and humidity level they hold. As a rule, it takes from 3 to 5 hours to dry them.

Apply cement mixtures need a layer of 2 to 5 cm.

Plaster

Gypsum-based mixtures are very strong and reliable, and they are much cheaper than the same cement options. However, they are not recommended for use in rooms with high humidity.. This is because in the process of absorbing moisture, the plaster material becomes much softer and becomes larger in volume. In such conditions, the finishing flooring may be subjected to various deformations. As a rule, the thickness of the plaster layer is about 100 mm.

Quick dry

Different self-leveling mixtures differ from each other not only in their performance, but also in drying time. It is not recommended to buy quick-drying options for the first time, because in the absence of relevant experience it is unlikely to be able to quickly and accurately handle such a fill.

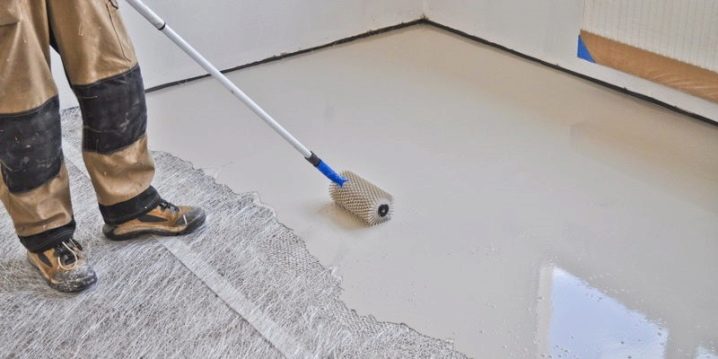

Within 15 minutes after you knead the solution, you need to have time not only to lay out the entire mixture on the base, but also to smooth it well with a roller (this is necessary to eliminate air).

If the room has a large area, then the floor will have to be poured into it in portions, maintaining an interval of no more than 10 minutes.

Base and Finish

In all mixtures there is a special filler.The main purpose of the composition directly depends on its fraction.

Variants in which there is a large fraction of filler, as a rule, are used as base layers, with the help of which it is quite good to hide various base defects. However, such mixtures have a slightly rough surface. The base layer is applied in a more dense layer and dries for a long time.

If in the mixture there is a fine fraction filler, then it should be used to level small defects, as well as to prepare a coarse base for the floor covering. These compounds are applied in a small layer and dry quickly enough.

Depending on the type of base and its technical condition, the self-leveling floor may consist of one layer (be single-layer) or be two-layer (thicker, both specified mixtures are used in it).

Calculate the flow

Whatever mixture you choose for the floor, it must be correctly calculated, otherwise you may not have enough. In this case, the mass is divided into two main types - on requiring the participation by manual labor and on self-leveling.The latter option requires a particularly accurate and correct calculation, because you need to put the composition at one time. If you add other substances to it to change its mass, it can lead to its separation and loss of useful qualities.

Starting to calculate the required amount of the mixture per 1 m2, it is necessary to assess the condition of the base of the floor. Be sure to consider the presence of nicks and potholes. If the depth of some of them is 5-8 cm, then the liquid composition of the floor should be abandoned. In such situations, it is first necessary to eliminate defects using a coarse-grain base solution.

After that it is necessary to find the zero level on the basis. The plot at the highest angle from the floor is projected onto the walls in the room. Small values are taken for the thickness of the screed from the mixture.

After that, the consumption of the composition, written on its packaging, must be multiplied by the layer thickness and the immediate area of the available space. So, you get the desired result. But it's not that simple. All calculations made will be approximate. In order to prevent serious mistakes, you need to add 10-15% to the result obtained. After that it is necessary to divide the resulting figure into kilograms indicated on the package with the mixture. So you can find out how many bags you need for all the work.

Required tools

Laying high-quality self-leveling floor should occur using following important tools:

- Capacious capacity in which it is possible to mix necessary solutions. It is better to purchase plastic containers or take a usual galvanized bucket.

- Special construction mixer.

- Squeegee necessary for extruding the resulting solution.

- Level or laser level.

- Lighthouses. It is better to use special point beacons-reper.

- Special needle roller. This tool will be needed to eliminate air bubbles.

- Paint shoes (special shoe lining or rubber slippers with special soles).

As for additional materials, here you will need:

- Priming.

- Damper tape.

- Fiberglass or reinforcing mesh.

Preparing the solution

On packages with different mixtures most often applied basic instructions relating to the mixture of the solution.The main issue in this regard is information relating to the rate of water consumption for the mixture. Fluid temperature should not be below 15 and above 20 degrees.

To begin with, it is necessary to pour in the bucket the necessary amount of pure water that does not have different impurities and additives. Then you need to gradually pour the mixture into it and stir using a construction mixer. This should be done until the composition becomes homogeneous. Lumps in it should not be.

The resulting solution will only be viable and ready to use for a certain time, which largely depends on the base binder. As a rule, this time period does not exceed 30-60 minutes.

Consider that the raw material, in the composition of which there is cement, forms an alkali when in contact with water, therefore, when working with such materials, it is necessary to avoid contact of the mixture with skin and eyes. It is also recommended to wear a respirator so that no harmful dust accumulates in the lungs.

Do not use too much water, as it is detrimental to the self-leveling flooring. Because of this, the solution can disperse into layers, and after drying it can crack and lose its strength characteristics.

Floor preparation

Preparing the floor before applying a self-leveling coating is an important process that should not be neglected. So, the old concrete platform must be dismantled using a perforator. With the help of this device individual pieces of concrete are simply beaten off and removed. It is also necessary to remove all concrete dust from the room.

Reinforced concrete slab to start is subjected to primer. This process is necessary for better adhesion with a liquid coating. After you complete all the cleaning work, a special damping tape is installed on the walls (along the perimeter). It is useful for removing the voltage of the planned filler plate.

If the installation takes place in a wooden house, then there will be a difficult preparatory work. This is due to the fact that wood does not tolerate the effects of moisture and moisture, so you need to ensure the highest quality waterproofing of the sexual base. Old boards must be strengthened.

If their condition does not cause serious concerns, then the joints remaining between them should be puttied, and the plinth should be removed. All seams should go overlap and should be fixed with tape.

Floors with ceramic tiles do not need to be completely dismantled. To prepare such bases for future alignment, it is only necessary to check the fastening of each part. You also need to make sure that there are no defective elements and voids left by the crumbled solution. After that, the floors are plastered flush with the remaining coatings. It is recommended to use a special primer for ceramics.

Remember that the application of mixtures should occur exclusively in closed windows (in the absence of drafts). Otherwise, the composition will not lie on the base in the form of a uniform coating and air bubbles will remain in it.

Fill

If you do all the work yourself, then you should know that you need to fill the floor with liquid quickly, without losing a single minute. To do this, it is better to take an assistant, who will knead the next portion of the mixture, while you will lay out and level the already prepared mass.

Do not think that self-equalizing compositions absolutely do not require labor. In fact, it is worthwhile to work with them with a special needle roller in order to expel excess air.Also useful is a wide trowel with a long handle to evenly distribute the composition at the corners of the room.

Experts advise to fill the floor portions, for individual parts of the base. Try not to miss a single centimeter of available space. After the “ripening” time indicated on the package has passed, its surface can be polished and treated with a special polymer varnish

If you want to form interesting 3D images on the floor, then they can be purchased separately, glued to a perfectly smooth surface of the self-leveling floor and coated with epoxy along with varnish. This floor can be used no earlier than a week after all the work done. If there are still some flaws in the room, then they can be reached in 24 hours.

How long does it dry?

Drying time of the self-leveling floor depends on its composition and manufacturer:

- Today there are special quick-drying solutions that dry in 2-5 hours.

- Cement-based coatings harden longer, and this can take from 1 to 2 weeks.

- Polymer surfaces used for industrial purposes dry from 2 to 6 days.

- Polyurethane compounds dry in 10-15 hours.

- Gypsum mixtures for complete fixation and hardening need about 2 days, and furniture and other items are allowed to put no earlier than 10 days.

- The drying time of an epoxy floor depends on the amount of the mixed composition and the number of its layers. As a rule, it takes from 2 to 5 days.

Creating a decorative coating

Bulk floor can be not only monotonous and quite simple, but also more interesting and bright. It was previously stated that special stickers with various images can be applied to such surfaces and coated with lacquer formulations for shine. Today, such design solutions are especially popular, as many people tend to design their home as fresh and interesting as possible.

You can create a unique 3D coating by contacting experts, or you can do it yourself. It takes a lot of time and effort, but as a result you will get exactly what you want to see in your home. It is worth considering that modern 3D floors are more expensive than classic versions. On average, for 1 square. m of such material pay from 5500 rubles.

It can be natural compositions, sea prints, contrasting patterns in oriental and artsy styles, the effect of beautiful painting and rocky shores.To do this, it is enough to find the appropriate coatings with the desired images and carefully apply them to the surface of the self-leveling floor. Even today the floors imitating marble are extremely popular. They are often used in the magnificent interiors executed in the aristocratic directions.

If you do not want to see floors in your house with different images and patterns, you can choose a simple color material of your favorite shade. Most consumers today prefer the original glossy options.

It is not recommended to contact too bulky prints or images of small objects., which are given a large size. Such decisions look tasteless and even coarse.

Designers are not advised to refer to images that demonstrate too bright and flashy colors, as well as their contrasts. They will excite the nervous system of the household, and with time they will begin to annoy.

Popular manufacturers

Today, the market has a huge number of different brands that produce practical self-leveling floors. Will consider Rating of the most popular and well-known manufacturers who collect positive feedback on their products:

- Bergauf. This large brand produces dry building mixtures, which occupy a leading position in the Russian construction market. The Bergauf range includes high-quality leveling compounds that are designed for customers with different budgets.

- "Hercules". The range of this brand is very large. In it you can find a quick-hardening and simple self-leveling floor. All materials are moisture resistant, high strength and have a beautiful glossy surface.

- Weber-Vetonic. This brand produces both commercial and household self-leveling floors. They are distinguished by excellent flowability, a fairly quick set of necessary strength, a perfectly smooth and neat surface, as well as the possibility of both manual and mechanized installation.

- "Miners". This is another well-known brand that produces high-quality cement-based mixtures. In their composition there is quartz sand, which makes products more durable and wear-resistant.

- Vetonit. This French brand produces self-leveling floors of unsurpassed quality. They also make them based on cement and sand (or limestone), as well as acrylic (with cement) options.

- Knauf.It was impossible to ignore the popular products of this famous brand. Knauf liquid floor coverings are made on the basis of cement and polystyrene foam. These varieties not only have excellent performance characteristics, but also look aesthetically pleasing.

Care instructions

Self-leveling floors are sufficiently durable and wear-resistant, so they can be cleaned with electric brooms, steam mops, simple brooms and even coarse brushes. This fact is particularly pleasing in those cases when a liquid floor is present in the bathroom and toilet, as well as in the hallway, on the balcony and in the hall. Many types of floors are not afraid of even abrasive products, but still you should not conduct experiments in the finish.

The only thing that can happen during the use of a self-leveling floor is the formation of scratches. These defects most often appear as a result of moving heavy furniture (or items with sharp edges) around the room, as well as walking in rough shoes. It is also worth considering that even such durable and reliable coatings may lose their brightness and shine over time.

To extend the service life of the self-leveling floor, it should be treated carefully.

Bulk floor can be repainted. For this it is better to buy special paints with non-aggressive composition. In addition, the new color (either white, black or brighter) is recommended to be supplemented with polymer varnish. However, painting is not recommended at low temperatures, otherwise the new color will not last long.

Owner reviews

Today, self-leveling floors are very popular, as they are distinguished by their beautiful design and are quite reliable. All owners of such floor coverings note the ease of their application, the reliability of the resulting material, as well as its perfectly smooth surface.

As a rule, consumers are disappointed by the too high price of liquid floors. The same people who decided to save money and purchased cheaper formulations, they were not happy for long. After some time, low-quality coatings can crack and lose their attractive appearance.

Beautiful examples

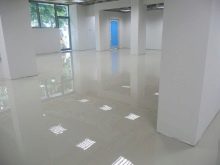

Designers offer to apply the following options:

- Self-leveling floors look very nice and presentable. Moreover, they are an excellent choice for people who want to move away from old traditions and bring more fresh and original notes to their homes.So, an unusual transparent floor is a bold and bold decision. It should be installed in a bright room with plenty of natural and artificial lighting. Such an ensemble will look more spacious and modern.

- Such floors are suitable not only in the device living rooms and kitchens, but also in bedrooms, corridors and even in bathrooms. Fans of pompous and artsy ensembles often prefer similar coatings that mimic expensive marble. They can be laid in the kitchen, in the dining area, in the toilet, and in the bathroom. Against the background of this floor it will look great the same light or contrasting furniture, as well as decorative rugs with a high pile of gray tint.

- Universal are snow white glossy floors. They will look equally stylish and fashionable, as in classic or fancy ensembles, and in modern or futuristic settings. On a similar background, both bright and contrasting dark furniture looks great. One has only to consider that in too white rooms it is worth using bright accents of different colors, which will dilute the excessive whiteness.

- If you want to bring notes of originality into the interior of a house or apartment, then you should turn to interesting floor coverings with 3D effect (with a picture). They look simply inimitable! However, you should be careful with them. Avoid too motley and ridiculous prints, as well as huge and distorted images. Such elements not only do not decorate the interior, but make it hopelessly tasteless. So, in a small bathroom or toilet it would be nice to look at the floor with an imitation of the seashore (with pebbles and shells), and in the hall - an imitation of small pebbles diluted with wooden floor covering and LED lighting between them.

- The image of waves and other marine motifs will be the perfect solution for light or light gray rooms in a modern style. In such situations, snow-white furniture and objects made of glass and metal will find its place. You can dilute the interior with light wood details and chrome-plated elements (legs of tables and chairs, for example).

To learn how to make a self-leveling floor with your own hands, see the video below.