Repair of self-leveling floors: causes of cracks and methods for their elimination

The popularity of self-leveling floors is growing every day, as their relatively low cost is combined with good performance indicators.

They have high wear resistance for a long time, they are not exposed to many chemicals. Nevertheless, even compliance with all the rules in their manufacture, as well as high-quality and professional installation can not completely exclude the likelihood of various damages that require repair and updating.

Causes of defects

The main reasons for the appearance of damage of various types are related to the violation of technologies at the initial stages:

- wrong or poorly mixed composition;

- poorly prepared work surface;

- use of low quality materials.

In most cases, a bulk floor equip on a concrete coupler. It is important to ensure that it is completely dried. Also, it should not be any pollution. Any dust, dirt or grease stains will further lead to defects in the operation of the floor.

If you leave the base wet, then the release of excess moisture will certainly lead to the fact that parts of the floor will crack or swell.

The screed must be primed. Any irregularities lead to the fact that the polymer composition and the concrete base do not adhere well, and this leads to the appearance of cracks.

It is necessary to prepare and pour the mixture, following all the rules and instructions of the manufacturer. The self-leveling floor will be brittle if the work is performed under the wrong temperature conditions. During pouring the floor temperature in the room should not exceed 25 degrees.

It is also impossible to carry out work in a cold room with a temperature below 15 degrees.

In rare cases, damage to the self-leveling floor may occur if it is used improperly. Incorrectly chosen detergents and cleaners can compromise the integrity of the top coat layer, and then it will crack.Excess moisture can also cause problems with self-leveling floors.

Common problems

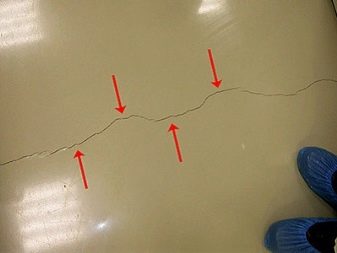

Cracks are often encountered problems with self-leveling floors. They are shallow, and may reach the concrete base. Most often, their appearance is due to the fact that the base for the floor was made poorly. If it was fragile, mobile or insufficiently dried, it will inevitably lead to the appearance of various kinds of cracks during operation.

The self-leveling floor also often cracks if the mixture was improperly prepared. The reasons may be the addition of too much water or the use of a solution that has expired.

In some cases, it is not necessary to completely fill the floor, and you can get by using a self-leveling mortar.

It happens that the appearance of cracks in the self-leveling floor is accompanied by detachment. Another name for this phenomenon is coveting. When bucking a part of the surface on which cracks appear, can tear off from the base. Then she starts to creak and move. A whip may occur in the event if no waterproofing layer was applied to the substrate or if there are cracks on the concrete screed. Then the moisture easily leaks out, and the connection between the self-leveling floor and the base is broken.

Hilly uneven bulk floor or surface with dimples does not look neat at all. In addition, any irregularities will significantly complicate the laying on the floor of other coatings.

These defects are often caused by inaccurate pouring the mixture or non-compliance with the proportions in its preparation.

Features of repair

Repair of polymer coatings, as a rule, requires only the surface treatment of the upper layer or its removal. For more serious defects, you may need to dismantle the coating, or you will have to redo the concrete screed.

To restore the original shine or eliminate scratches from the surface is possible using polishing. This operation is carried out with a special rotary polishing machine using felt circles. They put a special composition. Restoration of polyurethane floors is performed with the use of protective varnish.

Before any surface treatment is very important to thoroughly clean it from dust and dirt, as well as degrease.

After grinding the surface layer and removing small defects such as bubbles or swellings from it, it is enough to fill the finish layer. Various cracks and delaminations require complete removal of the coating from the polymer. Sometimes it is enough to restrict a certain area, but you may need to replace the surface layer around the perimeter, with the coating cut to concrete, grind the concrete screed.

Next, perform the same steps as in the initial installation of the self-leveling floor:

- degrease the surface of the screed;

- ground it;

- put the necessary layers.

When updating a small area of the floor, it is important to carefully grind all the joints, to process them with a special mastic.

Usually a complete replacement of the self-leveling floor is done if the damage affects at least 30% of the area. Repair of the concrete screed may be required if its poor quality and possible irregularities provoked defects in the self-leveling floor.

If the concrete is of satisfactory quality, but there are cracks in the screed, need to restore the substrate. To do this, the gaps are embroidered to a sufficient level, then everything is dedusted, ground and filled with repair compound.

Alternatively, you can use injection technology. First remove the layer from the polymer to completely expose the crack. Then a hole is made in the concrete at an angle, the packers are introduced there. With the help of an injection pump, a composition for waterproofing is introduced through the packers until it completely fills the crack.

Cracks or delaminations rather quickly increase in size, therefore do not delay repair time, so that instead of a separate section, you do not have to re-fill the entire floor.

Ways to eliminate cracks

If the floor has cracked, you need to fix the damage as quickly as possible. Ways to eliminate them depend on the depth of the crack and its size. With minor damage of no more than 1 cm in length, there is no need to re-pour the flooring.

It is enough to perform the following actions:

- with the help of tools, the crack is expanded to 2 cm in its entire length;

- all dirt is removed with a vacuum cleaner;

- on the basis and walls the crack is treated with a primer;

- then the polymer mixture is poured into the slots, leveling the surface.

If the area on which the floor is cracked is quite large, it is necessary to remove and reload the entire section of the flooring with damages. Do this as follows:

- filler layer chip, clean and look the base;

- if the concrete base contains cracks, use cement putty;

- clean the area from dirt;

- they are engaged in priming of exposed side surfaces, grounding the concrete base itself;

- all poured a new solution and level.

Instruments

To make the repair of self-leveling coating in the apartment, you need to stock up on a certain set of tools and accessories. Recommend to use a respirator. For high-quality mixing of the solution, it is better to use a powerful electric drill, since a poorly mixed compound will cause further defects on the self-leveling floor.

To level a surface or to remove the spoiled layer it is possible by means of the grinding machine.

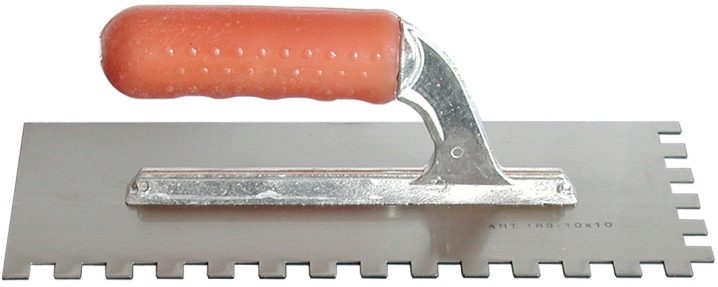

If repair of the coating requires a complete refilling or application of a topcoat, use a notched trowel. This tool is easier to distribute the substance on the concrete base, and then the tool itself is aligned on the surface.

It is important to choose a tool with a height of teeth half the thickness of the layer. The width of the trowel must not exceed 1 m.

The finishing layer is usually applied using a doctor blade. This tool is similar to a notched trowel, but it can adjust the width and length of the teeth, so it is possible to evenly cover the surface with a thin finishing layer.

By means of the needle roller it is possible to restore a site of a bulk floor of any area. They evenly distribute the mixture, and remove air bubbles. Depending on the area of the repaired area, choose a tool of different width and with different length of spikes.

The construction level controls how even the base of the floor and the finish are obtained. In this case. it is better to use a device about 2 m long. Using a roller, apply a primer to the areas from which the damaged material was previously removed.

It is advisable to choose a long nap.

All tools must be placed in a solvent for at least 4 hours to remove preservative grease. Otherwise, oil may get on the floor, which again will lead to the formation of defects.

To restore the self-leveling floors in the warehouse, you may need additional tools.You should never delay the repair of even minor cracks in the self-leveling floor, since their timely removal will help avoid the occurrence of more serious problemswhich will lead to the need for a complete refilling of the solution.

You will learn how to seal cracks in the concrete screed in the next video.