Bulk floor: calculation of the consumption of materials per 1 sq. Km. m

Self-leveling floors appeared relatively recently. From year to year they are becoming more popular. There is nothing surprising. The source material for casting exceptionally flat surfaces is available in every decent store of goods for construction. Instructions for use are printed on the package. The technology of arrangement is so simple that anyone will master it, and the result is always excellent.

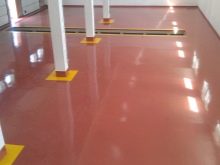

Seamless floors can be mirrored, glossy or matte. Buyers are given a huge choice in color. Floors do not deteriorate from shock loads, do not wear out from hundreds of soles. They are unpretentious to care. Any contamination can be removed with warm water and detergent.

The appearance of self-leveling floors is pleasant and elegant.

Special features

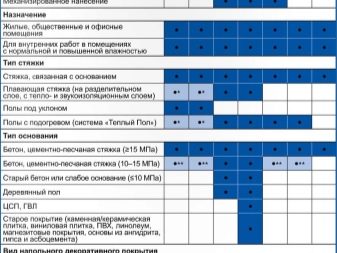

Bulk floors, depending on the composition are divided into several types:

- cement-polyurethane;

- methyl methacrylate;

- epoxy;

- epoxy-urethane;

- polyurethane.

Cement-Polyurethane floors withstand heavy loads. Their distinguishing characteristic is resistance to abrasion and other mechanical stress. In addition, they are not damaged by contact with chemicals.

Methyl methacrylate, unlike others, can be poured at air temperatures from + 8 degrees. The main advantage is increased frost resistance. Installation of such a floor requires professionalism, since the hardening occurs very quickly, and the process itself is accompanied by the release of an unpleasant smell.

Methyl methacrylate floors are appropriate in unheated industrial premises.

Floors epoxy withstand physical impact, resistant to moisture, oils, aggressive chemicals. Are established in chemical laboratories, at the enterprises of pharmaceutics.

Epoxy-urethane Combine strength and elasticity. This species has an increased durability and does not react to chemicals. Such floors are equipped in shopping centers, subways and where thousands of people pass during the day.

Polyurethane are most in demand because they have a lot of positive qualities. Among them:

- long service life;

- excellent view;

- indifference to sudden changes in temperature.

Thanks to resistance to oils, alkalis and other aggressive chemicals polyurethane floors began to appear frequently in industries with high demands on hygiene. They can be seen at the enterprises processing agricultural products, meat processing plants, bakeries, industrial freezers and other similar premises.

Recently, the floors on the basis of polyurethane are used in residential construction.

What affects the quantity?

Bulk floor is expensive. The thrifty owner will not be willing to spend too much, and will definitely find out what may affect the consumption of the mixture.

There are several factors that influence the amount of material required.

The most obvious are: the area to be treated and the thickness of the floor. The rest are not so obvious, but no less significant.

Assume that the draft floor, which is planned to be applied in bulk, is in good condition, then for 1 square meter. m will go less mixture than at the same thickness, but with poor quality basis.

The fact is that each crack cracks the precious liquid of the self-leveling floor.The plastic mixture, spreading over the rough overlap, fills its every defect, is absorbed into the pores, penetrates into the gaps and hollows. Conclusion: consumption depends on the quality of the base.

Matters the purpose of the floor. If it should simply level the surface under the subsequent floor covering, the thickness can reach several cm, and the flow rate should be decent. With a thickness of a few millimeters self-leveling coating in the apartment is a finishing finish. Consumption in this case is significantly reduced.

To determine the flow you need to focus on the shelf life of the material, as well as its density. If we take into account the average density, then it is different in different species:

- 1.25 - 1.35 kg / l for polyurethane compositions;

- 1.4 - 1.65 kg / l for epoxy;

- 1.6 kg / l for acrylic-cement solutions.

Calculation of the norm

In order to calculate the need for self-leveling floor, you need to take the original value. The starting point for any mixture is taken as one. It is that to obtain a layer in height of 1 mm per 1 square meter, 1 liter of composition is required. In this case, the fillers are not taken into account.

Further calculation involves making adjustments based on the density of the material used. For example, if the density is minimal and equal to 1.2 kg / l, then the same square meter with a layer height of 1 millimeter will have not 1, but 1.2 liters of the mixture.

Know the density of the material is easy. Manufacturers always indicate it on the packaging of the goods. Knowing the density data, it is easy to calculate the flow rate for a specific case.

For example, take a room of 20 m2. Assume that the pouring should be 2 cm thick, and the self-leveling floor is selected on an epoxy basis. According to the manufacturer, the density is 1.5 kg / liter.

Multiplying the values of the density of the material, the area of the room and the thickness of the fill, we obtain the need of the material in kilograms.

1.5 x 20 x 20 = 600 (kg)

If we consider that the dry mixture is sold in bags of 25 kg, you can find out the number of bags:

600 kg: 25 kg = 24 bags

At the finishing self-leveling floor will require less material, since in this case the thickness is much less - from 3 to 5 mm. However, on the basis of cement without its pre-treatment may take more than the calculated value,as the cement absorbs part of the liquid substance.

How to reduce consumption?

A negative factor is the high cost of self-leveling floors. Fortunately, there are ways to significantly reduce costs. You only need to carefully examine them, and then take advantage of the knowledge gained.

Unproductive consumption of valuable material may occur when pouring on an unprepared base. Losses can be 20% or more. In order to avoid losses, you need to take all the responsibility for the arrangement of the foundation.

Old floor should be carefully inspected. All identified flaws must be repaired: potholes, shells, chips should be embedded with the solution, small gaps - putty.

If there are stains of paint, oil or other liquids on the subfloor, a solvent is used. On the ground there should be no stains, dirt and dust.

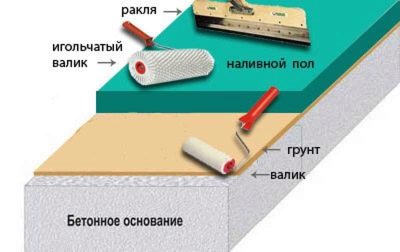

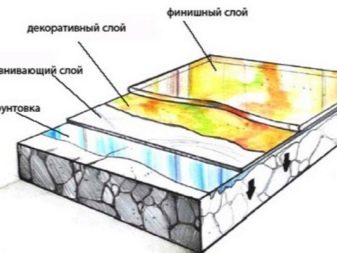

The cleaned surface is primed. This operation is performed after the mortar has completely frozen and puttyed. If necessary, the primer is applied in two layers.

If the base is badly damaged, do not waste time on local repair. The best solution would be the arrangement of a complete screed.Before you pour a self-leveling floor, a new screed is also primed on a mandatory basis.

Instead of a cement screed with insignificant differences in height, a leveling agent can be used to level the surface under the floor.

Specialists working with self-leveling floors, make litter when working with polymer coatings. After pouring the base, quartz sand is poured on its still frozen surface. When the base is set, the excess sand is removed. This simple technique significantly reduces the consumption of the mixture.

On the basis of the prepared using a laser level, make a mark of the horizon, determine the elevation differences, then do the calculation of the fill volume. By volume, find the required number of bags of dry mix. The more accurate measurements and calculations are made, the fewer mistakes the builder will make, and more finances will be left for other related work.

In carrying out the calculations, you need to remember about the possibilities of various types of self-leveling floors. So, for an epoxy type, the maximum possible layer thickness is 6 mm, and for polyurethane only 3 mm.

The thinner the layer of the self-leveling floor, the less material consumption.A thin layer can be obtained from high-quality mixtures of proven manufacturers. Despite the fact that the liquid mixture is leveled on its own, it is useful to mark the end horizon with beacons. For point landmarks used screws.

And the last thing that will not allow the mixture to be overrun is to precisely follow the rules for pouring it.

The composition of the mixtures

The best liquid floor is obtained from self-sufficient mixtures. They already contain everything you need to get a perfect coating. It remains to stir the dry contents in water to the desired consistency and pour it on the base.

Due to the high cost, preference is often given to cheaper combined formulations. In such mixtures, a significant proportion is given to cement. It acts not as an ordinary filler, but is a full constituent part with its unique task. In this case, the cement takes care of making the mixture viscosity.

The second part consists of several elements. This mineral supplements, and polymer fillers, and modifiers. This also includes fractional sand. The listed ingredients provide the mixture with the ability to smoothly flow, quickly set, forming a solid monolith.

Special additives can turn a universal self-leveling floor into a unique one.For example, the solution may acquire the properties of insulation or sound insulation, become frost-resistant or fire-resistant.

Domestic industry offers customers relatively inexpensive self-leveling floor mixes. brand "Hercules".

Dry mixtures "Hercules" are used for the floor of the finish under the finish. The main characteristics, in addition to the democratic cost, are:

- moisture resistance;

- good adhesion with any, including painted surfaces;

- elasticity;

- no deformations with a sharp change in temperature;

- strength;

- resistance to stress.

Self-leveling floor "Hercules" can be poured into the bathroom without additional coatings.

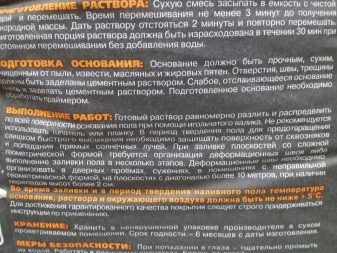

In the preparation of the solution is nothing complicated. You just need to follow the instructions. Exact step-by-step execution of the manufacturer’s instructions provides excellent results.

"Hercules" can be used in residential areas. When preparing the solution, the mixture instantly reacts with water. Dust does not rise during kneading, the working area remains clean, which means that it does not have to be further processed.

Professional Tips

Bulk floor will delight impeccable appearance and long service life if:

- Well prepared base. When applying the solution to the cement screed, it should be leveled, cleaned from dust and grease stains. Otherwise, delamination will occur in dusty and polluted areas.

- During the works maintained temperature. Do not pour floors at sub-zero temperatures. In the solution may be ice crystals. When the temperature rises, they melt, and the structure of the floor is broken. The heat also negatively affects the composition of the mixture. Excessively rapid setting of the solution at high temperatures leads to its heterogeneity.

- It is better to work together. One person makes a mixture, the second fills it and aligns it. The composition begins to harden within half an hour. If time is missed, the mixture will become unusable, which will entail additional costs.

Do not be afraid of the high cost of the self-leveling floor. Reliable, beautiful and practical coverage simply cannot be cheap. And if you count on the duration of its service life (at least 20 years), it turns out that the price is quite low.

On how to make a self-leveling floor, see below.