Polyurethane floors: advantages and device

Polyurethane floors are at the height of fashion in the interior. They are often used in private homes and spacious apartments. Shops offer a wide range of mix options for creating this type of coverage. But before choosing such a floor, you should familiarize yourself with all its inherent characteristics, as well as the characteristics of the fill.

Only if you take into account all the nuances you will make the flooring in your home ideal.

Special features

Polyurethane floors are self-leveling coatings, which include special polymers consisting of two components. The unusualness of such products is in their special elasticity and strength. By peculiar chemical reactions, synthesis of polymer material takes place and self-leveling floors are obtained.

In its original form, this type of coverage is liquid polyurethane mixture, which resembles the paint on the consistency. Such materials create a monolithic texture upon drying.

The popularity of such floors has increased due to their use on uneven coatings or on the foundation with flaws in the form of cracks and porous recesses.

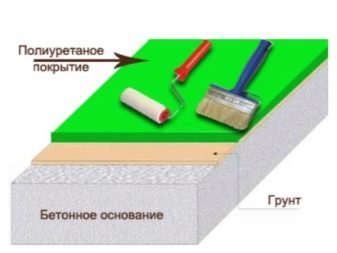

Despite the compromise of the coating in relation to irregularities, it is less adapted to other materials. Polyurethane liquid linoleum requires the preparation of a base surface before pouring. Usually a floor of this type consists of two layers. The bottom is equipped with a special impregnation that allows the material to cling to the base surface. The top coat has a protective function.

Like any floor covering, liquid linoleum with polymers has its positive and negative characteristics.

Benefits:

- Seamless device. In the process of pouring the composition and after drying it does not form joints and nicks, which can often be observed on the parquet floor or ordinary linoleum.

- Bulk floor is popular for all types of premises. It is used both in ordinary apartments and in large warehouses.Sometimes it is even used for freezers and workshops.

- The coating is resistant to high and low temperatures. The floor does not lose its presentable appearance even when in contact with open fire.

- The surface of the product has a special strength. This quality explains the durability of the coating.

- Filling floors is easy to implement on their own. They do not require the use of complex technology.

- Easy to care. For polyurethane coatings there is no need to do regular cleaning. In case of contamination, it is enough to wipe the surface with a dry or damp cloth.

- Floors of this type have high impact resistance. They are not so easily mechanically damaged, thus avoiding the need for frequent restoration.

- Polyurethane compositions are presented in huge variations of design. Among the range you can find such a color and ornament, which will be combined with different styles of interior.

- Floors create an additional level of sound insulation.

- The composition of the liquid floor does not include harmful solvents, which allows not to worry about their health during installation and during operation of the floor.

- Coatings are able to reflect the effects of chemical components, therefore, it is possible to clean particularly complex contamination with the help of special means.

Among the negative qualities of the polyurethane coating include the following features:

- Such a floor can not be dismantled. If you want to change the surface, then you have to place the new material directly on the liquid linoleum.

- Filling is made only in the apartment, the house or other indoors. Due to the possibility of changing weather conditions, it cannot be carried out in open areas without a canopy. The temperature range during pouring should not exceed 10 degrees.

- When the composition is not dry, it has a peculiar smell that not everyone will like.

- Not even a small amount of moisture is allowed on the basis of the floor.

- Such a coating, as compared with traditional ones, has a higher cost. It is also necessary to take into account the high consumption of material that will increase financial expenses, especially when finishing the overall premises.

- The composition has some degree of toxicity. Some manufacturers make the material, including elements such as phenol.

- Laying polyurethane coatings requires a considerable amount of time.Sometimes the process can take more than a week.

- When ready, the floor surface feels cool to the touch. Not for all, this nuance will be a factor in the comfort of the room.

How to choose?

Among the range of polyurethane coatings, it can be difficult to determine which one is best for your home. Single component compositions are selected as a layer of additional protection. The texture of the material is similar to oil paint, which is a layer of at least 0.4 mm.

Two-component solutions are needed to create a more dense coating. The components of the composition are mixed with each other, and only after that the material is applied to the prepared base surface. Two-component liquid linoleum has the property spreads poorly in the process of pouring, but forms a more dense layerwhose thickness can reach 2.5 mm.

Choose a mixture depending on the load that the filling coating will experience.

The single-component version carries a slight or moderate degree of load, which is quite suitable for apartments. A more dense layer that can withstand strong shocks, suitable for warehouse and industrial premises.

Consider the style in which your room will be decorated. For some areas, certain colors are preferable, as well as matte or glossy textures.

Please note that the 2-component polymer floor has different types depending on the types of surfaces on which it is applied. There are variations for:

- Capillary-porous mineral floors - for brick, concrete pavement and slate.

- Metal surfaces in which iron, steel and other alloys may be present.

- For wooden foundations, including hardwood floors, plywood and parquet.

Before going to the store, carefully review the reviews of various manufacturers and correlate the prices they offer for products with the planned level of financial expenses.

Training

Preparation of the base coat is one of the most important steps in laying the polyurethane floor. It needs to be carried out in several stages:

- If you have concrete coatings, it is necessary to fix all irregularities with the help of cement. In the case of a wooden floor, wash the surface thoroughly and wait for it to dry completely. Ceramic floor requires replacement of unstable areas of the tile.

- To rid the surface of excess dust should be using a construction vacuum cleaner. If this is not done, the pollution will cause the material to peel off in the future.

- To create the ideal surface for concrete floors, a self-leveling compound is sometimes used. After drying it is necessary to grind it.

- After it is necessary to cover the floor with a layer of primer. It is applied using a construction roller. If the soil mixture is absorbed quickly, then several layers should be applied. When there is no rapid absorption, give the composition from 1 to 3 hours for the final drying. The presence of a primer will contribute to better adhesion of liquid linoleum with the base surface.

After the surface of the floor has been treated, it is necessary to start making the composition for pouring and directly on the procedure for creating a filling layer. The mixture is made according to the instructions:

- Using needle equalizers distribute the first layer of the mixture. Its thickness, depending on the type of premises varies from 1.5 to 3 mm. In order not to damage the structure of the coating in the process of its installation and to move freely around it, wear special needle shoes - paint-shoes.

- At the stage of freshly laying the first layer, decorative elements may be applied to the surface.

- Until the mixture is completely dry, add additional flatness to the coating using a studded construction roller.

- Readiness depends on the temperature range. Going beyond its limits can provoke a longer drying time.

- Along the perimeter of the room, it is necessary to install temperature-shrink grooves, which will ensure uniform drying of polyurethane. The grooves are made by cutting. Formed seams should be filled with sealant.

- The finishing layer is poured after a minimum of 6 hours after the first layer dries, depending on the recommendation of a particular manufacturer. The process is carried out on the same technology.

Decorative design

Decorative elements allow you to create a floor of exclusive design. The main types of design are the following materials:

- Paint. It is applied between the layers in the process of pouring. Using paint, you can create an imitation of natural materials in the coating, for example, marble. This creates a luxurious appearance of the surface.

- Volume spangles that can be made of polyester. They are also made from special aluminum foil. Spangles come in various textures and colors - sparkling, fluorescent, monochromatic, multi-colored. To create images on the floor, designers often combine different types of glitters together.

- Volumetric drawings and abstractions between polymer layers look beautiful. They can occupy the entire surface of the floor or create a partial ornament.

- For decoration use such additional elements as stones, shells, colored glass.

- Sometimes liquid linoleum is even supplied with such an element as illumination.

Expert advice

Experienced creators of polyurethane coatings are advised to listen to certain recommendations in the process of pouring structures:

- For a more harmonious and complete appearance of the coating, you can equip it with polyurethane baseboards.

- When laying a polyurethane floor, add quartz sand to the soil mix. It will help ensure a better grip fill with the base surface.

- The most preferred variant of the base coating under the polymer solution is a concrete floor.With him in polyurethane particles the strongest coupling occurs.

Polyurethane coating is a great alternative to ordinary linoleum, creating an unusual accent in interior design.

Making the surface in this way, you will provide yourself with a durable floor covering that will delight you and your guests every day.

To learn how to make a self-leveling polyurethane floor with a pattern, see the following video.