Advantages and technology of epoxy flooring

Epoxy flooring is one of the best in rooms where you need to maintain constant cleanliness, there is a high probability of mechanical and even chemical damage to the surface, and there is also no time to periodically replace the floor. It is not surprising that many industrial enterprises choose this floor covering for arranging their workshops. In recent years, more and more people are considering it as an option for home use. This solution has both advantages and disadvantages.

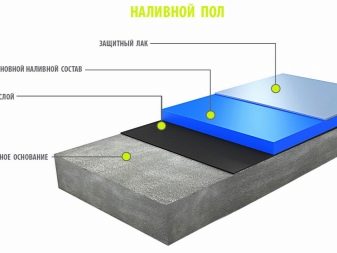

Features and device

Epoxy floors are radically different from all classical types of flooring, because they are laid by pouring a special liquid mass.The composition is based on a polymer base, so after a certain time after pouring the surface, which, like any liquid, takes a perfectly horizontal position, freezes, forming a smooth, but non-slip floor. At the same time, it looks as completely as possible, since it does not provide for any seams in its construction.

The strength of such a frozen material favorably distinguishes it from any competitors, since the hardened mass stretches well, contracts or bends. Thanks to these properties, even in the face of a strong earthquake, the flooring remains holistic and suitable for further use until the concrete base beneath it breaks. By itself, the fall of any, even rather heavy, objects has practically no effect on such material.

Given that modern polymers are chemically neutral, an epoxy floor is very appropriate even in a chemical laboratory.

Advantages and disadvantages

It should be noted that epoxy floors are used more often in industry rather than at home. Consequently,their advantages should acquire certain specifics at home, but the drawbacks that seem uncritical in production facilities can play a decisive role in home use. In this regard, it is worthwhile to particularly consider the main characteristics of epoxy floors in a normal apartment.

So, when used in the home, the following qualities deserve the commendable words:

- Full safety coverage for humans. In their own home, nothing should be a danger to the owners, and even more so - the floors. The chemical formula of epoxy composition makes it completely neutral, such a floor does not emit any vapors, and therefore it is appropriate even in those houses where there are small children or animals. In addition, this type of coating is non-combustible material, so it will not exactly cause the occurrence or spread of fire.

- Resistance to most external influences. Shocks and wiping, extreme temperatures and humidity, any caustic chemistry - all this does not care about epoxy floors, which makes them a worthy option when it comes to repairing a kitchen, bathroom or even a garage.Where the owner would like to spend money on any other coating, the epoxy polymer will cope with all the effects.

- Ease of cleaning and minor repairs. Since this coating does not imply the presence of seams, dirt, bacteria and fungus do not have too many chances to settle down in the kitchen or in the bathroom, and chemical resistance allows you to wipe the surface with any cleaning agent without harming the floor. In fact, to maintain cleanliness, the coating must be periodically wiped with a damp cloth - that’s all the care. It is noted that an epoxy floor without mechanical damage can last for two decades, so the need for its repair or replacement is unlikely to arise.

However, even if the owner somehow managed to damage the surface, it can be quite easily repaired, the bay from above with a small amount of the same mass.

However, it is not for nothing that a huge number of our fellow citizens still prefer repairing other floor coverings. The fact is that the use of epoxy floor at home is associated with a number of disadvantages. Here are the most notable of them:

- The high cost of material. Naturally, if you wish, you can find more expensive types of flooring than those made on the basis of epoxy materials, but for a kitchen, bathroom, or, especially, a garage, the purchase of expensive and sophisticated materials is unlikely to be justified. For all its price, the epoxy floor is only practical, but not chic, so many people prefer to save a lot of money on the purchase of traditional materials, even if they are somewhat inferior in performance.

- Low variety of designs. In recent years, developers, focusing on growing demand, have created several samples of epoxy flooring for home use, each of which has a certain aesthetic appeal. However, the variety of options available is still small, which pushes the potential consumer into a narrow frame, forcing the entire interior of the room to be customized for the product available for sale.

- Yellowness. Amazingly, a material that does not lend itself to almost any destructive effect is capable of quite quickly losing its original appearance under the influence of ordinary sunlight.As a result, an expensive acquisition may lose its appearance and stop fitting into the interior.

- Difficulties in repair now and in the future. Installing a self-leveling floor only seems to be the simplest procedure, but in most cases you can only entrust it to professionals, because the slightest mistake will lead to damage to the expensive coating. However, even professionals will not make such repairs quickly, because the solidification of the epoxy coating in some cases requires almost a week of waiting, without the ability to walk on it. But if the old self-leveling floor gets bored, or, worse, gets corrupted during the pouring process, it will be almost impossible to replace it simply because it engages too securely with everything around.

Naturally, another flooring can be laid directly on top of the polymer layer, but this will inevitably lead to a decrease in the height of the room.

Style and design

By itself, the composition used to fill a self-leveling floor is usually monophonic or simply transparent at all, so for a unique design you will need a special decor. The best designers of modern times usually come out of the situationoffering the so-called 3D floor, in which some foreign objects are built in, designed to decorate the interior.

The technology is pretty simple - the floor just fits. in two layers. The bottom one is chosen in color - the color that the customer deemed appropriate as a base. At first, they pour such a foundation and wait until it thickens a little - not until it solidifies, but only ceases to flow. Usually this happens on the second day after pouring, which means it’s time to start decorating.

Decoration is carried out with the help of items such as coins, multi-colored small pebbles and even colored sand. The decoration elements are laid out neatly over the slightly frozen bottom layer, forming patterns and any desired shapes. After the bottom layer finally hardens and “grabs” these decorative elements, a fixing transparent layer is poured in from above, through which the coloring of the lower layer and all the decorating elements will be visible.

Due to this, the artistic value of such a flooring significantly increases, and repair masters have the opportunity to deviate from the standard colors offered by manufacturers.

Necessary tools and mixes

Although, in general, epoxy resin-based flooring seems to be a simple task, you will need a variety of tools and materials to complete it. In the first place, of course, the mass itself, which after solidification will become a floor. It should be noted that the bulk mixtures are not only epoxy, but it is precisely those varieties that are made on the basis of epoxy resin that are distinguished by maximum durability and resistance to all types of damage. Another thing is that the mass of this type is extremely expensive, even compared to other self-leveling floors, so any attempt to choose a cheaper product may result in serious losses in quality.

In addition, the required materials for casting are cement mortar and primer. A concrete base, with a two-layer layer (from the bottom - a semi-liquid layer for leveling, on top - finishing) is necessary so that the floor covering has a reliable support, while the primer gives the maximum adhesion of the mass to the concrete, due to which the coating does not flake and does not tear.

At the same time, the old (but well-preserved) screed and the carefully repaired wooden floor can also act as the bottom layer of the concrete base, however, the finishing layer of cement is always laid.

Finally, if the screed is poured from scratch, additional waterproofing may be needed. Selection of tools depends on who performs the filling of the self-leveling floor and on what area. Repair of industrial premises often involves the replacement of coatings on an area of hundreds and thousands of square meters and is carried out by serious contractors who use special equipment - different types of grinders and industrial vacuum cleaners for cleaning surfaces.

In the conditions of home, many men today prefer to try to fill their own, and in this case, of course, the tools are somewhat more modest. To perform such tasks, a drill with a special nozzle for stirring liquid building materials, large capacity (at least in two buckets of volume), spatulas of various shapes, aeration roller with spikes and the same spiked paint gutters are necessary.

Preparatory work

The durability and reliability of the poured epoxy floor is very dependent on how well the foundation is made of cement screed. If you already have one, and it is in a normal state, you can use it, after doing minor repairs - expanding the existing cracks and carefully sealing them with a solution.Similarly, the basis can serve as an old wooden floor, but its cracks are sealed with a special wood putty, and also carefully polished.

If the concrete screed is still made from scratch, it is recommended to make the lower layer semi-fluid. Due to this, the top will rise perfectly horizontally. After the bottom layer is ready, apply the top, finish. Requirements for it - reliability, perfect horizontal orientation, and cleanliness.

Therefore, after the top layer hardens, it is carefully vacuumed (professionals do it with super-power industrial vacuum cleaners), and also cleaned of any dirt and grease, including with the help of solvents. In some cases, additional grinding of the concrete surface is also used, because any unevenness of the base will greatly affect the mass flow for pouring. After that, the base is thoroughly impregnated with a primer, and twice.

The second coat of primer is applied only after the first one has dried. Only after both layers finally dry, you can start pouring.

How to do?

Epoxy floor includes several different types of mass, but the technology of the casting is generally the same.The coating for casting based on epoxy resin, which in future forms a self-leveling floor, is thoroughly mixed in a large vessel to the very bottom, and then simply poured onto a concrete screed and evenly accelerates with spatulas over the entire area of the room.

The self-leveling properties of the fluid somewhat help with installation, since there is no need for strict leveling of the surface, but experts still recommend disperse the mass. In terms of composition, such a floor is always two-component; in it, a rapidly hardening epoxy resin is diluted with a liquid hardener. For example, we can say that the water-epoxy floor dries due to the evaporation of water, and epoxy-polyester coatings, respectively, due to polyester evaporation.

Although many people believe that the self-leveling floor is the same mass with which the surface is poured, in fact it consists of a huge number of components, starting with a concrete base and epoxy resin and ending with various decorative inserts. For the overall quality, the quality of each individual element is important, since the same soil, selected according to the “cheap and angry” principle, can lead to further peeling of the coating, as a result of which it will last for a few years.

A separate moment is the inclusion in the mass of additional materials solely for aesthetic purposes - for example, small natural stone. Often with the same purpose can be used and wear-resistant paint, crushed to small pieces or to crumb.

Sometimes, for additional protection, enamel is also applied over the epoxy floor, but in general this move seems superfluous, and it’s not a fact that such protection is stronger than what it is meant to protect.

Epoxy based floors are somewhat limited in the color palette, which forces designers to dilute the material with different inserts. However, given the most popular places of application of such a mass, a somewhat negligent attitude towards interior diversity is excusable. The most popular colors of an epoxy floor are white and transparent, the first one being more often used as a lower layer, on top of which, after its partial solidification, they lay out any adornments made of “foreign” objects, such as coins, stones, colored sand.

In the same quality, that is, in the form of a base, the mass is used in any other color. The decorative inserts are poured with a transparent mass on top so that they can be seen, but at the same time they are protected from damage, and the floor as a whole has a flat horizontal.

With all its qualities to make a choice in favor of the epoxy floor is not always. High performance is a plus, but under the conditions of an ordinary bedroom they are hardly needed in full, and the highest cost and relatively small selection of design solutions force us to use epoxy coatings only where complex conditions are provided.

At home, such floors should be poured in a room where there is an increased humidity and the possibility of using caustic and pollutants, as well as where a high mechanical load on the floor is likely or a fall of heavy and sharp objects is possible. I.e the real area of use of the epoxy floor is limited to the bathroom and kitchenless often such a decision is appropriate in the corridor and toilet.

If we talk about private households, then this repair is also relevant for the garage. As for the living quarters, experts recommend a different type of floor in them - for example, polyurethane.

Reviews

If you examine the reviews on the use of epoxy floors in industrial conditions, then all comments, of course, have a positive connotation, because it was for such conditions that the coating was created.The use in the conditions of apartments and private houses is mentioned less often, but this topic is more important for us.

If we discard complaints about too high cost or complaints that the cheaper option did not meet expectations, it turns out that for home conditions the epoxy floor is a kind of panacea for all ills. Firstly, it is extremely durableAfter all, for the entire existence of this type of material, it has not been established for how long it will become unusable.

That such the floor will remain whole even decades later - this is a fact, so even the significant costs of its installation should not stop the consumer.

When operating in a kitchen or garage, the epoxy floor is very good in the simplicity of maintaining cleanliness, because such a coating is seamless, which means that dirt and microbes have no place to hide. In addition, the high resistance of the material to the effects of any caustic chemistry allows the owners to use any cleaning products, if a certain complex contamination (the same paint) still appears.

However, it is worth being careful of those people who like to frequently change the interior.Due to the high adhesion of the coating with a concrete screed, the obvious plus of durability turns into a minus for subsequent repairs, since you just cannot remove the old floor and the new one will have to be laid directly on top.

This may not seem to be a problem if the ceilings in the house are high, and all the doors are made with outstanding thresholds, but in an old apartment it will make the task a bit more difficult.

An important critical moment is the fact that with constant sunlight, the epoxy floor burns out pretty quickly. If the garage is not so critical, as well as for the bathroom, then the owners of the kitchen can be ashamed.

We have already said that saving on building materials in this situation will result in a significant loss of quality. Cheaper grades of epoxy coating can burn out much faster or less adhere to the screed. Most often criticized in this way mixtures based on polyester. It should be noted separately that for the reliability of repair all components play an equally important role, so there is no point in buying the most expensive self-leveling floor, if everything else is chosen on the principle of austerity.

Successful examples and options

Many consumers are still suspicious of such flooring, while the more progressive part of our fellow citizens already use this material in their own apartment, and sometimes even pour it with their own hands.

For example, a kitchen is a place where even a “dull” epoxy floor requires maximum aesthetics. Most often it is still the same color, but here is a great example of how a creative approach adds coziness to “industrial” repair.

In the bathroom, an epoxy coating, if it is decorated, does so necessarily with a three-dimensional effect, revealing the underwater theme in full. It will cost you amazing money, but it's hard not to admit - the result is fascinating.

In the garage, of course, all these designer delights are not to be found, because the main thing here is the maximum practicality of use. However, this does not mean that the interior of the room should be devoid of taste.

How to perform an epoxy floor with quartz sand, see the following video.