Ways and rules of floor warming

At the present time, when choosing flooring for city apartments or for country cottages, sales consultants advise buying additional insulation. Someone purposefully uses it when covering the walls and in the decoration of balconies.

Features: pros and cons

The main purpose of insulation - is the creation of comfort and coziness in the room, the preservation of heat even in severe frost. Accordingly, the use of insulation guarantees substantial savings of money on electricity. In addition, floor insulation contributes to the creation of a noise absorbing layer thanks to which extraneous sounds will not penetrate into the room. When weatherate the floor, you can reduce heat loss in the room by 20%. This not only saves money on heating, but also allows you to evaluate all the advantages of flooring.

For example, without a high-quality substrate, the floorboard can dry out, become unusable, start squeaking, and in the future you will need to dismantle the floor and lay a new building material.

Heated floors are protected at the joints and corners from low temperatures, so that condensation on the walls is not formed. Wallpapers will not get wet, mold fungi will not appear under them, and the paint will not crack and will not disappear. In a private house thanks to the insulation of the floors of the attic and the basement average temperatures can be stabilized, make them the same in winter and in summer.

Properly laid insulation can protect against insects and rodents. This is especially important for flooring in your own home, because mice are often populated under floorboards. Gnawing through the plinth, they get out. Rats and mice can gnaw through electrical wiring, which will eventually lead to de-energizing, forced repair, or even a fire.

The downside of floor warming is considered high price. Many people do not understand why warm cottage, if there is a boiler. Experts answer that thermal insulation is done once, that is, it is a one-time expenditure, and you have to spend constantly on heating. Unfortunately, over the years, fuel only becomes more expensive, therefore, in terms of economy, insulation is necessary.

The better to warm?

Extruded polystyrene is great for creating a warm floor. First, it is a cheap building material, and secondly, it has good thermal insulation properties. In addition, he is not afraid of water, which allows him to insulate not only the inside of the room, but also the space outside, including the foundation. Of the minuses can be noted that expanded polystyrene is a synthetic material, and under the influence of high temperatures it emits styrene - a substance that can adversely affect the health of not only young children, but also adults.

It is unacceptable to set fire to building materials, since in case of a fire, foam will release phosgene, inhalation of which may be fatal. Polyfoam does not recommend to warm wooden structures because of its vapor-tight properties.

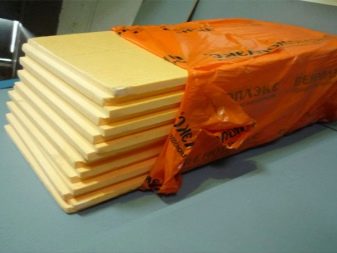

A type of styrofoam is penoplex. Penoplex sheathe the floors of country houses and city apartments. Unlike foam, this building material has high strength properties: moisture penetrates only into the outer layer, so that deformation does not occur.Even a “liquid” penoplex is capable of not letting in cold air from the street, so it is used to warm the floor in the attic.

Penoplex for wet rooms is recommended, and due to its low weight even a girl can lift it. It is cut with an ordinary stationery knife. The manufacturer guarantees a 50-year lifetime. In addition, penoplex is neutral with respect to chemicals - alkali, chlorine, paint, concrete mixtures.

Among non-combustible, environmentally friendly materials can be noted mineral wool. Minvatoy warm not only concrete floors, but also wooden structures, because it has a high vapor permeability. Mineral wool is "afraid" of moisture, so it is not recommended to use it in rooms with high humidity. In addition, during the operational period, it rolls down, which negatively affects the conservation of heat. The manufacturer occupies a special place on the building materials market. TechnoNIKOL, which produces several varieties of mineral wool:

- "Teplorol";

- "Tehnoblok";

- "Technoacoustics";

- "Rocklight".

Another natural material is sawdust.Lime shavings have been insulating private houses for several decades. This is an environmentally friendly material.which some people can even get for free. Unfortunately, it is necessary to tinker with sawdust: first dry, treat with lime and antifungal preparations, and later add gypsum, which will give lightness.

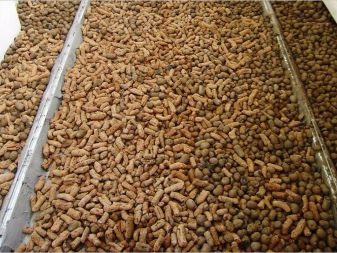

Expanded clay is used when you need bulk insulation. This is a kind of burnt clay, which is also foamed at the production stage. It is sold at a low price, but since this building material cannot interact with moisture, most often it acts as a filler.

Polyurethane is used in cases where they want to replace the poorly permeable air foam or non-moisture-resistant mineral water. Since polyurethane foam is an analogue of rubber, it is also suitable as a heat insulation layer. Of the minuses note that it has a high cost, and for its application It requires not only special skills, but also experience. Under the action of high temperatures or directly in the event of a fire, polyurethane emits harmful chemicals that are dangerous not only to health, but also to human life.

Keep in mind that doronit is a geotextile film for insulation, it is not used as a heat insulator separately. It is used in conjunction with other building materials: waterproofing membrane, drainage material and sand-cement mixture.

Folgoizol or penofol can be used as insulation for concrete under the screed. It is made of polyethylene foam and "wrapped" foil layer. Neither polyethylene nor aluminum foil are thick building materials; therefore, they do not use penofol as a base - only in conjunction with other materials.

A novelty in the store is foamed glass, which is made from foamed glass. Because of this, foam glass is an environmentally safe material, fire resistant and water resistant. It is produced in the form of granules. For industrial premises used foam glass in the form of plates and blocks.

Reviews

When analyzing customer feedback, it was not possible to find a single opinion, because some people use a heat-insulating layer in an apartment, and others in a country house. It is important to consider the thermal conductivity of the material: the lower it is, the better.Low thermal conductivity ensures that less material is needed so that the heat does not leave the room. This will provide substantial cash savings. Buyers pay attention to such quality as hydrophobicity - interaction with moisture.

It is especially important to take this into account when working in rooms with high humidity: in bathrooms, in kitchens and balconies. If the insulation rolls down when in contact with water, its thermal conductivity increases, and the heat, respectively, is not conserved.

For safety reasons, building materials should not emit harmful chemicals during combustion or burn in a few minutes. The less the insulating material weighs, the less is the load on the concrete or wooden base. Heavy insulation is most often used outside, and light inside. Equally important are the ease of installation and the final cost of the product. Summarizing, we can come to the following conclusions:

- For the floor any insulation is suitable.

- Minvat, like expanded clay, eventually settles, the thermal conductivity changes.

- When warming the floor, it is necessary that the insulating layer has a high performance.hydrophobicity, since moisture will periodically evaporate from the basement or from the concrete basement.

- The best bulk option is considered to be expanded clay.

- Near fireplaces and stoves, only fire-resistant heat-insulating materials are used: basalt fiber, mineral wool, glass wool, perlite, vermiculite or glass fiber.

- The use of synthetic building materials is fraught with not only damage to property, but also harm to the health and life of households.

Preparatory work

Before laying the insulation on the floor, it is necessary to complete all previous work: apply plaster or fix logs, treat with antiseptic or paint slats. In different rooms, as well as depending on the base, these stages will differ. The base is cleaned, in most works a spatula is used. If desired, the floor is processed solution against fatty spots.

If the room has high humidity, it is necessary to dry the base. If after this white plaque appeared, it should be removed. Additionally, the surface is treated with a primer.

Do not neglect antifungal treatment.The fungus most often appears in humid unventilated areas, mold can appear on wooden beams. As a fungicide, you can use not only special equipment, but also resort to popular advice. Folk remedies are suitable for those families in which there are small children or allergies, as it uses more "gentle" chemistry. The most commonly used ammonia, citric acid, soda, acetic essence, salt or soap solution.

By the way, not only floors, but also carpets are disinfected with soap.

It will be necessary to seal up all cracks with an elastic putty or construction foam, to walk with sealant. All excess should be removed after drying with a clerical knife. This will prevent damage to the insulating material.

It is important to calculate in advance how much building material is needed for laying insulation. In some areas, due to the design features (niches, protrusions), certain places may not be warmed. In special cases, experts recommend strengthening the base.

Keep in mind that dust, wood chips and other debris must be removed from the floor after carryingpreparatory work. If this is not done, then when laying the insulation particles of dust or sawdust will remain under it. This will adversely affect the thermal insulation qualities of building materials, so it is important to make not only the treatment with a vacuum cleaner, but also wet cleaning. Remember that the following steps are carried out only after the base has dried.

Technology

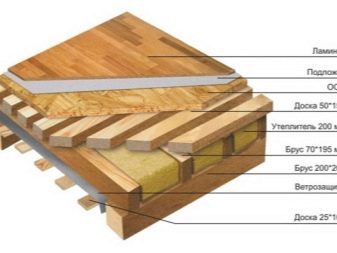

Proper floor insulation is a guarantee of coziness and comfort. If this technology is not made in compliance with the rules, then the heat in the room will not linger for long. In addition, I would like to note the fact that the structure of the floor resembles a cake, in which the substrate also has other qualities - sound insulation and waterproofing.

Next will be considered the scheme of laying insulation in a private house, but if desired, these methods can be applied in a city apartment. The required layer, fraction, proportions - all this will depend on the material and on the room in which the work is performed. It is possible to warm the first floor of a private house by lags and without opening. This will require leveling the base of the subfloor.

Material

When a concrete floor is insulated, often the thickness of the heat-insulating layer depends on climatic conditions.In regions with a warm climate, this indicator should be equal to an average of 75 mm, with a cold one - exceed 100 mm. Provided that the surface is already prepared and the cracks are sealed with cementFitted waterproofing layer. Modern building materials have not only hydrophobicity, but also vapor barrier properties. Thanks to this, you can save money and time. Heat-insulating sheets overlap, overlay should be within 10-15 cm.

It is important to glue the joints after installation. To do this, suitable metallized adhesive tape. You can also use coating waterproofing: bituminous mastic, liquid rubber. In some cases, resort to bitumen-polymer mixtures. Apply a waterproofing coating with a roller or brush, and it is important to capture the wall.

Plasterer-painters recommend applying at least three layers, each of which is applied after the previous one has dried.

After that logs are installed, they must be equal in height to the thickness of the insulation. The distance at which it is necessary to mount logs depends on the width of the building material. remember, that thermal insulation must fit tightly, gaps are unacceptable. Fix logs with screws or dowels. When using self-tapping screws, the work is done by a screwdriver.

Thanks to special tools, you can complete this step in a few minutes. Additionally, logs can be fixed with construction foam, but it is important that the wooden beam is treated with an antiseptic.

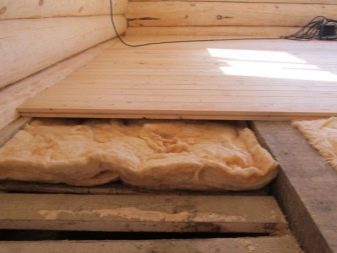

Thermal insulation, for example, mineral wool, is placed in the formed cavities. Remember that it is necessary to consider the size of the opening: the insulation should not protrude on the surface. A hydromembrane is installed on top of the relief side to the heater. The waterproofing membrane is able to divert excess moisture, including by evaporation.

The next step involves the installation of plywood sheets. Instead, you can use a sheet piling board. Keep in mind that laying should be perpendicular to the lags. Attach plywood screws or nails. If necessary, the surface is treated with a grinder. It remains only to produce the final finish: to install cork floor or floor of the boards, put tile.

Often, instead of mineral wool used polystyrene plate. This is due to the further pouring of the cement-sand screed. Polystyrene has good water permeability, so it is used in rooms with high humidity: in bathrooms, on balconies and in kitchens.

The preparatory work is not much different, but an important feature is that the polystyrene foam plates have special projections - grooves. Installation is greatly facilitated by these projections, the seams are virtually absent, and therefore, "cold bridges" are not formed.

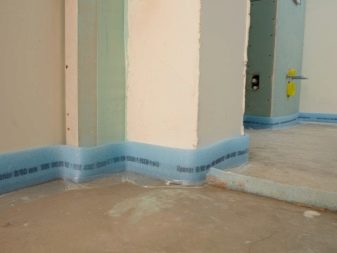

First you need a damper tape to paste over the perimeter of the room. This will help avoid deformation of the screed and improve the performance of the floor. Some products are equipped with a glue base, and if not, then fasteners are made with hardware. Over heat insulation overlapped polyethylene. remember, that the denser it is, the better. Connecting seams are taped. Polyethylene film will prevent liquid screed from entering the insulation.

The next step is to lay the metal mesh and pour the concrete. Do not forget to use metal beacons. The evenness of the fill all the time you need to control the construction level. As a rule, the concrete screed dries completely in 30 days, for integrity, the floor is covered with cellophane. Such a measure will eliminate the possibility of cracks on the surface,but still you should additionally periodically moisten the base with water.

After that it is possible to make installation of heating elements. By the way, in the prefabricated houses the laying of water floor heating is prohibited. This is due to the fact that the connection is made to the central heating system, and this may adversely affect the common property. Having certain experience and special equipment, it is possible to put the sprayed heat insulation. After drying, the insulation gets an expanded appearance, no seams are formed.

Spray produced by logs, without forgetting to periodically wet the concrete base for better fixation. Unlike concrete, foam dries in 24 hours, after which plywood, board, fiberboard or drywall can be laid on the logs.

You should know that polyurethane foam under the action of ultraviolet begins to turn yellow and crack, so prolonged contact with direct sunlight should be excluded.

In some rooms resort to the use of expanded clay as thermal insulation. In total there are three ways of laying this building material:

- dry. Expanded clay falls asleep between the lags.Pre-necessary to lay a waterproofing layer. It is best to use the clay of different fractions, mixing before filling;

- wet. With the wet method, the claydite mixes with the concrete screed, not only leveling the floor surface, but also achieving the fastest possible drying. Expanded clay as a light building material has virtually no effect on the overlap. As a minus one can note the fact that heat losses will be higher than with the dry method;

- combined.

In a country house, close attention should be paid to the ground. Few people will be surprised by the fact that during the cold season the frost can negatively affect the foundation. For ground insulation, extruded polystyrene foam is most often bought, since it perfectly interacts with moisture and has an increased durability. Additionally, experts advise to fill the structure with sand, while not forgetting the drainage holes.

The room

As a rule, it is the bathroom and the balcony that are insulated in panel houses. In this case, together with the heat-insulating layer, the electric heating system is also used.Since the bathroom often keeps ceramic tiles or tiles - cold building materials that need to be heated even in the summer, you can not do without a warm floor.

It must first be noted that installation of cable systems under the bathroom or under furnitureso, before buying a product, it is important to make the right measurements. On the cleaned surface fit insulation. Penofol, folgoizol or any other variant that has a foiling layer is suitable for a bathroom. It is important here that the heat-reflecting aluminum foil be placed on top.

The location of the thermostat is selected and marked on the wall. A metal grid or any guides into which the cable will be easily mounted are placed on top of the insulation. Installation is carried out under the scheme "snake" or "snail".

Remember that the wire can not be deformed and cut, otherwise the product will fail, perhaps even the occurrence of a fire.

According to the instructions, the cable heating system is connected. The product must be powered by the shield. The sensor is mounted in a corrugation.The working capacity is checked, after which the cement-sand screed is poured. Further activation of the heating system is possible only after the cement has dried, otherwise the floor will crack. The finish is mounted directly onto the cement screed. With proper connection, a warm floor will last for decades.

It is easier to install heating mats. When weathe loggia or balcony, experts recommend the use of infrared heated floors, since there is no need to pour the screed. Beforehand, you need to glaze the balcony, and to warm the walls with the ceiling - only in this case you will be able to achieve a tangible effect. Glazing is performed using a five-chamber plastic profile. If you use aluminum construction, then the cold will linger inside the loggia. The three-chamber double-glazed window detains frost penetration. Walls and ceilings are most often sheathed with foam or mineral wool. Unfortunately, it’s impossible to bring the batteries out onto the balcony, this is prohibited by law.

The substrate is laid on the aligned and disinfected base.When choosing a thermal insulation layer, it is important to start from the manufacturer's recommendation. The film is laid on top of the insulation. It can be cut only by special hatching. Laying the film overlap is strictly prohibited; the joints should not be wider than 3.5 cm.

Before the product must bring the cable and install the thermostat. Directly through it will be set temperature. When using laminate or wood board as a topcoat, it is important to remember that deformation and deterioration of the substrate occur at elevated temperatures. The temperature should not be above 28 degrees.

There are no restrictions when installing linoleum or tile, but when laying tile do not forget to lay a metal grid. Thanks to it, a high-quality fixation of the tile is achieved. Glue at the same time must be special, designed for underfloor heating.

Unacceptable moisture accumulation on the infrared heat floor. Before you install it, you must get rid of condensation on the balcony. Some people do not dismantle the old base and make the installation of electric heating system, but if the floor has significant differences, then effective heating is not achieved.

The main advantage of an infrared heating system is its easy installation. Installation according to the instructions can make any person, so you can not call professionals.

Typical mistakes

It is very important to make a plan in advance, which will reflect all the dimensions and structural features, such as projections, niches, window blocks and interior doors. Due to this, it is possible to calculate the necessary amount of material in advance. The main error in the installation of insulating building materials is considered to be the presence of cracks. Their appearance is due with the wrong selection of the width and thickness of the product. Thanks to the “cold bridges”, the heat does not linger, but evaporates, therefore, experts strongly recommend that the plates should be stacked tightly on top of each other, excluding the occurrence of seams.

When laying the insulation layer in no case should not compress the product, change its thickness, as this has a negative effect on thermal conductivity. By the way, extruded polyurethane foam and mineral wool during the period of operation settle naturally.

Keep in mind that even locally pinch building material should not be. This can occur if the hole depth is not properly selected or when using the wrong fastener. Alternatively, Isover can be recommended, which is mounted without fasteners, while one person can cope with the installation procedure, because the material is lightweight.

Dowels should not be embedded in the base - it will damage the insulating layer. At the same time, the fastener cap protrudes above the surface; this will eventually lead to bloating.

It is important to make cutting insulation according to the manufacturer's instructions. If the cutting is done incorrectly, the probability of heat loss increases. Mounting allowances should not exceed 5 mm: so the material will fit snugly to the base. The complete elimination of allowances is unacceptable, however, if you go too far when cutting with them, then the insulation deformation will occur, which will lead to a decrease in the air layer between the base and the product.

Often there are difficulties when installing on surfaces that are not leveled and not cleared of debris and dust. If you neglect to treat antifungal treatment, you can harm the health of not only households, but also guests.

No way It is not allowed to use raw building materials. Unfortunately, very often when building a house, the insulation is purchased in advance and stored for several months under the open sky. Precipitation (rain, snow) is absorbed into the mineral wool. It is important to dry the insulation before installation, otherwise the wooden bars will rot, and the metal profile will rust. According to the recommendations of the manufacturers, the insulation should be positioned with a reflective surface in the direction of the air gap. Often, an inexperienced installer does the opposite, and thermal insulation does not work properly. It is also important to respect the size of the air gap, which should be on average 15 mm.

The basement profile is not only a guide for the lower layer of thermal insulation, but also protection from the entry of insects and rodents. In addition, it takes on some load, which has a positive effect on the floors of the house. Laying is done only in a staggered manner, only this is achieved by excellent indicators of heat preservation. Plates should be offset by half relative to the next row.If the rows are laid parallel to each other, the heat loss will double.

Do not forget that the floor insulation resembles a “pie”, in which each layer is responsible for a certain indicator. If you want to save money by eliminating or replacing any layer, you can significantly influence the thermal insulation.

It is important to take into account the periods between the laying of subsequent layers. Also required to comply with the temperature regime. At low rates (less than 5 degrees), the drying processes slow down, and at temperatures above 30 degrees they increase. In unheated rooms in the winter, additional sheds should be made to increase the performance to acceptable limits. It is undesirable to combine mineral wool with polystyrene foam, since they have different characteristics, and the installation of both has a number of nuances.

By the way, extruded penopotirol is recommended for insulation of basements, and mineral wool is suitable for floors on the upper floors.

Plasters-painters strongly recommend, in addition to hardware, to apply glue solutions when installing a warming layer. Such double fastening provides the long term of operation. No need to try to save, using dubious adhesive mixtures or changing the consistency. Glue is applied to the insulation not only in strips, but also in a continuous layer - it depends on the varieties of building material and base. Keep in mind that proportions for dilution of glue are usually indicated on the package. It is also necessary to seal the seams in the layer of insulation. For this purpose, suitable mounting foam. If this is not done, then “cold bridges” will appear, which means that the heat will “fly away”.

Successful examples and options

The apartment is most often insulated loggia. To do this, you can use the cheapest material - foam with a reflective layer of aluminum foil. A good effect is guaranteed provided that the balcony is glazed with a plastic profile, and the heating infrared system is laid on the floor. By the way, the infrared type of the electric heating system does not contribute to the cracking of the laminate, and therefore it is installed in kitchens. It is important that the laminate at the same time was of an increased durability class. and suitable for heating system.

When installing the insulation layer with your own hands on the 1st floor of a wooden house, it is strongly recommended to take into account the vapor resistance of the product.

Remember that the basement is the most damp place, and moisture evaporating can destroy the base. Be sure to pay attention to such a parameter as hydrophobicity.

In conclusion, I would like to note the fact that modern insulation options are suitable not only for city apartments, but also for garden houses, private cottages. They differ both in cost and in size, which means that you can easily choose insulation for both exterior and interior decoration. In the old frame house it is necessary to warm not only the room inside, but also outside.

Keep in mind that heavy building materials may adversely affect the design. For interior decoration is often used lightweight insulation, including in the attic.

For information on how to insulate the floor with extruded polystyrene foam, see the following video.