How to make the floors in a wooden house?

The wooden floor in the house is an excellent solution for those who want to create a warm and comfortable atmosphere in the room. No modern materials will replace this environmentally friendly material. Of course, a tree cannot “boast” strength and reliability, like concrete or composite, but its appearance will win for many more years.

Special features

The base of the tree, like any other, has both advantages and disadvantages. The advantages include the following characteristics:

- environmentally friendly material, respectively, safe for humans. The tree does not contain harmful substances;

- you can make any design;

- All work can be done with the simplest tools and materials. Without experience in the construction industry, you can install wooden floors yourself.

In order for the floors in a wooden house to serve for many years, it is necessary to treat their installation with utmost care, be sure to observe all installation requirements.Because of this, you will not allow the floor to sink, because if this happens, you will need to either replace the floor or raise it. In addition to the advantages, the floors in the log house have several disadvantages. Wooden floors will be expensive, and all the work will take a lot of time. In addition, it will be difficult to install the floors yourself. The design is not easy to align, but possible.

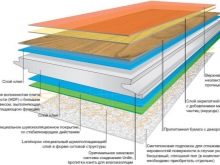

To install the floor yourself, we must remember that it consists of a subfloor, layers of heat and waterproofing, a clean floor and a floor covering.

The floor is double layered or single.

Types of construction

It so happened that in wooden houses and floors are made of wood, so it makes sense to light them. There are several types of wooden floors, depending on the raw materials:

- array

- glued wood;

- parquet;

- laminate.

Each material has distinctive characteristics. For example, a large mass of the array is not suitable for homes with a fragile foundation, and the fragile laminate is not suitable for rooms with high humidity. The floorboard is made of durable wood. Its length can be from 90 cm to 6 m, and thickness - from 1.8 to 6 m.There are grooves on one side of the board, and a comb on the other. Boards are made from solid wood, such as oak, larch and the like. Consider that conifer boards with overlapping wear out quickly.

The advantages of the floorboard is durability. Even after a few years, it will not lose its attractive appearance. Additional advantages - durability and reasonable price. In addition, the board has a low thermal conductivity. From the outside, the board is painted with varnish, which increases its service life. Sometimes boards are coated with a special oil that prevents wood from rotting and fungus formation. In some cases, make a double coating.

Glued wood represents the boards which are stuck together with each other. In such cases, conifers are used. To make the boards better glued, they are carefully leveled, eliminating all defects. The strength of laminated wood is greater than that of wood. Parquet is a plank made from wood. There are the following types:

- Piece - planks made of solid wood;

- floorboard - the first layer is made of precious wood, other layers are made of coniferous trees;

- artistic parquet - piece material, make a complex ornament from it.Differs in high cost;

- modular - includes strips of various shapes from different tree species, the result is a specific pattern.

Laminate is a material that imitates wood. It includes several layers:

- stabilizing - prevents deformation of the material and increases the level of rigidity;

- Fiberboard - the main layer, which is treated with water-repellent substances. It is this layer that affects the quality of the entire board;

- decorative - paper with a pattern;

- top layer - protects against mechanical stress. It is made from acrylic or melamine plastic.

Laminate flooring is a little thick, so it can be safely installed in rooms with low ceilings, and it practically does not take up free space. This material can be installed on a concrete base.

Please note that the surface must be flat, otherwise there will be problems with the laying of the laminate.

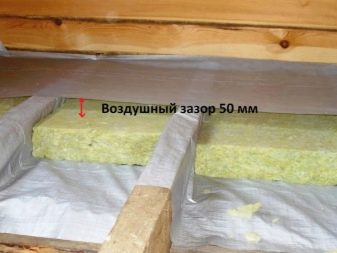

If the floor is cold, then a heating system is installed between the draft and the finishing construction. Often the floor is set on logs. The advantage of this installation is that it can be performed both on concrete and on simple soil.When installing along the ground, it is convenient to hide all communications, and leveling the floor is not difficult - either lags or chips should be placed. This design will rise by about 15 cm, so floors of this type are not installed in rooms with low ceilings.

Sheathing laminate floor can be made of concrete, as well as the design on screw piles, not leveling it in the first stages. Due to the wide range of laminate, you can choose any interior, and low weight makes it possible to stack this material between floors, in the attic. Popular is the "floating" design. It is not attached to the walls or to the base of the building. Accordingly, it is completely independent of shrinkage or other changes in the foundation of buildings. The covering keeps structure at any processes at the heart of construction.

Materials

Often in the house or garage they decide to lay the floor with the usual planed planks. The selection of material for the floor in the house of wood should be treated with the utmost care. Boards should not be wet or, conversely, too dry. If poor quality materials will be used for laying, then after a while the floor may deform.If the floor is made of plywood, then check that there are no defects on the material. It is best to use such tree species as oak or birch, but such a choice is completely optional. Board lengths from 2 m are applied: with a minimum length suitable for the garage, and for residential premises options are taken longer.

Please note that before using the plate, DSP, OSB, chipboard should be well treated with antiseptic agents from the inside. They protect the wood from reproduction of harmful microorganisms, including mold fungi. Experts recommend treating the material with fire-fighting agents that reduce the combustible properties of wood. Before laying the board, it is necessary to level, remove all defects, chips and barbs on the surface.

For the floor to serve for a long time, provide good sound insulation and save heat, it must be laid in several layers, that is, to make a “pie”.

Laying instructions

Laying the floor in a wooden house on the first and on the second floor should be carried out in accordance with all established rules, thanks to which the highest quality and durable coating will be obtained.First of all, sand the boards and lay them on the uneven boards to perform the marking. The floor is laid so that the age-old rings of the material “look” in different directions. For comfort it is recommended to number the boardsin order not to do additional polishing and not to adjust the material in size.

The floor is laid from the wall. Do not forget to leave the vent gap. In the future, it will be closed with plinth. Nails are hammered at an angle, slightly deepen the cap into the material. When you install the first plank, move about 40 - 60 mm from the edge and drive brackets into the bars with a small indentation. The protective rail is inserted into this gap. Between the batten and the wedge, another wedge is driven in, its width should be slightly larger than the space left.

Boards are hammered with nails, and then staples are removed. Install several boards, fix them with a batten and a wedge and nail them to the bar. The following boards must be sealed with a mallet, only after that fasten with nails. For the bathroom a prerequisite is material processing by special meanswhich are resistant to increased moisture levels.

It does not matter if you make the floor in the country or in the house of your permanent residence - take into account even the smallest details.

How to paint?

Today, different types of coatings are used to finish a wooden floor and for its durability. When buying a coating, keep in mind that wood has a different level of softness, therefore, it is necessary to choose the one that will correspond to the properties of wood:

- varnish. This tool protects wood from mold, mildew, insects, makes the surface shiny. Polyurethane varnishes or organic solvents emphasize the natural shade of the material, and they also dry quickly. Note that after a few years the wood may become a few shades darker. A tree cannot be varnished if it has been treated with linseed oil or other substances that contain oil. Also, experts do not recommend painting with varnish floors in rooms with high humidity;

- painting oils significantly increases the life of the wood. With the help of these substances, you can save the natural color of the tree or give it any shade. Floor with such a coating can not be used in rooms with a high level of humidity, as well as with sudden temperature changes;

- wax coating. Its basis is wax and linseed oil.Floors with such a coating perfectly preserve the natural color and texture of wood, and the surface gets a silky shade - with a golden overflow. Floors with such a coating do not tolerate the effects of abrasives.

In addition to transparent coatings, they are also used opaque. These include colored paints, which paint the material in a different color and hide its texture. You can choose enamels of different shades - oil, alkyd, pentaphthalic, and also paints - acrylic and latex. Enamels have a wide range of colors, and after dyeing and drying, they create a durable film. Thanks to this film, the floor will be resistant to moisture and sudden temperature changes.

To make the right choice, you must carefully examine all the characteristics of wood and the conditions of use of the floor.

Useful tips from professionals

Those who are faced with installing a wooden floor for the first time are advised to consider Advice of professionals who significantly facilitate the work:

- Before laying on the logs of the board it is necessary to try on, adjust and number.

- In order to make a high-quality floor, it is necessary to choose the right heat-insulating material.The modern market offers a huge selection of technologies for floor insulation, for example, roll or slab-type materials, bulk and sprayed products. It is best to use proven methods for years: clay, wood chips, sawdust, foliage.

- Professionals do not recommend saving on materials. The choice of cheap and low-quality coatings can further lead to surface deformation.

- Do not save on the technology of the device floor. If the project requires an insulation layer, then you should not forget about it.

- If you are unable to perform any work yourself, immediately contact the specialists for help.

Beautiful examples in the interior

The most popular today are dark wood floors combined with black in design. Also often used light floors. They give the interior comfort and coziness. Previously, in almost every room it was possible to find wooden floors of rusty brown color, but today such a shade is not in demand.

Modern manufacturers are trying to preserve the natural color of wood. Untreated, coarse, it retains all the useful features and properties.Such floors can be installed in any interior, they will look spectacular everywhere.

The fashionable trend is hand-cut wooden floors. As a result, the grooves remain.

Fans of natural colors of wood will be suited to such a method of treatment as smoking smoke. Thanks to this method, the material acquires the original color. With the help of the equipment, the material is smoked to brown color, and depending on the type of tree and the place where it is grown, different colors are obtained.

Separate attention worthy of smoked floors with the effect of decal. The decal includes repeated application and removal of paint and wax. As a result, the wood looks aged, and the floor takes on an antique look.

Which floors to lay in your home is an individual decision. When choosing the best coverage, do not forget to take into account the operating conditions of the floors, their cost and the quality of the materials used. Knowing the pros and cons of each coating, painting and processing technology, you can achieve excellent results and create a truly unique interior. Do not be afraid that the wooden floor will require special care.With proper installation it will not be a problem.

You will learn more about how to make floors in a wooden house in the following video.