How to lay the floor in the apartment?

Laying a new flooring in the apartment is a time consuming and energy consuming process. But the result is definitely worth it, especially when it comes to overhauling the house. It is possible to perform basic work independently, having some skills. Repair is carried out in stages. Determine the degree of deterioration of the floor can be visually. Next you need to carry out the necessary calculations and select materials.

But before you get down to business, you should assess in advance the scope of work. In addition, it is important to determine the option flooring.

Special features

Modern floors have a lot of advantages. This applies including new technologies laying in the apartment. Many people dream to make the floors in the house more beautiful, spectacular, in accordance with the fashionable design. And then the team of masters comes to the rescue, or the owner himself decides to relocate the foundation.

Anyway, you must first remove the old coating, check the quality of the base, repair the basic structure if necessary. Then, as a rule, it is necessary to make a leveling tie. At the final stage is laying floors.

What to choose?

Each flooring option has its own characteristics. The device and the design of the floor today is taking into account the overall design of the room. The choice of material for flooring is also often associated with the characteristics of the interior. Reliability, durability and aesthetics - the basic requirements for modern flooring. They are of several types and are made of different materials.

Wooden

To carry out a major overhaul of the floor, it is enough to choose one option for coverage. So, the most popular are wooden floors. With them in the house there is always a feeling of warmth, cleanliness and comfort. These are eco-friendly floors made from natural materials. They are easily mounted on logs, overlapped with noise absorbing material. The floorboard is laid on plywood mounted on the logs. Features of the operation of wooden floors:

- they are applicable to almost any type of room;

- can absorb third-party odors, so they are not always used in the kitchen;

- it is not recommended to lay wooden floors in the bathroom;

- can be used in the hallway, but taking into account the features of installation and strength of the base.

Before a wooden flooring is required, a number of relatively difficult lagging operations are required. It should be a stable, durable structure, where the level is displayed to a perfectly horizontal state. The lags here are an ordinary wooden beam, which is beyond doubt. In the course of work, adjustable supports and brackets are installed. Flooring wooden floorboards is possible directly on the logs or on plywood.

Laminate

For laminate flooring is used material from wood-polymer composite. This option is one of the most popular types of flooring. The fact that such floors are surprisingly comfortable to imitate natural coverings serves to spread the laminate fashion. Material is available in the price. Some types of laminate even surpass wooden floors in quality due to the main advantages of this coating. Floors with laminate are not afraid of moisture and high loads, are distinguished by wear resistance, durability, a variety of textures.

A wide range of modern laminate allows you to expand the boundaries of external performance. True, we should not forget that such floors contain wood composites and resins. It depends on the class of flooring. In some cases, for example, for the children's room, it is better to pick up other material.

The laminate itself, despite its universal qualities, requires careful attention. For example, its flooring requires just an ideal surface. To this end, the coating is placed on a concrete base on a special substrate. Also as the basis the self-leveled floor is used.

Linoleum

Despite the emergence of all new types of flooring, linoleum is losing its position in the construction market. Its popularity is quite understandable price affordability and technical possibilities of styling. Do the work yourself under the force and inexperienced master. Colorful linoleum is a standard floor covering option for most typical apartments. Although you should not forget about the benefits of modern materials.

The new linoleum will be markedly different qualities such as durability, interesting decor and moisture resistance. As for the environment, the linoleum coating meets the basic safety requirements. The coating itself is soft, flexible, pliable during operation.

Externally, the material may vary in thickness and insulated base. Linoleum is purchased in the form of rolls of different widths. For the bathroom, of course, it does not fit.

For laying linoleum requires a perfectly flat base.

Carpet

Carpet floors are not such a rarity today. Although relatively recently, the fashion for him experienced a real boom. Over time, it became clear that this material is not without flaws. But first things first. Supporters of the exclusive floor are attracted by the quality and aesthetics of the material, the ability to vary the interior design.

A characteristic feature of the coating remains indescribable aesthetics, which looks advantageous. However, over time, scuffs on the floor becomes more, which will inevitably affect the image of the house.

It must be remembered that gradually the carpet becomes faded and shriveled, loses hairiness and color. And spots on a monophonic background are practically not displayed. About the dust is no question.

It is better to use carpet in a separate room, for example, in an office or bedroom. Modern solutions attract interesting design, bright colors, so this material can be changed. You can lay the carpet in the event that you plan to carry out frequent wet cleaning. In the entrance rooms, the floors with carpet will last very long. The living room is a legitimate place for this material.

But the material should not be used in homes with pets. Laying is made on a clean, perfectly smooth surface.

Ceramic tile

Beautiful floor tiles in the house can be made of ceramic tiles. Such a finish is more appropriate in a room with high humidity. Achieve perfect coverage can be subject to proper installation. The material is not afraid of not only moisture, but also of spilled oil, fat on the surface. Caring for such a floor is quite simple. The tile maintains the increased loadings at intensive use, for example, in a hall or in a corridor. Wash the pollution here is not difficult. You can use a variety of detergents.

Modern ceramic tiles are available in a rich variety in color, size, texture. The material mainly has a microrelief surface.Roughness is needed for safe operation to avoid slipping on wet floors. But the convenience of the material does not end there. Ceramic coating can be laid on almost any surface after preparation.

If conditions allow, then ceramic tiles can be put directly on top of the old coating without exhausting dismantling.

With all the advantages of coating do not forget about the important features of the material. It is durable, tough and cold, which reduces the degree of comfort of such a floor. You can not sit on it. Therefore, ceramic flooring is rarely seen in a residential area. Although it is possible to improve the situation by installing underfloor heating. Then additional thermal insulation is not required.

Materials and tools

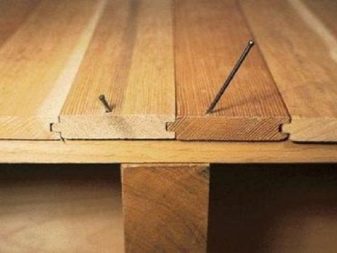

The choice of quality material for laying the floor - a fundamental rule before starting work. When choosing natural materials (parquet or oak board), it is important to consider the method of processing wood. So, the best wooden floor will turn out from coniferous breeds of which grooved boards are made. Such floors visually look more attractive. They are suitable for prolonged use.

It is worth noting that today you can pick up the material at a favorable ratio of price and quality. It is difficult to overestimate the aesthetics of the floor, for example, from oak or walnut, although their value is higher.

In general, boards are carefully selected for any flooring. The material must be dry, without cracks and flaws. Subsequently, the boards can be coated with a special varnish, creating a dense floor surface for better protection.

When laying the floor of natural materials It is important to ensure that all structural elements are antiseptic with special preparations. This is usually done in the factory. The final exterior coating treatment is painting. This applies to wood or vinyl coating.

There are many options for using the flooring, as well as options for laying. So, you can use the method of mounting OSB on lags. GVL can be used for the floor. Correctly perform flooring installation possible, having a high-quality professional tool. The laying itself is traditionally performed on a concrete base using expanded clay as a heater.In the course of work the construction level is used.

Before proceeding with the installation, it is necessary to calculate the consumption of materials around the perimeter of the room. Useful devices will help to carry out our plans: dismantle old coatings, level and prime the base, make a gradual installation of the finishing coating. For this, in addition to the usual tools, you will need special equipment.

Necessary tool

The set of tools varies depending on the specific type of work and flooring options. To remove the old coating and prepare the surface of floors requires a universal tool. For new wood cladding or ceramic tile you will need:

- mixer (or drill with mixing nozzles);

- construction levels;

- scrapers, as well as a set of abrasive brushes;

- rulers and special roulette;

- all for screed;

- size brushes (and / mom rollers);

- primer and adhesive formulations.

For laying carpet needed:

- cutters and special knives;

- threads;

- tape overlochnaya;

- tape (for gluing on the surface);

- ruler and special clamps;

- the rolling roller;

- dimensional rollers to eliminate irregularities;

- notched trowel.

For laying parquet required:

- pillow;

- jigsaw;

- construction pencil;

- metal brackets;

- restrictive wedges;

- hacksaw (for wood).

For laying linoleum necessary:

- strip cutters;

- welding dryer (nozzles required);

- knives and cutters of different sizes;

- rusting;

- spatulas;

- rollers and rollers;

- boards (for alignment).

A set of tools and professional skills allow you to perform the whole range of work yourself, saving on material and laying time.

General installation rules

For laying the floor in an apartment you need to determine the quality of the existing coating, In this regard, work is being done in two directions:

- replacement or repair of existing flooring - you can relocate individual areas, make decorative adjustments, or remove a loose hill at the base;

- dismantling the floor and a new concrete base;

- ensuring vapor barrier;

- use of penoplex, OSB, chipboard.

Overhaul of the floor with a concrete screed is required in the case when redecoration is clearly not enough.Concrete screed is the basis for a smooth and even floor of any type. After work with a concrete screed, floors must withstand the entire warranty period of service. For the strength of the floor on the concrete screed:

- it is possible to use the usual mixture (cement with sand);

- you can use ready-made dry cement mixture;

- Sheets can be laid (special gypsum fiber material) to obtain a dry screed.

Concrete screed

Old flooring is being removed, floorboards and logs are removed. Clears all underground space. If necessary, slabs are opened (in the absence of the old screed). Now you can lay waterproofing (plastic film overlaps, the gap - no more than 10-12 cm). A damper tape is glued along the walls in order to compensate for the expansion / contraction of the screed, for example, with temperature changes.

Special guide beacons are laid. The site is filled with expanded clay (with a dry screed). Reinforcement with metal mesh is usually used. In the next step, the screed is directly poured / laid.In general, the formation of the floor is carried out according to a proven scheme.

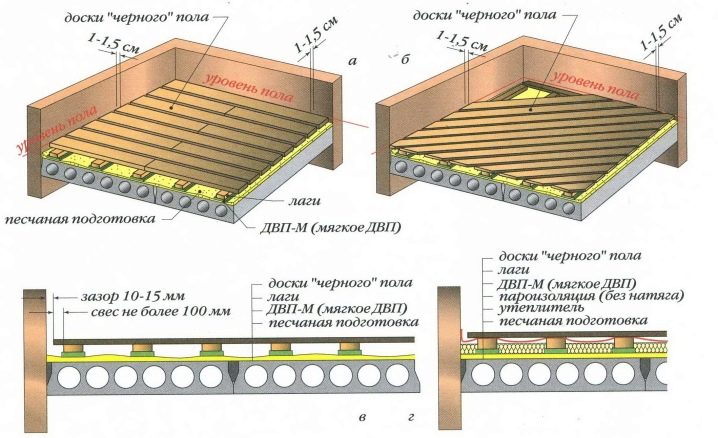

Device lag

Wooden bars - logs, are necessary as supports on which the floor is laid. Two kinds of logs are used: from oak and larch. A more dense and durable structure of the structure, for example, is needed when arranging the floor in a house, on a terrace or on a veranda. Lags must withstand increased loads, withstand extreme moisture, do not rot. For these reasons, spruce or pine is also used.

But these rocks are softer, so they are most often used for arranging floors in apartments. Laying the floorboard occurs on the logs after polishing is done.

Landing cover on the logs is performed in the process of creating a subfloor. An additional foundation of the floors is chipboard. Laying drywall will improve the performance properties of the flooring. The distance between the lags largely depends on the thickness of the flooring. For reliable coverage, of course, you need to use more durable and thicker boards.

In this case, the installation of the lag is rare columns around the perimeter. Thinner flooring is possible with frequent lag installation.Thus, the use of boards from 20 mm implies the placement of lags at a distance of 30 cm from each other, with a board thickness of 40 mm, the distance is 70 cm.

Layout lag from the walls is usually 30 mm. Fastening is carried out from the sides of the beams. The horizontal of the installed logs can be checked with control rails. Fastening goes to the screws. In the event that the main beams are located too far in relation to each other, double lags are performed.

There are 2 ways of placing a log on a concrete base. In the first case, a special lining is used to eliminate deformations, squeaks, bending. In the second, a cement screed is used that fits evenly on the logs. In order that the concrete base with lags does not absorb moisture, it must be waterproofed (you can use a plastic film of 200 microns).

Also, the next layer is insulation. This may be a substrate of cork or polyethylene (1-4 cm).

You can not lay logs on the soft insulation, as the floors will be unstable.

Foundation preparation

A modern floor can be seamless (self-leveling floor), made of stone, cork, carpet or laminate, etc. Accordingly, it is required to provide a solid and reliable base for it.Covering the floor involved after the necessary installation and construction and finishing works. In the course of all work, the possibility of contamination or wetting of the surface is taken into account, which affects the shrinkage.

Whatever the coating, it is laid on the screed after the pebbles and attached to a perfectly flat surface. Today it is possible to sort through various flooring options by independently checking the reliability of the lags and the distance between them. Then you can do the adjustment or laying of the base.

Today, different types of floor bases are used:

- Concrete or cement-sand screed. It is made from a solution of concrete. Laying screed is carried out only on the prepared, cleaned surface with heat and sound insulation. The thickness of the screed in a new building is usually set by the project.

- For self-laying floor often used ready dry mixes with reinforcing filler. A single layer tie is performed along the beacons for proper installation and is controlled by level. Within 3-7 days, the screed completely hardens.

- Screed from special ready-made solutions performed at a comfortable temperature of not less than 5 degrees Celsius. Such a rough laying is enough to lay the floorboard, install aquapanels on expanded clay.

- Cast asphalt screed done similarly cement-sand and using lighthouses. Laying the black tie is done gently with stripes using slats. After laying the asphalt is rolling. Unformed areas are roller. On top of the screed, a hardboard is laid, which will be used for laying parquet or floor boards.

Piling

When carrying out major repairs, for example, in a frame house, it is often required to change the floor covering. Repair of wooden floor with the replacement of individual boards is required with a satisfactory condition of the structure. For example, there could be a little loose floorboards in the most passing places. It is necessary to lay them on the posts.

Sometimes it's even enough to fix the floorboards.

Below is a step-by-step instruction for those who decide to tidy up the floor with their own hands. For this you need:

- remove dust, varnish and paint from the floorboards to be replaced with a grinder;

- check the boards for rot;

- remove unreliable parts of the boards, especially if they are cracked; the remaining floorboards are checked for the degree of fixation to the logs (drive deeper into the nails, additionally plant the self-tapping screws);

- close the gap filler, cover the fossa, for deeper openings use chopik;

- walk on the surface of the boards with a vacuum cleaner and a damp cloth;

- replace old boards with new ones; apply on the floor a new paint or varnish.

The job of replacing the floor (wooden planks, parquet panels, linoleum) includes the treatment of flooring with fire-fighting equipment and the safe installation of modern technologies. Easier to do the woodwork. Arrangement of the floor in the house of the bar has similar technical work, although in this case, the flooring is performed on the ground floor.

Be sure to perform scraping flooring - this is the technology of leveling the floor surface. It is possible to erase by manual cycle or by special mechanical equipment.

Frequent errors and their consequences

Poor quality cheap material, ignoring the rules of laying the floor, the lack of basic repair skills can lead to serious consequences when laying new floors.Errors most often relate to the conditions of storage of materials, timing and sequence of work. For example, someone can install a new coating on the old untested lags, which are also not designed for the thickness of the new floor.

The use of especially durable materials, for example, marble, is possible on dense broad lags, evenly spaced around the perimeter of the square. Thin fiberboard can be laid, for example, when laying carpet.

It is also worth more attentive to the quality of the screed, to the use of modern waterproofing materials. A wet concrete base will lead to the loss of such floor qualities as durability, strength, durability of the structure. Uneven flooring of moisture-resistant material will lead to irreversible processes - the appearance of putreflective formations, the spread of mold. For tightness always use mastic or special glue.

Expert advice

Installing the floor is done before finishing the apartment. In the course of work, the necessary tools, beacons for the accuracy of calculations are used. The main thing is to choose the appropriate material, study the technology of working with him and be patient. According to experts, a beautiful and even floor is the result of a creative search, suitable design and competent execution of work.

Independent installation of the floor should be carried out in accordance with the material’s instruction manual. You can lay new floors in the nursery, in the living room, in the kitchen, in the hallway. Attach suspended floor or adjustable floor should be on solid logs, provided that the whole structure will have a small weight. Such floors are suitable, for example, for balconies and loggias.

Carpet can be laid in small rooms subject to constant care for the surface. Flooring options with polystyrene insulation are suitable for laying on large living spaces.

See how to lay the wooden floor in the next video.