GVL for the floor: advantages and disadvantages

Before you put on the floor finishing, you need to take care of its evenness. For this you can use a variety of materials. Today we will talk about the advantages and disadvantages of gypsum-fiber boards or gypsum fiber boards intended for leveling the floor.

Special features

Nowadays in most homes there are no perfectly flat walls and floors. This problem is not uncommon, and many users face it. Fortunately, this defect will fix. Especially for smoothing various bases in the building stores are sold suitable materials.

So, for leveling the floor before laying a decorative coating, you can use GVL. These materials are found in many retail outlets and are in great demand.

Gypsum fiber boards are a special extruded material in which there is reinforcement with dissolved waste paper.. This coating is durable and reliable.Gypsum in its composition plays the role of a binder.

The main feature of GVL sheets is their homogeneous structure, which is under the cardboard layer - gypsum plasterboard. At the same time, the density of the latter is much less, so we can safely say that GVL-plates are reliable and strong coatings.

Thanks to these features, this material can be laid on the floor without fear of the formation of damage on it.

Currently, there are two types of GVL sheets. They are simple and moisture resistant.

Lay such materials should be solely on a dry and well-prepared floor.. And it should also be borne in mind that there may be many problems with the cement-sand or concrete screed during the installation of gypsum-fiber sheets, since the base for such material must be completely dry. In cases where the gypsum plasterboard is used as flooring on a subfloor, the result is a dry and tidy base. It is permissible to immediately lay decorative finishing coatings on it.

Most often, gypsum-fiber sheets are mounted in two layers. In the stores you can also find originally glued panels designed for the floor.At their ends there are folds. Similar parts are easy to install.

Advantages and disadvantages

Gypsum fiber sheets are great for leveling the floor. However, such materials have not only advantages, but also disadvantages.

To begin with, let's consider what advantages are typical for GVL-plates.

- Such panels are considered universal. They can be laid in different rooms. The main thing is to competently approach the choice of suitable plates.

- Both professional and home craftsmen argue that working with such material is very simple. Installation of gypsum-fiber boards does not take much time and money.

- This material is eco-friendly. There are no aggressive chemical components in its composition; therefore, even under conditions of high temperatures, it does not emit harmful substances.

- You can return to the repair work immediately after laying the GVL-slabs. This suggests that you will not lose too much time.

- These leveling materials are distinguished by wastelessness during the installation work.

- High-quality GVL-sheets withstand serious loads, as they have the strength and resistance to wear. Such leveling materials are more reliable than ordinary drywall, so they can be put on the floor.

- GVL-plates can be put even in the bathroom or steam room.For such premises it is necessary to buy moisture resistant materials. They are not afraid of increased moisture and moisture.

- Such materials do not bend or creak with time.

- Do not exude unpleasant odors.

- Such panels can be combined with water or electric floor heating, which attracts many owners.

- During installation, such coatings do not need to knock.

- Gypsum fiber sheet is a non-combustible material. In addition, it is not subject to deformation under conditions of high temperature values.

- But it should also be noted that GVL-plates have insulating characteristics. Indoors with the floor leveled by a similar material will always be warmer and more comfortable.

- In addition, these coatings can boast soundproof qualities.

- GVL-sheets - available and popular material, which is sold in many stores. He will not have to search for a long time As for the installation of panels, you can easily make it yourself, without turning to professionals.

Due to the large number of advantages and their safety, GVL-plates are in great demand. However, this material has its drawbacks.

- GVL-plates have considerable weight.Due to the severity of the design, working with it is not very convenient.

- If installed or stored gypsum fiber plates incorrectly, they can become fragile and short-lived.

- Such materials are more expensive than regular drywall.

- In the process of installation it is recommended to treat gypsum-fiber sheets with care as they may be damaged.

Specifications

Let us consider in more detail what technical characteristics GVL-plates possess:

- their standard length is 2500 mm;

- width - 1200 mm;

- thickness - 10, 12.5, 15, 18, 20 mm;

- level of fracture strength - more than 5.5 MPa;

- hardness level - more than 22 MPa;

- density is about 1200 kg / cu. m;

- thermal conductivity - 0.22-0.35 W / m0С.

Of course, in the shops you can find gypsum-fiber sheets, the parameters of which differ from the specified values. For example, simple GVL sheets that are very similar in appearance to standard drywall are on sale. Their dimensions are 1200x1500 mm.

And also for the alignment of various bases use small-format gypsum-fiber sheets. Their dimensions are 1200x600 mm and 1500x500 mm.

Subtleties of installation

Laying GVL panels is permissible to hold their own hands. Let's get acquainted step by step with this work.

- First you need to remove the old flooring, and with it the boards and chipboard with logs, which was the old finish. Absolutely all materials must be removed so that as a result only a bare ceiling is left.

- It is necessary to get rid of all debris and dust.

- On a clean and degreased base, cracks and holes may be present. Such defects need to get rid of. To do this, pour in the damage quick-setting cement mortar with a marking of at least 150. Instead, you can use a special assembly mixture or alabaster.

- Next you need to make a mark of the top level of the backfill. To do this, use a laser or bubble level. The height of the marks can vary from 2 to 6 cm. This indicator directly depends on the degree of unevenness of the floor.

- As a result, the base layer should be 2 cm higher, since a double sheet of GFL will be added to it.

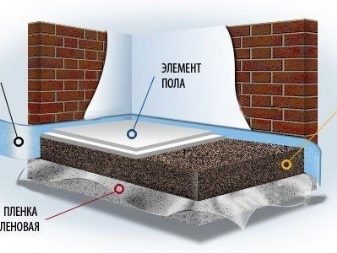

- After that, the floor is ready for waterproofing. First, on the basis of the need to lay a film of polyethylene, if the overlap is concrete. If the floor is wooden, then it is permissible to put parchment and bituminized paper on it.

- Waterproofing material must be put overlap. His sheets should cover each other by 20-25 cm. Edges need to be fixed with adhesive tape.

- It should be noted that the film should go on the wall floors. Its extreme part should be set at 2 cm (minimum) above the marks set using the level. Glue the waterproofing material with a special mounting tape.

- If communications are under the gypsum-fiber web, then all the wires should be removed into a special protective corrugation and secured to the base.

- Keep in mind that between the corrugation and gypsum-fiber panels should be filled with expanded clay. Its layer should be at least 2 cm. If necessary, change the height of the marks set.

- To prevent the so-called sound bridges from appearing on the floor, it is possible to produce 2 types of work. For example, it is possible to glue the perimeter of the room with an edging foam tape, which is 10 cm wide and 1 cm thick. To save time, you can buy self-adhesive tape.

- And also for sound insulation of the base, it is permissible to use edgebands of mineral wool or polyethylene.Such materials will protect the finish coating from deformation at high temperatures.

- After completing the installation of sound insulating tapes, you need to cut off the excess, relying on the upper part of the floor.

- Now you need to make the filling of expanded clay. These elements need to be poured onto the vapor barrier material. Expanded clay should have a fraction of not more than 0.5 cm. It is recommended to wear a respirator for such works.

- Then you need to align the claydite on the base. To do this, you can install beacons of metal profiles. Produce such work should be with the level.

- Keep track of the quality of tamping beside the walls, as well as in the doorways and corners of the room.

- After that, you need to remove the guides. There will be voids on the floor. They need to fall asleep claydite.

- To smooth and tamped clay is not deformed, you can use the "islands" of GVL. For such work it is permissible to use other similar materials. For example, it can be pieces of plywood or chipboard sheets. Note that the size of the "islands" must be at least 50x50 cm.

- It is possible to provide the base with additional heat and thermal insulation.To do this, it is permissible to lay a penoplex or drywall under the gypsum-fiber canvas.

- Laying GVL plates need from the corner, which is located as far as possible from the door. Thus, you will save coverage from possible damage.

- The edge of the panel, located next to the wall, should rest against the edge band.

- The seam edges of the slabs that are nearby should be lubricated with a sticky compound. PVA glue is suitable for this. It is necessary that the "locks" were more reliable.

- Then every 10-15 cm you need to screw the screws. Their length must be at least 2 cm.

- Now we are laying the second row of gypsum fiber panels. Shift their joints in such a way as to achieve the effect of brickwork.

- To fit the panel in size, use a jigsaw.

- If the room has a floor with noticeable irregularities, and the thickness of expanded clay backfill is 6-10 cm, then we sheathe the second one over the starting layer of leveling sheets.

- The installation of the second layer must also be made starting from the far corner. Make sure that the joints between the panels of the first and second layers do not coincide and do not lie on top of each other.

- When you have fixed all the GVL sheets on the floor, the seams between them and the areas with the screws screwed in need to be puttied.

- It is permissible to fasten the reinforcing tape.

- If you are going to install a leveling coating in the bathroom or in the kitchen, then you should use high-quality waterproofing materials to finish the joints between the panels.

- The installation of a clean floor covering can be started a day after the installation of gypsum-fiber sheets is completed. In 24 hours, the glue and the layer of putty will be completely dry. On such a basis, you can glue the tiles, put linoleum or laminate, and pour the liquid floor.

If necessary, place a special substrate on the base.

Tips and tricks

Leveling the floor with gypsum-fiber panels is a simple job. The result will not upset you if you adhere to the appropriate technology of laying material. However, in the process of such work it is necessary to take into account the recommendations of professionals to avoid many mistakes and shortcomings.

- If there is a warm water or electric floor in the room, the wet screed may not always be used. In this case, GVL-sheets - ideal.

- If in the course of laying the panels of their seams showed signs of excess glue, then you need to get rid of them as soon as possible. Be sure to fill the joints. For the treatment of such bases need primer.

- In the process of leveling the floor can be used GVL sheets of different sizes. As a rule, the first layer is laid out from small-format panels, and the second - from standard sheets.

- Before buying floor gypsum sheets, you need to carefully inspect them for damage. If the material shows cracks or chips, then it is better to refrain from buying it.

- It is recommended to calculate in advance the required amount of materials in order not to overpay for unnecessary parts.

- In the store you can find a dense two-layer material. If you have only single-layer sheets, then you can glue them together before laying.

- In the process of preparing the base, you must make sure that the floorboards are in proper condition. If the quality of these elements does not inspire confidence, then they must be replaced.

- When laying sheets, care must be taken that the gaps between them do not exceed 2 mm.

- If on the basis there are impressive irregularities that exceed the mark of 10 cm, then you need to install a third layer of panels. However, it should have the same thickness as the previous two.

- To level the floor in spaces with high humidity levels, you can use only moisture-resistant sheets of material. Simple panels in such conditions will not last long.

- For finishing the floor may require additional installation log. It all depends on the specific decorative material that you are going to put on the base of the house or apartment.

- When choosing a primer mixture must be repelled by the glue used. These compounds must be compatible with each other.

- When installing GVL-sheets can not do without pre-marking. It should be applied at the level of backfill. For this useful bubble or laser level.

- When laying the last layer GVL need to cut sheets of a small format.

- Instead of expanded clay, you can use crushed stone or slag pumice. This material is not very warm, but it is cheap.

- If on the basis there are no serious defects and drops, then gypsum-fiber sheets can be laid with a pattern of half a sheet. In the first row, you need to put the whole panel, and in the second - cut in half.

- If we take into account consumer reviews, we can conclude that gypsum-fiber sheets are an excellent substitute for the old wooden floor in the house.If all the work was done correctly, then even a tile can be laid on such a base.

It is possible to level the floor with gypsum-fiber panels not only in a private, but also a multi-storey building.

How to install GVL for the floor, see the following video.