Knauf moisture resistant sheets for floor covering: dimensions and characteristics

Often when repairing it is necessary to level the floor. The result of such work depends on the appearance of the room. Any coating is better placed on a flat surface. Looks like this finish is also more presentable. An excellent choice for these purposes is the gypsum-fiber sheet (GFL) from the company Knauf, which is often called the “Superlist”.

Features and properties

Gypsum fiber appeared on the market later than drywall (gypsum board). However, the material was able to quickly win the love of buyers.

As the name implies, the basis of such sheets is gypsum. Unlike GCR, gypsum-fiber sheets do not have an outer casing (cardboard). In addition to gypsum, they have a reinforcing component in the form of cellulose waste paper and technological additives, which makes the sheets stiff. The front side of such sheets is smooth, as is the back surface of the products. Sheets have a grayish color.GVL are non-combustible material, since gypsum, on the basis of which they are created, and cellulose fibers that are in conjunction with it, do not burn.

Qualitative characteristics of Knauf fiberglass sheets:

- strength, durability and moisture resistance;

- environmental friendliness;

- resistance to open fire and high temperatures;

- ease of installation;

- thermal insulation properties;

- soundproofing;

- the ability to absorb excess moisture from the air and just as quickly give it away.

Also material:

- can fit almost on any surface;

- suitable for use as a base for linoleum, parquet, laminate;

- suitable for weight reduction of building structures;

- facilitates the subsequent finishing;

- minimizes construction waste.

The disadvantages include three points. First of all, despite the high strength, the sheets are quite fragile. With careless installation it is likely that the sheet will simply break. Also the price of GVL is higher than the cost of drywall sheets.

It is worth noting the fact that experts do not advise to use the material to cover warm floors.

Kinds

Gypsum fiber sheets can be divided into four categories depending on their size:

- 1200x600x10 mm;

- 1200x1200x10 mm;

- 2500x1200x10 mm;

- 1200x600x20 mm.

One square meter of sheet 10 mm thick has a weight of about 12 kilograms. A square meter of slab 20 mm thick weighs about 18 kilograms. Knauf company also produces moisture-resistant gypsum-fiber sheets (GFVL). Unlike conventional sheets, these sheets are treated with a water repellent. Thanks to him, HVL can be used to finish the floor in rooms with high humidity (such as kitchen and bathroom).

Experts point out that high-quality ceramic tile glued to the base of GFBL 1200x2500 can serve for twelve years or more.

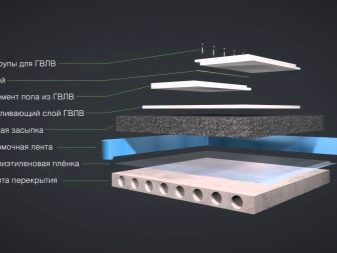

The plate size of 1200 to 600 mm and a thickness of 20 millimeters worthy of a separate, more detailed consideration. It is an element of the “Superfloor” design and is called the “floor element” (EP). The plate consists of two sheets 1200x600x10 glued together. This plate has a seam edge (FC), like a laminate board, only without grooves. This is a difference in half the thickness of the sheet by 50 mm around the perimeter.

We can say that the smaller sheets are superimposed on each other with a slight offset. Thanks to such an edge, the installation of the plates is notably easier, although it is necessary to adapt first.

FC helps to facilitate the further processing of seams. For example, to seal the joint between the plates using serpyanka on a fabric or fiberglass-based and putty is not difficult.

Material laying

Preparation for work

Experts advise to lay GVL on the floor in two layers with a thickness of 10 millimeters, and in one layer, if we are talking about plates of the “floor element” type. This method has significant differences from conventional concrete screed:

- does not require additional materials;

- forms much less debris and dust;

- does not require waiting for the mortar to set.

Like drywall, gypsum fiber must be brought in advance to the room where installation is planned. This is necessary for the "acclimatization" of the material (so that the sheet does not crack during the work).

Before installation, it is necessary to mark the contour of the future floor on the walls using levels and plumb lines. These actions must be performed with maximum accuracy. Otherwise, the floor may swell or "float." Also, the floor surface must be cleaned from dust. For this you can use a construction vacuum cleaner. During this process, noticeable cracks and irregularities can be detected.They need to cover up. The prepared surface must be primed using a deep penetration solution.

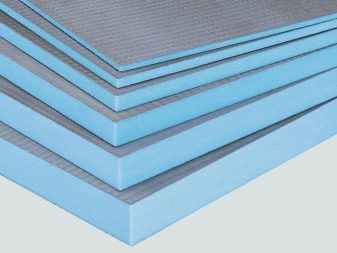

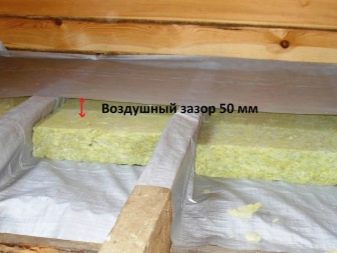

The next step is waterproofing. Polyethylene film, roofing felt or parchment is suitable for this. The edges of the waterproofing must be mounted on the upper edge of the contour marking. This is necessary to improve the result. After waterproofing is a layer of insulation. You can use polystyrene foam, foam plastic, mineral wool or expanded clay. In the first three cases, in addition to marking the contour, it is necessary to mount guides from a metal profile or a wooden bar.

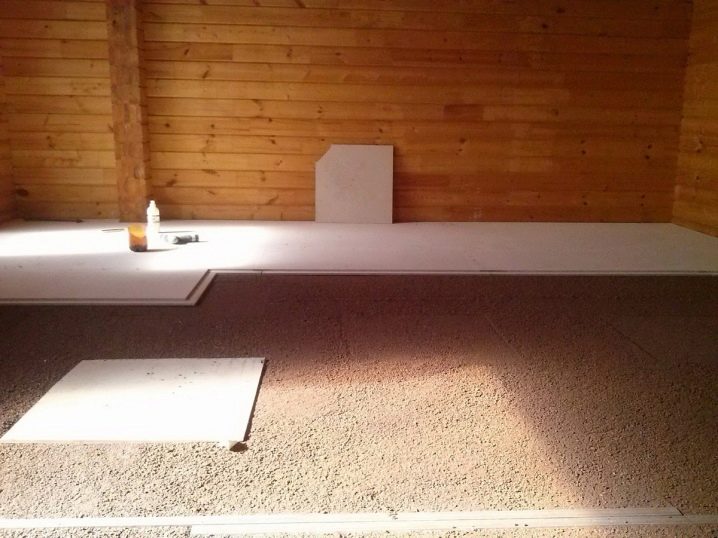

If it is decided to use expanded clay for thermal insulation, then a number of rules must be observed. Granules should be small (no more than five centimeters in diameter). After backfilling, the surface should be leveled relative to the level, focusing on the contour and guides. Particular attention should be paid to the corners of the room.

Also, the clay must be carefully tamped to the surface turned out as smooth (as possible) and dense.

Plate Mounting Technology

After all the preparatory activities, you can proceed directly to the installation of GVL.There is nothing difficult in this, although it may not work out the first time. The installation of plasterboard sheets is also called dry screed. This is a rather laborious and responsible process. It can be divided into three stages. The first stage is the installation of sealing tape. It is carried out around the perimeter of the room in the places of the supposed GVL junction and walls. The tape itself looks like a finely porous material of polyethylene foam, usually on a sticky basis. Its use has several advantages:

- sound and noise insulation;

- vibration damping;

- moisture repellency;

- vapor barrier;

- resistance to aggressive external environment;

- smoothing of wall irregularities.

When installing the tape should follow a number of rules:

- tape width must match the width of the plate or profile;

- unwind the tape and remove the protective film;

- before pasting the surface must be degreased;

- Apply the tape to the adhesive side of the surface, not too stretching;

- after pasting the tape must be pressed to the surface using force.

The second step is the installation of gypsum-fiber boards. Start at the corner closest to the front door.

It is recommended to fasten the sheets to the crate using self-tapping screws with a double-thread and a sunken head. If they could not be found, you can use ordinary screws on wood or drywall.

The third stage - applying to the edge of the adhesive solution and the installation of the second row of plates. It is better to do it in a checkerboard pattern. Upon completion of installation, it is necessary to process and putty the seams, as well as the heads of the self-tapping screws. Otherwise, water will leak through them. Professionals advise to consider a few nuances:

- the seam width should not exceed two millimeters;

- excess adhesive solution must be removed in a timely manner;

- upon completion of installation, it is desirable to apply a coat of primer;

- FC should be cut if they are adjacent to the walls;

- warm floor can be mounted only on top of GVL, but not under them.

If desired, after completion of all the work panel can be painted.

How to choose?

Before buying, you must ensure the integrity of the plates. They should have a flat, smooth surface and blue markings. Each sheet should indicate the size, the name of the manufacturer and the date of issue.If you have any doubts, you can request from the seller a certificate of conformity.

Next, see the review of moisture-proof sheets GVL Knauf for the floor.