How to warm the floor in a private house?

It so happens that in the house, despite the excellent performance of the heating system, it is still cool. This suggests that the room loses heat. To restore a comfortable stay in the house, it is necessary to take measures and engage in floor insulation.

Special features

Often in a wooden or brick house with thick ceilings there is a cold coming from somewhere below. High-quality thermal insulation will not only cost the owner of the house cheap, but also allow to achieve maximum comfort in your home.

Advantages of using systems for floor insulation in a private house:

- Losses on the heat carrier considerably will decrease, therefore, economy of money resources will be noticeable;

- If you warm the floor, the area of the premises will heat up evenly;

- Increased comfort in previously cold rooms;

- The bottom of the room will be much warmer;

- Dryness in the air will not be felt. The latest technology will delay the flow of heat in the apartment;

- There will be more free space, because the use of heating systems minimizes the number of radiators;

- The heating process is faster, heat transfer increases;

- Such systems have a long service life.

Types of insulation

All heaters can be divided into two categories: technological and using heat insulating materials. Technological types are divided into electric floors and water heating. The electric floors include infrared film, heating mats and heating copper cables, and water heating - a piping system with water coolant.

Insulators, which include heat insulating materials, also come in several varieties:

Oriented strand board (OSB)

Its composition includes natural ingredients (wood). It is made by pressing using chips (sawdust) and adhesive ingredients.

There are four varieties:

- OSB-1. The moisture resistance of this modification is rather low - less than 20%.This brand is intended for internal work and contains the minimum number of harmful substances in the composition of the adhesive;

- OSB-2. It has a more durable construction and is used for covering elements of a dry room, because in a wet structure such material will be harmful to the human body;

- OSB-3 and OSB-4. They are the most resistant to moisture and increased loads, but they are the most toxic materials in this line.

But, despite the danger of such material, its use is quite often practiced not only in Russia, but also abroad.

Advantages of using this material:

- Cost savings. The cost of such products is quite low;

- Easy installation. Such material is very easy to cut and fix. It differs in ease, so that with its transportation there will be no special problems;

- Long service life;

- Ubiquitous use. This material has been used in wall cladding, in roofing and flooring;

- Proper installation is a guarantee of resistance to a wide variety of hazards: corrosion, moisture, and the appearance of microorganisms.

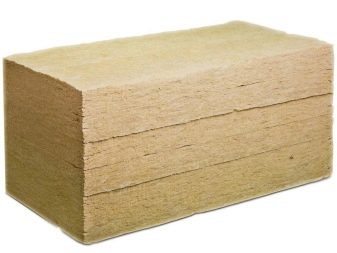

Mineral wool

According to regulatory documents, this material includes glass wool, slag wool and stone wool.

Glass wool fibers are miserable: the thickness is from 5 to 15 microns, and the length reaches only 50 mm. This structure allows it to be quite strong and elastic. When working with this material you need to be extremely careful - there may be various dangerous situations. So, for example, inhaling glass dust, you can damage the lungs, and if glass strands break, there is a high probability that they will hit the skin and eyes.

Fibers produced from slags, or slag wool, have such quality as residual acidity. This has a negative effect on metallic surfaces in damp areas. The material absorbs moisture well and is quite fragile. Inapplicable for insulation of plastic and metal water pipes.

Stone wool differs from slag wool in that it is not barbed, therefore, it is much safer to work with such material. The most widespread variety of it is basalt wool, it has the best characteristics, but it does not contain any mineral or binding components. It can be formed into rolls or sheets, stuffed into mats. When heated above the permissible temperature, it does not burn, but only melts.

Advantages of using mineral wool:

- Excellent noise insulation;

- Low cost;

- Long service life;

- The ability to achieve maximum effect when waterproofing the base material;

- Used in the overhaul and construction of buildings.

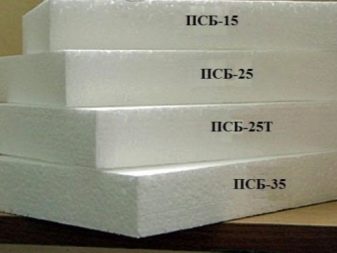

Styrofoam

This material is produced using natural or carbon dioxide, as well as polystyrene and styrene copolymers. Most of this material is used for insulation and is the most popular in this area.

This product is divided into several types: pressless, extruded and extruded. Bespressovy is not a lot of heterogeneous structures. It absorbs moisture well. Marking - PSB CX, where X is the density designation of the product.

Pressing has tight pores, so it is considered a reliable and high-quality insulating material. It becomes dense and fairly durable. Marked letters PS.

Extruded, or penoplex, is similar in structure to extruded polystyrene foam, but its pores are much smaller. Marking - EPPS (XPS-X). The second letter X denotes its density.

From the distinctive qualities of this material can distinguish the following positions:

- Thermal conductivity. The best thermal conductivity - at Penoplex. The denser the material, the higher this figure. Therefore, the insulation penopleks choose the lion's share of consumers.

- Vapor permeability This characteristic varies in the range of 0.019-0.015 kg / (m * h * Pa), whereas in the foam it is practically zero.

- Moisture permeability With full immersionless water immersion in water, absorption takes place in the amount of 4% of the volume of the material, and the extruded variant - 0.4%.

- The product has a medium or high density, and has high strength characteristics.

- Styrofoam is not destroyed when exposed to such substances as soap, soda, fertilizer, lime, cement. Damage can be done with turpentine, acetone, drying oil, some alcohols, varnishes, as well as oil refiners.

- Ultraviolet rays for this material are harmful. This applies to absolutely all its modifications. Initially, its strength and elasticity are lost, and then its complete destruction follows.

- Noise isolation and sound absorption.To mute impact noise, the material must be laid in several layers. Noise waves can not be neutralized.

- Reproduction of microorganisms. Styrofoam is resistant to mold and fungal parasites. However, rodents and insects can lay their moves in it.

- Open air for this material is destructive, since oxidation processes will begin to occur here, which are usually accompanied by the release of toluene, benzene and other substances harmful to a living organism.

- Fire resistance This type of material belongs to combustible. In addition to the release of acrid smoke, the insulation releases toxins: hydrocyanic acid, hydrogen bromide and phosgene.

- Lifetime. This material is durable. Subject to the rules of installation, he can serve for more than 30 years.

Product advantages when using:

- Low thermal conductivity. For example: if you use polystyrene foam with a thickness of 120 mm, its thermal conductivity characteristics will correspond to a brick thickness of 210 cm or wood at 45 cm;

- Low weight products. Such material is convenient to use, because its low weight allows it to be mounted and transported without assistance;

- Water resistant.This material can be used as a waterproofing component, because it is resistant to moisture;

- Resistance to deformation loads. The product has excellent compression strength parameters. This allows it to be used for insulation and waterproofing under the screed to the floor;

- Resistance to temperature jumps. Products from expanded polystyrene are resistant to cold and high temperatures;

- Easy installation. An ordinary user will be able to install, cut off the edges or cut a part of the material; it is enough to have a knife at hand;

- Low cost and lower heat costs.

Styrofoam

This insulation is a foam structure, which contains air (98%) and polystyrene (2%).

In the process of thermal insulation, several types of foam are considered suitable: polystyrene, polyurethane, polyvinyl chloride and polyethylene.

For domestic use, polystyrene foam is most often used.

In form and structure, it can be divided into:

- Sheet. It refers to the universal types of insulation, as it can be used for thermal insulation of walls, ceilings and floors.The size of the foam of this modification can be varied;

- In the form of balls. Used as backfill in various cavities;

- Liquid. Other name of this heater - penoizol. The purpose is the same as that of the previous type of foam.

The advantages of its use are many: the versatility, ease of installation, light weight, low cost, hypoallergenic and long service life.

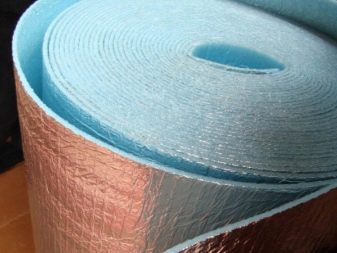

Izolon

It is one of the newest developments in the field of construction, allowing to keep the comfort and warmth of a home hearth.

There are two main groups of such material: izolon PES and izolon IPE. Izolon PES is a crosslinked cross-linked polyethylene foam, and PES is an extruded version that differs from the previous one in its molecular physics and unstitched structure.

The advantages of such material:

- High quality thermal insulation. For comparison: the characteristics of the heat-insulating material with a thickness of 1 cm are equal to 1 layer of brickwork, which allows you to save additional space;

- The presence of waterproofing properties;

- Protects from moisture and steam;

- High noise absorption performance;

- Strength;

- Resistance to chemical reagents;

- This is an environmentally friendly material;

- Long service life - over 100 years;

- Reusability;

- Elasticity and low weight characteristics.

The disadvantages of using this material include the high cost, the need to comply with the installation technology, compliance with storage requirements and careful transportation.

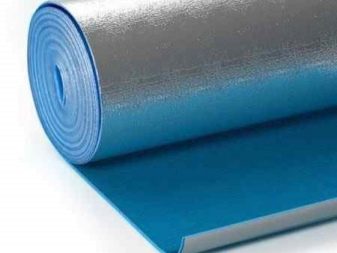

Penofol

This product is a roll of polyethylene foam with a layer of foil. The effect of penofol is built on the obstacle of convection due to polyethylene foam and an increase in parameters (up to 97%) of thermal reflection due to the presence of foil.

Varieties of this product can be distinguished by marking, which is indicated by the letters:

- A. This modification of insulation is endowed with an aluminum foil-coated surface on one side only. It can be applied together with other types of material.

- B. This variant of penofol is used as an independent material for insulation. It has in its structure a layer of foil covering both surfaces of the product.

- C. This category is easy to install because it is equipped with a moisture-resistant self-adhesive surface on one side and a foil coating on the other.

- ALP.This type additionally has a polyethylene film on the foiled surface.

- R and M. The product is distinguished by a relief surface with applied foil layers on one side.

- Super NET. It is used for insulation of communications.

- AIR. It is used to create structures for the air outlet.

Positive aspects of using penofol:

- Ease;

- Easy installation;

- This is an environmentally friendly material;

- Fire resistance;

- Low vapor permeability;

- Low material cost.

The disadvantages of thermal insulation with penofol can be attributed to its softness, since any insignificant pressure can cause material damage, poor adhesion and high electrical conductivity (special care should be taken with electrical wiring, since aluminum conducts electrical current well).

Expanded clay

This type of material is made in granules with a diameter of up to 5 cm. The rejected elements are crushed. Thus, there are three types of expanded clay: granules, sand and small gravel.

Advantages:

- Ecological purity;

- Durability and durability;

- Resistance to temperature extremes;

- Fire resistance;

- Excellent qualities of thermal insulation and noise absorption;

- Affordable price.

The disadvantages are its quantity, which is required for good thermal insulation. This material should be in a layer of at least 50 cm.

It is possible to use expanded clay in the insulation of floors made with a concrete screed or with boards on the ground, as well as over concrete. This material has also been used in the insulation of the underground of a private house, as an addition to waterproofing, in the insulation of the floor on the loggia and the first floor with unheated basements.

Tips for choosing

The right choice of material for floor insulation in a country house should always be based on the technical characteristics of the product. They can be found on the packaging of the product.

Below are the parameters that are better to pay attention to when buying a material:

- Flammability coefficient. It is denoted by the letter G. The most non-combustible material is labeled with G1. It is ignited only by direct contact with fire.

- Water absorption coefficient. The unit of measure is percentage. The lower this figure, the less moisture it can absorb. Consequently, the material will break down less and retain its properties better.

- Coefficient of thermal conductivity.This indicator is responsible for the thermal insulation of the premises. The lower it is, the warmer it will be in the room.

- Density. Indicates how much heavier the floor will be. The larger this indicator, the stronger should be the overlap and the subfloor.

- If the owner of the house is planning not to spend much on floor insulation, then you can use the budget option. Extruded polystyrene foam is ideal for concrete floors. It is compatible with a warm water floor system.

- Under the screed floor can be used and expanded clay. It will serve for a long time and can be used in high-rise buildings.

There are a number of non-combustible insulation, which received decent attention among the domestic buyer. The most popular brands are: Isover, Ursa, Knauf Insulation, Termolife.

The materials based on flax, basalt, coconut and jute can also be classified as non-combustible insulation.

Often a person doing a major overhaul of a private house, thinks about the insulation of the veranda. But here you can also save on finances. To do this, you can use foam and mineral wool. However, the foam has the property when burning to allocate life-threatening substances - this should not be forgotten.

To make the room truly warm, do not forget about the insulation of the attic floor. For the wooden suitable bulk variant of insulation - this will allow the roof to "breathe." Heavy options in the form of slabs can be used by the owners of the house, if the floor is made of concrete, and for environmentally friendly materials, you can use rolled insulation.

Old houses that were built at the beginning of the 20th century are distinguished by the fact that they have an earthen floor. It is also possible to warm it, but before that it is necessary to thoroughly sweep and tamp it. Then - according to the technology: waterproofing in several layers, insulation, finishing floor. As a heater you can use foamed polyethylene.

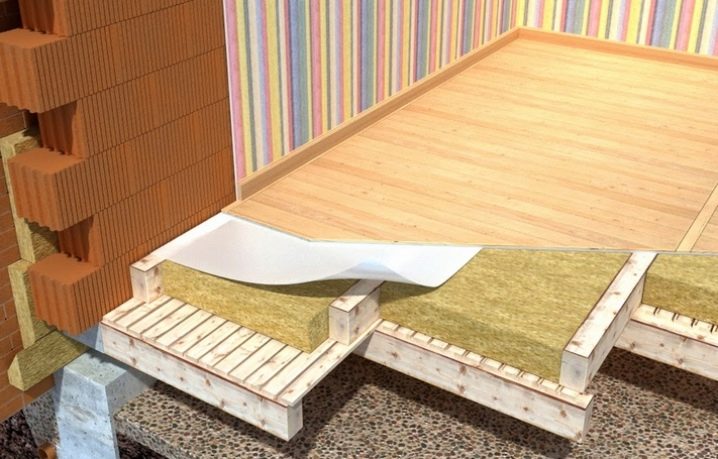

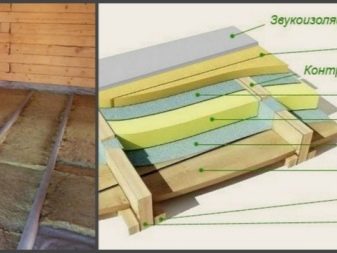

Thermal insulation of wooden base

Warming of a floor from a tree is usually carried out by means of mineral wool on logs. Old wooden floor cleaned. After inspecting the boards, it is necessary to remove the old paint, sand and treat them with antiseptic substances. After they are dried, you need to put them horizontally.

Garbage and dust from the draft base must be removed.The decayed lags need to be replaced, and the resulting structure must be treated with an antiseptic, allowed to dry. When laying dense polyethylene joints, it is desirable to insulate with construction tape. Fix the waterproofing to the logs with a stapler.

Then you need to cut the mineral wool and tightly lay it between the lag. Next, it is necessary to provide a vapor barrier layer on top of the whole structure, connect the joints with adhesive tape and fix it with a stapler.

The next step will be the installation of old boards and the installation of plinths. The protruding parts of the waterproofing must be trimmed and then painted over.

Polystyrene insulation should start with the removal of fine finish. Then you need to inspect the base and check its level. In case of exceeding the height difference of 1.5 cm per linear meter, it is necessary to level the base.

Then you need to remove debris and dust, as well as pour the cement screed of the desired height, wait for drying.

We cut out expanded polystyrene, we stack dense polyethylene. We join the edges of the canvas with tape, we plant on the walls and fasten.

Laying insulation should be done in two layers.The first layer should be laid with ligation of vertical joints. The second - in the same way, only its location should be strictly above the seam of the first layer;

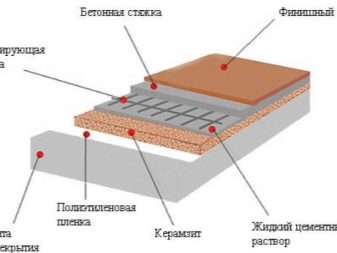

Install a reinforcing mesh with a height of 3 cm racks. Preparing the mixture for screed. Concreting the base is performed in parts, smoothing the compartments with a trowel and checking the level, we expect drying (this process usually takes a whole month). We carry out final finishing.

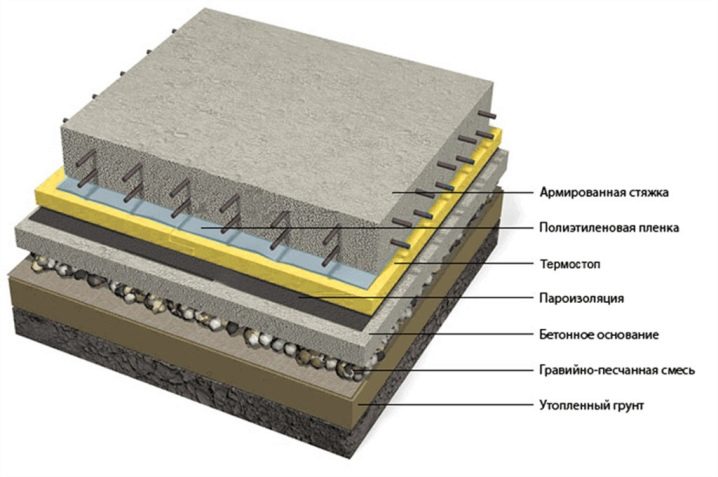

Concrete insulation

The minus of the concrete floor is poor insulation. Therefore, in this case it is necessary to use insulation.

Here are some ways to warm the concrete floor in the country with their own hands:

- The concrete floor is covered with expanded clay, and a screed is poured on top of it;

- Mixture to create a screed supplemented with fine clay or expanded shredded foam;

- On top of the flooded screed, you can lay another layer of insulation. To do this, you need to mount the bars, and from the inside to perform a layer of the selected material for insulation. Then lay a layer of vapor barrier, and close the top with boards or plywood;

- Installation of any type of floor heating.

In order to make a warm floor in a country house, it is best to use the services of a specialist. But in order to save money, people spend their time and energy on it.

Below is a brief guide on how to arrange a warm floor in your own home:

- For a start, prepare a place for the collector. It is necessary to control the temperature in the room.

- Preparation of roofing material and other insulation materials - they will be required for the waterproofing layer. The first thing you need to roll them on the surface of the base. Laying overlap by 10 cm.

Joints are glued together. To do this, you can use the effects of high temperature or adhesive tape.

- Preparation of the insulation layer. Commonly used foam with high density. The layer should be at least 5 cm thick.

- The next stage is a vapor barrier. Thick polyethylene film may well fit. Laying is overlapped by 10 cm, after which it is glued together with adhesive tape.

- On the resulting "cake" is the laying of a reflective film to direct upward flow of thermal energy. A reinforcing mesh with cells 150x150 mm is placed on it.

- The laying of the contours of the heating pipes with a maximum length of 80 m is performed on top of the reinforcing mesh.

- Fastening pipes with coolant must be performed with clips to the grid.

- Gulf finish screed.Additionally, you can use a plasticizer - it will not allow cracking of the screed when heated.

- The final stage - laying around the perimeter of the room damper tape and topcoat.

Errors

Below are some points that should not be allowed in the process of floor insulation:

- It is impossible to warm the room partially, if they require major repairs;

- In the presence of a conventional counter, it is unacceptable to use an infrared or water floor;

- Cheap materials in most cases are harmful to health. They can cause not only allergies in humans, but also lead to undesirable consequences;

- In the process of installing a floor heating system during pouring the screed, it is not possible to keep the heating circuits empty. Heating must be absent;

- It is prohibited to use foamed polystyrene and foam in filling the space between the beams in a wooden structure, which consists of several floors. When fastening sheets, they are poorly insulated, therefore, are available for oxygen. Therefore, in the process of ignition the fire can easily get inside.

Errors when weatherizing the floor in a private house can be viewed in the next video.