Leveling the floor: features of the choice of material

The overhaul often forces the owners to resort to leveling the available surfaces, and this applies not only to vertical, but also to horizontal areas. Proper preparation of the base has a direct impact on the durability and attractiveness of finishing materials, so this issue should be approached with the utmost responsibility. Today we will talk about how to properly level the floor and which means are best suited for this.

Special features

If you want your home to look aesthetic and it was not a shame to show the guests, then it is necessary to think over and modify all the details. This applies not only to the color of the finish or design of the furniture, but also to the neat and smooth appearance of the surfaces. It's no secret that the "wavy" floors or floors are most often striking.Such defects can spoil even the most stylish and original interior with their unpresentable.

To avoid such trouble It is worth aligning the surfaces that need it. To produce such work is necessary before you decide on the floor finish. This may be good old linoleum, laminate, parquet, expensive solid wood, soft carpet or tile. All of the listed coatings require a perfectly flat base of the floor. If you put them on a rough rough base, they will look sloppy and will not last very long.

Leveling the floor can be done by hand. In this case, you need to be as careful as possible. In no case do not proceed to work without reading the instructions for the selected material. Wrong actions can lead to noticeable deformations of the base, which will not be easy to get rid of.

It should be noted that the alignment of the floor must be addressed not only in the process of repairing a city apartment, but also in a private house. Modern manufacturers produce many varieties of leveling compounds, the drying of which does not have to wait too long.

In addition, due to the wide range there are different ways of laying an equalizer on the base of the floor, so each consumer will be able to choose the best option for himself.

Materials

Do not think that to level the floor only dry mixes are sold, which need to be diluted with water. In fact, other practical materials that are easy and convenient to work with are excellent for such purposes. Consider them in more detail.

Plywood

This material is most practical for dry leveling. Screeding the floor using such parts is less expensive, especially when compared with the use of special expensive mixtures.

If you are going to repair the room in which there is a high humidity, then It is worth turning to moisture-proof raw materials. In addition to the good old plywood, you can use GVLV, MDF, OSB, chipboard or chipboard.

The choice of plywood base should be approached quite seriously. Depending on the height of the floor drops, you should select sheets of appropriate thickness. Also, the purchase of leveling plywood is influenced by the type of topcoat you choose and the method of its installation.So, for soft carpet or elastic linoleum, it is permissible to install sheets of plywood of small thickness. This choice is due to the fact that these finishing products do not require a perfectly flat base.

If we are talking about such popular coatings as laminate or wood flooring, then you should buy plywood, whose thickness is not less than 12 mm. It should be thicker, since the above-mentioned floor coverings require the most even surface to be installed.

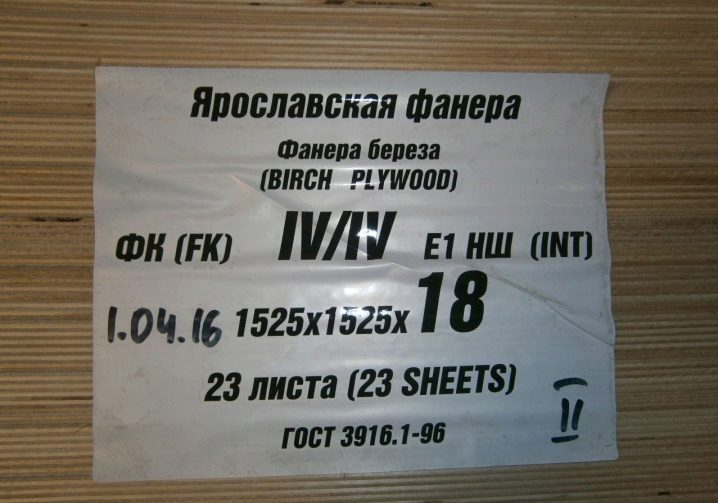

Experts recommend before buying such leveling sheets to pay attention to their brand. For individual construction is to purchase copies of FC or FSF.

In the composition of the sheets of FC there are no phenols and other similar compounds. Such materials are absolutely safe for human health even in high temperature conditions. In addition, FC specimens have an average moisture resistance and resistance to mechanical damage.

If high humidity is kept in space, then it’s worth contacting to plywood brand FSF. This material is more durable and wear resistant. He is not afraid of temperature extremes.However, plywood acquires such good performance characteristics of FSF due to the use of harmful formaldehyde resins in the production process. These substances are toxic and dangerous to human health.

In accordance with GOST, plywood sheets of the following grades are produced:

- 1st grade. These are products with the highest quality. On their surface there is not the slightest defect. However, GOST completely allowed small cracks (no more than 20 cm), as well as the presence of minimal material warping.

- 2 grade. For this grade, materials are produced in which minimum percolation of glue and wood inserts are permissible. On the surface of such sheets, you can notice scratches and dents, which occupy about 5% of the total area of the existing surface.

- 3 grade. Material in this category may have visible traces of wormholes on the surface, as well as knots that have grown together and fallen off.

- 4 grade. Such materials are the lowest quality. They have many different defects that appear in the process of their production. But despite the great disadvantages, the veneer, as a rule, is glued qualitatively and reliably.

Most experienced craftsmen advise contacting plywood 2 grades.

Among other things, this leveling material is ground and unpolished. This parameter is denoted by the letter "W":

- The designation "Ш1" means that the plywood is made with one-sided polishing;

- "W-2" - two-way;

- "NS" - unpolished material.

On the polished plywood sheets, you can find the designations of the emission class of free formaldehyde (as in the case of chipboard):

- "E-1" means having 10 milligrams for every 10 g of plywood;

- "E-2" - 10-30 mgm per 100 g dry weight.

Expanded clay

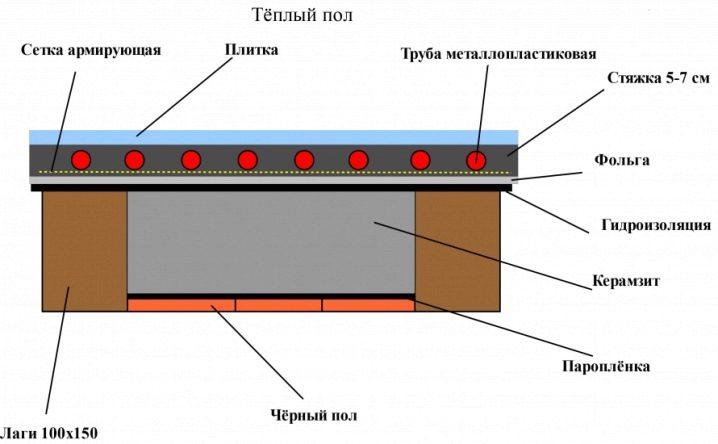

Currently, there are many different materials that are most often used in leveling the sex base before finishing. However, there are times when there is nothing better than preparing the foundation with expanded clay. This old and well-known material is indispensable in the following cases:

- If the difference in the height of the base is more than a mark of 10 cm. If you install a classic concrete screed on such a surface, then its weight can form a serious load on the floor. Expanded clay is recognized as one of the easiest and undemanding materials. He does not overload the floor structure at all.

- If the base is represented by a reinforced concrete slab. This material is cold. This is noticeable in the conditions of the lower floors. With the help of expanded clay it is possible to correct this problem, as it is able to make the floor a little warmer.

- If under the sexual level there are various additional communications or electric heating systems.

- If the repair budget is significantly limited. It is worth noting that leveling the floor with expanded clay will cost the owners much cheaper than a heavy concrete screed.

The following distinctive characteristics can be attributed to the main advantages of expanded clay:

- Environmental friendliness. Expanded clay, even in conditions of temperature drops, does not emit harmful substances and does not contain hazardous compounds.

- Durability. It serves for a very long time and does not create any problems during operation.

- Heat insulation characteristics.

- Sound insulation properties.

- Fireproof. Expanded clay is not a flammable material.

- Resistance to temperature extremes.

- Low cost.

Experts say with confidence that such material is considered to be an excellent solution for leveling hopeless foundations.It is often used to put in order the bases with holes and a slope greater than 10 cm.

In addition, with the help of expanded clay, you will not only make the floor even, but also provide him with additional noise and heat insulation.

Drywall

To level the genital base, you can use sheets of drywall. It is placed on the subfloor only after it has been completely cleaned from the former decoration and debris / dust. In addition, to finish the base with drywall, it must be sprinkled with sand. It must completely cover all cracks and irregularities that are visible at the base.

The sand on the floor should be properly loosened and qualitatively leveled so that its layer becomes as smooth as possible and located on the entire area of the room. It is worth considering that sand layer should not be thicker than 2-3 cm.

If there are small depressions in the base, they must be eliminated using a cement-sand composition.

Only after this can drywall be laid out on the floor. Between its plates you need to leave a small gap of 5 mm. During this period it will be necessary to fill the sealant with special protective properties.The ideal option would be a special composition designed for ceramic plates. It can be found in almost any hardware store.

Immediately after the sheets of gypsum board are laid out on the sand layer of the base, the resulting coating should be treated with a special primer. It should be different deep penetration. After all the actions performed, it is quite possible to proceed to the installation of the finishing floor material. For example, today beautiful self-leveling floors are very popular, under which a gypsum board leveling base is often installed. From above they can be supplemented with laminate or floorboard.

Fiberboard

This is another common material used in leveling the floor. Today, many consumers turn to fiberboard because it is inexpensive and its installation is fairly straightforward. For the manufacture of such coatings are used remnants of wood production (chips, sawdust). The characteristics and properties of the chipboard largely depend on the level of its density, which, as a rule, varies in values from 150 to 950 kg / sq m.

It is worth noting that quality fiberboard has good thermal insulation propertiestherefore, it is often chosen as a leveling coating. Often these sheets are stacked on top of the cement screed. Also, many consumers opt for sheets of fiberboard because of environmental friendliness. In their composition to a greater extent there is a waste of natural wood.

Such coatings are installed quite easily and quickly. Even a person who is far from repair work can easily cope with this work.

If you install the plates of hardboard correctly and accurately, then they will last for many years and will not give the household any trouble.

Mixtures

For leveling the floor are used not only a variety of hard and dry bases, but also the appropriate mixes. They differ from each other in composition, drying speed and other performance characteristics. Let's get acquainted with the most common products that are popular with modern buyers.

Cement and cement-sand

These mixtures are among the most sought after. They are classified as universal, because there are many modifications.Due to the wide range of cement and cement-sand compositions can be selected for any room and any operating conditions.

Currently, in stores you can meet quality options for leveling the base, having a different structure, a different number of flows and grooves. Most high-quality cement formulations do not shrink.

It is possible to increase the strength characteristics of this equalizer using ordinary PVA glue. It should not be too much.

But it should be borne in mind that the hardening of the composition with the adhesive substance will take a little less time, which means that all the work will have to be done even faster. To do this, you can pour it in small portions on different parts of the available space in the room. It is also worth noting that Stripping putty with PVA glue is more labor intensive. Some people turn to stronger tile glue. It will be even harder to work with him.

Plaster

Gypsum levelers are recommended for use only in rooms with a low percentage of humidity. Also, they are not advised to install in areas subject to regular jumps in temperature values.These recommendations are due to the fact that gypsum mixes are able to absorb moisture. This can lead to swelling of the base and loss of its beneficial characteristics. Such defects are unlikely to act positively on the finishing flooring.

A distinctive characteristic of gypsum bases is their vapor permeability and no shrinkage. Often, such a mixture is addressed in the case of not the most reliable sexual base. In addition, all factory mixtures are separated according to their main purpose and application technology.

Leveling

Such compositions are necessary for the primary finishing of the rough surface, which has many defects and irregularities. With the help of these tools are very strong and reliable bases up to 50 mm. As a rule, these types of levelers are applied by hand. The material is used exclusively as a special layer. This is because in the composition of the leveling means there are large particles of sand that do not allow to form ideally smooth and regular coatings.

Self leveling

Such mixtures are used for the implementation of the finishing coating.Its thickness can be from 2 to 10 mm. As a rule, such a self-leveling has a viscous consistency. In its composition there are fine fine-dispersed particles, which evenly spread over the required area with the help of independent spreading.

There are special self-leveling quick-drying mixtures. To fill this tool is quite enough one filling material. Often, with the application of fast-hardening agents, a small working team manages in which one or another function is assigned to each of the workers. For example, it may be the direct preparation of the required amount of the mixture, pouring the solution onto the base of the floor, distributing it over the surface of the substrate using a special tool, as well as the necessary elimination of air bubbles using a roller.

Some work teams in leveling the floor use a rotband. However, according to users, this composition is not durable and durabletherefore, its use is generally discarded in favor of more reliable formulations.

Level determination

The level of the floor can be determined in different ways. To do this, you can use the following tools:

- Rack level bubble. The standard line of this device, as a rule, is 1 m, but in the shops you can meet two-and three-meter products. These items are inexpensive, easy to use and very easy to use. In addition, bubble levels do not depend on electricity, which makes them autonomous and more practical. True, too large spaces they can not be measured.

- Hydro level. Bubble levels allow you to determine the condition of the floor only in small or medium rooms. For more spacious premises it is worth buying a quality hydro level. It consists of special tubular vessels. In the interior of this device is colored water, with which the determination of the surface level occurs.

- Laser. It is very easy and simple to use. Most models have a high performance. To determine the desired parameters, it is enough to fix the tool in the desired position (for this it is worth reading the instructions). All other actions will produce a level independently.

- Rotary. With this device, you can not only determine the level of curvature of the floor, but also to expose and design the obtained values. As a rule, such high-tech items are used by professionals, because it is quite expensive.

- Optic. Such devices are more common to measure the territorial areas of the outer part of the room. However, this does not interfere with their use in matters of determining the curvature of the floor. Optical levels are very similar to rotational levels, but their use in spacious rooms will give more accurate results.

Surface preparation

Before direct alignment of the sexual base it is necessary to make its proper preparation. You should not neglect this process if you want the floor to last you for a long time and without problems.

First you need to carefully measure the room in which you plan to level the floor. Then you can proceed to the selection of suitable materials and methods of their installation. During the preparatory work is often identified various problems associated with flooring.At the same stage it is necessary to study the level of the existing base. For this purpose, different levels, both liquid and laser (the list is listed above) are used.

The maximum leveling efficiency is ensured by the use of a material that would fit to irregularities on the surface of the base. For a floor that is in almost perfect condition, it is recommended to use high-quality leveling means or self-leveling of famous brands.

If on the basis there are noticeable drops, then it is better to turn to sheet leveling or use cement-sand screeds.

Wood coating

Absolutely any gender with time can lose its attractive appearance and imperceptibly deform. This trouble did not bypass the high-quality wooden coverings. Over time, old and dry floors may warp and sag, irretrievably losing their perfect evenness. Ugly gaps often appear between individual boards. It is impossible to lay out decorative materials for such bases correctly and carefully, therefore without leveling the existing system in this case is not enough.

You can give the plank base a smooth surface with your own hands using the following methods:

- scraping;

- leveling using flat materials based on wood (plywood, fiberboard or MDF);

- leveling with the use of personally made mix consisting of putty for sawdust and natural wood;

- fillings of the special self-leveled structures.

Most often, people choose the alignment of such structures with the help of plywood, as the differences between the boards of a wooden floor are often quite impressive. For such works it is recommended to use a sheet of plywood of standard dimensions. It is cut into 4 parts. Cutting should be done very carefully so that there is no separation on the edges of the sheets.

After these actions, it is quite possible to proceed to laying the levelers on the base. Joints between the laid coverings should be above the lags. In areas where communications are located and in other necessary places, plywood must be trimmed (just as carefully so as to prevent stratification). After that, the sheets are attached to the base on the screws with hidden heads.This leveling method is not the most aesthetic, but for the finishing layer it is an excellent solution that will perfectly hide all the irregularities of the wooden base.

Concrete base

Quite often it is necessary to produce leveling in rooms with a concrete base floor. In this case, there is a simple step-by-step instruction that will help to carry out all actions to update the surface quickly and correctly.

If the concrete base has not too sharp and noticeable drops, then it is best to use modern self-leveling mixes that are sold in every hardware store. As a rule, the main component in them is cement. To perform work with a similar tool you need:

- pour the dry composition with water;

- stir well so that there are no lumps and dry particles left in it;

- gradually (in portions) lay it on concrete (for this you can call an assistant for help).

The self-leveling solution should fill with itself absolutely all the cracks and cavities present in the concrete base, forming a neat and smooth surface. Such mixtures dry out pretty quickly.You can walk on them in 3-4 hours, and in a day it is permissible to start laying decorative coating, for example, tiles.

If the irregularities on the concrete floor are more impressive and noticeable, then It is worth referring to high-quality and reliable concrete screed. This leveling method is one of the cheapest and most popular. The installation technology of a concrete screed, primarily, is based on the installation of special beacons. They are installed on the floor (the distance between the beacons should be 500-800 mm), aligning in the same plane with the level.

After that, it is necessary to knead the solution with the necessary consistency and add special plasticizers to it. Then you can proceed to the calculation of the resulting mixture on the concrete base of the floor. When the screed “grabs”, all guides will have to be removed, and the remaining grooves to fill with a solution. The surface of the concrete screed must be grouted, however it is possible to start this work only after 4 weeks.

Also, it will need to be strengthened with a high-quality primer treatment.

Useful tips

Before embarking on a self-leveling floor, you should familiarize yourself with some simple tips to avoid serious mistakes in the process:

- Avoid penetration of drafts into the room in which you are leveling the sex base. And if everything is quite simple with a bathroom or a toilet, then in other rooms (living room, bedroom, hallway, kitchen and balcony) all windows should be closed and doors should be covered (as is the case with wallpapering walls).

- Do not use any ventilation equipment.

- Be sure to adhere to the drying time of the solution indicated on its package / box. They can be broken only if the composition is applied in a thin layer. Double-layer coatings should not be “disturbed” until they are completely cured.

- Before pouring the existing base, it is recommended to treat the entire area of the room using a special primer. It is needed to provide improved adhesion.

- Use only reliable and high-quality tools, as well as materials and mixtures. Otherwise, the floor may not turn out the way you planned it.

- Do not look for too cheap and affordable leveling tools. Too low cost may hide the poor quality of the product.

- Do not forget that the old floor must be completely cleaned from the previous coating.Otherwise, the leveling layer may not quite perfectly lie, which will affect the decorative floor finish.

- If, on the basis, visible seams and large gaps (for example, between boards) are observed, then they should definitely be covered with a putty or the same leveling compound. For such work is worth kneading thicker and viscous compositions.

- Do not neglect the preparation of the base. This stage is one of the most important in this work, so experts recommend taking it as seriously as possible.

- In the process, always wait for the full shrinkage of dust. Vacuuming the room is possible. Do not leave on the basis of even the smallest garbage.

- Alignment of the floor in a residential area can be done with your own hands, but this process is not the easiest and fastest.

Starting the treatment of the sexual base, you must stock up with all the necessary tools, materials and, of course, patience.

To learn how to make a high-quality floor screed on your own, see below.