Floors in a private house: device options and rules of care

Every morning, waking up in his home, a person lowers his feet on the surface, which will be in contact with the whole day. Regardless of what kind of housing it is, whether it is an apartment in a high-rise or private ownership, the floors in it are a three-layer construction, including a rough base, a leveling layer and a finishing covering.

Special features

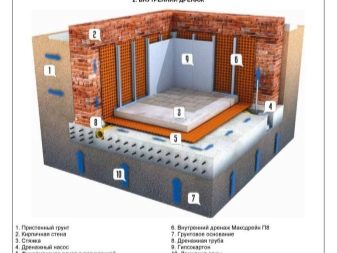

The floor in a private house is somewhat different from the one that is mounted in the apartment. To he served for a long time, it must be protected from the interaction with water, that is, to perform waterproofing. Waterproofing - it is an independent procedure aimed at protecting the surface from the adverse effects of moisture in the environment, which can harm any substance.

Kinds

Depending on the materials used, the floors in a private house are concrete or wood.The choice of material for the floor depends mainly on what the walls are made of. If the walls are wooden, then the floor is made of wood. If the walls are brick or concrete, then the floors will be of concrete. Often the concrete base acts as a substrate for a wooden coating. Whatever type of device is used, it is important to strictly align all its layers, otherwise, you get an uneven surface.

Wood

Wooden floor is an environmentally friendly coating with good thermal insulation characteristics. With good waterproofing, such a floor will last for many years. Depending on the technology used, wooden floor is built:

- on the lags on the ground;

- on pillars;

- on cement screed.

Concrete

Concrete floor is considered, perhaps, the most impact-resistant and hardy. The cement monolith, which serves as a concrete surface, will become an insurmountable obstacle to the fungus, mold and other microorganisms. The disadvantage of it is that, using concrete, it is necessary to provide additional floor heating, as the concrete cools rapidly, it does not hold heat at all.

What to choose?

The preference given to a particular structure depends on the purpose of the building. In the summer kitchen or in the country, which are operated in the summer, there is no need to create complex structures. In this case, the boards are stacked on the logs. Of course, this floor will not keep warm.

In the capital house, used for living all year round, it is better to use more massive structures.

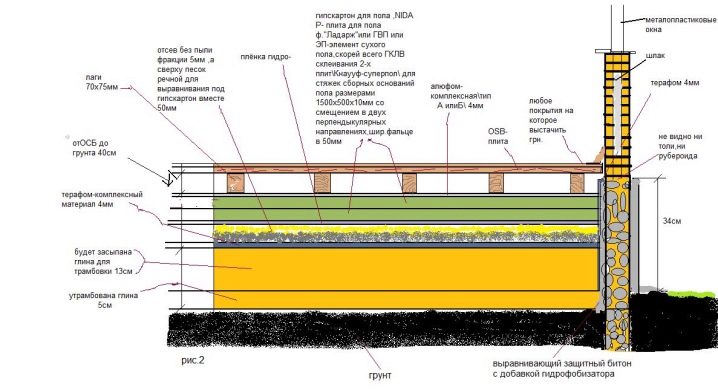

If there is no basement in the house, then the most budget and less complex in execution is the construction of the ground floor floor over the ground. In this case, two options are possible: either use a concrete base (the so-called screed), or install multi-layer wooden floors on the logs.

What will be the floor on the second floor, is directly dependent on the method of installation of floors between floors. When wooden grounds use beams and logs. If the floor is reinforced concrete, then only lags are used. The floor on the second floor, as on the first, can be on beams, on logs, on concrete slabs.

If the building has a basement or cellar, then the floor must meet certain standards. Due to the proximity of the land, it should be as insulated and stable as possible. The material is chosen depending on the further purpose of operating the room: if a living room is planned in the basement, then wood is preferred, if a workshop is created, a concrete screed will be appropriate, and if a cellar is equipped with winter stocks, then there is nothing better than clay.

In order to avoid unpleasant surprises, when setting up a cellar, it would not be superfluous to find out the depth of the groundwater.

Walkthrough

When building a country house is often preferred wood surfaces. This is explained by the fact that wood is an environmentally friendly material. In addition, laying such a floor is easy to do with your own hands from scratch. Installation does not take much time, there is no difficulty with the repair in the future. The poor thermal conductivity of wood will help the wood flooring to keep the house warm. A big plus will also be a long service life and an attractive, “natural” appearance.

New floor

New floor in the house begins with the selection of materials. The final result depends on the choice. So, you need:

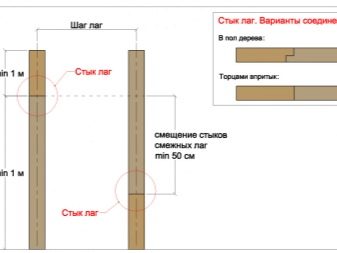

- Wooden beam or round timber for the manufacture of lags. Lags are cross beams on which the floor is located. The height of the cross section of the timber should be one and a half or even two times its width.

- Unedged board for rough coating.

- Grooved floorboard on fair flooring.

- Material for thermal insulation: sawdust, expanded clay or mineral wool.

- Materials for waterproofing.

To determine how many boards will be needed, the following example will help. Suppose it is planned to lay the floor in a room measuring 5x6 m. The lath has a length of 2 m, a width of 0.13 m, and a thickness of 0.05 m. For such a board, the logs are laid in 1 m steps. Calculations are carried out according to the following algorithm:

- The length and width of the room multiply, getting its area. In this case, 6 * 5 = 30 m2.

- Find the volume of required sawn timber in cubic meters, multiplying the thickness of the board in meters by the area of the future floor: 30 m2 * 0.05 m = 1.5 m3.

- Calculate the volume of one board, multiplying its length, width and thickness: 2 m * 0.05 m * 0.13 m = 0.013 m 3.

- Determine the number of boards by dividing the total volume of sawn timber by the volume of one board: 1.5 m3 / 0.013 m3 = 115 boards.

In the same way is determined by the amount of building material for rough coating.Since the floor surfaces in the house are subject to mechanical pressure, for their construction it is necessary to choose high-quality wood without cracks and chips with humidity up to 12%. Pine, cedar, larch are considered more suitable. Before starting work, all building materials are treated with an antiseptic and impregnated with flame retardants. Mounted wooden floor in the following sequence:

- Remove soil layer around the perimeter of the room.

- Install support posts.

- Cover the gravel with a thickness of at least 10 cm.

- Cover the sand layer.

- Tamper

- Lay ruberoid or other waterproofing material on the supporting posts

- Prepare lags. If round logs are used as lags, then it is necessary to cut one side.

- Lags fasten on the support pillars.

- Make double weatherization. For this purpose, plywood sheets are laid on the sides of each log, on which a heat insulating base is placed.

- Place the rough coating, tightly fitting the boards to each other and fixing them with self-tapping screws to the logs.

- Leave a gap up to 2 cm wide between the walls and the flooring around the perimeter. It will provide ventilation and protect the walls of the house when the floor expands during its drying.

- Place a waterproofing layer on the subfloor. For this you can use a thick (from 200 microns) polyethylene film. The joints of the polyethylene strips are glued with a wide scotch tape, the edges are wrapped on the walls to the height of the finishing coating.

- Lay the finish coat. If the surface of the floor in the house remains wooden, then the finishing covering is made immediately from a grooved board, which is sufficient to be varnished. Varnish will highlight the beauty of natural wood.

If you plan to lay a laminate, linoleum or other decorative material, then the expensive tongue-and-groove board is replaced with cheaper plywood.

If the room is required to make a floor of concrete, then it is poured according to this algorithm:

- preparatory work.

- To clear soil from the top layer, to stamp.

- Pour a layer of gravel, ram.

- Pour a layer of sand, rammed.

- Cover the entire area with thick plastic wrap for waterproofing

- Cement strainer.

- Set the levels.

- If the screed is more than 5 cm high, or the installation of a heated floor is planned, then a reinforcing mesh should be laid on the waterproofing.

- Prepare a solution consisting of cement grade not lower than M-300, screening of sand and water. For added strength, add a plasticizer to the solution.

- Pour the solution.

- To level surfaces in the direction from a wall to a door.

- After the concrete has set, remove the lighthouses, fill their tracks with the same concrete. Fill and align all the slots.

- Cover the floor with polyethylene and leave to dry for at least a month, occasionally moistening it with water.

- Until the concrete is completely dry, a warm floor cannot be turned on, as this will lead to cracking of the surface.

- To lay the top decorative covering.

With full compliance with the technology, the floor will delight the owners both in the heat and in cold times, without requiring costly repairs.

Warm coating

The floor in the house should be not only beautiful, but also warm. Modern technologies allow at the stage of construction or repair to build in the floor heating system. Most often, preference is given to the following systems:

- Cable floor using a special heating cable. The cable emits heat when electric current passes through it. Laying method depends on which cable (single-core, two-core or self-regulating) is used in the system. Such a floor is usually installed under the tile.

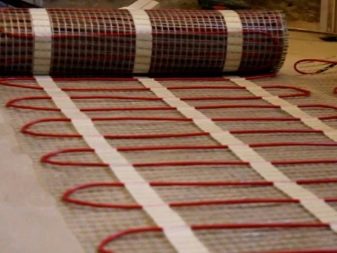

- Heating mat, unlike cable floor, does not require a cement screed. It is a thin cable attached to a synthetic mesh. A heat insulator with a reflective surface, such as foil, is laid out under the finishing coating. On top of an unrolled roll is fixed with tape or glue. To change the direction of the layout, you need to notch the base without damaging the cable. On top of the finish covering. You can use tile, laminate and other materials.

- Film or infrared floor It is a special film that can emit infrared radiation when an electric current is passed through it. The film is ultra-thin, and the infrared radiation it emits is harmless to humans. All the advantages lie in simplicity: it is enough to spread the film and cover it with any floor covering. If several webs are used, they are connected by wires. The heating temperature is controlled by a thermostat.

Arrangement of floor heating with the use of modern technologies will not only give comfort to use, but will not cause any particular difficulties in the case of repair.All repair work is reduced to the replacement of the failed item or area.

How to care?

Care for the floor should be based on the rules of care for the material of its finishing coating. The floor is one of the main elements of the interior, so it is important that you follow the established requirements when choosing materials for the floor. Coverage is selected depending on the purpose of the room. For example, linoleum does not withstand a large load, and parquet does not like moisture.

The materials used for the finishing coating can be classified in various ways: hard and soft, stone and wood, synthetic and natural. Each type of material has its own styling and methods of care.

Hard materials include tile and stone. They are durable, not afraid of moisture. Modern technologies allow to lay tiled floor not only in the bathroom and kitchen, as before, but also in other rooms. If desired, the tile can easily be replaced by another. The tile can be made of natural stone: marble, granite, and if financial possibilities allow, then of malachite, jasper, rhodonite.

Synthetic materials, such as, for example, vinyl, concrete, are practical, but they are afraid of humidity, temperature fluctuations, as well as chemical and mechanical effects. Rubber for the floor is a mixture of cement, cork, rubber, marble chips and chalk. It is flexible, durable, resistant to mechanical stress and temperature changes.

Natural, oddly enough, is linoleum. It is made by applying a hot mixture containing gum, beeswax and linseed oil to the fabric base. Natural linoleum is an expensive, but very effective material.

The most common surface is wood. Wooden coatings are made from various types of wood. The most durable and very expensive is an oak coating. Maple, beech, elm, ash, linden, birch, cherry and pine are also used. Modern wood material is laminate, which is represented by a multilayer structure. It has a top layer made of wood. Laminate flooring is easy to install, inexpensively priced, and looks like natural wood.

Not less now spread and carpet.Carpet is a pile fixed on the substrate. The carpet can be either synthetic, consisting of nylon or acrylic, or natural silk or wool. It is simple to lay, and if necessary - replace.

In modern conditions it is important not only to properly cover the floors with a suitable covering, but also to know how to take care of it. Even the most durable materials are sometimes susceptible to some cleaning products.

If the coating has a smooth surface, then it can be washed: moisten with water a small area of the floor, immediately wipe it dry.

Wooden surfaces are wiped with warm water with the addition of neutral agents, moving in the direction in which the parquet or floorboards are laid. It is not necessary to wet the surface abundantly, especially if it is lined with parquet. He can swell from this. Instead of soap it is better to use a little vinegar. In this case, there will be no streaks on the surface. In addition, the vinegar perfectly refreshes the color of the wooden coating.

The floor of stone, slate, ceramics is treated with a solution of warm water and neutral means. For unglazed tiles, the cleanser is replaced with acetic acid.It will remove stains from the surface and cause it to shine evenly, muffled. Slate floor periodically rubbed with citrus oils. Marble coating is simply moisturized and thoroughly wiped. Marble does not tolerate waxes, oils. It spoils them.

Linoleum floor can not be wet. After treatment with a solution of warm water with a neutral agent, wipe it dry, and then rub it with wax.

Vinyl and synthetic floors, perhaps the easiest to clean. The treatment consists of washing with water using universal detergents and rinsing with clean water. It is necessary to monitor the composition of detergents: there should be no solvents in them, otherwise the surface will become porous and rough to the touch.

Carpet should be vacuumed at least twice a week, and if the material permits, wash it twice a year using a special shampoo. If the coating is made of natural materials, and it is impossible to wash with water, once a month it is treated with a special dry powder according to this scheme:

- Vacuum the surface.

- Scatter over the entire area of the powder

- After two hours, re-vacuum.

High-quality materials, modern technology and proper care - these are the three components of a good floor.

How to make a warm floor in the house without mistakes, see the next video.